Poly(lactic acid) (PLA) is an aliphatic polyester which can be derived from 100% renewable resources. PLA fibres can be dyed with disperse dyes, just like PET fires, although a modifid wet processing processes are employed. A variety of wet processing applications (pretreatment, dyeing, clearing, and subsequent finishing treatments) that imparts the greatest chemical and physical effect on the PLA fires necessitate major attention. Part II of this review reviews the wet processing (pretreatment, dyeing, clearing, subsequent finishing treatments, washing etc.) of PLA fibre and its effects on the fibre. This was accomplished through a broad literature survey including recent research and development in the area.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Poly(lactic acid) (PLA), the first melt-processable natural-based synthetic fibre produced from annually renewable resources [1, 2], combines ecological advantages with excellent performance in textiles. It is an aliphatic polyester which can be derived from 100% renewable resources such as corn [3] (Fig. 1). The processability of PLA is equivalent to that of petroleum-based synthetic materials, where PLA polymer uses conventional polyester type fibre melt spinning processes. PLA fibres use conventional spinning machinery. PLA fabrics also use conventional dyeing and finishing machinery.

PLA fibres can be dyed with disperse dyes, just like PET fires, although modified wet processing processes are employed. A variety of wet processing applications that imparts the greatest chemical and physical effect on PLA fibres necessitate major attention. A better understanding of PLA fibre and the possible effects of different wet processing treatments during production and after-care procedures during usage by the consumer is vital. Finding the best conditions and methods for wet processing and after-care applications for PLA-based textile products will increase the performance of this natural-based melt-spinnable PLA fibre. The aim of Part II of this review paper is to review the wet processing (pretreatment, dyeing, clearing, subsequent finishing treatments, washing etc.) of PLA fibre and its effects on the fibre. Poly(lactic acid) (PLA) fibre and its production, properties, performance, environmental impact, and end-use applications were reviewed and summarized in the first part of this review.

Wet Processing of PLA fibres

PLA shows many properties that are similar to those of other synthetic fibres. PLA fibres can be manufactured by bulk dyeing before spinning using a polymer concentrate of the same dyes as for PET fibres [4]. However, PLA requires modified dyeing and finishing techniques to maximize its benefits. It can be dyed with disperse dyes, just like PET fibres, under high temperature and pressure although a modified dyeing method is employed since PLA has low affinity to conventional water-soluble dyes [5]. Conventional processes and finishing technologies can be used for processing PLA fabrics [6]. The processing temperatures conventionally used for PET need to be reduced since the melting point of PLA is lower than that of PET.

Owing to the poor alkali resistance of PLA, strong alkalis can cause strength loss via hydrolysis in conventional wet processing [7]. Scouring, dyeing, and reduction clearing must all therefore be carried out according to this sensitivity. Dyeing, heat setting, bleaching, and scouring can have an influence on the physical strength of PLA fibre [8–10]. The pH during all wet-processing stages should be kept in the range of 4-7 to minimize hydrolysis [11, 12]. With this in mind, suitable conditions have been developed for wet processing of 100 % PLA that do not degrade the polymer. Blends of PLA with cotton, lyocell, and wool are common apparel applications. Suitable wet processing of PLA/cellulosic blends for all stages of wet processing have also been developed [8, 9].

Scouring

All knitted fabrics need to be scoured to remove knitting lubricants, stains, mill dirt, and other impurities prior to subsequent wet processing activities such as dyeing and softening. Scouring minimizes the risk of poor dye uniformity, stains, and dye fastness issues by removing oils, waxes, and fats that may be present in knitted fabrics [13, 14]. For example, no deleterious effects on either molecular weight or fabric burst strength were observed after alkaline scouring using 2 g/liter soda ash and 0.5 g/liter Kieralon Jet B concentrate (nonionic surfactant, BASF) for 20 minutes at 60°C [8].

Bleaching

Producing white fabrics by destroying the coloring matter with the help of bleaching chemicals with minimum degradation of the fibre is the main purpose of the bleaching process [14]. Phillips et al. [9] stated that producing an optic white on a PLA/cotton blend with alkaline peroxide bleaching of the cotton component would be regarded as being technically acceptable, although there was a reduction in the mechanical properties of PLA fibre.

Dyeing

Cautious selection of pH and temperature during dyeing is crucial to getting the right depth of shade without affecting the physical properties of the PLA fibre or fabric [11]. Decreases in tensile strength and molecular weight of PLA fibre have been observed with excessive temperatures and/or extended times during dyeing [8, 15]. Yang and Huda [16] also reported that although a high dyeing temperature provides better dye uptake, this leads to greater loss of strength and elongation of the PLA fibre. It was also stated that the best strength and elongation of PLA were observed with a weakly acidic dyebath [16]. A more acidic (pH 4 or lower) or more alkaline (pH 7 or higher) pH dyebath resulted in substantial loss of fibre elongation and/or strength [17]. The pH of the dyeing bath for PLA should be cautiously controlled so as to have color consistency [17].

