Abstract

High amounts of tailings with a low recycling rate are generated during mining and smelting processes, and a lot of environmental problems were caused by heavy metal leaching from tailings. Temperature is a key point in heavy metals leaching, and knowing the effects of temperature on tailings leaching is useful for tailings management. A small-scale batch leaching experiment was conducted at different temperatures to test temperature-driven heavy metal leaching from tailings in the arctic area. The variation in the leaching of heavy metals from tailings was investigated by a small-scale batch leaching experiment. Results showed that 10 °C is a threshold temperature for the leaching activity of the tested elements. Fe, Cr, and Cu are significantly correlated with temperature in the leaching. Leaching rates of Cr, Cu, and Ni increase as temperature rises. Leaching rates of Cr, Cu, Ni, V, and Zn change by a polynomial model with temperatures, whereas that of Fe changes with a linear model. V shows an antagonistic relationship with Cu, Fe, and Ni in the leaching. However, Cu, Cr, Ni, and Fe show a synergistic relationship. Discovering the threshold temperature of leaching tailings in the arctic area and concluding the influence factors and the relationship between heavy metals leaching and temperature are useful for tailings management.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The mining industry is growing rapidly as societal demands for minerals and metals increase. Mining activity increased from 9418 megatons (Mt) in 1984 to 16,863 Mt in 2012, a 79% change (Dold 2014; Ramirez-Llodra et al. 2015). The rapid expansion of the mining industry generates large amounts of tailings (Jenkins and Yakovleva 2006), which can range from 90 to 98% for some copper ores (Wills and Finch 2015). Most of the tailings deposits are in wild fields or tailings dams. The tailings contain certain amounts of residual sulfide minerals, which can lead to significant environmental problems without proper management (Fu and Wei 2013).

The deposition of sulfidic tailings leads to the formation of acid mine drainage and the dissolution and leaching of heavy metals and other contaminants to the surrounding environment (Lu 2016). The leached heavy metals and other contaminants are transported to soil and water, leading to the degradation of soil and water quality (Hu et al. 2014; Lu 2016; Jingyong et al. 2006; Xiaojuan et al. 2012; Zhang et al. 2011; Zhang et al. (2014). In addition, crops that grow in the local soil become polluted through their absorption of more toxic elements from contaminated soils and water; this is harmful to human health if the contaminated crops are eaten (Li et al. 2015). Heavy metals are not degradable and persist in the environment (Islam et al. 2012). Acid mine drainage (AMD) from tailings deposits has a long-lasting impact on the natural environment, as the process can last for hundreds or thousands of years (Alghanmi et al. 2015; Xianwei et al. 2009).

The leaching of heavy metals from tailings is becoming an increasingly urgent problem worldwide (Alghanmi et al. 2015). Heavy metals and other hazardous substances leach at different rates when precipitation or surface water passes through the tailings (Wiertz and Marinkovic 2005; Yan et al. 2008). Heavy metals leached from tailings vary with the season and the temperature changes (Guo et al. 2003). The leaching solution causes pollution of the soils, surface water, and groundwater. Many factors affect the leaching of heavy metals from tailings, such as soil’s physicochemical properties (Alghanmi et al. 2015), precipitation, temperature (Wiertz and Marinkovic 2005), climate change, and microbial decomposition (Guo et al. 2003). Of these factors, climate change plays a key role in the transportation of heavy metals from tailings. As an important parameter reflecting climate change, temperature is a key factor affecting the rate of heavy metal leaching (Baba et al. 2008; Daishe et al. 2004; Shaojian et al. 2002; Simona et al. 2009; Xiaolan et al. 2009). Changes in environmental temperature caused by seasons and climate affect the temperature at the tailings’ surface and create internal changes in the tailings. An internal change in temperature in the tailings can accelerate or slow down the internal chemical reaction rate and the associated bacterial activity to affect the leaching rate (Baba et al. 2008; Duo 2007). According to research on abandoned mines’ tailings, the leaching rates of heavy metals increase with increasing temperatures and vary with the seasons (Guo et al. 2003; Azcue and Nriagu 1995). Temperature change affects the biochemical reactions between the tailings and the solution, resulting in changes in the solution’s pH and heavy metal dissolution (Xiaojuan et al. 2012). Temperature changes affect the tailings’ mineralogy and geochemical reactions, thus affecting the release of heavy metals and causing the cumulative acidification of wastewater, which releases metal ions (Wiertz and Marinkovic 2005). A large temperature gap between internal and external tailings increases biochemical reactions and promotes heavy metal dissolution (Duo 2007). High temperature accelerates sulfide oxidization and acid drainage and changes the solution’s pH and the capability for ion-exchange adsorption in the tailings (Tianhu et al. 2001; Yuebing et al. 2007).

