Abstract

Based on the panel data of 30 provinces (cities) in China, this paper first measures the total factor energy efficiency, technical efficiency index and technological progress index from 2003 to 2018 by using the DEA-GML index method. Then, a panel Tobit model is constructed to analyze the impact of different industrial agglomerations on total factor energy efficiency and its components. It can be found from the empirical results that the agglomeration of manufacturing industry has no significant impact on the performance of total factor energy efficiency, and the agglomeration of producer services and the collaborative agglomeration of manufacturing and producer services promote the improvement of energy efficiency. Among them, the main way for industrial agglomeration to improve total factor energy efficiency is technological progress, and the promoting effect of technological progress is enough to make up for the inhibiting effect of industrial agglomeration on technical efficiency. Further research finds that the impacts of manufacturing agglomeration, producer services agglomeration and collaborative agglomeration in different regions on total factor energy efficiency are different. Specific suggestions to improve total factor energy efficiency are put forward, such as accelerating the deep integration between industries, improving technological innovation ability, implementing differentiated development strategy, and improving the market mechanism about energy conservation and emission reduction strategies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

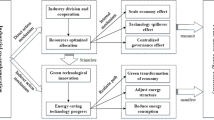

With the continuous improvement of China’s economic strength, environmental pollution and energy consumption have become the focus of attention from all walks of life, which has a serious impact on people's daily life. The improvement of energy efficiency is a significant means for China to achieve green transformation and sustainable development targets. How to improve total factor energy efficiency is urgent need to be solved (Lin & Liu, 2015; Shi & Li, 2020). In addition, industrial agglomeration, as an important organizational form affecting factor mobility, has a great influence mainly through the factors of technological progress on economic development (Fan et al., 2014). Theoretically, industrial agglomeration can produce externality, which has a positive effect on enterprises through technology spillover and knowledge diffusion effect in the same region, thereby affecting economic development. (Fujita et al., 1999). However, the negative externality led by industrial agglomeration also brings a series of energy and environmental problems. For example, excessive industrial agglomeration produces crowding effect that accelerates energy consumption and increases cost loss of enterprises, resulting in reduced marginal effect of agglomeration and diseconomies of scale. As a result, enterprises are unable to make effective use of energy and inhibit the improvement of energy and environment problems (Chen et al., 2018; Futagami & Ohkusa, 2003; Li, 2011; Pan et al., 2017). Therefore, under the goal of carbon peak and carbon neutralization, exploring the relationship between industrial agglomeration and total factor energy efficiency as well as its transmission pathway has great theoretical and practical significance for China to achieve green transformation and sustainable development.

Industrial agglomeration has two different types: single industrial agglomeration and multiple industrial agglomeration (Zhao & Sui, 2015). From the perspective of China' s economic development trend, industrial agglomeration is not only manifested in the geographical concentration of single industries such as manufacturing agglomeration and producer services agglomeration, but also more developed into collaborative agglomeration. Manufacturing agglomeration, producer service agglomeration and collaborative agglomeration all have impacts on total factor energy efficiency, but the impact intensity of three types of industrial agglomeration needs to be verified. Therefore, industrial agglomeration and total factor energy efficiency interact through a certain transmission mechanism, but what is the difference between single industry agglomeration and collaborative agglomeration on total factor energy efficiency? How do they affect total factor energy efficiency? In terms of impact intensity, is it easy to realize in the single industrial agglomeration of manufacturing agglomeration and producer services agglomeration, or is it easier to realize in the collaborative agglomeration? Due to the heterogeneity of regional politics, economy, culture and geography in China, whether there is regional heterogeneity in the face of different types of agglomeration patterns? How should each region make plans for its own differences? These issues remain to be further explored.

In view of this, firstly, the DEA-Global Malmquist–Luenberger productivity index is adopted to calculate and decomposed the total factor energy efficiency of 30 provinces from 2003 to 2018, and the decomposition variables—technological progress and technological efficiency, are studied as explained variables. Secondly, manufacturing agglomeration, producer services agglomeration and their co-agglomeration are calculated by location entropy method. Finally, the panel Tobit model is used to empirically study the heterogeneous effects of three agglomeration modes on total factor energy efficiency and its two decomposition factors. The overall research goal of this paper is not only to analyze the impact of different types of industrial agglomeration on energy efficiency, but also to refine the impact of industrial agglomeration on the main decomposition components of total factor energy efficiency and their degree comparison, so as to enrich relevant research, so that local governments can formulate industrial policies with a targeted aim to achieve the saving energy and reduction of emissions. The theoretical significance of this paper mainly reflects the following aspects: First, it enriches the research of China's total factor energy efficiency. This paper introduces energy as a production factor into the production function and uses the Global Malmquist–Luenberger (GML) index method to compare and analyze the total factor energy efficiency and decomposition efficiency at different levels. The second is to enrich and expand the research objects. Based on the existing research on industrial agglomeration and total factor energy efficiency, the relationship between them is further extended to different industrial categories and decomposition efficiency, and the effects of heterogeneous industrial agglomeration and collaborative agglomeration on total factor energy efficiency and decomposition efficiency are studied, respectively. The practical significance of this paper is to analyze the impact of industrial agglomeration on the overall and regional heterogeneity of total factor energy efficiency, so that local governments can formulate industrial policies according to the differences and provide guidance and suggestions for the overall improvement of total factor energy efficiency and development level, which is helpful to achieve the goal of energy conservation and emission reduction in China and promote the comprehensive, coordinated and sustainable development of economy and society.

2 Literature review

Combing the existing literature and research results, it is found that there are abundant studies on the influencing factors of total factor energy efficiency. Most of them investigate the influence characteristics of the changes from the aspects of technological progress, energy price, structural factors, marketization level, environmental regulation and openness, but the conclusions are different. Firstly, technological progress plays a vital factor in the energy research. Sinton and Levine (1994) believed that technological progress has a marked improvement in total factor productivity of the energy industry. Technological progress can reduce energy input under the same output or increase output under the same input (Fisher-vanden et al., 2004; Li & Zhou, 2006). Clarke et al. (2006) examined the sources of technological progress in the energy sector, arguing that spillover effects of R&D and learning within and outside an industry played an important role in technological progress. Some studies show that technological progress could lead to a rebound effect, which increases energy consumption to some extent, making the final impact of technological progress uncertain (Qiao et al., 2015). Secondly, energy prices are one of the economic instruments that affect energy efficiency (Birol & Keppler, 2000). Higher energy prices create reverse mechanisms, which can reduce energy demand and improve energy efficiency according to the principle of supply and demand. (Newell et al., 1999; Zhao et al., 2013). However, Tang and Li (2014) showed that China's energy market is not market-oriented and prices are dominated by the government, so that energy prices do not play their due role in the reverse mechanism. Thirdly, the research of structural factors mainly analyzes from economic structure, industrial structure and energy consumption construction. Farla and Blok (2000) studied the energy efficiency situation in the Netherlands from 1980 to 1995 and found that changes in economic structure had no significant effect on improving energy efficiency. Jiang (2004) concluded that the adjustment of economic structure could improve energy consumption per unit output value and further improve energy efficiency. Wei and Shen (2008) concluded that the industrial structure adjustment with “retreating from the second to the third” as the main idea could promote energy efficiency, while Zang and Liu (2012) believed that industrial structure had an inhibitory effect on energy efficiency. Energy consumption structure is also a representative factor in influencing energy efficiency. For energy consumption structure, the larger the percentage of coal consumption is, the less conducive it is to improve the energy efficiency. While the proportion of electricity and oil in total energy consumption is proportional to energy efficiency (Chen, 2014; Murtishaw & Schipper, 2001; Sinton & Fridley, 2000). In addition, urbanization level, environmental regulation, foreign trade level and many other factors also affect the total factor energy efficiency (Hancevic, 2016; Lin & Liu, 2015; Poumannyvong & Kaneko, 2010; Yang & Wei, 2018). For example, Lin and Du (2013) found that factor market distortions could significantly reduce energy efficiency by analyzing China's energy efficiency from 1997 to 2009. Liu (2022) found that trade liberalization has contributed to corporate energy efficiency, mainly through scale expansion and total factor productivity gains.

