Abstract

Biomedical waste (BMW) incineration is the most used alternative disposal method in developing countries, such as Ghana. The improper disposal of incinerator-generated bottom ash (BA) is a significant concern due to the hazardous nature of waste. A study was conducted at Tema Hospital (TGH) and Asuogyaman Hospital (VRAH) incinerator sites. The BA samples were sent to the Council for Scientific and Industrial Research, Institute of Industrial Research, Ghana. The BA samples were weighed with fisher analytical balance, ground, and sieved with standard grade meshes of 120, 100, and 80 to determine the BA particle size distribution. The chemical composition and heavy metals were analysed using X-ray fluorescence spectrometry (XRF) and atomic absorption spectroscopy (AAS) techniques. The results indicated the chemical composition of the analysed BA samples was CaCO3 (49.90%), CaO (27.96%) and MgCO3 (6.02%) for TGH and CaCO3 (48.30%), CaO (27.07%), and SiO2 (6.10%) for VRAH, respectively. The mean concentration (M) (kg m−3) and standard deviation (SD) for TGH in the BA were 7.082 ± 0.478 (Ti), 4.657 ± 0.127 (Zn) and 4.271 ± 1.263 (Fe), while that of VRAH consisted of 10.469 ± 1.588 (Ti), 7.896 ± 2.154 (Fe) and 4.389 ± 0.371 (Zn). Therefore, the heavy metals’ mean concentration at the BA is above the WHO permissible limits of soil, i.e., 0.056 kg m−3 (Ti), 0.085 kg m−3 (Pb), 0.100 kg m−3 (Cr) and 0.036 kg m−3 (Cu). Furthermore, the heavy metal mean concentrations of TGH and VRAH present in the BA analysed samples were ranked in descending order: Ti > Zn > Fe and Ti > Fe > Zn, respectively. It is therefore recommended that BA must be properly disposed of because of the hazardous nature of heavy metals present in the analysed samples, which are able to cause environmental and public health issues.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The recent population growth and the outbreak of diseases such as the Ebola virus, severe acute respiratory syndrome (SARS), coronavirus disease of 2019 (COVID-19) and other illnesses (Bucătaru et al., 2021) have significantly increased medical activities globally. Unfortunately, medical activities have also contributed to the rising generation of biomedical waste (BMW), making it difficult to be managed (Olaniy et al., 2018; Chisholm et al., 2021), especially in developing countries such as Ghana (Debrah et al., 2022b, d, e). Improper handling of BMW contributes to the rising volume of infectious BMW. In sub-Saharan Africa (SSA), for instance, in Addis Ababa, Ethiopia, health facilities generate about 41% of infectious BMW (Debere et al., 2013). A study by Oli et al. (2016) also revealed that more than 40% of infectious BMW is generated in Southeast Nigeria health facilities. Infectious BMWs (49.1%) are generated in six selected healthcare facilities in Eastern and Greater Accra regions (Debrah et al., 2021a), and 49.6% infectious BMW is generated in health facilities in Kumasi (Oduro-Kwarteng et al., 2021), in Ghana. These values are higher than the recommended 15% limit by the World Health Organization (WHO, 2018), to 35–50% (Debere et al., 2013; Debrah et al., 2021a; Oduro-Kwarteng et al., 2021; Oli et al., 2016).

This could adversely affect the environment and public health through uncontrollable disposals, like dumping in the open space and pit burning (Debrah et al., 2021a, b, c; Debrah et al., 2022a, b, c, d, e, f; Leal Filho et al., 2022a), so common in Africa. The improper handling of BMW has hindered achieving of some of the sustainable development goals (SDGs) in most developing countries, specifically good health and well-being (SDG3), clean water and sanitation (SDG6) and climate action (SDG13) (Leal Filho et al., 2022b, c). It is the case in Ghana.

Considering the significant volume of infectious BMW produced by health facilities in SSA countries, the incineration method is currently used to minimize generated BMW and reduce the problems posed by BMW infectious waste (Awodele et al., 2016), negatively impacting the environment (Debrah et al., 2021a). Studies in developing countries have shown that incineration reduces the weight of BMW by more than 70% (Xiao et al., 2018; Zhao et al., 2010) and the volume by 90% (Debrah et al., 2021a; Xiao et al., 2018). After the incineration, significant combustion residues remain in the form of bottom ash (BA). Although BMW incineration disposal is widely used in SSA, its environmental impact has resulted in public health problems caused by gases being released (Rahman & Singh, 2019). A few epidemiological studies in developed countries have shown that incinerator workers/operators and residents closer to incinerators (< 10 km) present diseases related to their work environment. These include laryngeal cancer (Michelozza et al., 1998), gastric cancer (Dockery and Pope III 1994; Rapiti et al., 1997), liver cancers (Elliott et al., 1996), and urinary mutagen (Landrigan et al., 1987). Other research also indicate that incinerator operators can present a significant level of mercury in their hair (Kurttio et al., 1998), lead and cadmium in blood (Wrbitzky et al., 1995) and hexachlorobenzene in blood/urine (Angerer et al., 1992). These effects show why some industrialized nations, such as the United States of America (USA), Germany and the Netherlands, have prevented the usage of incinerators in the management of BMW (Abor & Bouwer, 2008). Instead, most countries have opted for the most acceptable alternative available technology to handle BMW, such as microwave, plasma pyrolysis and ionized autoclave, with minimum environmental and fewer health issues (Dharmaraj et al., 2021; Xu et al., 2020; Zhao et al., 2021; Zimmermann, 2018), representing less threat to the environment and human health (Zhao et al., 2021). In developing countries, especially in SSA, these alternative technologies to handle BMW are rare due to financial implications associated with its purchasing and management (Leal Filho et al. 2022d; Dinis et al., 2022; Debrah et al., 2022a). Although current modern incinerators operate within a temperature range of 850–1200 °C, BA containing metals that are non-biodegradable affects the entire ecosystem and human health (Dwivedi et al., 2019; Premkumar et al., 2018; Wei et al., 2021). Recent studies by Agnihotri and Kesari (2019), Tait et al. (2020), and Wallace et al. (2020) revealed that heavy metals such as Cd, Hg and Pb could cause chronic diseases like cancer and long-term neurological conditions, leading to possible morbidity (Bennett et al., 2001; Yang et al., 2020). Also, these and other heavy metals can leach through the soil and contaminate drinking water (Kapoor & Singh, 2021; Mukherjee et al., 2021), which is then absorbed by plants, animals, and other organisms in the food chain (Feng et al., 2020; Manzoor & Sharma, 2019; Sonone et al., 2020). Meanwhile, the accumulated heavy metals cause chronic and acute toxic effects in the various living beings in nature.