In general, temperature plays an important role in the release and leaching of heavy metals from tailings. According to the IPCC (AR5) report, the outline of Global Warming is 1.5 °C. Climate change is faster and more severe in the Arctic than in the rest of the world. The Arctic area is warming at a rate almost twice that of the global average, so the effect of temperature change on the leaching of heavy metals in the Arctic should differ from that of other areas. Although many researchers have studied the influence of temperature on heavy metal leaching, few studies have focused on the Arctic region (Skjelkvåle et al. 2006; Tsai et al. 2003; Tyagi et al. 1996; Xiaojuan et al. 2012). Therefore, it is necessary to study the influence of temperature on the leaching and transport of heavy metals in the Arctic.

In this paper, we focus on analyzing the effects of temperature variation on the leaching of heavy metals from a tailings deposit in Ballangen, northern Norway. The leaching of heavy metals from the tailings under different temperatures was investigated by performing a small-scale laboratory batch leaching experiment. The leaching capacities of Cr, Cu, Fe, Ni, V, and Zn at various temperatures were studied, as well as the threshold temperature that affects the leaching process. This is beneficial for understanding the effect of temperature on heavy metal leaching from tailings in the arctic area and useful for controlling pollution from tailings leaching.

Method and materials

Study area

In this study, a nickel mine “Nickel and Olivine A/S” tailings deposit in the Ballangen municipality in Nordland county was selected as the study area (Fig. 1). Ballangen is in the mining municipality of Ofoten, a municipality in Nordland county, Norway (Juve 1967). The first attempts at mining in northern Norway in the area surrounding Ballangen date back to the 1600s. Since then, there have been several attempts at mining, with varying success. In 1988, Nickel & Olivine A/S started violation norite for the extraction of nickel, copper, olivine, and crushed stone. Mining for nickel and olivine concentrate in this mine occurred from 1988 to 2002. The annual ore production was approximately 700,000 tons, and 6,942,750 tons of tailings were deposited from 1988 to 2002 (Newman 2015; Iversen and Berge 2001).

The mean annual temperature and precipitation of Ballangen were 4.1 °C and 1420 mm in 2016, respectively (Fig. 2). The monthly mean temperature increased from March to July and decreased from August to November. The maximum monthly temperature was 14 °C in July and the minimum monthly temperature of − 5 °C occurred in January. Almost no freezing occurred from April to October. The total and monthly precipitations of this unfrozen period were 648 mm and 22 mm, respectively. The mean monthly temperature of this period was 9 °C, with a minimum of 0 °C and a maximum of 14 °C. The minimum and maximum daily temperatures of that period were − 3 °C and 15 °C.

Tailings collection and analysis

Both the covered and uncovered tailings were collected from the Ballangen tailings deposit in July 2016. The samples were stored in polyethylene bags, transported to the lab, and stored at 4 °C for chemical and other analyses. Samples were sent to ALS Scandinavia AS (https://www.alsglobal.se/en) for chemical composition analysis. Tailings determination was performed at 105 °C, according to Swedish standard SS 028113. Tailings were dried, melted with LiBO2, and dissolved in HNO3 (1:1 nitric acid and water), according to ASTM standard 3682. The samples were measured using inductively coupled plasma atomic emission spectrometry (ICP-AES). The concentrations of the elements tested in the tailings are presented in Table 1. Cr, Co, and Ni showed higher concentrations in oxidized tailings than in the unoxidized tailings, whereas the concentrations of Fe and Zn were lower in the oxidized tailings than in the unoxidized tailings (Fu and Lu 2018).