Very little disperse dye is taken by PLA fibre during dyeing below the temperature of 80°C [17, 18]. Lunt and Bone reported [12] that disperse dyes migrate on-tone on PLA fibres and show considerably improved migration values over those typically seen on PET. Medium energy disperse dyes exhibited equally good on-tone build-up on PLA as on PET [12]. The critical temperature range (CTR) over which disperse dyes exhaust onto PLA is 70–110°C, which is about 20°C lower than for PET [12]. The dyeing conditions recommended by DyStar [19] are 15-30 minutes at 110–115°C at a pH of 4.5–5.0. The dyeing time at maximum temperature should be kept as short as possible so as to minimize loss of fibre strength by hydrolysis [19]. L.E. Scheyer and A. Chiweshe reported [20] that maximum dye exhaustion occurred within 30 minutes for most dyes studied on both low and high crystallinity PLA fabrics. PLA fabric may be dyed for 30 minutes at 115°C for very heavy depth of shades to achieve maximum color yield [21]. It is recommended [17] that holding the dyeing temperature at 90–95°C for 5 minutes might be appropriate to obtain good levelness when the levelness for dyeings is difficult to achieve. Finally, at the end of the dyeing, the dyebath temperature should be decreased to 50°C, which is below the glass transition temperature (Tg) of PLA, before removing the fabric from the bath to avoid fabric creases [17]. It is stated [16] that a gradual decrease in dyebath temperature will further enhance dye exhaustion on the PLA fabric as dye sorption is exothermic. The recommended disperse dyeing cycle for PLA is shown in Fig. 2.

Nakamura et al. [22, 23] stated that the liquor ratio is an important factor, which affects dye uptake, for light and medium depth of shades. Variation of the relative liquor ratio should be pondered for color matching for dyeing of PLA blends [22, 23]. It is claimed [22, 23] that in the case of heavy depth of shades, the dyeing temperature plays the most significant role with respect to the maximum equilibrium dye uptake.

Bach et al. [24] studied dyeing PLA fibres in supercritical carbon dioxide. PLA fibres were completely dyed using disperse dyes at temperatures equal to or above 50°C. It is stated that fibre damage and elongation at break in scCO2 were similar to optimum water-based processes. Dye uptake increased considerably at temperatures equal to or above 80°C. However, dyeing temperature in supercritical carbon dioxide should not go beyond 90°C to avoid remarkable losses in fibre quality as a result of hardening and crumpling of PLA fabrics [24]. Although deep shades in black or navy blue on PLA dyed in scCO2 with the dyes tested were not achieved yet, it is stated that scCO2 has potential for finishing PLA fibres [24].

Wet processing of PLA/cellulosic blends needs to be adapted by reason of the sensitivity of PLA to alkali treatments [25]. Phillips et al. [8] reported that the two-stage dyeing of PLA/cotton blends using disperse dyes followed by either warm or hot dyeing reactive dyes after an alkaline scouring process (for cotton) did not cause excessive reduction in molecular weight and the strength of PLA fibre. It is claimed [8] that this dyeing process for PLA/cotton blends should not cause a considerable reduction in the strength of the PLA fibre under commercially realistic processing conditions. However, prolonged dyeing times, particularly at neutral or alkaline pH, might cause problems if an unusually large number of shading additions needed to be carried out [8]. It is suggested [8] that a simulated one-bath (‘all-in’) dyeing of PLA fibre using disperse and reactive dyes under neutral pH conditions should be avoided due to observed significant depolymerization and severe strength loss on PLA fibre. Although there was a reduction in physical strength of PLA fibre when warm and hot reactive dyeing processes were carried out on PLA/cotton blend after alkaline bleaching, simulated high-temperature dyeing, and reduction clearing, the difference in mechanical properties of PLA fibre was not significant [9]. Phillips et al. [9] concluded that physical strength will be retained at a technically and commercially acceptable level provided that prolonged high-temperature processing times are not employed.

Dyeing of PLA/wool blends does not need to be adapted due to the sensitivity of PLA to alkali treatments, since both fibres exhibit same characteristic regarding alkali [25].

K. Sawada et al. [5] investigated the possibility of dyeing PLA fabrics with conventional indigo dyes. It is reported that PLA fabrics could be dyed in deep shade by a similar method of dyeing cellulose fibres with vat dyes. A temperature of 373 K was the lowest temperature for dyeing PLA with indigo to achieve high color yield, from the energy-saving point of view. The PLA color strength (K/S) gradually decreased with increasing dyeing time from 1 hour to 5 hours, which was quite different from the dyeing behaviors of conventional dyeing processes [5]. One hour of dyeing time was chosen to be the optimum dyeing time for the rest of their study. The color yield of PLA was at its peak when the dye concentration was 5% owf, where K/S values decrease at higher concentrations. Effects of auxiliaries (NaOH, Na2S2O3) on the dyeability of dyes were significant and were negative at the high-concentration range. It is claimed [5] that optimum concentrations of auxiliaries and dyes could be estimated with a simple linear experimental equation.

