Abstract

Reuse is one of the most important waste-prevention strategies. Although the importance of preparation for reuse is clear, preparation centres for reuse are not common in the traditional waste management supply chain. An analysis of their contribution in waste-prevention strategies is therefore needed. Our research evaluates three preparations for reuse scenarios in municipal solid waste management with an analytic hierarchy process (AHP). These alternatives were assessed with three criteria: economic, social and environmental. Sensitivity analyses were performed to study the impact on the final ranking of changes in various parameters. Results highlight that the best alternative is to include the preparation for reuse in the waste management supply chain, with a moderate recourse to it. The study sheds light on how managers can better plan preparation for reuse activities and provides new trajectories for future research.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

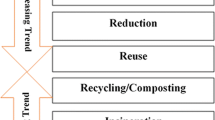

Waste prevention is the most desirable option as indicated in the “mandatory” five-level hierarchy introduced by Waste Framework Directive (EC 2008), followed by preparation for reuse, recycling, recovery, and disposal as the last option (Zorpas and Lasaridi 2013; Gelbmann and Hammerl 2015). Despite the constantly growing attention on waste prevention, at both European Union (EU) and Organisation for Economic Co-operation and Development (OECD) level, the total amount of waste generated has only slightly decreased in the last 10 years while landfilling continues to be one of the most important waste treatment option (EUROSTAT 2015; OECD 2016). Therefore, more efforts are necessary to increase prevention and make it as a reliable option.

Reuse, in the framework of waste-prevention policies, means any operation by which products or components that are not waste are used again (with or without modifications) for the same purpose for which they were conceived (EC 2008), focusing, therefore, on the consumer waste sector (Gelbmann and Hammerl 2015). When a product is donated or sold in second-hand markets (e.g. shops, markets, the web), it generates an immediate reduction in waste, regardless of the operations needed for it to be effectively reused (Gelbmann and Hammerl 2015; Milovantseva and Fitzpatrick 2015; Hofmann 2013; Östlin et al. 2009).

When the same kind of product is delivered to a waste collection system, it is still possible to reuse it, by several operations but following a waste regulation system. This is the case of preparation for reuse, which is ranked in the second position of the European Waste Hierarchy (EC 2008) and is defined as “checking, cleaning or repairing recovery operations, by which products or components of products that have become waste are prepared so that they can be reused without any other pre-processing” (EC 2008).

Preparation for reuse typically involves different operations such as: inspection, cleaning, safety and function testing, repairing (Luger and Herrmann 2010; Gharfalkar et al. 2015). After those processes, reusable products are redistributed with different models. Those can be sold directly to end-users or distributors and retailers.

The number and typology of actors involved depends on the organization of the activities in the supply chain (Kissling et al. 2012). Generally, collection and sorting activities are managed by local authorities (i.e. waste management companies), while preparation for reuse activities are conducted by ad hoc profit (or non-profit) organizations (Kissling et al. 2012).

Examples for preparation for reuse concern repairing bicycles, furniture, or electrical or electronic equipment (WEEE), which have been previously discarded by their owners (EC 2012a).

Environmental benefits of reuse are very well described in literature. Several studies have confirmed that reused products generate lower environmental impacts comparing to those resulting from the manufacturing and distribution of news product from raw materials (Williams et al. 2008; González et al. 2017). Reuse is widely considered a way for reducing the environmental impacts of electrical and electronic equipment (EEE) (Williams et al. 2008; Devoldere et al. 2009; Truttmann and Rechberger 2006; Kissling et al. 2012). Reuse design and manufacturing by reusing have been demonstrated heavily reduce the environmental impacts for different items (Tecchio et al. 2017; Castellani et al. 2015). Authors described how the choice to treat many products as waste—instead to repair or reuse them—lead to severe environmental impacts (Tecchio et al. 2017; McCollough 2009). González et al. (2017) have assessed the value of environmental costs saved thanks to the promotion of reuse. These kind of social benefits (e.g. better environmental conditions, healthier environments, etc.) are mainly addressed to the preparation for reuse process and distribution phases and are calculated having in mind the costs for manufacturing new products from raw materials (González et al. 2017). Ready to reuse products are very often produced and reused locally, this does not happen very often with new products. Therefore, in the majority of cases, reuse systems have a local dimension, packaging is limited and costs for transport are lower (Tecchio et al. 2017; Stahel 2013).

Social and economic benefits of reuse (including the preparation process) are described in literature: from providing job and training opportunities for unemployed and for disadvantage people to providing good product for low-income people both in developing and developed countries, supporting the digital development (Kissling et al. 2012; O’Connell et al. 2010; Anon 2012a, b). From the same perspective, second-hand products represent an important source of IT equipment for business and educational organizations in the developing countries (Kissling et al. 2012; Streicher-Porte et al. 2009; Kahhat and Williams 2009).

Furthermore, it is possible to consider the avoided costs of collection and disposal as socio-economic benefits (Cole et al. 2014).

Nowadays, no research has been done in order to determine a decision-making model for the inclusion of preparation for reuse in waste management scenarios.

According to the European Commission preparation for reuse clearly contributes to prevention objectives (EC 2012b). Indeed, waste-prevention programmes, which are mandatory for Member States, must include the promotion of preparation for reuse of appropriate discarded products or of their components (EC 2008).

The available data show a huge potential for preparation for reuse in terms of prevention objectives. At the same time, there is a wide agreement regarding the need of “robust and comprehensive quantitative data” on preparation for reuse (Cox et al. 2010; Sharp et al. 2010).