In Ghana, BMW disposal equipment has changed from the traditionally built container through open brick (De Montfort) to the current covered brick 6-regulator cylinder gas incinerator. Only a limited number of medical centres have this new 6-regulator cylinder gas incinerator equipment. However, few studies referring to incinerators have addressed the BWM BA in Ghana. For instance, a study by Amfo-Otu et al. (2015) showed that heavy metals such as Pb, Cd, Hg and Cr were found in the BA of a De Montfort-type incinerator, with a concentration of Pb equal to 147.50 mg/kg. Also, a similar study by Adama et al. (2016) reported the release of Hg, Pb, Zn, Ag, Cr and Cd in the De Montfort incinerator. However, to this study authors’ best knowledge, there is not yet a study in Ghana on particle size distribution, the main chemical composition and the concentrations of heavy metals residuals present in the 6-regulator cylinder gas incinerator involving BA.

Therefore, this study aims to assess and determine the significant elements in terms of chemical components found in the BA in two cases: the Tema Hospital (TGH) and the Asuogyaman Hospital (VRAH) in Ghana. The particle size distribution and the concentration of heavy metals present in the BMW BA were obtained from the 6-regulator cylinder gas incinerator in TGH in Greater Accra Region and VRAH in Easter Region, Ghana.

Materials and methods

The BA samples used in this study were collected from TGH and VRAH facilities, with bed capacities of 409 and 55 patients, respectively. TGH and VRAH generate an estimated amount of 1.10 kg/day and 2.30 kg/day of BMW infectious waste, representing an accumulated value of 3.20 tons and 0.90 tons per week, respectively. BAs (0.27 tons and 0.07 tons) were produced every week after the incineration of BMW from TGH and VRAH incinerators. The incinerators used in TGH and VRAH were constructed with bricks and covered with corrugated iron sheets. The walls of the incinerators are composed of three layers to reduce the heat transmissions during the combustion process. In addition, fibres were placed between the walls and the covered corrugated iron sheets to prevent heat transfer. The incinerators have 2 chambers, a blower with six outlets and a front-loading window with 7 BA outlets. The two chambers operate within a temperature range of 800 ± 50 °C and 1100 ± 50 °C respectively, which is powered by gas from two gas cylinders with six regulators. Infectious BMWs collected from the various wards of TGH and VRAH are loaded directly into the incinerator by the operators and combusted continuously within 2–3 h with a maximum temperature of 800 °C. The BA generated from VRAH is hauled to the landfills, while the TGH is dumped close to the incinerator. Figure 1 shows the incinerators of TGH, VRAH.

Data sources and study period

Qualitative data on the incineration process of BMW in TGH and VRAH were obtained through critical observation and BA analyses. The time frame for the data collection was a month, i.e. March 2021. There was a daily check and observation of the waste type fed into the incinerators and how the BA was disposed of after incineration. In addition, the incinerated BAs were collected and sent to the Council for Scientific and Industrial Research-Institute of Industrial Research (CSIR-IIR), Ghana laboratory, for analysis.

Sampling preparation

Granulated BA samples (0.300 kg) were collected from the VRAH and TGH 6-regulator cylinder gas incinerators every 9 days within March 2021. The collected BA also contained other coarse materials such as glasses, bricks, concretes and heavy metals (Ti, Fe and Cu), resulting from medical bottles and needles in the BMW or used in the construction of the incinerators. The hot BA samples were cooled at room temperature and then dried at 105 °C for 24 h, similar to Bakkali et al. (2013) procedure. Each dried BA sample was ground gradually using laboratory mortar and pestle into smaller particle sizes to allow the exchange between residue phases and the extraction solutions (Bakkali et al., 2013; Guérin, 2000). The grounded BA was sorted into sizes with shaker-fitted standardized grade meshes of 120, 100, and 80. However, within 20 min, the sampled BAs were sieved to the particle size below 125 µm, 125–150 µm and 150–180 µm and above 180 µm.

BA chemical composition

X-ray fluorescence spectrometry analysis

The elemental composition in the BA was determined using X-ray fluorescence (XRF) spectroscopy. Portions of the 0.300 kg prepared bottom ash sample of TGH and VRAH were pressed into a cake. The chemical components of the BA were qualitatively analysed using S2 Ranger Energy Dispersive equipment to determine the unknown elements.

Heavy metal analysis

Before heavy metals were analysed using the SP-IAA320 Atomic Absorption Spectrophotometer (AAS) model, with a range of 190–900 nm and an accuracy level of ≤ ± 0.5 nm, the laboratory was thoroughly cleaned to eliminate possible contamination affecting the results. Dried sample (0.001 kg) was transferred into a round-bottom flask with 10 cm3 HNO3, evaporated over 1 h on a hot plate. The residue obtained from the evaporated mixture was digested with concentrated HNO3 and HClO4 in the ratio of 3:1 for 10–15 min at 25 °C. The digested mixture was steadily heated at 300 °C for about 120 min on a hot plate until all HClO4 gases evaporated. The mixture was allowed to cool at 25 °C and then filtered with Whatman No. 42 filter paper. The filtrate was kept in a 0.001 m3 well-labelled polyethylene bottle, ready to be analysed. The same procedure was carried out with estimated trace metals recorded and analysed with the ASS.

Results and discussion

Particle size distribution

The sieved particle size distribution of BA from TGH and VRAH is shown in Fig. 2. Most BA particles in this study were found above 180 µm and below 125 µm. This could result from the treatment of the sample, such as grinding or quantity of grounded sample on the sieve surface.

Figure 2 shows that the mass percentage of the particle size above 180 µm of VRAH is reduced by 9% of the total 70% TGH BA sample. The difference in the percentage might be due to the high content of the glass, ceramics, and other materials found in TGH BMW incinerated. The mass percentage content of the BA particles decreases with the particle size, from 180 to 125 µm. Below 125 µm, VRAH mass percentage particles increased by 12% (34% of the VRAH mass samples and 24% TGH particle mass sample) due to the high content of the heavy metals present in VRAH BA. The particle size distribution of this study is similar to a study by Yu et al. (2013), which was carried out in China, but opposite to a study conducted by Bakkali et al. (2013) in Rabat, Morocco.