Dye Exhaustion

Dye build-up properties, dye exhaustion, and color strength on fibres are very important parameters for dyeing, where the exhaustion of dye on fibres should be as high as possible to optimize batch-to-batch shade reproducibility and thus to decrease dyeing costs and reduce color in the effluent [19, 26]. Dye selection for dyeing PLA is very crucial. Dye selection has to balance many factors, including exhaustion levels, color yields, fastness requirements, reproducibility, and levelness [25].

Scheyer and Chiweshe [20] studied a range of disperse dyes applied on PLA at a concentration of 2% owf at 100ºC; seven of the nine dyes studied exhibited exhaustion levels of below 80%. The exhaustion of nine disperse dyes, applied at varying depths of shade, was compared by Lunt and Bone [11, 12]. All the dyes examined had 80% or more exhaustion on PLA dyed at 110ºC for 60 minutes. Five of the nine dyes applied to PLA exhibited very similar performances in terms of percentage exhaustion to that observed with PET. The degrees of dye exhaustion are generally equal to or lower than that on PET. Yang and Huda [26] studied the exhaustion of 10 disperse dyes on PLA and PET fabrics dyed at 2% (owf). Dyes on PLA also exhibit greater variation in exhaustion levels compared to dyes on PET [26]. Yang and Huda [26] found that the percentage dye exhaustion of the disperse dyes studied on PLA was lower than that on PET substrates. A limited number of commercial disperse dyes have been found to have good exhaustion on PLA at the appropriate dyeing conditions [10, 12, 17, 27–30].

Scheyer and Chiweshe claimed [20] that small linear dyes must be used for dyeing PLA since PLA fibre crystallinity inhibits dye diffusion. Disperse dyes with multiple carbonyl (-C=O) groups did not exhaust well on PLA [20]. It is claimed [20] that disperse dyes with carbonyl groups and anthraquinone dyes should be avoided. It is stated that conventional medium-energy disperse dyes are the most suitable for dyeing PLA [11]. According to research undertaken by DyStar on the dyeing of PLA, medium-energy disperse dyes were found to provide the most consistently high levels of exhaustion, whereas high- and low-energy disperse dyes gave variable and low levels of dye bath exhaustion respectively [19].

Scheyer and Chiweshe stated [20] that the dyebath temperatures used (70 and 100ºC) may result in greater crystalline fibre structure, causing a reduction in the fibre interstices and leading to reduced uptake of dye. Morphological structural characteristics of PLA fibre during disperse dyeing were examined by Lowe and Negalescu [31]. They suggested to equilibrate the morphology (crystallinity) of PLA fabrics by including a preliminary annealing step in the technological program of the disperse dye application so as to control the exhaustion of the dyebath by PLA fibre.

The exhaustion and color yields can be altered by varying the proportions of the D- and L- isomers [32]. PLA fibre with high D-isomer levels exhibits higher exhaustion and higher color yield compared to low-D fibres due to its more amorphous, less crystalline nature [32].

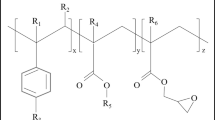

The individual dye behavior on PLA is quite different from dyeing on PET [25]. PLA fibre dyed with C.I. Disperse Red 60 exhibits high diffusivity and low saturation dye uptake characteristics [22]. It is reported that the rate of dye diffusion in PLA is much higher than that of PET [22]. It is known that the low saturation balance of PLA fibres leads to a lower dye (C.I. Disperse Red 60) uptake and poor build-up properties compared to PET [22]. Low dye exhaustion is generally a sign of high dyeing costs and high color concentration in the effluent [24]. What is more, high dye exhaustion shows that the dye has a high affinity for the fibre, leading to good color fastness [27]. It is important to state that the commercial disperse dyes used at present for dyeing PLA were actually developed for dyeing PET. Therefore, some researchers have recently tried to explain disperse dye exhaustion on PLA and claimed that dyes with solubility parameters near that of PLA (20.2 (J/cm3)0.5) tend to have high exhaustion on PLA [28]. Disperse dyes that have solubility parameters less than 25.0 (J/cm3)0.5 exhibited greater than 70% exhaustion on PLA fibre at 2% owf. Karst and Yang [28] proposed general structures for new disperse dyes, that could be made commercially for PLA fabrics and that may have high exhaustion on PLA. The authors stated that disperse dyes with solubility parameters close to that of PLA are mainly azo dyes and other dyes that contain more –NR2, –NHCOR, –NHR, –COR, –OR, or –COOR groups than –NO2, –NH2, –OH, –CN, and halide groups, and the groups are –CH3, –(CH2) nCH3, or a phenyl [28]. The solubility parameters of most of the anthraquinone dyes are not close to that of PLA. The authors claimed that anthraquinone dyes may have close solubility parameters to that of PLA if they contain only functional groups with an R group, which should be a large –(CH2)nCH3 groups [28].

Furthermore, D. Karst et al. [27] studied the effect of disperse dye structure on dye exhaustion on PLA fibre using molecular modelling with the interaction energies between the disperse dyes and PLA. They found that disperse dyes that form stronger interactions with PLA exhibited greater percentage exhaustion on PLA. The functional groups within the dyes that form the strongest interactions with PLA are –N(C2H4OCOCH3)2, –(CO2)NC3H6OCH3, –SO2NHC6H5, –NO2, – CN(NH)C6H4, and –CH(CO)2C6H4, and the groups that form the weakest interactions with PLA are –Br and –Cl [27].