Waste prevention and preparation for reuse are required by the transition to a circular economy, because both contribute to the reduction of waste (Tecchio et al. 2017; Geissdoerfer et al. 2017; Parajuly and Wenzel 2017; Sauve et al. 2016; Cole et al. 2014). The Roadmap to a Resource Efficient Europe (European Commission 2011) encourages to conceive reuse as an economically attractive option for public and private actors. The increase of reuse is considered also by the Circular Economy Package (European Commission 2015, 2017). To prove this, Geissdoerfer et al. (2017) show that reuse is one of the most important subtopics of circular economy. The circular economy paradigm emphasizes the role of product–service systems as one of the most promising business model in this field (Michelini et al. 2017) and the manufacturing-centred take-back systems as the most efficient way to reuse, disassemble, refurbish and recycle materials within the same value chain (Singh and Ordoñez 2016). However, these models and systems are far from being considered the reality we face: the material collection system in place is waste management. For this reason, it is necessary to maximize the potential of reuse in waste management system, for circularity and resource efficiency purposes, but also for making it a reliable step for enable future take-back systems (Singh and Ordoñez 2016). The waste management system can contribute to create value from discarded product, but if these products must be prepared for reuse, the collection phase should be significantly improved (Parajuly and Wenzel 2017).

While preparation for reuse contributes to waste-prevention goals, to date, its potential has not been fully developed. A full understanding of its role in the waste management system, as well of its potential contribution to waste prevention is still lacking. This paper addresses this gap by identifying the best scenario for preparation for reuse activities in municipal solid waste management. We developed a multi-criteria analysis, applying an analytic hierarchy process (AHP), which is a comprehensive methodology designed to facilitate decision-making with both empirical data and subjective judgments. AHP provides a systematic methodology to rank concrete alternatives (Behzadian et al. 2010) and has been widely used in the reverse supply chain field (Pochampally and Gupta 2003) and particularly in the waste management field (Nixon et al. 2013; Kondili et al. 2012; Pabule et al. 2015; El Hanandeh and El-Zein 2007; Roussat et al. 2009). In particular, AHP method is the most used method in MSW management decision-making (Soltani et al. 2015). Notable applications of AHP to different MSW management issues concern the minimization of infection risks from health care waste in developing countries (Brent et al. 2007), the optimal siting of MSW facilities (Demesouka et al. 2013; Gorsevski et al. 2012; Tavares et al. 2008), logistic aspects in waste management decision (San Martin et al. 2017), the strategy to expand the MSW in a sustainable way (Pires et al. 2011) and the comparison of different technologies in obtaining energy from waste (Corsini et al. 2018). In several cases, AHP is used as support instrument in MSW management decision-making in combination with other techniques; for example, there are several researches (Mahjouri et al. 2017; Ouyang and Guo 2016; Ouyang et al. 2015) using such approach in exploring the wastewater sector.

2 Materials and methods

2.1 Data collection

The model for assessing the scenarios was grounded on raw data from the city of Vicenza, which is located in Veneto in north-eastern Italy, where the implementation of a reuse centre was assessed. The city has an estimated population of 113,599 (ISTAT 2015), and a production of municipal solid waste of 616.7 kg per inhabitants per year (ISPRA 2015).

The data on generated waste were taken from ISPRA (2015) while other data were grounded on the technical output of the Prisca (Pilot project for scale reuse starting from bulky waste) LIFE + project,Footnote 1 financed by the European Commission through the Life Plus Environment 2011 programme (Prisca 2015). The project, financed by the European Commission through the Life Plus Environment 2011 programme, tested the feasibility of reuse centres, where reusable goods from solid urban waste flows are sent for preparation for reuse operations to enter a second life, instead of being disposed to landfill.

2.2 AHP methodology

The Analytic Hierarchy Process, developed by Saaty (1980), allows dividing the decision problems into understandable parts; each of these parts is analysed separately and integrated in a logical manner. It is a comprehensive methodology designed to facilitate the decision-making process by using both empirical data and subjective judgments, allowing to derive a scale of priorities that are valid to make complex decisions. Such method has been used for solving complex decision-making problems in various disciplines and currently is widely used in the field of waste management (Soltani et al. 2015).

According to the axioms on which the AHP methodology is based (Vargas 1990), we structured the goal of the delineation of the best scenario for preparation for reuse activities in four levels. In detail, we structured the decision hierarchy according to the goal in the following order: the objectives from a broad perspective, through the intermediate levels (criteria on which subsequent elements depend) up to the lowest level (a set of the alternatives). According to Fig. 1, the hierarchical structure of the decision-making consists of the following levels: the first level represents the ultimate goal of the decision hierarchy (assessing the best preparation for reuse scenario), the second level introduces the criteria, the third level shows the sub-criteria that are utilized in this work and finally the fourth level shows the alternatives.

2.3 Scenarios

Our research assessed three alternatives with respect to the delineation of the best scenario for preparation for reuse activities in municipal solid waste management. Those are presented in Fig. 2. The first alternative is represented by a business as usual scenario (Scenario 0) where preparations for reuse activities are not included in the waste management supply chain. In this case, the municipal solid waste system includes, after the sorting stage: material recovery (plastic, glass, paper and the other recoverable materials); composting (for the organic flow); thermal recovery for the refuse-derived fuel. The landfilled flow includes direct flows of municipal waste and the secondary flows of the recovery phases.