Small-scale batch leaching experiment

A small-scale batch leaching experiment was conducted to investigate the impacts of variation in temperature on heavy metal leaching from the tailings. The experiment was performed at four temperatures (5, 10, 15, and 20 °C) and at a stable precipitation rate (20 mm/week), based on the monthly average temperature and maximum monthly average precipitation (Fig. 2). Ten grams of tailings were added into four 50-ml centrifuge tubes. Ten milliliters of deionized water was added and the tubes were sealed and put into four incubators set at 5, 10, 15, and 20 °C at a shaking speed of 150 rpm. The tubes were placed in the incubator for at least 24 h. Thereafter, the tubes were removed from the incubator and centrifuged. The leachate was collected with a pipette and placed into a new 20-ml test tube. Afterwards, 10 ml of deionized water was added to the 50-ml centrifuge tube and replaced in the incubator. The same procedure was repeated for cycles. The pH of the collected leachate was tested and sent to ALS for analysis of Cr, Cu, Fe, Ni, V, and Zn (following EPA method 200.8), measured by ICP-AES. The experiment stops when the leaching concentrations were below detection limit.

Mathematical analysis

Leaching rate and cumulative leaching fraction are widely used to evaluate the potential of heavy metals and other hazardous chemicals that leach from waste (Bai et al. 2011; Bin et al. 2014; Shi and Kan 1989; Yan et al. 2008). In this study, leaching rate and cumulative leaching fraction were used to identify leachability under different temperatures. Leaching rate was calculated by the method recommended by the Chinese National Standard GB7023-86 (Bai et al. 2011). The leachability of heavy metals was expressed by the leaching rate R (cm d−h) in the following equation:

where

- i :

-

is the heavy metals in leaching matrices;

- \( {C}_n^i \) :

-

is the mass of leached heavy metal i at a certain period (g);

- \( {C}_0^i \) :

-

is the mass of initial heavy metal i in the specimen (g);

- A :

-

is the geometric area of the specimen (m2);

- V :

-

is the volume of the specimen (m3), and tn is the leaching time at period n.

Descriptive statistics, Pearson correlation analysis, and principal component analysis (PCA) were carried out using SPSS v.24 (SPSS Inc., Chicago, USA).

Results and discussion

Concentrations of heavy metals in the leachate

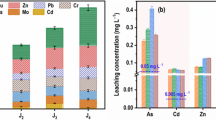

The leaching concentrations of Cr, Cu, Fe, Ni, V, and Zn in each cycle at different temperatures are shown in Fig. 3. The highest leaching concentration of Cr was at 20 °C in the fourth cycle. From 15 to 20 °C, the leaching concentration of Cr increased in the first 4 cycles and decreased thereafter. At 15 °C and 20 °C, Fe and Cu showed a similar leaching trend to that of Cr, with the leaching concentration initially increasing and decreasing afterwards. Generally, the concentration of Ni in the leachate increased with increasing temperature and decreased with leaching time. There is no clear trend for the concentration of Zn in the leachate as the temperature and leaching time changed. The leaching concentration was kept stable, at a mean concentration of 2.68 μg/l.

All the tested heavy metals except V and Zn showed higher leaching concentration in the first 4 cycles. The leaching concentrations of Ni, Fe, Cu, and Cr decreased from the fourth to the sixth cycle under all temperatures. The leaching concentrations of Cr, Cu, Ni, and V at 10 °C were lower than those at other temperatures in each leaching period. However, the highest leaching concentration of Zn was at 10 °C. The influence of temperature on leaching ability varied for the different elements. Heavy metal elements show different toxicity and environmental behaviors in different actual forms (valence state, combination state, binding state, and structure state) of some ions or molecules in the environment (Wei et al. 2016; Igwe et al. 2017; Cervantes-Ramírez et al. 2018). For example, Cu mostly exists in organic bond state, while Zn mostly exists in residue state in the tailings (Cheng et al. 2018). The change of temperature affects the elements of different forms of heavy metals, thus leading to the differences of heavy metal leaching activities (Liang et al. 2010; Fan et al. 2016).