New dyes for PLA fibres

L. He et al. [33, 34] have developed new hydrophobic anthraquinone dyes with high affinity for PLA as an alternative to the existing commercial disperse dyes. Several model dyes with hydrophobic chains were synthesized [33]. These developed dyes (Dyes 1-6, Fig. 3) with hydrophobic aliphatic and aromatic chains exhibited greater than 85% exhaustions at 2% owf with good wash fastness properties whereas three commercial anthraquinone dyes (C.I. Disperse Blue 3, C.I. Disperse Blue 56, and C.I. Disperse Blue 73) had less than 50% exhaustions [33].

Anthraquinone dyes containing an aliphatic chain exhibited higher exhaustion improvement compared to anthraquinone dyes containing an aromatic chain [33]. This suggests that dyes that have a structure similar to PLA (aliphatic polyester) will have high affinity with PLA. [33]. Although the introduction of alkyl chain to the anthraquinone ring was a necessary factor to increase the dye exhaustion, the length of the alkyl chain should not be very long, which leads to lower dye exhaustion due to possible decreased dye penetration [33, 34].

After-clearing treatments

Because of their limited water solubility, disperse dye molecules are deposited on the surface of the fibres as relatively large particles as the dyebath is cooled down. These surface deposits of ‘unfixed’ dye can lead to a reduction in fastness, particularly rubbing and wet fastness, as well as dulling of the shade. Apart from the presence of dye on the surface of the fibre, depending on the type of dyeing process, surface-active agents and carrier residues may also be present. The removal of surface-deposited dye, as well as auxiliaries, by treatment with a detergent or reductive or oxidative treatment, ensures optimum fastness of the dyeing to washing, light, rubbing, and heat setting, and also improves the brightness of shade. To this end, a reduction-clearing process is generally applied to polyester fibre after dyeing [35–37], especially for medium and heavy depths of shades [38]. Maximizing the wash-fastness without affecting the shade of the substrate is an essential objective in defining the appropriate conditions for reduction clearing. Reduction clearing of dyed PET fibres is usually carried out using 3g/liter sodium dithionite (‘hydros’) and 3g/liter sodium hydroxide, at 70–80°C, for 10-20 minutes.

Although Phillips et al. [9] concluded that no adverse significant effects on the physical strength (in terms of its molecular weight and tensile properties) of PLA fabric occurred as a result of either after-acid (using 2ml/liter Cyclanone ECO (BASF) at 70°C for 20 minutes) reduction clearing or after-alkali reduction clearing (using 5 ml/liter caustic soda and 3 g/liter sodium dithionite at 70°C for 20 minutes), the milder alkali soda ash is preferred as an alternative to sodium hydroxide for clearing purposes due to the higher sensitivity of PLA to alkali than PET. Since PLA is alkali sensitive, it loses molecular weight and fibre strength by hydrolysis. Avinc et al. [39] investigated the optimum alkaline reduction clearing conditions for PLA fibres in order to minimize shade change on processing and to maximize wet fastness. It is reported [39] that the preferred conditions are 15 min at 60°C in the presence of 2 g/liter sodium carbonate and 2 g/liter ‘hydros,’ conditions that avoid any significant change of shade by color loss and lead to optimized wash fastness. During alkaline reduction clearing of the PLA fabric, at temperatures above the glass transition temperature, the fibre opens up and increases its free volume, leading to a stripping effect of the dye, which results in a reduction in visual color yield (K/S) and the molar dye content of the dyed and reduction-cleared PLA [39].

Bach et al. [24] after-cleared the dyed PLA fabric with cold supercritical carbon dioxide. This treatment decreased the color depth of PLA fabric and led to nonuniform dyeing [24].

Burkinshaw et al. [40–42] studied the possibility of clearing of PLA fibres using ultrasound and ECE detergent instead of the traditional reduction clearing process using Na2S2O4 and Na2CO3. It is reported [40] that clearing with ECE detergent removed surplus dye and also improved the chroma of dyeings, whereas clearing with only water exhibited very little effect on the color strength and color of dyeings, even in the presence of ultrasound. The effectiveness of either the ECE detergent or the reduction clearing processes neither impaired nor overly enhanced the use of ultrasound [40]. It is further [41] stated that traditional reduction clearing was slightly more effective than ECE detergent in improving wash fastness despite the fact that the ECE detergent resulted in higher levels of rub fastness. In terms of rub fastness, ultrasound increased the effectiveness of both reduction clearing and ECE detergent [41]. Burkinshaw et al. [42] claimed that clearing treatment using 2 g/liter ECE detergent in the presence of ultrasound may replace the traditional reduction clearing process using Na2S2O4 and Na2CO3. This proposed treatment may offer a reduced risk of hydrolytic damage to the fibre, reduced chemical consumption, and more environmentally acceptable effluent [42].