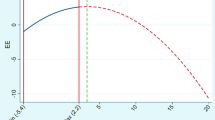

Under the logic framework of external economies of scale theory and new economic geography, industrial agglomeration is one of the material factors affecting economic development and production efficiency. In general, through theoretical and empirical research, some scholars divide the relationship between industrial agglomeration and total factor energy efficiency into one-way linear relationship and nonlinear relationship. Liu, Cheng, et al. (2017), Liu, Jiang, et al. (2017)) found that although industrial agglomeration promotes energy efficiency in central and western China, there are differences, that is, the promoting effect of industrial agglomeration on energy efficiency is stronger in the western region. Wang et al. (2020), from the perspective of transportation expansion, believed that it affects the flow of resources between regions and promotes intra-industry agglomeration, while industrial agglomeration further promotes energy efficiency through technology spillover, economies of scale and market competition. Han et al. (2014) confirmed that the economic spatial agglomeration has a significant role in promoting energy efficiency by using urban panel data. And Combes (2000), using a linear test model, argued that industrial agglomeration hinders total factor productivity. Shi and Ren (2019) found that government intervention could lead to apparent industrial agglomeration, which had a significant negative impact on energy efficiency. However, some scholars have found that the relationship may be nonlinear. For example, Shi and Shen (2013) believed that because of the 'free-rider' tendency of government intervention and environmental governance, the expected effect of industrial agglomeration on energy efficiency cannot be shown. Then, energy efficiency and urban density characterized by regional agglomeration show a U-shaped change. Zhao and Lin (2019) found that with the increasing scale of agglomeration, the effect of industrial agglomeration on energy efficiency has showed positive first and then negative. The nonlinear relationship reflects the rich influence relationship between industrial agglomeration and total factor energy efficiency. For this, scholars have theoretically analyzed the action mechanism of the two and summarize the positive and negative effects of industrial agglomeration on the improvement of total factor energy efficiency. The positive effect is mainly reflected in the scale economy effect, technology spillover effect and correlation effect. Firstly, the effect of economies of scale is the most important factor in the process of industrial agglomeration (), which is reflected in the industrial agglomeration to expand the production scale of enterprises, improve production efficiency and reduce production costs, so as to improve the optimal allocation of resources and promote the improvement of energy efficiency (Liu & Chen, 2020; Zhang & Chen, 2019a, 2019b). Secondly, industrial agglomeration promotes the rational allocation of talents and information exchange, produces technology spillover effect, and promotes the continuous progress of technology (Doms et al, 1995). Fisher-Vanden et al. (2004), Chen and Hu (2008) and Guo and Sun (2019) believed that the technological progress brought by industrial agglomeration can enhance the competitive advantage of the industry, stimulate the improvement of the level of technological innovation, and then cause the continuous increase in Solow surplus in the region, so as to improve the total factor energy efficiency. Thirdly, industrial agglomeration can affect energy efficiency through sharing effect, including infrastructure sharing effect, intermediate input sharing effect, information sharing effect, talent sharing effect, and so on. These sharing effects promote more refined production, realize more efficient and rational utilization of factor resources, achieve the purpose of reducing link energy consumption, and then improve the utilization efficiency of all factor energy (Chen & Tang, 2018; Connell et al., 2014; Liu, Cheng, et al., 2017; Liu, Jiang, et al., 2017). The negative effects of industrial agglomeration on total factor energy efficiency are reflected in crowding effect, crowding effect and free-rider effect. Firstly, excessive industrial agglomeration can produce crowding effect, leading to the imbalance of resource allocation, the decline of agglomeration marginal effect and the uneconomic scale, which hinder the improvement of energy efficiency (Henderson, 1986; Pan et al., 2017; Wu, 2019). Then, industrial agglomeration attracts a large number of production factors, resulting in the crowding out of other resources and increasing the sunk cost of enterprises. Affected by these factors, some inefficient enterprises cannot easily enter and exit, which is not conducive to the improvement of overall energy efficiency (Wang et al., 2021; Zhang & Chen, 2019a, 2019b). In addition, the various sharing effects of industrial agglomeration deepen the inertia and dependence of some enterprises, the free-rider effect is becoming more and more common, and the scientific research and innovation ability of industrial agglomeration decrease, which affects the improvement of energy efficiency.

Throughout the existing research, although the current research on industrial agglomeration and total factor energy efficiency is quite numerous and mature, there are many differences in the conclusion. Overall, the existing researches have the following deficiencies. Firstly, most literature studies the relationship between the two variables mainly from the perspective of overall industrial agglomeration or single agglomeration and rarely conducts comparative studies from three aspects of heterogeneous industrial agglomeration (namely, manufacturing and producer service industry agglomeration) and coordinated development. Secondly, there are differences in efficiency calculation methods, such as accounting growth accounting method, non-parametric DEA accounting method, parametric accounting method (Fan & Guo, 2019), and Solow residual value method. Most of them ignore environmental problems such as resource input and pollutant emissions. Thirdly, most of the existing studies simply study the influencing factors and lacks of analysis of the internal factors, so that the policy recommendations are lack of pertinence. Compared with previous studies, it is mainly expanded from the following aspects. Firstly, the total factor energy efficiency is calculated by using GML index, which includes non-consensual output environmental pollution indicators, and further the decomposition variables are compared and analyzed at different levels. Secondly, the decomposed technological progress and technological efficiency are also used as explained variables to empirically test the relationship between heterogeneous industrial agglomeration and its coordinated development and total factor energy efficiency and its decomposition efficiency, so as to comprehensively explore the relationship. Thirdly, since the economic scale and resource endowment of different regions in China jointly determine the significant differences among regions, the impact among different regions is analyzed.

3 Measurement framework and results of the total factor energy efficiency

3.1 Measurement method

Based on directional distance function proposed by Chung et al. (1997), the Malmquist–Luenberger productivity index calculation method has been widely used in the efficiency calculation (Yang et al., 2017), but this method has some problems. For example, the linear programming may be unsolvable, and it does not meet the conditions of transitivity and cyclic accumulation. Oh (2010) improved the ML index and proposed a global DEA linear programming to solve the directional distance function. After transformation, Global Malmquist–Luenberger (GML) index was obtained. Therefore, GML index is chosen to calculate and measure China's provincial total factor energy efficiency and its decomposition.