The second alternative is represented by a scenario where preparation for reuse activities is included in the waste management supply chain allowing the diversion of 1% of waste still reusable. In Scenario 1, the preparation for reuse is included into the system and calls for the 1% of the total of municipal solid waste. The preparation for reuse entails a light processing stage (including cleaning and refurbishment) after which the goods can be reused.

Finally, the third alternative (Scenario 2) is represented by a scenario where preparation for reuse activities is included in the waste management supply chain allowing the diversion of 5% of waste still reusable. Scenario 2 considers a bigger recourse to preparation for reuse, allowing a greater diversion from landfill (5% of the total municipal solid waste). Scenarios are fully described by Fig. 2.

2.4 Criteria

We selected most of the sub-criteria for assessing the scenarios after an in-depth analysis of the literature regarding similar studies on waste management scenarios. More in detail, after having selected all the relevant literature a worksheet was designed in order to collect the most useful criteria used in similar evaluations. Then, each of the criteria was read independently and iteratively discussed by the four researchers involved in the project, thereby ensuring reliability through consensus and minimization of bias. Through this process, useless criteria were rejected, reaching a final number of 7 criteria. Those are: economic indicators (i.e. capital costs and operational costs), social indicators (i.e. job creation and the increased environmental awareness of citizens) and environmental indicators (GHG emissions in CO2 equivalents, amount of waste landfilled, probability of a prepared for reuse good to return waste). The following paragraphs give a short presentation of the chosen indicators.

2.4.1 Economic criteria

We addressed economic aspects through capital and operational costs of running a preparation for reuse centre in a waste management supply chain. Those costs are frequently considered for evaluating alternatives in multi-criteria studies (Pabule et al. 2015; Yap and Nixon 2015).

The capital cost is the amount required to construct the waste management plants, including: land costs, design and construction of landfills, waste treatment facilities, and transportation. Similar capital costs have been used in multi-criteria studies (Pabule et al. 2015; Milutinović et al. 2014). For the assessment of the Scenario 0 only the capital costs (and fix costs) of the waste management supply chain were taken into account with the exclusion of the costs related to the cleaning of the streets, as we assumed that preparations for reuse activities are not included in the waste management supply chain. On the contrary, for the assessment of Scenario 1 and Scenario 2 we added to the capital costs of the waste management supply chain the cost for running a preparation for reuse centre. Those in detail are: staff costs, services costs (e.g. insurance costs), cost of vehicles maintenance other direct management costs (e.g. energy, water, etc.). Details of capital costs are presented in Table 1.

Operational costs in details include: waste management supply chain operational costs and operational costs for the preparation for reuse centre. For the assessment of the Scenario 0 only the operational costs of the waste management supply chain were taken into account with the exclusion of the costs related to the cleaning of the streets, as we assumed that preparations for reuse activities are not included in the waste management supply chain. On the contrary, for the assessment of Scenario 1 and Scenario 2 we added to the operational costs of the waste management supply chain the cost for running a preparation for reuse centre. Those in detail are: staff costs, services costs (e.g. insurance costs), cost of vehicles maintenance other direct management costs (e.g. energy, water, etc.). Pires et al. (2011) claim that revenues are also significant for assessing waste management scenarios. Details of capital costs are presented in Table 2.

Finally, the economic indicators measured in €/ton for each scenario are presented in Table 3.

2.4.2 Social indicators

Social sustainability in waste management means the ethical behaviour of the waste management system toward society (social acceptability, social equity and social function) (Den Boer et al. 2007). The social function (i.e. the benefit of the waste management system) can be measured through the employment rate (Den Boer et al. 2005), which is the indicator used in this study. For the assessment of the Scenario 0 only jobs of the waste management supply chain were taken into account as we assumed that preparations for reuse activities are not included in the waste management supply chain. Also in this case, the number of people employed for the services related to the cleaning of the streets was not taken into account. We adjusted the employment rate on the basis of the literature in this field suggesting that 460 tons of materials in the waste management supply chain create 1 job in a scenario with no preparation for reuse (O’Connell et al. 2013). Then, grounding on the available literature (O’Connell et al. 2013) and evidences from Prisca project we estimated a workforce 14% greater is needed in a scenario with a moderate recourse of preparation for reuse (Scenario 1) and a workforce about 23% greater is needed in a scenario with an intensive recourse of preparation for reuse (Scenario 2). The number of jobs for each scenario is presented in Table 4.

Among the social criteria, we also included the environmental awareness of citizens concerning waste prevention, which is crucial (OECD 2000; EC 2009; Polanec et al. 2013; Read et al. 2009). This sub-criterion refers to the positive impact of preparations for reuse centres in the waste management system on the education of citizens regarding waste prevention. In particular, we considered the generation of no environmental awareness in Scenario 0 where preparation for reuse activities are not included in the waste management supply chain; on the contrary, we considered the generation of an equal amount of environmental awareness in Scenario 1 and 2 as the introduction of reuse centres in general could foster a stronger environmental awareness in citizens despite the amount of waste diverted form landfill. We assessed this criterion qualitatively using the 9-level scale established by Saaty (1980).

2.4.3 Environmental indicators

Many studies (inter alia, Ardente and Mathieux 2014; Bakker et al. 2014) have demonstrated that extending the lifetime of the products can determine life-cycle environmental benefits (depending on different issues, as, for instance the category of impact, the impact of repair, etc.).

We assessed the environmental aspects through three criteria: GHG emissions in CO2 equivalents; amount of landfilled waste; the probability of prepared-for-reuse goods to return waste. GHG emissions are one of the criteria used by the European Environmental Agency to measure the performance of municipal waste management in 32 countries (EEA 2013). Similar criteria including GHG emissions, or pollutant emissions in general, are considered in many multi-criteria studies (El Hanandeh and El-Zein 2010; Roussat et al. 2009).