Dye Shades

The color of the dyed fabrics is a very crucial key driver especially when buying a new garment. Dye shades on PLA are a different tone, hypsochromic (maximum absorption at a shorter wavelength) and brighter compared to PET [1, 22] (Fig. 4), since the lower refractive index of PLA leads to deeper and brighter shades on PLA than on PET [1]. It was also claimed that the color yield of dyed PLA was higher than that of PET at the same dye applied due to the lower reflectance of PLA [26, 43].

Choi and Seo [44] stated that the yellow and blue dyes were greener in hue on PLA than on PET, whereas orange/red dyes were yellower. PLA dyeings showed greater L* and C* values compared to PET dyeings [44, 45]. Hue angle values (h) were also consistently greater for PLA dyeings compared to the PET dyeing. [45]

Dark shade dyeing (especially black shades) of PLA is more problematic compared to PET due to lower exhaustion levels [25]. Very good black shades are obtained on high-D PLA fibres, while a more brownish black is achieved on low-D PLA fibres because of the lower exhaustion of the blue component of the mixture [32].

Color Fastness

The color fastness of dyed PLA tends to be slightly lower than that of PET at similar depths of shade. Yang and Huda [26] reported that the disperse dyes studied exhibited lower washing and rub fastness on PLA than on PET. Choi and Seo [44] reported that wet fastness of each PLA dyeings (at 4.0% o.w.f.) was either similar or up to 1 point lower that its PET counterpart. However, L.E. Scheyer and A. Chiweshe claimed [20] that most disperse dyes on PLA fibre would have acceptable wash fastness for apparel applications. The wash fastness of high- and low-D PLA fibres exhibit very little difference due to their close glass transition temperatures [32]. Bach et al. [24] reported that wash and rub fastness of PLA fibre dyed in scCO2 was good to very good when PLA was not after-cleared in cold scCO2.

L.E. Scheyer and A. Chiweshe reported [20] that fume fading would not be a problem in apparel PLA applications since disperse dyes on PLA exhibited good resistance to fading by nitrogen gas fumes.

Yang and Huda [26] reported that the differences in light fastness between dyed PLA and PET fabrics were smaller than that in washing and rub fastness. L.E. Scheyer and A. Chiweshe stated [20] that PLA fabrics exposed to outdoor light, which has more wavelengths in the UV region leading to more color fading, faded slightly more than those exposed to indoor exposure due to the difference in the wavelength distribution of the light source. PLA exhibits much higher transmittance of UV radiation in the 370-240nm range than PET (Fig. 5), leading to inferior light fastness properties of disperse dyes in PLA due to the possible destruction of sorbed dye, especially for blue dyes [18, 22, 46].

Mogi et al. [47, 48] studied the light fastness of azo and anthraquinone disperse dyes on PLA fabrics. PLA fabrics’ (dyed with 12 commercial azo disperse dyes at 1% owf) discoloration increased with rise in exposure time when these fabrics were exposed to a carbon arc light source [47]. The azo disperse dyes containing cyanoethyl (C2H4CN) or acetoxyethyl (C2H4OCOCH3) groups as substituent (such as in the case of C.I. Disperse Red 50, Red 82, and Orange 30) exhibited high light fastness. Mogi et. al. [47] reported that the cyano or chloro group exhibited a positive effect on light fastness, whereas the methyl group showed a negative effect. PLA fabric with deeper color, having more sorbed azo disperse dye, tended to exhibit a higher light fastness than a paler colour one [47]. PLA fabrics dyed with 13 commercial anthraquinone disperse dyes were exposed to a carbon arc light source to examine their photofading behavior [48]. Similarly as in the case of azo disperse dyes [47], the deeper color PLA fabric generally showed a tendency to have higher light fastness than the paler one [48]. Mogi et al. [48] reported that PLA fabric dyed with C.I. Disperse Red 127 and Violet 27 exhibited the highest light fastness grades. The photofading behavior of PLA fabric dyed with a mixture of C.I. Disperse Red 127 and Violet 27 was decelerated as compared with the individually dyed PLA fabrics [48].

On the other hand, Choi and Seo [44] reported that the photostabilities of nitrodiphenylamine, monoazo, and anthraquinone dyes on PLA were very similar to those observed on PET apart from the case of one blue monoazo dye (C.I. Disperse Blue 284).

L. He et al. [33] claim that the introduction of halogen atoms into the anthraquinone dye generally can improve the light fastness on PLA. It is also reported [34] that the light fastness of anthraquinone dyes with aromatic amino or cyclo-fatty amino groups was higher than that of anthraquinone dyes with fatty amino group.

The selection of proper dyes and the use of suitable UV absorbers could be a solution obtaining higher light fastness results [22]. Mogi et al. [49] studied the effects of an UV absorber of benzotriazole type on the light fastness of dyed PLA fabrics. The light fastness of PLA fabrics dyed with C.I. Disperse Orange 25 and Orange 44 azo disperse dyes were increased by 0.8-1.8 grades. On the other hand, there seems to be a slight or detrimental effect in the case of the anthraquinone disperse dyes C.I. Disperse Red 60 and Red 127 [49]. It is concluded [49] that the UV absorber protected dyed PLA fabrics against photofading more effectively on lighter depths of shades than on heavier depth of shades.