Chemical composition of BA samples analysed by XRF

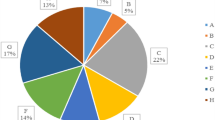

XRF analysis is the main technique used to determine the status of BA elements of BMW. The composition of determinant elements depends on the toxicity of the waste in the incinerator (Bakalár et al., 2021; Li et al., 2004), furnace type, and gas velocity (Chang et al., 2009). Table 1 presents the chemical composition of the oxides obtained from XRF analysis samples of TGH and VRAH incinerators. The results obtained show that each BA analysed sample contains a higher percentage of CaCO3 than all the remaining oxides. For TGH, the main BA elements consist of CaCO3 (49.90%), CaO (27.96%), MgCO3 (6.02%), MgO (2.87%), SO3 (2.34%) and SO4 (2.80%), while the main components of VRAH are constituted by CaCO3 (48.30%), CaO (27.07%), SiO2 (6.10%), MgCO3 (6.12%), MgO (2.93%) and Al2O3 (3.74%). The high percentages of the oxides from TGH and VRAH BA samples show that most of the BMW incinerated include domestic waste, which emphasizes the need to proper segregation at the source.

Although BA contains CaCO3, its high content in this study, with a mean of 49%, may be due to the presence of papers in incinerating BMW (Chang et al., 2017). It could also be due to the presence of the marbles in constructing the incinerator (de Oliveira et al., 2021; Hashimoto et al., 2017; Krajewska, 2018) and possibly through the use of CaCO3 dietary supplements in the form of medication by patients (Salomão et al., 2017; Zhai et al., 2018). According to Schabel et al. (2014), He and Liu (2017) and Indriati et al. (2020), CaCO3 is used as a filler in paper production to ensure the brightness of the paper. The analysis of the BA from these researched hospitals indicated a silicon/calcium (Si/Ca) ratio of 8.64:55.03 and < 0.3, which is far less than a study conducted by Li et al. (2004) and Bakkali et al. (2013) in China and Morocco, with Si/Ca ratio of 3 and 5, respectively. Therefore, the Si/Ca ratio indicates the content of generated non-infectious waste within a BMW. This study’s 0.3 Si/Ca ratio revealed that BMW generated from the TGH and VRAH was not adequately segregated.

The laboratory analysis from the TGH and VRAH incinerators showed mixed results of oxide compositions. This could be attributed to the size of the hospital, the area situated and the nature of activities performed by each hospital (Christiana & Anushree, 2021). In this study, the level of SO4 and SO3 in TGH BA was greater than that of VRAH, oppositely for K2O. The content of SO3 can be due to the presence of papers, food waste, plastics, leather mix, rubber, textile, wood, glass, ceramics and metals, which remains residual in BA (Kaiser, 1968). Nevertheless, a higher concentration of SO3 in BA will be problematic since it converts into SO4 at temperatures below 500 °C, becoming corrosive (Hardman & Stacy, 1998; Jaworowski & Mack, 1979; Marier & Dibbs, 1974; Sarbassov et al., 2017).

BA heavy metal detection in TGH and VRAH incinerators

Heavy metals such as Zn, Pb, Cr, Ni, Cu and Cd are primarily used to manufacture or coat medical tools and photographic (Bakkali et al., 2013) due to their resistance to corrosion and antibacterial surface factor.

The results in Table 2 indicate the heavy metal concentration of the BA samples in TGH and VRAH. Even though TGH and VRAH BA samples showed different mean (M) and standard deviation (SD) concentrations, both had an amount of Ti, Cr, Mn, Fe, Ni, Cu, Zn and Pb. The mean concentrations of Ti, Fe and Cu heavy metals in VRAH BA were higher than in TGH BA, while Cr, Mn and Ni were opposite. The difference in the mean concentrations of the BAs from TGH and VRAH could be attributed to improper waste segregation, since coloured plastic materials in BMW contain heavy metals (Tufail, 2008). The results from the analysis for TGH and VRAH indicate that Ti has the highest value, 7.082 ± 0.478 kg m−3 and 10.469 ± 1.588 kg m−3. Ni has the least 0.030 ± 0.021 kg m−3 and 0.025 ± 0.011 kg m−3 for TGH and VRAH, respectively. The mean concentrations of TGH and VRAH heavy metals as ranked in order of descending are as follows: Ti > Zn > Fe > Cr > Pb > Mn > Cu > Ni and Ti > Fe > Zn > Cu > Mn > Pb > Cr > Ni. Heavy metals such as Fe, Zn and Cu are essential to humans but become poisonous in high concentrations. Pb and Cr heavy metals are hazardous and have a high negative effect on humans (Tchounwou et al., 2012). The order raking of the heavy metals in TGH and VRAH BA indicates that TGH BA is more toxic than VRAH.

This study allowed to obtain higher mean concentrations of Ti, Fe and Zn in TGH and VRAH, similar to a study conducted in China on pollutants of BMW BA (Zhao et al., 2010). The higher concentration of Ti, Fe and Zn in BA is because they are widely used as metal alloys in medical equipment (Dehghan-Manshadi et al., 2020; Hernández-Escobar et al., 2019; Kazemi et al., 2020). However, due to their high melting point, above the temperature used in incinerators, Ti and Fe tend to be present in BA.

Some metals found in BA could contain toxic contaminants that can be persistent in the environment (such as Pb, Ni, Cu and Cr) (Kumar et al., 2021; Thuy et al., 2021), negatively impacting it (Andreola et al., 2019; Lemly, 2018; Manzoor & Sharma, 2019; Yin et al., 2020). The mean concentration of Ti, Cr, Cu and Mn and Pb released from TGH BA and VRAH BA exceeded the WHO permissible limits of heavy metals in soil, including Fe from VRAH BA, as shown in Table 2. Due to its high content of heavy metals, the improper disposal of this BA could negatively impact the environment and public health. Each heavy metal has different properties and impacts, in terms of human health effects. As example, the exposure to high concentrations of Ti contained in BA samples could cause coughing, tightness and chest pains (Lenntech, 2022). Zn and Fe present in the BA may cause nausea, vomiting and anaemia (Kim et al., 2019; Njoku et al., 2020; Saria, 2016).

As seen by the results being presented, the disposal of BA resulting from BMW incineration needs to be properly addressed since the resulting BA can threaten ecosystems and humans. The heavy metal component in the BA can leach out into water bodies, groundwater and soil, polluting the environment and possibly causing cancer respiratory and other issues severely affecting human health (Mozhi et al., 2022; Munawer, 2018).