We calculated emissions—on the basis of literature (Ali El Hanandeh and Abbas El-Zein 2010; Roussat et al. 2009) and Prisca project results. In our assessment of GHG emissions in CO2 equivalents, we considered as boundaries of the system the point at which a material is discarded into the waste stream up to the point at which it is either converted into a useful material or finally disposed. In detail, the measurement of GHG emissions in CO2 equivalents took into account pre-treatment activities, recycling, composting, incineration and disposal of waste. In the calculation we sued the allocation cut-off by classification proposed by Ecoinvent (2016). In this case, the cut-off system model has, broadly speaking, the effect that recyclable materials are cut off at the beginning of the treatment processes, becoming available burden-free for following uses (Ecoinvent 2016).

More in detail, the material is recorded as a negative input, just as in the case of becoming a waste. Any non-waste by-products of a waste treatment (i.e. not other waste products) are cut off and do not give a credit to the system. For such reasons recycling and composting activities are cut off from the calculations. Details are presented in Table 5.

The amount of landfilled waste indicates the ability of the scenario to divert a certain amount of reusable product from the waste streams. The diversion rate is a typical goal in waste management strategies (Zeng and Trauth 2005). Since preparation for reuse diverts a certain amount of reusable product from the waste streams, Scenarios 1 and 2 have lower amounts of landfilled waste (Table 3). Finally, we considered the probability of a prepared for reuse good to return waste. Several reasons can cause a premature comeback to the waste stream. As an example, existing studies suggest that on-site evaluation of re-use potential tends to overstate reusability (Harris 2012), so the items selected in the first stages can prove to be scarcely attractive for consumers. Technical features, social and market factors are likewise critical in determining the longevity of a re-used item. We called this sub-criterion: “probability of a prepared for reuse good to return waste” and in our study we assessed qualitatively; therefore, also in this case, the 9-level scale established in the AHP method (Saaty 1990) was used for the assessment of this criterion.

2.5 Pairwise comparison

AHP methodology has been used for weighting criteria, analysing the collected data, and expediting the decision-making process. In general, AHP is used to establish priorities among the elements within each stratum of the hierarchy. This is conducted by asking a board of decision-makers to evaluate a set of elements in a pairwise comparison. In our case, to make a pairwise comparison, 5 experts working in the waste Italian management sector were consulted. This includes scientists working at the University in environmental and economic science as well as experts in the local government dealing with the problem of waste management.

In the AHP methodology, the hierarchy is broken down into a series of pair comparison matrices, and the participants are asked to evaluate the relationship with respect to the goal. A 9-point scale, ranging from 1 (indifference or equal importance) to 9 (extreme preference or absolute importance) is generally used. This pairwise comparison enables the decision-maker to evaluate the contribution of each factor to the objective independently, simplifying the decision-making process (Saaty 2000). In our case, a judgmental matrix, denoted as A, has been formed using the comparisons. Each entry aij of the judgmental matrix is formed comparing the row element Ai with the column element Aj:

The 9-point scale has been used to transform the judgements into numerical quantities representing the values of aij. All the entries aij has been governed by the following rules:

Because of the above rules, the judgmental matrix A resulted in a positive reciprocal pairwise comparison matrix. The weight coefficients of the ranking criteria and the decision sub-criteria have been calculated by finding the principal eigenvector w of the matrix A.

Finally, the grading values of all the criteria ware normalized to 1.

In order to test the consistency of the judgment matrix, the calculation of the consistency ratio coefficient (CR) has been performed according to the methodology proposed by Saaty (1990). In our case, CR resulted equal to 0.02. In general, a consistency ratio of 0.1 or less is considered acceptable indicating the overall consistency of the pairwise comparison matrix (Ramanathan 2001).

In order to elaborate all the calculations, we used Expert Choice 2000, developed by Expert Choice Inc., a software package able to implement AHP methodology by enabling the decision-maker solve the problem with a visualized hierarchy approach and then conduct pairwise judgments in an interactive mode.

3 Results

3.1 Scenario ranking

Following the pairwise comparison, the criteria weight with respect to the goal is shown in Fig. 3.

Among the environmental criteria, the “probability of a prepared for reuse good to return waste” was judged the most important one for evaluating the scenarios followed directly by the amount of waste not landfilled. On the contrary, GHG emission was considered the less important one among the environmental criteria and the second less important among the seven indicators. This might be because the volumes processed only allow minor reduction in GHG emission.

Among the economic criteria, the experts considered the operating costs to be more important than the capital costs. This might be because operating costs have a direct impact on taxation and, consequently, should be as low as possible. Conversely, capital costs were judged as less important. This might be because investments can be linked to the need of achieving a better arrangement of the municipal solid waste supply chain and, consequently, they may improve the environmental behaviour of citizens.

Among the social criteria, job creation was considered as less important than increased environmental awareness; indeed, the volumes processed only require few new jobs.

More details about the results achieved in assessing the priorities of the seven indicators with respect to the goal of the analysis are presented in the pairwise comparison matrix in Table 6.

Having assessed the criteria weight with respect to the goal, we calculated the results obtained by the criteria weight against the scenarios. The normalized performances of the three scenarios are presented in Table 7.