Heat Setting and Thermal Migration

After completion of the dyeing and reduction clearing processes, the fabrics must be dried, which is usually carried out by heat treatment in the mills. Additionally, PLA and PET fabrics generally receive some form of after-treatment (antistatic, crease-resist, water-repellent finish), which also involves heat. Post heat-setting is often needed in order to produce a dimensionally-stable fabric to a required width and/or when applying a chemical finish. Typical industrial practice uses heat setting conditions of 180°C for 30 sec for PET. However, PLA is sensitive to high temperatures, having a relatively low melting point (around 170°C). This property not only limits the dyeing temperature but also restricts pre-heat and post-heat setting temperatures for finishing processes. The effect of heat setting (under slack, tensionless conditions for 3 minutes) on dyeability and structural property of PLA was investigated by Bommu et al. [50]. They reported [50] that a continuous increase in dye uptake of PLA fibres was observed with increase in heat setting temperatures ranging from 110 to 150°C. PLA fibres responded slowly up to a critical temperature of heat setting of about 130°C. A rapid increase in crystallinity and crystal size and a steep drop in orientation were observed beyond the heat setting temperature of about 130°C [50]. D. Phillips et al. [10] studied the effect of heat setting (at 130°C under tension for 15, 45, 120, and 240 sec) on dimensional stability and dyeing properties of PLA yarns. They reported [10] that acceptable levels of dimensional stability can be achieved after heat setting at 130°C for 30-45 sec. It is further [10] concluded that the exhaustion level and color strength of the disperse dyes studied on PLA yarns are constant after heat setting times of approximately 45 sec. It is stated that heat setting of PLA can be employed without damage at 130°C for 30 sec [51].

Nakamura et al. [22] stated that the wet fastness of dyed PLA becomes inferior after heat treatment. During heat setting, some disperse dye can migrate from the interior of the fibre to the surface, and at the same time limited sublimation of the dye can take place to the surrounding atmosphere [52, 53]. Phillips et al. [54] reported that the wet fastness of PLA is generally lower than PET after heat treatment due to a higher degree of thermal migration of the disperse dyes on the PLA compared to PET, in spite of the lower temperature of heat treatment (30 secs at 130°C for PLA compared with 30 secs at 180°C for PET). It has been suggested that the absence of pPPp-pPPp bonding forces between the dye and the PLA polymer chain may be a factor responsible for the greater accumulation of dye at the surface of PLA fibres as compared with PET [54]. Nakamura et al. [22] claimed that the fact that much more dye appeared on the fibre surface via thermal migration could be a result of the significantly higher diffusivity of disperse dyes in PLA fibre as compared with PET fibre, leading to lower wet fastness. Dyed PLA fabric exhibited no loss of disperse dye due to sublimation during heat treatment for 30 sec at 130°C [54].

Finishing

Enzyme or chemical processing of fibres are usually carried out to improve handling, dyeability, water absorbency, etc. Sawada et. al. [55] studied the modification of PLA fibre with enzymatic treatment using various kinds of protease and lipase. PLA fibre was hydrolyzed by the proteases derived from Bacillus subtilis and Bacillus licheniformis, which easily gain access to the inside of the fibre. The hydrolysis of PLA fibres with these enzymes resulted in a serious drop in fibre strength, although fibre weight loss is lower as evaluated by measuring fibre weight loss, testing the tear strength, and observing the fibre surface with SEM [55].

Ferreira et. al. [56] tried to improve the hydrophilicity of PLA spunlaced nonwoven textile structures, used in nonwoven wipes applications, by plasma treatment. Wetting and capillarity properties of PLA nonwovens were measured after various air atmospheric plasma treatments. They concluded that plasma treatments increased the hydrophilic properties of PLA nonwovens [56].

Wei et. al. [57] studied the antibacterial properties of poly(lactic acid) nonwoven medical dressings coated with nanostructured silver. They examined the effect of the coating thickness of the nano-structured silver films on the antibacterial property of PLA. They stated [57] that nano-structured silver films exhibited very good antibacterial property on PLA nonwoven and the antibacterial properties were improved as the film thickness increased. The increased deposition time caused increased coating thickness, leading to improved antibacterial properties of PLA nonvowen medical dressing. It was also reported that the percentage decrease of both bacteria, Staphylococcus aureus and Escherichia coli, reached 100 % when the coating thickness reached 1 nm.

Washing and drying

Repeated laundering is a normal part of the life-cycle of most apparel fabrics. Repeated laundering might change the surface and mechanical properties of fabrics to some extent, since laundering almost always involves mechanical agitation coupled with the effects of elevated temperatures, water, and chemical detergents. No degradation and damage was observed as judged from molecular weight and burst strength measurements after repeated laundering with different washing cycles (from hand wash at 40°C to hot machine wash at 70°C), which simulate five washings [25, 58]. The PLA fabric appearance remains very good without creasing, with a very clean surface after washing [25].