This paper takes Chinese provincial administrative regions as research units and defines them as follows: Suppose that in the period of \(t(t = 1, \ldots ,T)\), N sample cities can be set as decision-making units (DMU). Then, it is assumed that the K production inputs used by all DMUs are \(x = (x_{1} ,x_{2} , \ldots ,x_{K} ) \in R_{K}^{ + }\), the M expected outputs are \(y = (y_{1} ,y_{2} , \ldots ,y_{M} ) \in R_{M}^{ + }\), and the I unexpected outputs are \({\text{b}} = (b_{1} ,b_{2} , \ldots ,b_{I} ) \in R_{I}^{ + }\) (Xie et al., 2019); then, the production possibility set of phase t is:

Under the assumptions that the input and expected output are strong disposable, the unexpected output is weak disposable, and the output term satisfies the null combination axiom, the directional distance function is (Ru et al., 2020):

In formula (2), γ is the directional distance function value of phase t with the goal of maximizing expected output and minimizing undesirable output, \((g_{y} ,g_{b} )\) is the directional vector. Based on the above distance function, Oh (2010) further improved and proposed the concept of global distance function:

It means that the production possibility set of each period can constitute a global frontier by envelope method. Thus, the global directional distance function can be obtained:

Direction vectors are generally represented by expected and undesirable outputs. Furthermore, current and global directional distance functions can be represented by \(D^{{\text{t}}} (x^{t} ,y^{t} ,b^{t})\) and \(D^{G} (x^{t} ,y^{t} ,b^{t})\). On this basis, the calculation method of GML index is:

As can be seen from the above equation, the dynamic relative change rate index of total factor energy efficiency (\({\text{GML}}^{t,t + 1}\)) is composed of technical efficiency index (\({\text{GEC}}^{t,t + 1}\)) and technical progress index (\({\text{GTC}}^{t,t + 1}\)). Among them, \({\text{GEC}}^{t,t + 1}\) measures the degree of the decision-making unit moving to the best Frontier (catch-up effect), which is usually considered to be the effect of management system and policy reform. The index greater than 1 indicates the improvement of technical efficiency as well as contribution to total factor energy efficiency growth. \({\text{GTC}}^{t,t + 1}\) measures the distance between the frontier surface and the global frontier from t to t + 1 period, which reflects the outward shift of production possibility boundary (growth effect) caused by technological progress. If the index is greater than 1, it represents that technological progress has contributed to total factor energy efficiency growth (Kang et al., 2020).

3.2 Measurement data

Total factor energy efficiency refers to the efficiency of analyzing the impact of energy, capital, labor and other input factors on economic output. This efficiency effectively considers the interaction between various input factors and better reflects the impact of a region's resource endowment on energy efficiency (Yang & Shi, 2008). Since GML index measures dynamic efficiency from t period to t + 1 period, for the purpose of maintaining full-text temporal consistency of the full text, this paper selects the input–output data of 30 provinces in China (except Tibet) from 2002 to 2018 to calculate the efficiency, and the efficiency value of the base period in 2002 is 1. Specifically, input indicators include employment, capital stock and total energy consumption. Taking GDP as expected output indicator. Unexpected output indicators are measured by carbon dioxide emissions and sulfur dioxide emissions, reflecting the concept of green development. The process and data sources of each variable are as follows.

-

1.

Input indicators. Input indicators choose labor, energy and capital indicators. With regard to labor input, the number of employed persons in each province over the years is selected as a substitute indicator. With regard to energy input, taking into account the regional differences in energy consumption types, the total regional energy consumption equivalent to standard coal is selected as a substitute indicator. With regard to the capital stock index, most scholars calculate the provincial capital stock by using the “sustainable inventory method,” that is \({\text{k}}_{t} = k_{t - 1} (1 - \delta_{t} ) + I_{t}\), where \(I_{t}\) means the total fixed capital formation in t period, \({\text{k}}_{t}\) means the capital stock in t period, \(\delta_{t}\) manifests depreciation rate of t-period. In the Shan (2008)’s research results, δ in this paper is uniformly selected as 10.96% to measure the provincial capital stock from 2002 to 2018, which is the constant price based on 2000.

-

2.

Output indicators. Output indicators are divided into expected output and undesirable output indicators. Expected output indicators selected regional gross domestic product (GDP) as an alternative indicator, excluding the impact of time and price factors, and reduced to constant price levels based on 2000. Unexpected output uses CO2 and SO2 emissions as proxy variables. This paper adopts weak disposition when dealing with undesirable outputs. Referring to the method of Li and Qi (2011), the emissions of fossil energy combustion and cement industrial production process are mainly considered in the calculation of CO2 emissions. According to Chen (2011), the CO2 emission factors of coal, oil and natural gas are 2.7412, 2.1358 and 1.6262 (million tons / million tons of standard coal), respectively. The CO2 emission factor of cement clinker is 0.5272, and the clinker content in cement is approximately 75%, that is, about 0.3954 tons of CO2 are emitted from the production of 1 tons of cement. The emission factors of coal, oil, natural gas and cement are multiplied by the total consumption of each province over the years and then aggregated as the total CO2 emission of each province (city).

3.3 Measurement results

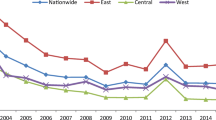

The dynamic total factor energy efficiency measured by the GML index, which reflects the rate of change in energy efficiency relative to the previous year. Figure 1 shows the dynamic trend of total factor energy efficiency (Gee), technical efficiency (Gec) and technical progress (Gtc) from 2002 to 2018 at the national level. Overall, the dynamic change of Gee is comparatively stable in the past decade, but energy efficiency increased significantly in the period 2015–2016. Since entering the '13th Five-Year' period, environmental protection is facing new situations and tasks, China has proposed a series of '13th Five-Year' green environmental protection ideas to improve overall energy efficiency. Another fluctuation was in the period 2007–2008, which may be due to since the 11th Five-Year Plan period, the fact that China has proposed to use energy saving indicators as binding indicators. In 2006, the central government first incorporated energy saving and emission reduction targets into the national economic development plan outline (Yu, 2021). The dynamic change trend of Gec is at a relatively stable level and fluctuates between 1, with the minimum value from 2015 to 2016. The dynamic change of Gtc has been above 1 since 2007, with the largest change from 2015 to 2016, indicating that technological progress has shown an increasing trend and contributed to the growth of total factor energy rate. Moreover, the trend of Gee and Gtc is similar. It can be roughly inferred that the change of total factor energy efficiency is mainly due to technological progress, and the later empirical evidence also confirms this view. The above analysis can predict that the impact of industrial agglomeration on overall total factor energy efficiency and technological progress may be similar in China. The specific results need to be further confirmed by econometric models.