Our results show that Scenario 1 (i.e. preparation for reuse activities are included in the waste management supply chain allowing the diversion of 1% of waste from landfill) represents the best alternative followed by Scenario 2. The graphical results, elaborated with Expert Choice 2000 are presented in Fig. 4.

More in detail, Fig. 4 shows how the best scenario performs compared to the second and the third scenarios by the overall priority from the intersection of the right y-axis and the overall priority for each scenarios. Moreover, on the left y-axis, the figure provides information on each criteria’s priority (based on the decision-makers’ pairwise comparisons). Finally, the scenarios priorities with respect to each objective can be seen from the right y-axis.

3.2 Sensitivity analysis

The last step is the sensitivity analysis, i.e. how the criteria weights influence the performance of each scenario. We used a sensibility analysis to show how different preferences could influence the results of the analysis; moreover, this analysis is essential to ensure the consistency of final decision. We tested the sensitivity using two different approaches: (1) gradient sensitivity (2) testing “what-if” scenarios.

3.2.1 Gradient sensitivity

Gradient sensitivity analysis allows showing the scenario priorities with respect to one criteria at a time. More in detail it allows to give additional information with regard to exactly at what point Scenario 1 takes over on the others for each criteria. Figures 5, 6 and 7—elaborated with Expert Choice 2000—present the gradient sensitivity for each criterion.

The vertical line represents the current priority of the criterion being considered. The slanted lines represent the scenarios. The current priority of a scenario is where the alternative line intersects the vertical criterion line.

For example, in Fig. 5, the dashed vertical line shows that when the priority of capital costs increases to 37% or beyond, Scenario 0 becomes the top choice. If two lines denoting scenarios never cross, this means that no matter how the quality criteria are weighted, the ranking of the design alternative will never change.

3.2.2 Equal weighing factor of 14.2%

In this case, all seven criteria were equally weighted with a 14.2% weighting factor. Scenario 1 (i.e. preparation for reuse activities are included in the waste management supply chain allowing the diversion of 1% of waste from landfill) still represents the best alternative (Fig. 8).

3.2.3 One criteria has a weighting factor of 100% and the other 0%

Three options were assessed:

Economic indicators have a weighting factor of 100% in total (each indicator has a weight of 50%);

Social indicators have a weighting factor of 100% in total (each indicator has a weight of 50%);

Environmental indicators have a weighting factor of 100% in total (each indicator has a weight of 33.3%).

The results are presented in Fig. 9. In this case, no single scenario emerges as the best. In fact, when economic indicators have a weighting factor of 100% in total, Scenario 0 was best. When social indicators have a weighting factor of 100% in total, Scenario 2 was best. Finally, when environmental indicators have a weighting factor of 100% in total, Scenario 1 was best. However, an analysis that takes into account the performance of one scenario against more than one criterion, would give clearer results (Antonopoulos et al. 2014).

3.2.4 Two criteria have a weighting factor of 100% each and the other 0%

In this case three options were assessed:

Economic and social indicators have a weighting factor of 100% in total (each indicator has a weight of 25%);

Environmental and social indicators have a weighting factor of 100% (each indicator has a weight of 20%);

Economic and environmental indicators have a weighting factor of 100% in total (each indicator has a weight of 20%).

Figure 10 highlights that “Scenario 1” was the best alternative.

Our sensitivity analysis shows that the evaluation made by the seven experts has a significant consistency.

4 Conclusions

We investigated the role of preparation for reuse in waste management and its contribution to waste prevention. Our study confirms that it is important to integrate the waste management system at local level with a preparation for reuse phase, due to the benefits that it can generate. Indeed, preparation for reuse contributes in achieving the CE purposes optimizing cycles of products, components and materials by keeping them at their highest utility and value (Parajuly and Wenzel 2017).

Our study suggests how a moderate recourse to preparation for reuse activities represents the best management option. This is mainly to avoid that the processed to reuse waste come prematurely back to the waste stream. Indeed, our results ranked the “probability of a prepared for reuse good to return waste” to be the most important criteria for assessing the best scenario for preparation for reuse activities in municipal solid waste management. A moderate recourse to preparation for reuse, as showed by Scenario 1, can guarantee a longer lifecycle to adequate volumes of good quality equipment that can be safely reused. Indeed, it is worth noticing that quality and safety of reused items are perceived as the most important success factors by consumers (Kissling et al. 2013).

On the contrary, taking to extremes the preparation for reuse would lead to overestimate the reusability of items, putting on the market items scarcely attractive for consumers and more likely ending in the waste stream again.

From a managerial perspective, our results support managers in shifting toward more circular models of waste management effectively including the preparation for reuse into their systems. Our results stress the importance of the role of waste managers and local authorities in identifying the best model tailored to fit to local needs and priorities determining also the best policy instruments that can be used to do so without the risk of creating expensive systems with the potential for inefficient outcomes. Policy makers should provide policies and regulations effectively aimed at:

supporting the provision of quality reusable items;

enhancing the market of second-hand products;

facilitating the preparation phase by clearly identifying which operation can be included within this process.

Finally, since the preparation for reuse is an important segment of the waste management supply chain, our findings could also be relevant in addressing choices of future market players of this sector.