Effect of temperature on accumulative leaching concentration

The accumulative leaching concentration is the value calculated by leaching heavy metals that amounts to a steady leachate volume (Blais et al. 1993; Shi and Kan 1989). The leaching rate and leaching concentration are two important indexes that explain leaching speed (Shi and Kan 1989). The cumulative leaching concentration indicates the amounts of leaching elements and their risk to the environment. The leaching rate and concentration varied for different heavy metals and at different temperatures. The accumulative leaching concentration of heavy metals from the tailings increased with leaching time (Fig. 4). The accumulated leaching concentration of Cr increased logistically with leaching time at 5 °C and 15 °C, increased linearly with leaching time at 10 °C, and increased polynomially at 20 °C. The accumulated leaching concentrations of Cu and Ni showed a similar trend in leaching time: both increased logistically with leaching time. The extent of increase was relatively large in the first several leaching cycles and slowed thereafter. The accumulative leaching concentration of Fe increased linearly with leaching time, similar to the results from a previous study (Ahonen and Tuovinen 2010). The accumulative leaching concentration of Zn showed a linear increase with leaching time at 5 °C, 15 °C, and 20 °C and a logistic increase with leaching time at 10 °C. The leaching velocity of Zn remained steady at 5 °C, 15 °C, and 20 °C and decreased with leaching time at 10 °C. The accumulated leaching concentrations of Cr, Cu, and Ni were lowest at the leaching temperature of 10 °C and highest at 20 °C. A temperature increase from 10 to 20 °C promoted the leaching of the tested heavy metals, Cu, Cu, Ni, and V, whereas a temperature change from 5 to 10 °C restrained their leaching. The opposite was shown for Zn. A change in temperature from 5 to 10 °C promoted Zn leaching whereas a change from 10 to 20 °C restrained Zn leaching. For Fe, increasing temperature promotes leaching. The present research showed that the accumulative leaching concentration increased with temperature and that temperature positively influenced heavy metals’ leaching (Blais et al. 1993; Cheng et al. 2018). As shown in Fig. 4, 10 °C is a good threshold temperature in the leaching of heavy metals. Leaching activity varies at this temperature. This may be the result of significant changes in the biochemical processes and physicochemical properties at the threshold temperature of 10 °C, so proper temperature will improve oxidizing activity of sulfur-oxidizing bacteria and promote heavy metal release (Fan et al. 2016; Li Jyur et al. 2003). Therefore, the heavy metals’ forms and the solution pH also change considerably at this temperature.

Effect of temperature on metal solubilization

Metal solubilization is a good index to identify the most valuable cycle throughout the leaching period (Blais et al. 1993). The metal solubilization of Cr, Cu, and Fe was between 68.7 and 97.7% in the first 4 cycles (Fig. 5), between 7.59 and 15.65% in the fifth cycle, and between 2.47 and 12.3% in the sixth cycle. The metal solubilization from the first to the fifth cycle accounts for 93% at 5 °C, 15 °C, and 20 °C. At the end of the leaching cycles, V maintained a high metal solubilization at 10 °C (24.1%) and 15 °C (13.92%). The metal solubilization of Ni was greater than 93% in the first 4 cycles, between 3.64 and 4.33% in the fifth cycle, and between 2.47% and 3.3% in the sixth cycle. Zn showed a similar metal solubilization in each cycle at different temperatures. Most of the heavy metals leached out in the early phases of leaching at different temperatures (Li Jyur et al. 2003; Ye et al. 2017). Increasing temperature increased the percentage of leaching concentration in the first 4 leaching cycles.