Figure 2 intuitively depicts the average level of dynamic changes in 30 provinces (cities). It is found that in the eastern and central regions, the Gtc is generally higher than that of Gee and Gec, while the Gtc is quite different and the Gec is higher in the western region. The reason may be that the western region’s overall development is relatively backward, and the implementation of institutional and policy reforms improves technical efficiency. In terms of provinces, the economic development of Beijing and Shanghai is at a high level, the policy is relatively perfect, the technological innovation ability of enterprises and the awareness of energy conservation and environmental protection are strong, so the energy utilization efficiency is high, while Heilongjiang, Liaoning and Inner Mongolia are the lowest. This is because these provinces use coal resources as the main energy, and there is a low contribution rate of coal to the economy and the problem of high energy and low efficiency of the secondary industry. For the index of technological progress, Inner Mongolia has the highest average value of technological progress, which is higher than that of economically developed regions such as Beijing. The possible reason is that technological progress represents the degree of technological progress relative to the previous period, and the implementation of the national western development strategy promotes technological progress. At the same time, Inner Mongolia focuses on high-tech industrialization, adapts to market economic norms, and continuously realizes technological progress and innovation. In addition, it can be seen that there are significant differences in the three efficiency indexes between different provinces, so it can be predicted that the impact of China's industrial agglomeration on them is different.

Further, Fig. 3 depicts the average level of efficiency in the eastern, central, western region and the whole country. The change trends of Gee and Gtc are basically consistent in the whole country and different regions, which again verifies the above conclusions. Specifically, there are significant differences in index levels in each region, so regional heterogeneity may exist.

4 Model, data, results and discussion

4.1 Econometric model

Considering the efficiency value calculated by GML index as nonnegative truncated data with truncated characteristics, it belongs to limited dependent variables, and the estimation results obtained by traditional OLS, GLS and GMM have deviations. Therefore, the Tobit model is more appropriate to obtain more accurate parameter estimates. Construct the following panel Tobit model:

In the formula, \({\text{Gee}}_{it}\) represents the total factor energy efficiency variable obtained by GML index, and aggl represents the industrial agglomeration variable. When n = 1, 2, 3, respectively, represents the manufacturing agglomeration level (maggl), the producer service agglomeration level (saggl), and the coaggl level of manufacturing and producer services (coaggl). \(\beta_{0}\) is a constant term, and \(\beta_{1} \beta_{2} \beta_{3}\) reflect the influence coefficient between variables. \(X_{it}\) represents a set of control variables. \(\gamma_{i} ,\eta_{t} ,\varepsilon_{it}\) denotes, respectively, regional effect, time effect and random disturbance term, i denotes 30 provincial units, and t denotes time.

In order to further investigate the internal causes of the impact of heterogeneous industrial agglomeration and coordinated development on total factor energy efficiency in various regions, this paper constructs the panel Tobit model with technological efficiency (Gec) and technological progress (Gtc) as explained variables. The specific forms of the model are shown in Eqs. (7) and (8):

4.2 Variable selection and data sources

Using location entropy to measure industrial agglomeration, the larger the location entropy is, the stronger the agglomeration ability is and the more advantages of scale and comparison are. The computing formula is as follows:

Industrial collaborative agglomeration refers to the correlation between manufacturing and producer services in the industrial chain, emphasizing the rational distribution of different industries in space and the formation of organic correlation between them, which makes the agglomeration between the two show a trend of copolymerization (Ellison & Glaeser, 1997). The calculation of collaborative agglomeration level draws on the calculation process of Chen et al. (2016) and Zhang et al. (2017). It is expected that the industrial collaborative agglomeration index can not only reflect the collaborative quality, but also reflect the depth and height of collaborative agglomeration. The specific formula is as follows:

maggl represents the agglomeration level of manufacturing industry, saggl represents the agglomeration level of producer services, and coaggl represents the collaborative agglomeration level of manufacturing and producer services, where E denotes the number of employees, i denotes different provinces, m denotes the manufacturing industry, s denotes the producer service industry, and k denotes the whole country.

The control variables selected in this paper are as follows: (1) Foreign direct investment (fdi): Select the actual use of foreign direct investment and GDP ratio to measure, including the actual use of foreign capital according to the RMB exchange rate against the United States dollar into billions of dollars. (2) Level of government intervention (gov): Select the ratio of government fiscal expenditure to GDP to measure. (3) R & D input level (rd): Select the ratio of internal expenditure of research and experimental development (R & D) funds to GDP. (4) Energy price (ep): Select raw materials, fuel, power purchase price index to measure, and converted to 2003 unchanged price as the proxy variable of the actual energy price. (5) Urbanization level (urb): Select the ratio of urban population and total population to measure. (6) Virtual variable of energy conservation and emission reduction (D2006): According to Shao et al. (2011), in 2006, the central government incorporated the energy conservation and emission reduction targets into the national economic development plan for the first time. Therefore, the dummy variable of energy conservation and emission reduction is added. Before 2006, it takes 0 and then takes 1 (Zhang et al., 2020). The detailed description of all the related variables is shown in Table 1.

This paper uses 30 provinces in China from 2003 to 2018 as research samples, and the lack of data in Tibet is too much to be eliminated. The data are mainly from the EPS data platform, the Statistical Yearbooks of various provinces, China Statistical Yearbook, China Environmental Yearbook, China Environmental Statistics Yearbook and China Energy Statistics Yearbook, data units and descriptive statistical results are shown in Table 2.

4.3 Empirical results and discussion

4.3.1 Empirical Analysis on the national level

According to the method of Qiu et al. (2008), this paper obtains the total factor energy efficiency and decomposition efficiency from 2003 to 2018 by multiplying the GML index. Firstly, Hausman test and likelihood ratio test are used to test the model setting, and the results show that the double fixed effect model is suitable. Then, the parameter estimation of Tobit model uses maximum likelihood method. Because the LR test of the model all passed the significance test, the use of Tobit regression model is reasonable.

Table 3 reports the empirical analysis results of the impact of heterogeneous industrial agglomeration and its collaborative agglomeration on total factor energy efficiency, technical efficiency, and technological progress. Columns (1)–(3) show the impact of three industrial agglomerations on total factor energy efficiency. It can be concluded that the positive effect of manufacturing agglomeration is not significant, while producer services agglomeration and collaborative agglomeration have significant positive effects. Columns (4)–(9) show the impact of three industrial agglomerations on technological efficiency and technological progress. It can be concluded that three industrial agglomerations are significantly positively correlated with technological progress, and negatively correlated with technological efficiency. This indicates that the three agglomeration modes are beneficial to the improvement of total factor energy efficiency and technological progress on the whole, but not conducive to the improvement of technical efficiency. Technological progress is the main way for industrial agglomeration to improve total factor energy efficiency.

At the level of manufacturing agglomeration, from the perspective of the impact on total factor energy efficiency, the coefficient of manufacturing agglomeration is positive, but does not pass the significance test. The possible explanations for the reasons are as follows. Firstly, due to the problems such as the increase in production costs, the difficulty of technological innovation and the crowding effect in the agglomeration areas, manufacturing enterprises in the agglomeration areas are faced with fierce homogenization competition. Then, they often adopt the development model of high pollution emissions, which is difficult to induce the spatial spillover of knowledge and technology in a strict sense, resulting in negative externalities and is not conducive to the emergence of positive effects. Secondly, the agglomeration of manufacturing industry in China is only located in the geographical location, and the effective way to exert the effect of industrial agglomeration is not mature, and the horizontal and vertical cooperation mechanism and competitive cooperation relationship between enterprises have not been formed. All these fail to exert the positive effect of manufacturing agglomeration on energy efficiency. From the perspective of the impact on technical efficiency and technological progress, the regression coefficients are − 0.103 and 0.086, respectively, both pass the significance test. These results show that manufacturing agglomeration is beneficial to technological progress, but unfavorable to the improvement of technological efficiency.