Conclusions

When improperly handled and inadequately disposed, BMW generated from diagnostics centres, healthcare centres, blood banks, research institutions and laboratories are hazardous and negatively impact the environment and public health. In SSA countries in particular, and also in Ghana, BMW is primarily incinerated. Although this incineration process reduces the volume and weight of BMW, it also produces BA that contains heavy metals and oxides, toxic to human health and the environment. Departing from the analysis of the results from this study, involving XRF and ASS techniques, the results from this study using BA from two healthcare facilities in Ghana, i.e. TGH and VRAH, revealed that the BA generated by the BMW incinerators from both healthcare facilities contains high concentration of significant non-hazardous waste containing CaCO3, CaO, SiO2, MgCO3, MgO, SO3 and Al2O3 in the incinerated BMW, resulting from materials used in the construction and domestic waste such as food waste, ceramics, plastics and papers. These values can be reduced if proper segregation is addressed prior to incineration. High concentrations of heavy metals, specifically Ti, Fe, Zn, Pb, Cu, Mn and Cr, were found in both incinerators, above WHO permissible soil limits, except Ni. In both TGH and VRAH incinerators, Ti heavy metal was the highest by-product in the BA, corresponding to 7.082 ± 0.478 kg m−3 and 10.469 ± 1.588 kg m−3, respectively, in TGH and VRAH. Ti is one of the most hazardous heavy metals, negatively impacting the environment and human health.

From the results obtained in this study, it is concluded that improper disposal of BA from incinerators may pollute the environment and water bodies through leachate, leading to possible health implications such as respiratory diseases and cancers, while also negatively impacting the environment. Ensuring proper disposal of BA through sanitary landfills may contribute to minimize the heavy metals and hazardous components in the environment, also protecting the human health. The advance of specific SDGs, such as SDG3, 6, and 13, strongly depend on actions aimed at contributing to better handling of waste in Africa. Accordingly, this study is of fundamental importance in Ghana, a developing country that needs to focus on environmental issues that also benefit human health. It represents a contribution to fulfil the gap of knowledge at this respect and the scarcity of studies in the SSA region.

Limitations and future studies

This study was conducted at a time when COVID-19 pandemic in Ghana was rising, and the selected hospitals were assigned as COVID-19 centres. The authors were unable to sort and classify BMW waste before being incinerated. Therefore, future studies must attempt to classify the types of BMW waste incinerated, as well as to analyse the percentage of limestone present in the BA of the incinerators, possibly used for binding materials.

Data availability

The datasets analysed during the current study are available from the corresponding author on reasonable request.

References

Abor, P. A., & Bouwer, A. (2008). Medical waste management practices in a Southern African hospital. International Journal of Health Care Quality Assurance, 21, 356–364. https://doi.org/10.1108/09526860810880153

Adama, M., Esena, R., Fosu-Mensah, B., & Yirenya-Tawiah, D. (2016). Heavy metal contamination of soils around a hospital waste incinerator bottom ash dumps site. Journal of Environmental and Public Health, 2016, 8926453. https://doi.org/10.1155/2016/8926453

Agnihotri, S. K., Kesari, K. K. (2019). Mechanistic effect of heavy metals in neurological disorder and brain cancer. In: Kesari KK (ed.) Networking of Mutagens in Environmental Toxicology. Springer International Publishing, Cham, pp 25–47. https://doi.org/10.1007/978-3-319-96511-6_2

Amfo-Otu, R., Kyerewaa, S. G., Ofori, E. A., & Sadick, A. (2015). Comparative study of heavy metals in bottom ash from incinerators and open pit from healthcare facilities in Ghana. Octa Journal of Environmental Research Jan – Mar Octa Journal of Environmental Research Res, 3, 50–56.

Andreola, F., Barbieri, L., Queiroz Soares, B., Karamanov, A., Schabbach, L. M., Bernardin, A. M., & Pich, C. T. (2019). Toxicological analysis of ceramic building materials – tiles and glasses – obtained from post-treated bottom ashes. Waste Management, 98, 50–57. https://doi.org/10.1016/j.wasman.2019.08.008

Angerer, J., Heinzow, B., Reimann, D. O., Knor, W., & Lehnert, G. (1992). Internal exposure to organic substances in a municipal waste incinerator. International Archives of Occupational and Environmental Health - Springer, 64, 265–273. https://doi.org/10.1007/BF00378285

Anjali, Rani, J., Kumar, A. (2018). Manganese: affecting our environment (water, soil, and vegetables). International Journal for Innovative Research in Science & Technology, 4, 8. Retrieved May 21, 2022, from http://www.ijirst.org/articles/IJIRSTV4I8001.pdf

Awodele, O., Adewoye, A. A., & Oparah, A. C. (2016). Assessment of medical waste management in seven hospitals in Lagos, Nigeria. BMC Public Health, 16, 1–11. https://doi.org/10.1186/s12889-016-2916-1

Bakalár, T., Pavolová, H., Hajduová, Z., Lacko, R., & Kyšeľa, K. (2021). Metal recovery from municipal solid waste incineration fly ash as a tool of circular economy. Journal of Cleaner Production, 302, 126977. https://doi.org/10.1016/j.jclepro.2021.126977

Bakkali, M. E. L., Bahri, M., Gmouh, S., Jaddi, H., Bakkali, M., Laglaoui, A., & Mzibri, M. E. L. (2013). Characterization of bottom ash from two hospital waste incinerators in Rabat, Morocco. Waste Management & Research, 31(12), 1228–1236. https://doi.org/10.1177/0734242X13507308

Bennett, P. M., Jepson, P. D., Law, R. J., Jones, B. R., Kuiken, T., Baker, J. R., Rogan, E., & Kirkwood, J. K. (2001). Exposure to heavy metals and infectious disease mortality in harbour porpoises from England and Wales. Environmental Pollution, 112, 33–40. https://doi.org/10.1016/S0269-7491(00)00105-6

Bucătaru, C., Săvescu, D., Repanovici, A., Blaga, L., Coman, E., & Cocuz, M. E. (2021). The implications and effects of medical waste on development of sustainable society—a brief review of the literature. Sustain Switz, 13(6), 3300. https://doi.org/10.3390/su13063300

Chang, C. Y., Wang, C. F., Mui, D. T., Cheng, M. T., & Chiang, H. L. (2009). Characteristics of elements in waste ashes from a solid waste incinerator in Taiwan. Journal of Hazardous Materials, 165, 766–773. https://doi.org/10.1016/j.jhazmat.2008.10.059

Chang, R., Kim, S., Lee, S., Choi, S., Kim, M., & Park, Y. (2017). Calcium carbonate precipitation for CO2 storage and utilization: A review of the carbonate crystallization and polymorphism. Frontiers in Energy Research, 5, 1–12. https://doi.org/10.3389/fenrg.2017.00017

Chisholm, J. M., Zamani, R., Negm, A. M., Said, N., Abdel Daiem, M. M., Dibaj, M., & Akrami, M. (2021). Sustainable waste management of medical waste in African developing countries: A narrative review. Waste Manag Res, 39, 1149–1163. https://doi.org/10.1177/0734242X211029175

Christiana, K., & Anushree, P. (2021). Review of current healthcare waste management methods and their effect on global health. Healthcare, 9, 284. https://doi.org/10.3390/healthcare9030284

de Oliveira, E. A., Debrah, J. K., de Simas Guerreiro, M. J. C., & Dinis, M. A. P. (2021). A new microbicidal pervious concrete pavement for hospital parking–lots: Assessment of the modulus of elasticity. Procedia Environmental Science, Engineering and Management, 8(2), 335–343.