Effect of temperature on the leaching rate

The leaching rate is considered a useful index for assessing the capability for heavy metal transport at different temperatures (Fan et al. 2016; Shi and Kan 1989; Yan et al. 2008). A lower leaching rate indicates a lower heavy metal transport ability and a higher level of safety for the surrounding environment (Alghanmi et al. 2015). The experimental test results are reported in Table 2. The leaching rates varied at different leaching temperatures. The leaching rate of Ni reached 10−3 cm d−1 at early leaching stages of 1 to 4 cycles. The ratio of Ni solubilization was 92 to 93% for cycles one to four and 2.4% to 3.3% for the fifth cycle. Although the other tested heavy metals had lower leaching rates, they attained higher leaching rates at the early stage of cycles one to four. The ratio of their solubilization is 69 to 86% for the first to the fourth cycles. This reveals that most of the leached Ni was produced with higher leaching velocity at early stages, which is caused by high sulfidation-oxidation and acid production in the leachate (Shi and Kan 1989). In underwater immersion, the leaching behavior is mainly controlled by the sulfidation-oxidation reaction and acid production. In later cycles of leaching, with the decreased dissolving of heavy metals, lower sulfidation-oxidation and lower acid production capacity, the leaching rate became very slow.

Leaching rates vary by temperature because temperature affects the sulfur-oxidizing activity and the solubility of heavy metals (Tyagi et al. 1996; Ahonen and Tuovinen 2010; Ye et al. 2017; Yin et al. 2018). From 5 to 10 °C, the mean leaching rate of Cr, Ni, Cu, and V decreased with an increase in the leaching temperature (Table 2); from 10 to 20 °C, these metals showed an increase with increasing temperature. From 10 to 20 °C, the sulfide and nitrate content accelerated oxidation with increasing temperature and decreased pH. This increased the solubility of the heavy metals and promoted their conversion from a residual state to dissolved state (Ahonen and Tuovinen 2010; Jing et al. 1994; Liancun et al. 1994; Ye et al. 2017). The changes in heavy metals’ form and acid solution creation improved leaching rates.

Effect of temperature on the relative leaching rate

In summary, 10 °C is a distinctive temperature for leaching ability in the study area. Both the leaching concentration and the percentage of leaching concentration change dramatically at this temperature. The relative leaching rate is an indicator that reflects the effect of temperature on leaching velocity, as it expresses the variation in leaching velocity at different temperatures. Thus, there is a relationship between the relative leaching rate and temperature (Fig. 6). The accumulated leaching concentration can explain the leaching amount and relative leaching rate expresses the relationship between the leaching velocity and temperature. The relative leaching concentrations of Cr, Ni, Cu, and V were greater than 1, indicating that their leaching velocities were higher than those at 10 °C. According to the variation trend, the relative leaching rates of Cr, Cu, Ni, Zn, and V showed quadratic polynomial change with temperature change, and their function inflection was 10 °C. Fe showed linearity, changing with temperature. From 5 to 10 °C, the relative leaching rates of Cr, Cu, Ni, and V decreased with increasing temperature; from 10 to 20 °C, they increased with increasing temperature. Zn showed an opposite trend. The relative leaching rate of Zn increased as the temperature increased from 5 to 10 °C and decreased as the temperature increased from 10 to 20 °C. According to the accumulative leaching concentration and relative leaching concentration analyses (Figs. 4 and 6), 10 °C is a threshold temperature for the leaching of Cr, Cu, Ni, Zn, and V.