At the level of producer services agglomeration, from the perspective of the impact on total factor energy efficiency, the regression coefficient of producer services agglomeration is 0.117 at the significance level of 1%. The reason is that first, the agglomeration of service industry, especially producer services, can effectively reduce the energy consumption, energy redundancy and pollutant emissions of industries in the secondary industry, indicating that industrial structure adjustment or substitution effect between industries can promote energy efficiency. Second, producer services agglomeration area has advantages in frontier knowledge and technology, and enterprises can produce strong spillover effects by face-to-face communication and interaction in the agglomeration area. From the perspective of the impact on technological progress, the regression coefficient is 0.117 at 1% significance level, which is close to the regression coefficient at overall energy efficiency, indicating that producer services agglomeration improves total factor energy efficiency mainly from the technological progress’s positive role. The possible reason is that the learning effect of agglomeration promotes the rapid transfer of advanced production factors and accelerates the absorption of new technologies and methods by enterprises, thereby improving the total factor energy efficiency.

At the level of collaborative agglomeration of manufacturing and producer services, collaborative agglomeration affects total factor energy efficiency in a significant positive way and has a significant negative and positive effect on the technical efficiency and technological progress of decomposition, respectively. The main reason is that in regions with higher degree of co-agglomeration, the spillover effects of knowledge and technology are more obvious. Manufacturing agglomeration effectively promotes the rapid development of producer services through the demand of producer services. Meanwhile, the agglomeration of producer services promotes the transformation and upgrading of the manufacturing industry through technology R & D, specialized division of labor and technology spillover, thus manufacturing industry and producer services to form the coordinated development of industry in a significant boost production technology level. This in turn improves energy efficiency. In addition, from the perspective of the influence coefficients of producer services agglomeration and collaborative agglomeration on energy efficiency, the influence coefficient of collaborative agglomeration is 0.107, which is smaller than that of producer services agglomeration 0.117. The reason may be that firstly, producer services agglomeration plays a major role in promoting energy efficiency (He et al., 2021), while the insignificant positive effect of manufacturing agglomeration is not conducive to the promotion of collaborative agglomeration on energy efficiency. The second is that collaborative agglomeration does not fully play a role, and there are problems of uncoordinated development and mismatch between single industrial agglomeration.

In addition, by comparing the regression coefficients of three kinds of agglomeration in technological progress, it can be found that three kinds of industrial agglomeration can strengthen technological innovation, play the positive externalities of agglomeration, and improve total factor energy efficiency through technological progress. However, the promoting effect of industrial co-agglomeration on technological progress is significantly higher than that of single industrial agglomeration, indicating that collaborative agglomeration plays a more significant role in technological progress. The reason is that where the industrial co-agglomeration is high, it is conducive to the industrial chain in the industrial cluster to achieve technological innovation through collaboration and communication. In the vertical direction, it is necessary to improve the innovation ability for common interests. In the horizontal direction, it will also stimulate technological innovation due to the driving force of competition. By comparing the regression coefficients of the three agglomerations in technical efficiency, it can be seen that the three agglomeration methods are not conducive to the improvement of technical efficiency. The reason may be that the technical efficiency index reflects the progress of the region in management system, resource allocation, and reform. On the one hand, industrial agglomeration puts forward new requirements for management system and resource allocation with the development, and the formation of management ability in this regard requires time accumulation and learning. On the other hand, the impact of industrial agglomeration on regional technical efficiency needs a cycle, that is, there may be a lag. To sum up, from the two aspects of technical efficiency and technological progress, the positive effect of different industrial agglomeration heterogeneity on technological progress is sufficient to compensate for the inhibition of technological efficiency, so as to enhance the overall level of total factor energy efficiency.

At the level of control variables, foreign direct investment (fdi) has a negative effect on the total factor energy efficiency at the significance level of 1%, and the coefficient is about − 0.94. This shows that fdi makes foreign enterprises transfer pollution sectors to China to some extent, and its technology spillover effect is not enough to achieve energy saving and emission reduction. The impact of government intervention level (gov) on overall energy efficiency, technical efficiency, and technological progress is significantly positive, positive and negative, respectively. This shows that although reasonable intervention of government has a promoting effect, but the intervention of economic activities may disrupt the rational allocation and flow of resources and make the energy elements fail to give full play to their maximum utility, which is not conducive to technological progress. R & D investment level (rd) impacts overall energy efficiency and technical efficiency in a significant positive way. This shows that the increase of R & D investment can enhance the managers and residents’ awareness of energy conservation and emission reduction, which promotes the spillover and absorption of green clean technology, stimulates technological innovation and improves technical efficiency. The coefficient of rd to technological progress is significantly negative. The explanation is as follows: Technological progress is the additional growth rate of output under the constant input mix, including the innovation and introduction of technology and the dividends brought by institutional reform (Tu, 2008). Although increasing the proportion of R & D investment encourages technological innovation to achieve the effect of technological progress, it is difficult to achieve technological spillover in a strict sense due to the negative competition of technology. In addition, China’s institutional reform remains to be improved, and there are problems in the allocation and use of R & D funds. Therefore, technological progress is difficult to achieve success. Energy price (ep) shows no significant positive effect, indicating that the increase in energy price promotes the improvement of energy efficiency. But due to the imperfect energy pricing mechanism in China, the role of energy prices on energy efficiency is relatively small, as well as the government intervenes in energy prices too much, which makes energy prices lack elasticity and adversely affects the rational allocation and effective use of energy factors. The regression coefficient of urbanization level (urb) is significant positive in total factor energy efficiency and technological progress, but not significant negative in technological efficiency. However, the implementation of energy conservation and emission reduction policy (D2006) has reduced energy efficiency, unlike Shao et al. (2019). The reason may be that although the central government included energy conservation and emission reduction in the 'Eleventh Five-Year Plan' for the first time in 2006, in response to the external disturbance of the international financial crisis in 2008, a large number of funds were selectively introduced to stimulate the economy, resulting in rapid expansion of energy-intensive industries and reduced energy efficiency.

4.3.2 Regional heterogeneity analysis

The above results analyze the impact of heterogeneous industrial agglomeration and its coordinated development on energy efficiency and its decomposition efficiency from the overall level, but do not take into account the differences between regions. The impact of heterogeneous industrial agglomeration and collaborative agglomeration on energy efficiency differences in different regions is shown in Table 4.

Specifically, for the eastern region, the manufacturing agglomeration has an indigenous negative effect on the two levels of total factor energy efficiency and technological progress, which may be due to the fact that the economic development advantage of the eastern region makes the manufacturing agglomeration generally at a high level. On the one hand, when the industrial agglomeration is too high, the economic benefit of the eastern agglomeration area can increase the production cost and produce the crowding effect. In addition, the effective way to play the manufacturing agglomeration effect is not mature, and the quality of regional industrial agglomeration is not high. These problems inhibit the improvement of total factor energy efficiency. On the other hand, over-agglomeration can lead to technology imitation due to the negative competition of technology, and it is difficult to achieve technological innovation breakthrough and technological spillover in a strict sense, thus inhibiting technological progress. Producer services agglomeration and collaborative agglomeration show positive effects at three levels. The influence coefficient of collaborative agglomeration is less than that of producer services agglomeration, which is consistent with the conclusion of the whole country.