Debere, M. K., Gelaya, K. A., & Alamdo, A. G. (2013). Assessment of the health care waste generation rates and its management system in hospitals of Addis Ababa. BMC Public Health, 12(13), 28. https://doi.org/10.1186/1471-2458-13-28

Debrah, J. K., Vidal, D. G., & Dinis, M. A. P. (2021b). Innovative use of plastic for a clean and sustainable environmental management: Learning cases from Ghana, Africa. Urban Science, 5, 12. https://doi.org/10.3390/urbansci5010012

Debrah, J. K., Vidal, D. G., & Dinis, M. A. P. (2021c). Raising awareness on solid waste management through formal education for sustainability: A developing countries evidence review. Recycling, 6, 1–21. https://doi.org/10.3390/recycling6010006

Debrah, J. K., Teye, G. K., & Dinis, M. A. P. (2022a). Barriers and challenges to waste management hindering the circular economy in sub-Saharan Africa. Urban Science, 6, 57. https://doi.org/10.3390/urbansci6030057

Debrah, J. K., Wahaj, Z., Sadaf, L., & Dinis, M. A. P. (2022f). Assessment of biomedical waste in Ghana. International Journal of Environmental Studies. https://doi.org/10.1080/00207233.2022.2135891

Debrah, J. K., Carlotto, I. N., Vidal, D. G., Dinis, M. A. P. (2021a). Managing medical waste in Ghana-the reality. International Journal of Environmental Studies. 1–17. https://doi.org/10.1080/00207233.2021.1994752

Debrah, J. K., Vidal, D. G., Dinis, M. A. P. (2022b). Environmental waste sustainability: organic valorisation and socioeconomic benefits towards sustainable development in Ghana. In: Leal Filho W., Vidal DG, Dinis MAP. DRC (eds.) Sustainable Policies and Practices in Energy, Environment and Health Research. World Sustainability Series. Springer, Cham, pp 425–437. https://doi.org/10.1007/978-3-030-86304-3_24

Debrah, J. K., Vidal, D. G., Dinis, M. A. P. (2022c). Sustainable pharmaceutical waste management: pharmacist and patients perception in Ghanaian hospitals. In: In Handbook of Sustainability Science in the Future., Walter Lea (eds.) Cham, Switzerland: Springer Cham pp 425–437. https://doi.org/10.1007/978-3-030-68074-9_131-1

Debrah, J. K., Vidal, D. G., Dinis, M. A. P. (2022d). Vulnerabilities of waste scavengers to COVID-19 impacts: outcomes of an exploratory study in Ghana. In W. Leal Filho (Ed.), Handbook of Human and Planetary Health (pp. 187–201). Springer, Cham. https://doi.org/10.1007/978-3-031-09879-6_12

Debrah, J. K., Vidal, D. G., Dinis, M. A. P. (2022e). Recovering from COVID-19 environment and social impacts in sub-Saharan Africa: the role of social engagement. In W. L. Filho, A. M. Azul, F. Doni, & A. L. Salvia (Eds.), Handbook of Sustainability Science in the Future: Policies, Technologies, and Education by 2050 (pp. 1–16). Springer, Cham. https://doi.org/10.1007/978-3-030-68074-9_132-1

Dehghan-Manshadi, A., Yu, P., Dargusch, M., StJohn, D., & Qian, M. (2020). Metal injection moulding of surgical tools, biomaterials and medical devices: A review. Powder Technology, 364, 189–204. https://doi.org/10.1016/j.powtec.2020.01.073

Dharmaraj, S., Ashokkumar, V., Pandiyan, R., Halimatul Munawaroh, H. S., Chew, K. W., Chen, W.-H., & Ngamcharussrivichai, C. (2021). Pyrolysis: an effective technique for degradation of COVID-19 medical wastes. Chemosphere, 275, 130092. https://doi.org/10.1016/j.chemosphere.2021.130092

Dinis, M. A. P., Neto, B., Begum, H., & Vidal, D. G. (2022). Editorial: waste challenges in the context of broad sustainability challenges. Frontiers in Environmental Science, 10, 964366. https://doi.org/10.3389/fenvs.2022.964366

Dockery, D. W., & Pope, C. A., III. (1994). Acute respiratory effects of particulate air pollution. Annual Review of Public Health, 15, 107–132. https://doi.org/10.1146/annurev.pu.050194.000543

Dwivedi, P., Mishra, P. K., Mondal, M. K., & Srivastava, N. (2019). Non-biodegradable polymeric waste pyrolysis for energy recovery. Heliyon, 5, e02198. https://doi.org/10.1016/j.heliyon.2019.e02198

Elliott, P., Shaddick, G., Kleinschmidt, I., Jolley, D., Walls, P., Beresford, J., & Grundy, C. (1996). Cancer incidence near municipal solid waste incinerators in Great Britain. British Journal of Cancer, 73, 702–710. https://doi.org/10.1038/bjc.1996.122

Feng, W., Guo, Z., Xiao, X., Peng, C., Shi, L., Ran, H., & Xu, W. (2020). A dynamic model to evaluate the critical loads of heavy metals in agricultural soil. Ecotoxicology and Environmental Safety, 197, 110607. https://doi.org/10.1016/j.ecoenv.2020.110607

Guérin, L. (2000). Devenir des polluants inorganiques contenus dans les résidus de combustion des déchets ménagers : spéciation et élaboration de tests de mobilité en vue de leur stockage ou de leur valorisation [Fate of inorganic pollutants contained in household waste combustion residues: speciation and development of mobility tests for their storage or recovery]. https://theses.fr/2000TOUL0005, https://www.semanticscholar.org/paper/Devenir-des-polluants-inorganiques-contenus-dans-de-Guérin/587b02fe789683f0a7543af86a8790ae41cc5638 (Retrieved on 12/9/2022).