Correlations between heavy metal leaching

Temperature not only affects a heavy metal’s single leaching ability but also affects the interactions between heavy metals. The relationship between temperature and their solubilization efficiency varied for different physicochemical properties (Anderson et al. 1998; Wang et al. 2015). Therefore, the leaching abilities of different heavy metals vary with different temperatures. The leaching concentrations of Zn and V showed a negative correlation with temperature whereas those of the other heavy metals showed a positive relationship with temperature. This indicated that the leaching of Cr, Cu, Ni, and Fe was more sensitive to temperature change than that of V and Zn. Cr showed a significant positive correlation with Cu and Fe. Cu showed a positive correlation with Fe and Ni (Table 3), which indicated that Cr, Cu, and Fe have a similar leaching source and that Cu, Ni, and Fe have a similar leaching source. Some sources may originate from tailing oxidation and some may originate from acid dissolution. The positive correlation reveals that Cu leaching accelerates the leaching of Fe and Ni and that Cr leaching accelerates the leaching of Cu and Fe in the tailings. Negative correlations were found between V and Ni, and Cu and Fe; this may indicate that V leaching will prevent Ni, Cu, and Fe from leaching. There leaching activity of Cr, Cu, Ni, and Fe was positively correlated and their leaching rates and relative leaching rates were positive relative to temperature (Fig. 6, Tables 2 and 3).

Conclusion

A small-scale batch leaching experiment was carried out to investigate the impact of temperature on heavy metal leaching from tailings in the Arctic area. The ability of heavy metal leaching varied by temperature. All the leaching concentrations in early stages were higher than those in later stages except Zn. In the front 4 cycles, the ratio of metal solubilization was over 68%. The accumulated leaching concentration increased with time, but the leaching rates decreased with time. The relative leaching rates of Cr, Cu, Zn, V, and Ni polynomially changed with temperature, and Fe showed a linear change. Results showed that 10 °C was a threshold temperature in the tailings leaching. Leaching concentration, leaching rate, and relative leaching concentration underwent a large transformation at 10 °C. Heavy metals kept different relationships in the leaching activity. V showed a significant positive correlation with Ni, Cu, and Fe leaching from tailings; Zn and V leaching was negatively correlated with temperature. Discovering the relationship between leaching characteristics and temperature and the threshold temperature for leaching is beneficial for understanding the transportation of leachates from heavy metals and controlling pollution from tailings leaching.

References

Ahonen, L., & Tuovinen, O. H. (2010). Microbiological oxidation of ferrous iron at low temperatures. Applied and Environmental Microbiology, 55(2), 312–316.

Alghanmi, S. I., Al Sulami, A. F., et al. (2015). Acid leaching of heavy metals from contaminated soil collected from Jeddah, Saudi Arabia: kinetic and thermodynamics studies. International Soil and Water Conservation Research, 3(3), 196–208.

Anderson, B., Brown, A., Watt, W., & Marsalek, J. (1998). Biological leaching of trace metals from stormwater sediments: influential variables and continuous reactor operation. Water Science and Technology, 38(10), 73–81.

Azcue, J. M., & Nriagu, J. O. (1995). Impact of abandoned mine tailings on the arsenic concentrations in Moira Lake, Ontario. Journal of Geochemical Exploration, 52(1–2), 81–89.

Baba, A., Gurdal, G., Sengunalp, F., & Ozay, O. (2008). Effects of leachant temperature and pH on leachability of metals from fly ash. A case study: can thermal power plant, province of Canakkale, Turkey. Environmental Monitoring and Assessment, 139(1), 287–298.

Bai, Y., Collier, N., Milestone, N., & Yang, C. (2011). The potential for using slags activated with near neutral salts as immobilisation matrices for nuclear wastes containing reactive metals. Journal of Nuclear Materials, 413(3), 183–192.

Bin, C., Meilin, Z., et al. (2014). Study on the release and migration of heavy metals in tailings and their bioavailability. Environmental Science & Technology, 37(7), 12–19.

Blais, J., Tyagi, R., & Auclair, J. (1993). Bioleaching of metals from sewage sludge: effects of temperature. Water Research, 27(1), 111–120.

Cervantes-Ramírez, L. T., Ramírez-López, M., Mussali-Galante, P., Ortiz-Hernández, M. L., Sánchez-Salinas, E., & Tovar-Sánchez, E. (2018). Heavy metal biomagnification and genotoxic damage in two trophic levels exposed to mine tailings: a network theory approach. Revista Chilena de Historia Natural, 91(1), 6.