From an academic perspective, the results could be used to better understand how future research should be directed. Firstly, more efforts should be done in order to position reuse of waste with respect to reuse of products and recovery operations, among waste prevention, waste minimization and waste management measures. Secondly, while reuse issues are widely investigated in current literature, preparation for reuse themes still remains mostly underexplored. For example, the “probability of a prepared for reuse good to return waste” resulted the most important criterion in the expert’s opinions. In our case we assessed this indicator in a qualitative manner, as it was not possible to assess it differently. For such reason, we believe that further efforts are needed to strengthen the performance measurement in the field of waste prevention through quantitative indicators. Nevertheless, our research provides data collected in a demonstrative project focused on preparation for reuse, endeavouring to overcome the chronic lack of data in this field. However, more information is needed. Furthermore, it should be deeply investigated both which operations may be performed in preparing for reuse activities and the optimal composition of the affected flow of waste. Close to this issue, it is also relevant the design of specific separate collection within integrated waste management system. Another significant issue is related to the assessment of extent to which industrial waste contributes to waste prevention objectives by the means of reuse and preparation for reuse-related activities.

Notes

EU-LIFE + Environment Policy and Governance LIFE/11/ENV/000277.

References

Anon. (2012a). http://www.unido.org/fileadmin/usermedia/Services/PSD/ICT/0Greenbusines.PDF.

Anon. (2012b). http://www.illinoisbiz.biz/NR/rdonlyres/8DD41FE3-A7ED-4447-87C0-DD05815F2747/0/EwasteFactSheet.pdf.

Antonopoulos, I. S., Perkoulidis, G., Logothetis, D., & Karkanias, C. (2014). Ranking municipal solid waste treatment alternatives considering sustainability criteria using the analytical hierarchical process tool. Resources, Conservation and Recycling,86, 149–159.

Ardente, F., & Mathieux, F. (2014). Environmental assessment of the durability of energy-using products: method and application. Journal of Cleaner Production,74, 62–73.

Bakker, C., Wang, F., Huisman, J., & den Hollander, M. (2014). Products that go round: Exploring product life extension through design. Journal of Cleaner Production,69, 10–16.

Behzadian, M., Kazemzadeh, R. B., Albadvi, A., & Aghdasi, M. (2010). PROMETHEE: A comprehensive literature review on methodologies and applications. European Journal of Operational Research,200, 198–215.

Brent, A. C., Rogers, D. E., Ramabitsa-Siimane, T. S., & Rohwer, M. B. (2007). Application of the analytical hierarchy process to establish health care waste management systems that minimise infection risks in developing countries. European Journal of Operational Research, 181(1), 403–424.

Castellani, V., Sala, S., & Mirabella, N. (2015). Beyond the throwaway society: A life cycle-based assessment of the environmental benefit of reuse. Integrated Environmental Assessment and Management,11, 373–382.

Cole, C., Osmani, M., Quddus, M., Wheatley, A., & Kay, K. (2014). Towards a zero waste strategy for an English local authority. Resources, Conservation and Recycling,89, 64–75.

Corsini, F., Gusmerotti, N. M., & Frey, M. (2018). Assessing WtE technologies by way of an analytic hierarchy process. In H. H. G. Post (Ed.), From waste to energy: Technology. The environment and the implications under EU law. The Hague: Eleven International Publishing.

Cox, J., Giorgi, S., & Sharp, V. (2010). Household waste prevention—a review of evidence. Waste Management and Research,28, 193–219.

Demesouka, O. E., Vavatsikos, A. P., & Anagnostopoulos, K. P. (2013). Suitability analysis for siting MSW landfills and its multicriteria spatial decision support system: method, implementation and case study. Waste management, 33(5), 1190–1206.

Den Boer, E., den Boer, J., & Jager, J. (2005). Handbook for municipal waste prognosis and sustainability assessment of waste management systems. Stuttgart: Ibidem Verlag.

Den Boer, J., Den Boer, E., & Jager, J. (2007). LCA-IWM: a decision support tool for sustainability assessment of waste management systems. Waste management, 27(8), 1032–1045.

Devoldere, T., Willems, B., Duflou, J. R., & Dewulf, W. (2009). The eco-efficiency of reuse centres critically explored—the washing machine case. International Journal of Sustainable Manufacturing,1(3), 265–285.

EC (European Commission). (2008). Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Waste Framework Directive). Brussels: EC.

EC (European Commission). (2009). Waste prevention overview on indicators. Brussels: EC.

EC (European Commission). (2012a). Guidance on the interpretation of key provisions of Directive 2008/98/EC on waste. Brussels: EC.

EC (European Commission). (2012b). Preparing a waste prevention programme. Guidance document. Brussels: EC.

Ecoinvent. (2016). Allocation cut-off by classification. Available at https://www.ecoinvent.org/database/system-models-in-ecoinvent-3/cut-off-system-model/allocation-cut-off-by-classification.html.

EEA, European Environment Agency. (2013). Managing municipal solid waste—a review of achievements in 32 European countries report no. 2/2013.

El Hanandeh, A., & El-Zein, A. (2007). A new stochastic multi-criteria decision analysis tool based on ELECTRE III method. In The ANZSEE conference: re-inventing sustainability: a climate for change; 3e6 July.

El Hanandeh, A., & El-Zein, A. (2010). The development and application of multi-criteria decision-making tool with consideration of uncertainty: The selection of a management strategy for the bio-degradable fraction in the municipal solid waste. Bioresource Technology,101, 555–561.

European Commission. (2011). COM(2011) 571 European Commission—communication: Roadmap to a resource efficient Europe doi:COM (2011) 571 final.

European Commission. (2015). COM(2015) 614 Final. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Closing the Loop—an EU Action Plan for the Circular Economy.

European Commission. (2017). COM(2017) 33 Final report from the commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on the Implementation of the Circular Economy Action Plan.