For the central region, manufacturing agglomeration and co-agglomeration are significantly positive to total factor energy efficiency, which are 0.406 and 0.231, respectively, while producer service agglomeration shows no significant negative effect. The possible reason is that on the basis of effectively undertaking the manufacturing transfer in the eastern region, the manufacturing industry of the central region has achieved rapid development, greatly improved energy efficiency. Meanwhile, the development of producer services lags far behind the development of manufacturing industry, which has no obvious promoting effect on the upgrading of manufacturing industry, so industrial collaborative agglomeration does not fully play a role. Therefore, the central region should take advantage of regional manufacturing level, accelerate the development of producer services, and better promote the development of collaborative agglomeration.

For the western region, manufacturing agglomeration and producer services agglomeration have no significant positive effect on total factor energy efficiency, and collaborative agglomeration’s impact is significant positive. However, compared with the technical efficiency and technological progress, the inhibitory effect is greater than the promotion. These results show that in the western region, the overall agglomeration level is weak, and the scientific and technological content of industrial types is low, resulting in the promotion of energy efficiency has not yet been played out. Meanwhile, the ability of management and resource allocation along the industrial agglomeration in the western region is insufficient, and it tends to the development of state-owned enterprises and large enterprises in the manufacturing industry, which makes the technical efficiency cannot be successfully realized smoothly and thus plays a large inhibiting role.

5 Robustness test

For further verify the reliability of the research conclusion, the robustness test is carried out from the following aspects.

-

1.

Taking into account the variables may have a time lag effect, the three variables of manufacturing agglomeration, producer services agglomeration and co-agglomeration in the regression model are replaced by a lag term \({\text{maggl}}_{i,t - 1}\), \({\text{saggl}}_{i,t - 1}\) and \({\text{coaggl}}_{i,t - 1}\) for regression analysis. Regression results as Table 5, the above results are consistent with the empirical results.

-

2.

According to Bel and Joseph (2015) and Hu et al. (2020) studies, the economic crisis that erupted in 2008 had an important impact on emissions reductions. Therefore, considering the impact of the economic crisis, the sub-samples from 2008 to 2009 are excluded for regression analysis. Regression results as Table 6, the two results are still consistent.

-

3.

Considering that openness is also an important factor affecting total factor energy efficiency (Shi, 2006; Wei & Shen, 2007), this paper adds the degree of opening to the outside world in the control variables to re-regression analysis, using the ratio of total import and export trade to GDP to measure. The above results are not substantially different from the previous research conclusions. The regression results are shown in Table 7. In summary, the conclusions of this study are relatively robust.

6 Conclusions and policy recommendations

Taking the data of 30 provinces in China from 2003 to 2018 as samples, this paper first adopts the DEA-GML index method to measure the total factor energy efficiency and analyze different dimensions. Then, it uses the panel model to study the influence and degree of heterogeneous industrial agglomeration and collaborative agglomeration on the total factor energy efficiency and decomposition component—technology efficiency and technological progress. Finally, it makes an empirical analysis of regional heterogeneity. The empirical results show that from the national level, manufacturing agglomeration affects total factor energy efficiency in a no significant positive way, while producer services agglomeration and collaborative agglomeration have significant promoting effect on total factor energy efficiency. The impact of heterogeneous industrial agglomeration and collaborative agglomeration on technological progress is significant positive, but the impact on technological efficiency is negative, indicating that industrial agglomeration is mainly the way of technological progress to promote total factor energy efficiency. From the results of sub-regional heterogeneity, in the eastern region, manufacturing agglomeration has a significant negative effect on total factor energy efficiency and technological progress, while the impact of producer services agglomeration and collaborative agglomeration upon energy efficiency, technological efficiency and technological progress is significant positive. The conclusions of central China are basically consistent with those of the whole country. In the western region, the inhibitory effect of industrial agglomeration on technological efficiency is greater than the promoting effect of technological progress. Through the above conclusions, the following suggestions can be made:

First, in the process of manufacturing agglomeration, we should strengthen the incentive of technological innovation, better play the spillover effect of knowledge and technology to reduce homogeneous competition, and create the agglomeration environment and mechanism of benign industrial competition. In the process of producer services agglomeration, various policies should maximize the advantages of knowledge and technology in the frontier of producer services agglomeration, so as to further enhance the effect of producer services agglomeration on total factor energy efficiency. In the process of collaborative agglomeration, it is essential for energy utilization to promote the deep integration of the development between the single industrial agglomeration of producer services and manufacturing industry and make the two collaborative agglomerations play the greatest role.

Second, improve technological innovation capability, bring the role of industrial agglomeration in promoting technological progress into full play, and consolidate the foundation of green economic development. Empirical research shows that heterogeneous industrial agglomeration and coordinated development on the performance of total factor energy efficiency are mainly through the improvement of technological progress, while technological efficiency inhibits total factor energy efficiency to some extent. Therefore, the coordination of regional innovation policies should be fully considered in the formulation of industrial policies, and the two-way promotion of industrial agglomeration and regional technological innovation should be played. At the same time, it is necessary to build an open and transparent management system, strengthen mechanism and institutional innovation, give full play to the effects of management system and policy reform, reduce the negative effect of technical efficiency, and thus improve regional total factor energy efficiency.

Third, implement differentiated regional policies, accelerate the development of regional economy. In view of regional heterogeneity, it is material to accelerate the adjustment and optimization of industrial layout. The analysis results of regional heterogeneity show that the development status of each region is different, so it is necessary to implement differentiated development strategies to promote the improvement of energy efficiency by overall industrial agglomeration. The development of manufacturing industry in the eastern region shows negative effect, which requires accelerating the transfer of labor-intensive manufacturing industry, vigorously developing high-tech industry and equipment manufacturing industry, and paying attention to the coordinated agglomeration development. The central and western regions need to recognize the current development situation, accelerate the process of new urbanization and new industrialization, as well as utilize the advantages of factor cost and resource market. More importantly is to actively undertake industrial transfer in the eastern region and jointly play the role of collaborative agglomeration.

Fourth, encourage enterprises to increase R&D investment, pay attention to attract foreign international capital. We need to improve the market-based reform of the energy pricing system as the starting point, accelerate the realization of domestic energy prices and international standards, rely on the market mechanism to reduce energy misallocation caused by price distortions. A cross-regional carbon emission trading market mechanism should be gradually established to reduce unnecessary government intervention and save trading costs. When formulating and realizing the development policies and objectives, more comprehensive consideration should be given to the actual differences in regional layout and industry characteristics, and further balance and coordinate the government's policies and economic growth goals. At the same time, to reduce the inconsistency of macroeconomic policies caused by discretionary choices, we should plan the market mechanism of energy allocation for a long time, reasonably guide the expectation, and simultaneously achieve the dual goals of economic growth and energy conservation and emission reduction.

References

Bel, G., & Joseph, S. (2015). Emission abatement: Untangling the impacts of the EU ETS and the economic crisis. Energy Economics, 49, 531–539.