Cheng, X., Danek, T., Drozdova, J., Huang, Q., Qi, W., Zou, L., Yang, S., Zhao, X., & Xiang, Y. (2018). Soil heavy metal pollution and risk assessment associated with the Zn-Pb mining region in Yunnan, Southwest China. Environmental Monitoring and Assessment, 190(4), 194.

Daishe, W., Baoshan, Z., et al. (2004). Study on leaching behavior and environmental impact of coal gangue - a case study of Panxie Mining Area in Huainan. Earth and Environment, 32(1), 55–59.

Dold, B. (2014). Submarine tailings disposal (STD)—a review. Mineral-Basel, 4(3), 642–666.

Duo M (2007). Leaching characteristics and releasing amount evaluation of Mo tailing. Master dissertation, Liaoning Institute of Technology, available from Cnki.

Fan, L. Q., Zhou, X., et al. (2016). Release of heavy metals from the pyrite tailings of Huangjiagou pyrite mine: batch experiments. Sustainability, 8(1).

Fu, S. and Lu, J. M. (2018). Column leaching test on oxidized and non-oxidized tailings in northern Norway. IOP Conference Series: Earth and Environmental Science, 191.

Fu, S., & Wei, C. Y. (2013). Multivariate and spatial analysis of heavy metal sources and variations in a large old antimony mine, China. Journal of Soils and Sediments, 13(1), 106–116.

Guo, Y., Huang, P., et al. (2003). Leaching of heavy metals from Dexing copper mine tailings pond. T Nonferr Metal Soc, 23(10), 3068–3075 (2013).

Hu MH, Yuan JH, Lai CT (2014). Pollution loss rate assessment of soil heavy metals in paddy field with sewage irrigation in Guixi city, Jiangxi province, China. In: Wang L (ed) International conference machinery, electronics and control simulation Vol. 614, pp 658–663.

Igwe, O., Una, C. O., Abu, E., & Adepehin, E. J. (2017). Environmental risk assessment of lead-zinc mining: a case study of Adudu metallogenic province, middle Benue Trough, Nigeria. Environmental Monitoring and Assessment, 189(10), 492.

Islam, M. N., Jo, Y.-T., & Park, J.-H. (2012). Remediation of PAHs contaminated soil by extraction using subcritical water. Journal of Industrial and Engineering Chemistry, 18(5), 1689–1693.

Iversen, E., Berge, J. (2001). Nikkel og Olivin A/S Utredning av konsekvenser i forbindelse med nytt deponi på Fornes.

Jenkins, H., & Yakovleva, N. (2006). Corporate social responsibility in the mining industry: exploring trends in social and environmental disclosure. Journal of Cleaner Production, 14(3), 271–284.

Jing, L., Renkou, X., Xin, J., Yongrong, B., & Wenfeng, T. (1994). Adsorption and desorption of Cu(II), Pb(II) and Cd(II) in two variable charge soils different in pH. Soil, 39(6), 992–995 (2007).

Jingyong, L., Xiangyang, C., & Xianglin, T. (2006). Review of heavy metal pollution in mine development process. Mineral Resources and Geology, 06, 645–650.

Juve, G. (1967). Zinc and lead deposits in the Håfjell syncline, Ofoten, northern Norway. Universitetsforlaget.

Li Jyur, T., et al. (2003). Effect of temperature on removal of heavy metals from contaminated river sediments via bioleaching. Water Research, 37(10), 2449–2457.

Li, L. H., Fu, Q. L., Achal, V., & Liu, Y. L. (2015). A comparison of the potential health risk of aluminum and heavy metals in tea leaves and tea infusion of commercially available green tea in Jiangxi, China. Environmental Monitoring and Assessment, 187(5), 228. https://doi.org/10.1007/s10661-015-4445-2.

Liancun, G., Guihua, H., Suping, F., Shureng, W., & Zhaojie, C. (1994). Solubility and exchange of Cu, Pb, Zn, Cr species in simulant acid rain. Environment and Chemistry, 13(5), 448–452.