Hardman, R., Stacy, R. (1998). Estimating sulfuric acid aerosol emissions from coal-fired power plants. https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&ved=2ahUKEwiFm53hnPf6AhVkYPEDHd_9AKcQFnoECAoQAQ&url=https%3A%2F%2Fdownloads.regulations.gov%2FEPA-R06-OAR-2014-0754-0008%2Fattachment_36.pdf&usg=AOvVaw0JM8AXKnNSEm2kZcuo_xSe (Retrieved on 21/05/2022).

Hashimoto, S., Kusawake, S., Daiko, Y., Honda, S., & Iwamoto, Y. (2017). Fabrication of pure phase calcium carbonate hardened bodies as a means of creating novel geomimetic ceramics. Construction and Building Materials, 135, 405–410. https://doi.org/10.1016/j.conbuildmat.2016.12.211

He, T., & Liu, M. (2017). Recovery of calcium carbonate waste as paper filler in the causticizing process of bamboo kraft pulping. Journal of Bioresources and Bioproducts, 2, 82–88. https://doi.org/10.21967/jbb.v2i2.147

Hernández-Escobar, D., Champagne, S., Yilmazer, H., Dikici, B., Boehlert, C. J., & Hermawan, H. (2019). Current status and perspectives of zinc-based absorbable alloys for biomedical applications. Acta Biomaterialia, 97, 1–22. https://doi.org/10.1016/j.actbio.2019.07.034

Indriati, L., Nugraha, M. A., Perng, Y. S. (2020). Stone paper, an eco-friendly and free-tree papers. Bogor, Indonesia, AIP Conference Proceedings 2243(1):030010. https://doi.org/10.1063/5.0001753

International Programme on Chemical Safety. (1982). Titanium. World Health Organization ; WHO Publications Centre USA [distributor], Geneva : Albany, N.Y. https://inchem.org/documents/ehc/ehc/ehc24.htm (accessed on 17/0772022).

Jaworowski, R. J., & Mack, S. S. (1979). Evaluation of methods for measurement of SO3/H2SO4 in flue gas. Journal of the Air Pollution Control Association, 29, 43–46. https://doi.org/10.1080/00022470.1979.10470750

Kaiser, E. R. (1968). The sulphur balance of incinerators. Journal of the Air Pollution Control Association, 18(3), 171–174. https://doi.org/10.1080/00022470.1968.10469112

Kapoor, D., Singh, M. P. (2021). 10 - heavy metal contamination in water and its possible sources. In: Kumar, V., Sharma, A., Cerdà, A. (eds.) Heavy Metals in the Environment. Elsevier, pp 179–189. https://doi.org/10.1016/B978-0-12-821656-9.00010-9

Kazemi, M., Ahangarani, S., Esmailian, M., & Shanaghi, A. (2020). Investigation on the corrosion behavior and biocompatibility of Ti-6Al-4V implant coated with HA/TiN dual layer for medical applications. Surface and Coatings Technology, 397, 126044. https://doi.org/10.1016/j.surfcoat.2020.126044

Kim, J. J., Kim, Y. S., & Kumar, V. (2019). Heavy metal toxicity: An update of chelating therapeutic strategies. Journal of Trace Elements in Medicine and Biology, 54, 226–231. https://doi.org/10.1016/j.jtemb.2019.05.003

Krajewska, B. (2018). Urease-aided calcium carbonate mineralization for engineering applications: A review. Journal of Advanced Research, 13, 59–67. https://doi.org/10.1016/j.jare.2017.10.009

Kumar, A. R., Vaidya, A. N., Singh, I., Ambekar, K., Prajapati, A., Kanade, G. S., Kale, G., & Bodkhe, S. (2021). Toxic / hazardous substances and environmental engineering leaching characteristics and hazard evaluation of bottom ash generated from common biomedical waste incinerators. Journal of Environmental Science and Health, Part A Environmental Science, 56, 1069–1079. https://doi.org/10.1080/10934529.2021.1962159

Kurttio, P., Pekkanen, J., Alfthan, G., Paunio, M., & Heinonen, P. (1998). Increase mercury exposure in inhabitants living in the vicinity of a hazardous waste incinerator: A 10-year follow-up. Achieves Environ Health International Journal, 53, 129–137. https://doi.org/10.1080/00039896.1998.10545974

Landrigan, P. J., Stein, G. F., Kominsky, J. R., Ruhe, R. L., & Watanabe, A. S. (1987). Common-source community and industrial exposure to trichloroethylene. Archives of Environmental Health, 42, 327–332. https://doi.org/10.1080/00039896.1987.9934354

Leal Filho, W., Dinis, M. A. P., Ruiz-de-Maya, S., Doni, F., Eustachio, J. H., Swart, J., & Paço, A. (2022a). The economics of the UN Sustainable Development Goals: Does sustainability make financial sense? Discover Sustainability, 3, 20. https://doi.org/10.1007/s43621-022-00088-5

Leal Filho, W., Salvia, A. L., Vasconcelos, C. R. P., Anholon, R., Rampasso, I. S., Eustachio, J. H. P. P., Liakh, O., Dinis, M. A. P., Olpoc, R. C., Bandanaa, J., Aina, Y. A., Lukina, R. L., Sharifi, A. (2022b). Barriers to institutional social sustainability. Sustainability Science, 1–16. https://doi.org/10.1007/s11625-022-01204-0

Leal Filho, W., Vidal, D. G., Chen, C., Petrova, M., Dinis, M. A. P., Yang, P., Rogers, S., Álvarez‑Castañón, L. del C., Djekic, I., Sharifi, A., Samara, N. (2022d) An assessment of requirements in investments, new technologies, and infrastructures to achieve the SDGs. Environmental Sciences Europe, 1–17. https://doi.org/10.1186/s12302-022-00629-9

Leal Filho, W., Wall, T., Barbir, J., Alverio, G. N., Dinis, M. A. P., & Ramirez, J. (2022c). Relevance of international partnerships in the implementation of the UN Sustainable Development Goals. Nature Communications, 13, 613. https://doi.org/10.1038/s41467-022-28230-x

Lemly, A. D. (2018). Human and ecological risk assessment : an international environmental hazard assessment of coal ash disposal at the proposed Rampal power plant. Human and Ecological Risk Assessment: An International Journal, 24(3), 627–641. https://doi.org/10.1080/10807039.2017.1395685

Lenntech. (2022). Chemical properties of titanium - health effects of titanium - environmental effects of titanium. In: Titan. - Ti. https://www.lenntech.com/periodic/elements/ti.htm#ixzz7VME6ci67. Retrieved 5 Jun 2022.