Birol, F., & Keppler, J. H. (2000). Prices, technology development and the rebound effect. Energy Policy, 28(6–7), 457–469.

Chen, G. J. (2014). Research on total factor energy efficiency of Chinese manufacture industry and its influence factors based on SFA. China Soft Science, 1, 180–192.

Chen, S. Y. (2011). Reconstruction of sub-industrial statistical data in China (1980–2008). China Economic Quarterly, 10(3), 735–776.

Chen, J. J., & Hu, C. G. (2008). Agglomeration effect of industrial agglomeration——theoretical and empirical analysis of Subregion of Yangtze River delta. Management World, 6, 68–83.

Chen, L., & Tang, X. H. (2018). Spillover effects of manufacturing agglomeration on urban green total factor productivity: Based on the perspective of urban grade. Finance and Trade Research, 29(1), 1–15.

Chen, D., Chen, S., & Jin, H. (2018). Indu1-126strial agglomeration and CO2 emissions: Evidence from 187 Chinese prefecture-level cities over 2005–2013. Journal of Cleaner Production, 172, 993–1003.

Chen, J. J., Liu, Y., & Zhou, M. M. (2016). The improvement of city productivity based on synergy and co-agglomeration of industries: Under the background of integrated innovation and conversion of driving force for economic development in China. Journal of Zhejiang University (humanities and Social Sciences), 46(3), 150–163.

Chung, Y. H., Färe, R., & Grosskopf, S. (1997). Productivity and undesirable outputs: A directional distance function approach. Journal of Environmental Management, 51(3), 229–240.

Clarke, L., Weyant, J., & Birky, A. (2006). On the sources of technological change: Assessing the evidence. Energy Economics, 28(5–6), 579–595.

Combes, P. P. (2000). Economic structure and local growth: France, 1984–1993. Journal of Urban Economics, 47(3), 329–355.

Connell, J., Kriz, A., & Thorpe, M. (2014). Industry clusters: An antidote for knowledge sharing and collaborative innovation? Journal of Knowledge Management, 18, 137–151.

Doms, M., Dunne, T., & Roberts, M. J. (1995). The role of technology use in the survival and growth of manufacturing plants. International Journal of Industrial Organization, 13(4), 523–542.

Ellison, G., & Glaeser, E. L. (1997). Geographic concentration in US manufacturing industries: A dartboard approach. Journal of Political Economy, 105(5), 889–927.

Fan, Q., & Guo, A. J. (2019). An improved Solow residual method for TFP calculating under the framework of spatial econometrical analysis. The Journal of Quantitative and Technical Economics, 8, 165–181.

Fan, J. Y., Feng, M., & Li, F. W. (2014). Industrial agglomeration and total factor productivity of enterprises. The Journal of World Economy, 5(5), 51–73.

Farla, J. C., & Blok, K. (2000). Energy efficiency and structural change in the Netherlands, 1980–1995: Influence of energy efficiency, dematerialization, and economic structure on national energy consumption. Journal of Industrial Ecology, 4(1), 93–117.

Fisher-Vanden, K., Jefferson, G. H., Liu, H., & Tao, Q. (2004). What is driving China’s decline in energy intensity? Resource and Energy Economics, 26(1), 77–97.

Fujita, M., Krugman, P. R., & Venables, A. (1999). The spatial economy: Cities, regions, and international trade. New York: MIT press.

Futagami, K., & Ohkusa, Y. (2003). The quality ladder and product variety: Larger economies may not grow faster. The Japanese Economic Review, 54(3), 336–351.

Guo, J. G., & Sun, H. (2019). Is specialization agglomeration of China’s manufacturing industry more conducive to energy efficiency than diversification agglomeration? Journal of Nanjing Audit University, 16(4), 93–102.

Han, F., Feng, P., & Yang, L. G. (2014). Spatial agglomeration effects of China’s Cities and industrial energy efficiency. China Population, Resources and Environment, 24(5), 72–79.

Hancevic, P. I. (2016). Environmental regulation and productivity: The case of electricity generation under the CAAA-1990. Energy Economics, 60, 131–143.

He, P., Sun, Y., Niu, H., Long, C., & Li, S. (2021). The long and short-term effects of environmental tax on energy efficiency: Perspective of OECD energy tax and vehicle traffic tax. Economic Modelling, 97, 307–325.

Henderson, J. V. (1986). Efficiency of resource usage and city size. Journal of Urban Economics, 19(1), 47–70.

Hu, Y., Ren, S., Wang, Y., & Chen, X. (2020). Can carbon emission trading scheme achieve energy conservation and emission reduction? Evidence from the industrial sector in China. Energy Economics, 85, 104590.

Jiang, J. H. (2004). Strategy analysis of improving energy efficiency and economic structure adjustment. The Journal of Quantitative and Technical Economics, 10, 16–23.

Kang, W. L., Zou, Y. K., Wang, L., & Liu, X. M. (2020). Measurements and factors of biased technological progress in China’s marine economy. Polish Journal of Environmental Studies, 29(6), 4109–4122.

Krugman, P. (1991a). Increasing returns and economic geography. Journal of Political Economy, 99(3), 483–499.

Krugman, P. R. (1991b). Geography and trade. MIT press.

Li, S. H. (2011). Industrial agglomeration, human capital and enterprise energy efficiency—A case study of high-tech enterprises. Finance and Trade Economics, 9, 128–134.

Li, K., & Qi, S. Z. (2011). Trade openness, economic growth and carbon dioxide emission in China. Economic Research Journal, 11, 60–72.

Li, L. S., & Zhou, Y. (2006). Can technological advances improve energy efficiency ?——Empirical test based on China’s industrial sector. Management World, 10, 82–89.

Lin, B. Q., & Du, K. R. (2013). The energy effect of factor market distortion in China. Economic Research Journal, 48(9), 125–136.

Lin, B. Q., & Liu, H. X. (2015). Do energy and environment efficiency benefit from foreign trade?—The case of China’s industrial sectors. Economic Research Journal, 9, 127–141.

Liu, X. H. (2022). Does energy efficiency benefit from the trade liberalization. Collected Essays on Finance and Economics, (3), 3–14.

Liu, S., & Chen, X. Y. (2020). The influence of collaborative agglomeration of producer service industry and manufacturing industry on the division status of global value Chain:—micro-data and upstream trade degree of Chinese industrial enterprises. Contemporary Economic Management, 42(11), 17–23.

Liu, J., Cheng, Z., & Zhang, H. (2017). Does industrial agglomeration promote the increase of energy efficiency in China? Journal of Cleaner Production, 164, 30–37.

Liu, L., Jiang, F. X., & Wang, Y. (2017). The influence of industrial agglomeration on green innovation—Inhibition or incentive? Science and Technology Management Research, 6, 235–242.

Murtishaw, S., & Schipper, L. (2001). Disaggregated analysis of US energy consumption in the 1990s: Evidence of the effects of the internet and rapid economic growth. Energy Policy, 29(15), 1335–1356.

Newell, R. G., Jaffe, A. B., & Stavins, R. N. (1999). The induced innovation hypothesis and energy-saving technological change. The Quarterly Journal of Economics, 114(3), 941–975.