PLA fabrics were washed 100 times at 43°C to determine their durability [59]. The repeated laundering of PLA fabrics causes no significant damage [25, 59]. The bursting strength decreased only slightly after 75 washes and there was no significant change in molecular weight or basis weight after 100 laundry cycles. Commercial after-care washing instructions for garments made of PLA fibres are generally limited to hand washing or machine washing at 40°C [60].

Y. Yang et al. [61] studied the effect of the pH (8 or 10) and water temperature (35 or 55°C) during washing and the effect of drying conditions (air dry at 21°C/65% relative humidity or tumble dry at 50 or 70°C) on the ability of PLA to retain its mechanical properties after repeated laundering (50 cleaning cycles). It is recommended [61] that PLA fabrics should be cleaned with detergents with a low pH (i.e., pH 8), and detergents with a high pH (i.e., pH 10) should be avoided because they result in lower breaking tenacity, breaking elongation, and modulus retention due to the possible hydrolysis of the PLA polymer under strongly alkaline conditions. It is reported that washing PLA fabric at a water temperature of 35°C and air drying it at 21°C 65% RH resulted in higher modulus retention than washing and drying at higher temperatures [61]. Hydrolysis of PLA polymer was stated to be the main cause of loss in mechanical properties. Hot washing temperatures should be avoided. Washed wet PLA fabrics should be air-dried; however if tumble drying is preferred, low temperatures should be chosen [61].

Conclusion

Although the use of PLA fibre is in its early stage compared with conventional synthetic fibres such as PET, PLA fibre consumption is expected to rise in the future due to its ecological advantages with very nice technical performance as a textile fibre. A better understanding of PLA fibre and the possible effects of different wet processing treatments during production and after-care procedures during usage by the consumer is vital. Finding the best conditions and methods for wet processing and after-care applications for PLA-based textile products will lead to increase in the consumption of this natural renewable resource-based melt-processable PLA fibre. New research and improvements in chemistry and wet processing of PLA fibres will obviously further expand the use of this fibre and new applications.

References

J. S. Dugan, Novel Properties of PLA fibers, Research Fiber Innovation technology, Inc, INTC 2000, Texas, USA, http://www.fitfibers.com/publications.htm, 2000.

D. J. Sawyer. Nonwovens World, 10 (2), 49 (2001).

R. E. Drumright, P. R. Gruber and D. E. Henton, Adv. Mater., 12 (No. 23), 1841 (2000).

K.E. Perepelkin, Fibre Chem., 34(No.2), 85 (2002).

K. Sawada and M. Ueda, Dyes Pigments, 74, 81 (2007).

Basic Fiber Properties. Fibers Information, Ingeo TM fi ber technical information, March 2003.

Fibre and Fabrics Properties Comparison. Fibers Information, Ingeo TM fi ber technical information, March 2003.

D. Phillips, J. Suesat, M. Wilding, D. Farrington, D. Sawyer, S. Sandukas, J. Bone and S. Dervan, Color. Technol., 120, 35 (2004).

D. Phillips, J. Suesat, M. Wilding, D. Farrington, S. Sandukas, D. Sawyer, J. Bone, and S. Dervan, Color. Technol., 120, 41 (2004).

D. Phillips, J. Suesat, M. Wilding, D. Farrington, S. Sandukas, D. Sawyer, J. Bone, and S. Dervan, Color. Technol., 119, 128 (2003).

J. Lunt and J. Bone, Properties and dyeability of fibers and fabrics produced from polylactide (PLA) Polymers. “Proc. AATCC Int. Conf. Exhibition,” Winston- Salem USA, 2000.

J. Lunt and J. Bone, AATCC Rev., September, 20 (2001).

Dyeing Knitted Goods from Filament Yarns. Downstream Information, Ingeo TM fiber technical information, February 2003.

S. R. Karmakar, Textile Science and Technology, “Chemical Technology in the Pre-treatment Processes of textiles,” Elsevier, 1999.

T. Kameoka, I. Kawamura, I. Ghoda, M. Ajioka, K. Takuma, A. Yamaguchi, and H. Suizu, U.S. Patent Number, 5,630,849, May 20 (1997).

Y. Yang and S. Huda, The balance between dyeing and physical properties of PLA, “Proc. AATCC Int. Conference Exhibition,” 2002.

Y. Yang and S. Huda, AATCC Rev., August, 56 (2003).

C. Hawkyard, “Synthetic fibre dyeing,” Society of Dyers and Colourists, 2004.

DyStar Textilfarben GmbH & Co. Deutschland KG, “IngeoTM Fiber Coloration Pack,” DyStar plc, 2004.

L. E. Scheyer and A. Chiweshe, Application and performance of disperse dyes on polylactic acid (PLA) fabric, “Proc. AATCC Int. Conf. Exhib.,” p. 298, 1999.

Ingeo™ Fibre Apparel Product Guidelines, Dyeing and Finishing, www.natureworksllc.com.

T. Nakamura, K. Ishii, H. Kubokawa, K. Mogi, and R. R. Bommu, An overview on dyeing properties of polylactic acid (PLA) fiber, “Proc. AATCC Int. Conf. Exhib.,” 2001.