Li, M., Xiang, J., Hu, S., Sun, L. S., Su, S., Li, P. S., & Sun, X. X. (2004). Characterization of solid residues from municipal solid waste incinerator. Fuel, 83, 1397–1405. https://doi.org/10.1016/j.fuel.2004.01.005

Manzoor, J., & Sharma, M. (2019). Impact of biomedical waste on environment and human health. Environ Claims J, 31, 311–334. https://doi.org/10.1080/10406026.2019.1619265

Marier, P., & Dibbs, H. P. (1974). The catalytic conversion of SO2 to SO3 by fly ash and the capture of SO2 and SO3 by CaO and MgO. Thermochimica Acta, 8, 155–165. https://doi.org/10.1016/0040-6031(74)85082-3

Michelozza, P., Fusco, D., Forastiere, F., Ancona, C., Dell’Orco, V., & Perucci, C. A. (1998). Small area study of mortality among people living near multiple sources of air pollution. Occupational and Environmental Medicine, 55, 611–615. https://doi.org/10.1136/oem.55.9.611

Mozhi, A., Prabhakar, A. K., Mohan, B. C., Sunil, V., Teoh, J. H., & Wang, C. H. (2022). Toxicity effects of size fractions of incinerated sewage sludge bottom ash on human cell lines. Environmental International, 158, 106881. https://doi.org/10.1016/j.envint.2021.106881

Mukherjee, I., Singh, U. K., Singh, R. P. (2021). An overview on heavy metal contamination of water system and sustainable approach for remediation. In: Singh, A., Agrawal, M., Agrawal, S. B. (eds) Water Pollution and Management Practices. Springer Singapore, Singapore, pp 255–277. https://doi.org/10.1007/978-981-15-8358-2_11

Munawer, M. E. (2018). Human health and environmental impacts of coal combustion and post-combustion wastes. Journal Sustainable Mining, 17, 87–96. https://doi.org/10.1016/j.jsm.2017.12.007

Njoku, P., Bennard, O., & Akudinobi, B. (2020). Potential health risk and levels of heavy metals in water resources of lead – zinc mining communities of Abakaliki, southeast Nigeria. Applied Water Science, 10, 1–23. https://doi.org/10.1007/s13201-020-01233-z

Oduro-Kwarteng, S., Addai, R., & Essandoh, H. M. K. (2021). Healthcare waste characteristics and management in Kumasi, Ghana. Scientific African, 12, e00784. https://doi.org/10.1016/j.sciaf.2021.e00784

Olaniy, F. C., Ogola, J. S., & Tshitangano, T. G. (2018). A review of medical waste management in South Africa. Open Environmental Science, 10, 34–45. https://doi.org/10.2174/1876325101810010034

Oli, A. N., Ekejindu, C. C., Adje, D. U., Ezeobi, I., Ejiofor, O. S., Ibeh, C. C., & Ubajaka, C. F. (2016). Healthcare waste management in selected government and private hospitals in Southeast Nigeria. Asian Pacific Journal of Tropical Biomedicine, 6, 84–89. https://doi.org/10.1016/j.apjtb.2015.09.019

Osobamiro, T. M., Awolesi, O., Alabi, O. M., Oshinowo, A. Y., Oshinowo, M. A., & Busari, F. A. (2019). Heavy metal levels of soil samples collected from a major industrial area in Abeokuta, Southwestern Nigeria. International Journal of Scientific and Research Publications (IJSRP), 9, 92125. https://doi.org/10.29322/IJSRP.9.08.2019.p92125

Premkumar, M. P., Thiruvengadaravi, K. V., Senthil Kumar, P., Nandagopal, J., Sivanesan, S. (2018). Eco-friendly treatment strategies for wastewater containing dyes and heavy metals. In: Gupta, T., Agarwal, A. K., Agarwal, R. A., Labhsetwar, N. K. (eds) Environmental Contaminants: Measurement, Modelling and Control. Springer Singapore, Singapore, pp 317–360. https://doi.org/10.1007/978-981-10-7332-8_14

Rahman, Z., & Singh, V. P. (2019). The relative impact of toxic heavy metals (THMs) (arsenic (As), cadmium (Cd), chromium (Cr)(VI), mercury (Hg), and lead (Pb)) on the total environment: an overview. Environmental Monitoring and Assessment, 191(7), 419. https://doi.org/10.1007/s10661-019-7528-7

Rapiti, E., Sperati, A., Fano, V., & Dell’Orco, V. (1997). Mortality among workers at municipal waste incinerators in Rome: a retrospective cohort study. American Journal of Industrial Medicine, 31, 659–661. https://doi.org/10.1002/(sici)1097-0274(199705)31

Salomão, R., Costa, L. M. M., & de Olyveira, G. M. (2017). Precipitated calcium carbonate nano-microparticles: applications in drug delivery. Advances in Tissue Engineering & Regenerative Medicine: Open Access, 3(2), 336–340. https://doi.org/10.15406/atroa.2017.03.00059

Sarbassov, Y., Duan, L., Jeremias, M., Manovic, V., & Anthony, E. J. (2017). SO3 formation and the effect of fly ash in a bubbling fluidised bed under oxy-fuel combustion conditions. Fuel Processing Technology, 167, 314–321. https://doi.org/10.1016/j.fuproc.2017.07.015

Saria, J. A. (2016). Levels of heavy metals in bottom ash from medical waste incinerators in Dar es Salaam. Journal of Multidisciplinary Engineering Science Studies, 2(6), 599–605.

Schabel, S., Putz, H.-J., Hamm, U., Kersten, A., Bobek, B., Hirsch, G., & Voss, D. (2014). Calcium carbonate in the paper industry - blessing for coated papermaking and curse for recycling processes. TAPPI J, 13, 47–54. https://doi.org/10.32964/TJ13.11.47

Sonone, S. S., Jadhav, S. V., Sankhla, M. S., & Kumar, R. (2020). Water contamination by heavy metals and their toxic effect on aquaculture and human health through food chain. Letters in Applied NanoBioScience, 10, 2148–2166. https://doi.org/10.33263/lianbs102.21482166

Tait, P. W., Brew, J., Che, A., Costanzo, A., Danyluk, A., Davis, M., Khalaf, A., McMahon, K., Watson, A., Rowcliff, K., & Bowles, D. (2020). The health impacts of waste incineration: A systematic review. Australian and New Zealand Journal of Public Health, 44, 40–48. https://doi.org/10.1111/1753-6405.12939