Oh, D. H. (2010). A global Malmquist–Luenberger productivity index. Journal of Productivity Analysis, 34(3), 183–197.

Pan, Y. R., Chen, Z., & Luo, L. W. (2017). The Non-linear Character Research of industry agglomeration’s influence on total factor energy efficiency—An empirical analysis based on the data from China’s energy industry. East China Economic Management, 31(11), 121–126.

Poumanyvong, P., & Kaneko, S. (2010). Does urbanization lead to less energy use and lower CO2 emissions? A Cross-Country Analysis. Ecological Economics, 70(2), 434–444.

Qiao, H. S., Hu, W. Y., & Zhong, W. Y. (2015). Specialized, diversified industrial agglomeration and energy efficiency—An empirical study based on Chinese provincial manufacturing panel data. Economic Survey, 5, 85–90.

Qiu, B., Yang, S., & Xin, P. J. (2008). FDI technology spillover channels and productivity growth of China’s manufacturing industry: An analysis based on panel data. The Journal of World Economy, 8, 20–31.

Ru, S., Liu, J., Wang, T., & Wei, G. (2020). Provincial quality of economic growth: Measurements and influencing factors for China. Sustainability, 12(4), 1354.

Shan, H. J. (2008). Re-estimating the capital stock of China: 1952–2006. The Journal of Quantitative and Technical Economics., 25, 17–31.

Shao, S., Zhang, K., & Dong, J. M. (2019). Effects of economic agglomeration on energy saving and emission reduction: Theory and empirical evidence from China. Management World, 35(1), 36–60.

Shao, S., Yang, L., Yu, M., & Yu, M. (2011). Estimation, characteristics, and determinants of energy-related industrial CO2 emissions in Shanghai (China), 1994–2009. Energy Policy, 39(10), 6476–6494.

Shi, D. (2006). Regional differences in China’s energy efficiency and conservation potentials. China Industrial Economics, 10, 49–58.

Shi, B., & Ren, B. P. (2019). Can industrial agglomeration improve energy efficiency? China Economic Studies, 1(1), 27.

Shi, B., & Shen, K. R. (2013). The government intervention, the economic agglomeration and the energy efficiency. Management World, 10(6), 18.

Shi, D., & Li, S. L. (2020). Emissions trading system and energy use efficiency—Measurements and empirical evidence for cities at and above the prefecture level. China Industrial Economics, 9, 5–23.

Sinton, J. E., & Fridley, D. G. (2000). What goes up: Recent trends in China’s energy consumption. Energy Policy, 28(10), 671–687.

Sinton, J. E., & Levine, M. D. (1994). Changing energy intensity in Chinese industry: The relatively importance of structural shift and intensity change. Energy Policy, 22(3), 239–255.

Tang, A. B., & Li, X. M. (2014). Research on the impact of energy prices and technological progress on China’s energy efficiency. Statistics and Decision, 15, 98–101.

Tu, Z. G. (2008). The coordination of industrial growth with environment and resource. Economic Research Journal, 2, 93–105.

Wang, J. T., Zhang, B. Y., & Fu, X. D. (2021). Research on the influence of industrial Coagglomeration on Urban TFP. Studies in Science of Science, 39(5), 842.

Wang, N., Zhu, Y. M., & Yang, T. B. (2020). The impact of transportation infrastructure and industrial agglomeration on energy efficiency: Evidence from China’s industrial sectors. Journal of Cleaner Production, 244, 118708.

Wei, C., & Shen, M. H. (2007). Energy efficiency and its influencing factors: An empirical analysis based on DEA. Management World, 8, 66–76.

Wei, C., & Shen, M. H. (2008). Can structural adjustment improve energy efficiency: Research based on provincial data in China. The Journal of World Economy, 11, 77–85.

Wu, X. F. (2019). Research on threshold effect of industrial co-agglomeration’ s impact on total factor productivity—Based on the empirical test of 246 cities in China. Economic Survey, 36(2), 72–78.

Xie, R., Yao, S., Han, F., & Fang, J. (2019). Land finance, producer services agglomeration, and green total factor productivity. International Regional Science Review, 42(5–6), 550–579.

Yang, H. L., & Shi, D. (2008). Energy-efficiency methods and comparing the energy efficiencies of different areas in China. Economic Theory and Business Management, 3, 12–20.

Yang, Z., Fan, M., Shao, S., & Yang, L. (2017). Does carbon intensity constraint policy improve industrial green production performance in China? A quasi-DID analysis. Energy Economics, 68, 271–282.

Yang, Z. S., & Wei, X. X. (2018). Total factor energy efficiency of the regions along the belt and road: Measurement, decomposition and influence factors analysis. China Environmental Science, 38(11), 4384–4392.

Yu, B. (2021). Ecological effects of new-type urbanization in China. Renewable and Sustainable Energy Reviews, 135, 110239.

Zang, C. Q., & Liu, Y. (2012). Analysis on total factor energy efficiency and its influencing factors of Shandong thinking about environmental pollution. China Population, Resources and Environment, 8, 107–113.

Zhang, G. S., & Chen, C. (2019a). Research on dynamic relationship between industrial agglomeration and urban ecological efficiency. Science and Technology Progress and Policy, 36(13), 48–57.

Zhang, Z. D., & Chen, J. (2019b). the influence of heterogeneous industry agglomeration and its coordinated development on economic efficiency—take the Yangtze River economic belt as an example. Journal of Industrial Technological Economics, 38(6), 97–104.

Zhang, H., Han, A. H., & Yang, Q. L. (2017). Spatial effect analysis of synergetic agglomeration of manufacturing and producer services in China. The Journal of Quantitative and Technical Economics, 34(2), 3–20.

Zhang, Y., Wang, W., Liang, L., Wang, D., Cui, X., & Wei, W. (2020). Spatial-temporal pattern evolution and driving factors of China’s energy efficiency under low-carbon economy. Science of the Total Environment, 739, 140197.

Zhao, H., & Lin, B. (2019). Will agglomeration improve the energy efficiency in China’s textile industry: Evidence and policy implications. Applied Energy, 237, 326–337.

Zhao, J. L., Li, G., Su, Y., & Liu, J. G. (2013). Regional differences and convergence analysis of energy efficiency in China: On stochastic frontier analysis and panel unit root. Chinese Journal of Management Science, 21(2), 175–184.

Zhao, W., & Sui, Y. (2015). The agglomeration patterns and wage-labor productivity difference between regions: Mechanism and evidence from China. Economic Research Journal, 50(6), 33–45.

Acknowledgements

This research was supported by General projects of the national social science foundation of China—“Precise, Efficient and Sustainable Financial Support for high-quality Development of China's Natural Resource Industry” (Grant No. 20BGL189).

Author information

Authors and Affiliations

Contributions

WZ was involved in conceptualization, validation, writing—review and editing. CJ contributed to writing—original draft, methodology, data curation, visualization, formal analysis. XL was involved in software, data curation, writing—reviewing and editing. ZZ contributed to formal analysis, supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, W., Cheng, J., Liu, X. et al. Heterogeneous industrial agglomeration, its coordinated development and total factor energy efficiency. Environ Dev Sustain 25, 5511–5537 (2023). https://doi.org/10.1007/s10668-022-02277-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-022-02277-8