T. Nakamura, ITB Int. Textile Bull., 4, 68 (2003).

E. Bach, D. Knittel, and E. Schollmeyer, Color. Technol., 122, 252 (2006).

R. S. Blackburn, “Biodegradable and sustainable fibres,” Woodhead Publishing Limited, 2005.

Y. Yang and S. Huda, J. Appl. Polym. Sci., 90, 3285 (2003).

D. Karst, D. Nama, and Y. Yang, J. Colloid Interface Sci., 310, 106 (2007).

D. Karst and Y. Yang, J. Appl. Polym. Sci., 96, 416 (2005).

I. Negulescu and N. E. Lowe, Polym. Prepr., 42, 611 (2001).

L. E. Scheyer, A. Chiweshe, AATCC Rev., 1(2), 44 (2001).

N. E. Lowe and I. I. Negalescu, “AATCC International Conference and Exhibition,” 2001.

R. S. Blackburn, X. Zhao, D. W. Farrington, and L. Johnson, Dyes Pigments, 71, 18 (2006).

L. He, S. F. Zhang, B. T. Tang, L.L. Wang, and J. Z. Yang, Chin. Chem. Lett., 18, 1151 (2007).

L. He, S. F. Zhang, B. T. Tang, L.L. Wang, and J. Z. Yang, Chin. J. Chem. Eng., 17(1), 156 (2009).

D. M. Nunn, “Dyeing of synthetic-polymer and acetate fibres,” Bradford: Dyers Company Publications Trust, 1979.

R.W. Moncrieff, “Man-Made fiber,” London: Butterworth & Co. ltd, 1975.

J. R. Aspland, Chapter 8: Disperse dyes and their application to polyester, Text. Chem. Color., 24(12), 18 (1992).

“Dyeing and Finishing of Polyester Fibres,” B 363e, BASF, Germany, 1975.

O. Avinc, J. Bone, H. Owens, D. Phillips, and M. Wilding, Color. Technol., 122, 157 (2006).

S.M. Burkinshaw and D.S. Jeong, Dyes Pigments, 77, 171 (2008).

S.M. Burkinshaw and D.S. Jeong, Dyes Pigments, 77, 180 (2008).

S.M. Burkinshaw and D.S. Jeong, Dyes Pigments, 77, 387 (2008).

M. Matsui and Y. Kondo, “35th International Man-Made Fibers Congress,” Dorbin/Austria, September 25–27, p.1-10, 1996.

J. Choi, W. Seo, Fibers Polym., 7(No.3), 270 (2006).

J. Choi, M. Kim, J. Park, J. Jeon, D. Kim, and A. D. Towns, Fibers Polym., 8(No.1), 37 (2007).

T. Nakamura, Fiber Prepr., 59 (2004).

K. Mogi, T. Nakamura, H. Kubokawa, H. Komatsu, Sen’i Gakkaishi, 57(No.8), August, 234 (2001).

K. Mogi, T. Nakamura, H. Kubokawa, H. Komatsu, Sen’i Gakkaishi, 57(No.8), August, 239 (2001).

K. Mogi, H. Kubokawa, H. Komatsu, and T. Nakamura, Sen’i Gakkaishi, 59(No.5), August, 198 (2003).

R. R. Bommu, T. Nakamura, K. Ishii, H. Kubokawa, K. Mogi and Y. Kamiishi, “AATCC International Conference and Exhibition,” 2001.

I. Holme, Knit. Int., 112(Issue: 1330), 24 (2005).

P. Richter and W. Bury, Melliand Textilber., 65, 692 (1984).

J. Shore, “Colourants and Auxiliaries, Volume 2,” Bradford: Society of Dyers and Colourists, 1990.

D. Phillips, J. Suesat, J. Taylor, M. Wilding, D. Farrington, J. Bone, and S. Dervan, Color. Technol., 120(5), 260 (2004).

K. Sawada, H. Urakawa, and M. Ueda, Textile Res. J., 77(11), 901 (2007).

M. Ferreira, S. Solarski, P. Vroman, E. Devaux, F. Leroux, C. Campagne, and A. Perwuelz, “Autex 8th World Textile Conference,” Biella, Italy, June, 2008.

H. Wang, Q. Wei, X. Wang, W. Gao, and X. Zhao, Fibers Polym., 9(No.5), 556 (2008).

P. Gruber and M. O’Brien, Biopolymer, Volume 6, Chapter 8, Polylactides: NatureWorks® PLA, June 2001

Cleaning method on 100% PLA knit Fabric, 100 washings and 50 drycleanings, www.natureworksllc.com.

S. Anton-Katzenbach, TVP 01, 24 (2005).

D. Karst, M. Hain, and Y. Yang, J. App. Polym. Sci., 108, 2150 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Khimicheskie Volokna, No. 1, pp. 59-69, January-February, 2010.

Rights and permissions

About this article

Cite this article

Avinc, O., Khoddami, A. Overview of Poly(lactic acid) (PLA) fibre. Fibre Chem 42, 68–78 (2010). https://doi.org/10.1007/s10692-010-9226-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10692-010-9226-7