Tchounwou, P. B., Yedjou, C. G., Patlolla, A. K., Sutton, D. J. (2012). Heavy metal toxicity and the environment. In: Luch, A. (ed.) Molecular, Clinical and Environmental Toxicology. Springer Basel, Basel, pp 133–164 https://doi.org/10.1007/978-3-7643-8340-4_6

Thuy, T., Nguyen, T., Hoang, A. Q., Nguyen, V. D., Nguyen, H. T., Vu, T. V. (2021). Concentrations , profiles , emission inventory , and risk assessment of chlorinated benzenes in bottom ash and fly ash of municipal and medical waste incinerators in northern Vietnam. Environmental Science and Pollution Research International, 13340–13351. https://doi.org/10.1007/s11356-020-11385-9

Tufail, M. (2008). Heavy metal pollution from medical waste incineration at Islamabad and Rawalpindi, Pakistan. Microchemical Journal, 90, 77–81. https://doi.org/10.1016/j.microc.2008.03.010

Ullah, N., Ur Rehman, M., Ahmad, B., Ali, I., Younas, M., Aslam, M. S., Rahman, A., Taheri, E., Fatehizadeh, A., & Rezakazemi, M. (2022). Assessment of heavy metals accumulation in agricultural soil, vegetables and associated health risks. PLOS ONE, 17, e0267719. https://doi.org/10.1371/journal.pone.0267719

Wallace, D. R., Taalab, Y. M., Heinze, S., Tariba Lovaković, B., Pizent, A., Renieri, E., Tsatsakis, A., Farooqi, A. A., Javorac, D., Andjelkovic, M., Bulat, Z., Antonijević, B., & Buha Djordjevic, A. (2020). Toxic-metal-induced alteration in miRNA expression profile as a proposed mechanism for disease development. Cells 7, 9(4), 901. https://doi.org/10.3390/cells9040901

Wei, W., Shi, X., Wu, L., & Ni, B. J. (2021). Insights into coconut shell incineration bottom ash mediated microbial hydrogen production from waste activated sludge. Journal of Cleaner Production, 322, 129157. https://doi.org/10.1016/j.jclepro.2021.129157

World Health Organization (WHO). (2018) health-care waste. Available online at: https://www.who.int/news-room/fact-sheets/detail/health-care-waste. Retrieved 10 October 2022

Wrbitzky, R., Goen, T., Letzel, S., Frank, F., & Angerer, J. (1995). Internal esposure of waste incineration workers to organic and inorganic substances. International Achieves of Occupational and Environmental Health, 68, 13–21. https://doi.org/10.1007/BF01831628

Xiao, H., Ru, Y., Peng, Z., Yan, D., Li, L., Karstensen, K. H., Wang, N., & Huang, Q. (2018). Destruction and formation of polychlorinated dibenzo-p-dioxins and dibenzofurans during pretreatment and co-processing of municipal solid waste incineration fly ash in a cement kiln. Chemosphere, 210, 779–788. https://doi.org/10.1016/j.chemosphere.2018.07.058

Xu, L., Dong, K., Zhang, Y., & Li, H. (2020). Comparison and analysis of several medical waste treatment technologies. IOP Conference Series: Earth and Environmental Science, 615(1), 012031. https://doi.org/10.1088/1755-1315/615/1/012031

Yang, A. M., Lo, K., Zheng, T. Z., Yang, J. L., Bai, Y. N., Feng, Y. Q., Cheng, N., & Liu, S. M. (2020). Environmental heavy metals and cardiovascular diseases: Status and future direction. Chronic Diseases Translational Medicine, 6, 251–259. https://doi.org/10.1016/j.cdtm.2020.02.005

Yin, K., Chan, W. P., Dou, X., Ahamed, A., Lisak, G., & Chang, V. W. C. (2020). Human exposure and risk assessment of recycling incineration bottom ash for land reclamation: a showcase coupling studies of leachability, transport modeling and bioaccumulation. Journal of Hazardous Materials, 385, 121600. https://doi.org/10.1016/j.jhazmat.2019.121600

Yu, J., Sun, L., Tang, H., & Song, X. (2013). Physical and chemical characterization of ashes from a municipal solid waste incinerator in China. Waste Management & Research, 31, 663–673. https://doi.org/10.1177/0734242X13485793

Zhai, Q., Yang, L., Zhao, J., Zhang, H., Tian, F., & Chen, W. (2018). Protective effects of dietary supplements containing probiotics, micronutrients, and plant extracts against lead toxicity in mice. Frontiers in Microbiology, 9, 2134. https://doi.org/10.3389/fmicb.2018.02134

Zhao, H. L., Wang, L., Liu, F., Liu, H. Q., Zhang, N., & Zhu, Y. W. (2021). Energy, environment and economy assessment of medical waste disposal technologies in China. Science of The Total Environment, 796, 148964. https://doi.org/10.1016/j.scitotenv.2021.148964

Zhao, L., Zhang, F.-S., Chen, M., Liu, Z., & Wu, D. B. J. (2010). Typical pollutants in bottom ashes from a typical medical waste incinerator. Journal of Hazardous Materials, 173, 181–185. https://doi.org/10.1016/j.jhazmat.2009.08.066

Zimmermann, K. (2018). Microwave technologies: An emerging tool for inactivation of biohazardous material in developing countries. Recycling, 3(3), 34. https://doi.org/10.3390/recycling3030034

Acknowledgements

The authors are grateful to the Council for Scientific and Industrial Research-Institute of Industrial Research (CSIR-IIR), Ghana laboratory, for analysis of the bottom ash samples.

Author information

Authors and Affiliations

Contributions

Conceptualization, Justice Kofi Debrah; data curation, Justice Kofi Debrah; methodology, Justice Kofi Debrah; supervision, Maria Alzira Pimenta Dinis; validation, Maria Alzira Pimenta Dinis; visualization, Justice Kofi Debrah and Maria Alzira Pimenta Dinis; writing-original draft, Justice Kofi Debrah and editing, Justice Kofi Debrah and Maria Alzira Pimenta Dinis. All the authors have read and accepted to the published version of the manuscript.

Corresponding authors

Ethics declarations

Ethical approval

All the authors have read, understood, and have complied as applicable with the statement on “Ethical responsibilities of Authors” as found in the Instructions for Authors and are aware that with minor exceptions, no changes can be made to authorship once the article is submitted.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Debrah, J.K., Dinis, M.A.P. Chemical characteristics of bottom ash from biomedical waste incinerators in Ghana. Environ Monit Assess 195, 568 (2023). https://doi.org/10.1007/s10661-023-11132-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-023-11132-w