EUROSTAT. (2015). Waste statistics. Available from http://ec.europa.eu/eurostat/statistics-explained/index.php/Waste_statistics.

Geissdoerfer, M., Savaget, P., Bocken, N. M. P., & Hultink, E. J. (2017). The circular economy—a new sustainability paradigm? Journal of Cleaner Production,143, 757–768.

Gelbmann, U., & Hammerl, B. (2015). Integrative re-use systems as innovative business models for devising sustainable product–service-systems. Journal of Cleaner Production,97, 50–60.

Gharfalkar, M., Court, R., Campbell, C., Ali, Z., & Hillier, G. (2015). Analysis of waste hierarchy in the European waste directive 2008/98/EC. Waste Management,39, 305–313.

González, X. M., Rodríguez, M., & Pena-Boquete, Y. (2017). The social benefits of WEEE re-use schemes. A cost benefit analysis for PCs in Spain. Waste Management,64, 202–213.

Gorsevski, P. V., Donevska, K. R., Mitrovski, C. D., & Frizado, J. P. (2012). Integrating multi-criteria evaluation techniques with geographic information systems for landfill site selection: a case study using ordered weighted average. Waste management, 32(2), 287–296.

Harris, B. (2012). SPMT12_002: The market potential and demand for product re-use introduction. Collaborative waste, resources and sustainable consumption evidence programme, Defra. United Kingdom.

Hofmann, P. (2013). Wasted waste—Disappearing reuse at the peri-urban interface. Environmental Science & Policy,31, 13–22.

ISPRA. (2015). Rapporto Rifiuti Urbani—Edizione 2015.

ISTAT. (2015). Indicatori demografici—Anno 2014.

Kahhat, R., & Williams, E. (2009). Product or waste? Importation and end-of-life processing of computers in Peru. Environmental Science and Technology,43(15), 6010–6016.

Kissling, R., Coughlan, D., Fitzpatrick, C., Boeni, H., Luepschen, C., Andrew, S., et al. (2013). Success factors and barriers in re-use of electrical and electronic equipment. Resources, Conservation and Recycling,80, 21–31.

Kissling, R., Fitzpatrick, C., Boeni, H., Luepschen, C., Andrew, S., & Dickenson, J. (2012). Definition of generic re-use operating models for electrical and electronic equipment. Resources, Conservation and Recycling,65, 85–99.

Kondili, L., Bartzis, I., Kapsali, M., & Kaldellis, J. K. (2012). Multicriteria analysis of municipal solid waste energy recovery technologies in Greece. Global NEST Journal,14(2), 225–234.

Luger, T., & Herrmann, P. D. I. C. (2010). Referenzprozessbasierte Gestaltung und Bewertung von Reverse Supply Chains. uwf UmweltWirtschaftsForum,18(2), 91–99.

Mahjouri, M., Ishak, M. B., Torabian, A., Manaf, L. A., & Halimoon, N. (2017). The application of a hybrid model for identifying and ranking indicators for assessing the sustainability of wastewater treatment systems. Sustainable Production and Consumption,10, 21–37.

McCollough, J. (2009). Factors impacting the demand for repair services of household products: The disappearing repair trades and the throwaway society. International Journal of Consumer Studies,33, 619–626.

Michelini, G., Moraes, R. N., Cunha, R. N., Costa, J. M. H., & Ometto, A. R. (2017). From linear to circular economy: PSS conducting the transition. Procedia CIRP,64, 2–6.

Milovantseva, N., & Fitzpatrick, C. (2015). Barriers to electronics reuse of transboundary e-waste shipment regulations: An evaluation based on industry experiences. Resources, Conservation and Recycling,102, 170–177.

Milutinović, B., Stefanović, G., Dassisti, M., Marković, D., & Vučković, G. (2014). Multi-criteria analysis as a tool for sustainability assessment of a waste management model. Energy,74, 190–201.

Nixon, D. J., Dey, P. K., Gosh, S. K., & Davies, P. A. (2013). Evaluation of options for energy recovery from municipal solid waste in India using the hierarchical analytical network process. Energy,59, 215–223.

O’Connell, M., Fitzpatrick, C., & Hickey, S. (2010). Investigating reuse of B2C WEEE in Ireland. In Sustainable systems and technology (ISSST), 2010 IEEE international symposium on (pp. 1–6). IEEE.

O’Connell, M., Hickey, S., Besiou, M., Fitzpatrick, C., & Wassenhove, L. N. (2013). Feasibility of using radio frequency identification to facilitate individual producer responsibility for waste electrical and electronic equipment. Journal of industrial ecology, 17(2), 213–223.

OECD. (2000). Working Party on Pollution Prevention and Control; STRATEGIC WASTE PREVENTION; OECD Reference Manual. http://www.oecd.org/officialdocuments/publicdisplaydocumentpdf/?doclanguage=en&cote=env/epoc/ppc(2000)5/final.

OECD. (2016). Municipal waste. OECD Environment Statistics (database). https://doi.org/10.1787/data-00601-en. (Accessed on 01 February 2016).

Östlin, J., Sundin, E., & Björkman, M. (2009). Product life-cycle implications for remanufacturing strategies. Journal of Cleaner Production,17(11), 999–1009.

Ouyang, X., & Guo, F. (2016). Paradigms of mangroves in treatment of anthropogenic wastewater pollution. Science of the Total Environment,544, 971–979.

Ouyang, X., Guo, F., Shan, D., Yu, H., & Wang, J. (2015). Development of the integrated fuzzy analytical hierarchy process with multidimensional scaling in selection of natural wastewater treatment alternatives. Ecological Engineering,74, 438–447.

Pabule, J., Blumberga, A., Romagnoli, F., & Blumberga, D. (2015). Finding an optimal solution for biowaste management in the Baltic States. Journal of Cleaner Production,88, 214–223.

Parajuly, K., & Wenzel, H. (2017). Potential for circular economy in household WEEE management. Journal of Cleaner Production,151, 272–285.

Pires, A., Chang, N. B., & Martinho, G. (2011). An AHP-based fuzzy interval TOPSIS assessment for sustainable expansion of the solid waste management system in Setúbal Peninsula, Portugal. Resources, Conservation and Recycling,56(1), 7–21.

Pochampally, K. K., & Gupta, S. M. (2003). A multi-phase mathematical programming approach to strategic planning of an efficient reverse supply chain network. In Electronics and the environment, 2003. IEEE international symposium on (pp. 72–78). IEEE.

Polanec, B., Aberšek, B., & Glodež, S. (2013). Informal education and awareness of the public in the field of waste management. Procedia-Social and Behavioral Sciences,83, 107–111.

Prisca. (2015). FINAL report. Available at http://www.progettoprisca.eu/it/doc/viewcategory/8-deliverables. Accessed on 10/1/16.

Ramanathan, R. (2001). A note on the use of the analytic hierarchy process for environmental impact assessment. Journal of Environmental Management,63(1), 27–35.

Read, M., Gregory, M. K., & Phillips, P. S. (2009). An evaluation of four key methods for monitoring household waste prevention campaigns in the UK. Resources, Conservation and Recycling,54(1), 9–20.

Roussat, N., Dujet, C., & Mehu, J. (2009). Choosing a sustainable demolition waste management strategy using multicriteria decision analysis. Waste Management,29, 12–20.

Saaty, T. L. (1980). The analytic hierarchy process: Planning, priority setting, resources allocation. New York, NY: McGraw.

Saaty, T. L. (1990). How to make a decision: the analytic hierarchy process. European journal of operational research, 48(1), 9–26

Saaty, T. L. (2000). Fundamentals of decision making and priority theory with the analytic hierarchy process, Analytic Hierarchy Process Series (vol. 6). Pittsburg: Auflage.

San Martin, D., Orive, M., Martínez, E., Iñarra, B., Ramos, S., González, N., et al. (2017). Decision making supporting tool combining AHP method with GIS for implementing food waste valorisation strategies. Waste and Biomass Valorization,8(5), 1555–1567.

Sauve, S., Bernard, S., & Sloan, P. (2016). Environmental sciences, sustainable development and circular economy: alternative concepts for trans-disciplinary research. Environment, Development,17, 48–56.

Sharp, V., Giorgi, S., & Wilson, D. C. (2010). Methods to monitor and evaluate household waste prevention. Waste Management and Research,28(3), 269–280.

Singh, J., & Ordoñez, I. (2016). Resource recovery from post-consumer waste: Important lessons for the upcoming circular economy. Journal of Cleaner Production, 134 (Part A), 342–353.

Soltani, A., Hewage, K., Reza, B., & Sadiq, R. (2015). Multiple stakeholders in multi-criteria decision-making in the context of Municipal Solid Waste Management: A review. Waste Management,35, 318–328.

Stahel, W. R. (2013). Policy for material efficiency—sustainable taxation as a departure from the throwaway society. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 371, 20110567.

Streicher-Porte, M., Marthaler, C., Böni, H., Schluep, M., Camacho, A., & Hilty, L. M. (2009). One laptop per child, local refurbishment or overseas donations? Sustainability assessment of computer supply scenarios for schools in Colombia. Journal of Environmental Management,90, 3498–3511.

Tavares, G., Zsigraiova, Z., Semiao, V., & da Graça Carvalho, M. (2008). A case study of fuel savings through optimisation of MSW transportation routes. Management of Environmental Quality: An International Journal, 19(4), 444–454.

Tecchio, P., McAlister, C., Mathieux, F., & Ardente, F. (2017). In search of standards to support circularity in product policies: A systematic approach. Journal of Cleaner Production,168, 1533–1546.

Truttmann, N., & Rechberger, H. (2006). Contribution to resource conservation by reuse of electrical and electronic household appliances. Resources, Conservation and Recycling,48(3), 249–262.

Vargas, L. G. (1990). An overview of the analytic hierarchy process and its applications. European Journal of Operational Research,48(1), 2–8.

Williams, E., Kahhat, R., Allenby, B., Kavazanjian, E., Kim, J., & Xu, M. (2008). Environmental, social, and economic implications of global reuse and recycling of personal computers. Environmental Science and Technology,42(17), 6446–6454.

Yap, H. Y., & Nixon, J. D. (2015). A multi-criteria analysis of options for energy recovery from municipal solid waste in India and the UK. Waste Management,46, 265–277.

Zeng, Y., & Trauth, K. M. (2005). Internet-based fuzzy multicriteria decision support system for planning integrated solid waste management. Journal of Environmental Informatics,6(1), 1–15.

Zorpas, A. A., & Lasaridi, K. (2013). Measuring waste prevention. Waste Management,33(5), 1047–1056.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gusmerotti, N.M., Corsini, F., Borghini, A. et al. Assessing the role of preparation for reuse in waste-prevention strategies by analytical hierarchical process: suggestions for an optimal implementation in waste management supply chain. Environ Dev Sustain 21, 2773–2792 (2019). https://doi.org/10.1007/s10668-018-0160-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-018-0160-9