Liang, B., Jiang, L. G., et al. (2010). Analysis of influence factors on heavy metal release from mine waste rock in Fu Xin mine area. Applied Mechanics and Mechanical Engineering, 29–32(Pts 1-3. H. H. Tan), 2570–2575.

Lu, C. (2016). Study on speciation distribution and leaching characteristics of heavy metals in pb-Zn. Master dissertation, Xinjiang University, available from Cnki.

Newman, H. R. (2015). The mineral industry of Norway. Minerals yearbook, 2012, V. 3, Area Reports, International, Europe and Central Eurasia.

Ramirez-Llodra, E., Trannum, H. C., Evenset, A., Levin, L. A., Andersson, M., Finne, T. E., Hilario, A., Flem, B., Christensen, G., Schaanning, M., & Vanreusel, A. (2015). Submarine and deep-sea mine tailing placements: a review of current practices, environmental issues, natural analogs and knowledge gaps in Norway and internationally. Marine Pollution Bulletin, 97(1), 13–35.

Shaojian, M., Zhiliu, H., et al. (2002). Experimental study on dissolution of heavy metal ions in tailings of sulfide ore. Journal of Guangxi University: Natural Science Edition, 27(4), 273–275 L.

Shi, H.-S., & Kan, L.-L. (1989). Leaching behavior of heavy metals from municipal solid wastes incineration (MSWI) fly ash used in concrete. Journal of Hazardous Materials, 164(2), 750–754 (2009).

Simona, C., Angela, R. F., & de Santo Amalia, V. (2009). Suitability of soil microbial parameters as indicators of heavy metal pollution. Water, Air, and Soil Pollution, 158(1), 21–35 (2004).

Skjelkvåle, B. L., Steinnes, E. et al. (2006). Trace metals in Norwegian surface waters, soils, and lake sediments-relation to atmospheric deposition. Norwegian Institute for Water Research, pp. 10–21.

Tianhu, C., Xiaohui, F., & Xiaochun, X. (2001). Advances in acid drainage and heavy metal leaching in tailings abroad. Environmental Pollution Control Technology and Equipment (Chinese), 2(2), 41–46.

Tsai, L. J., Yu, K. C., Chen, S. F., & Kung, P. Y. (2003). Effect of temperature on removal of heavy metals from contaminated river sediments via bioleaching. Water Research, 37(10), 2449–2457. https://doi.org/10.1016/s0043-1354(02)00634-6.

Tyagi, R., Meunier, N., & Blais, J. (1996). Simultaneous sewage sludge digestion and metal leaching effect of temperature. Applied Microbiology and Biotechnology, 46(4), 422–431.

Wang, Q., Liu, Y. et al. (2015). Experimental study on the dynamic leaching effect of simulated acid rain on tailings of Dexing copper mine.

Wei, Z., Alakangas, L., et al. (2016). Geochemical evaluation of heavy metal migration in Pb–Zn tailings covered by different topsoils. Journal of Geochemical Exploration, 165, 134–142.

Wiertz, J., & Marinkovic, F. (2005). Dissolved pollutant transport in tailings ponds. Environmental Geology, 47(2), 237–240.

Wills, B. A., & Finch, J. (2015). Wills’ mineral processing technology: an introduction to the practical aspects of ore treatment and mineral recovery. Oxford: Butterworth-Heinemann.

Xianwei, W., Youning, X., Ming, Y., & Yanjun, Q. (2009). Review on risk assessment methods for soil heavy metal contamination in mines at home and abroad. China Mining Magazine, 18(10), 54–56.

Xiaojuan, S., Shulan, Z., & Lian, D. (2012). Leaching characteristics of MSW compost heavy metals in soil under different temperatures and simulated acid rain. Chinese Journal of Environmental Engineering, 6(3), 995–999.

Xiaolan, Z., et al. (2009). Effect of simulated acid rains on Cd form transformation in contaminated soil. Soils, 41(4), 566–571.

Yan, Q., Xiaochun, X., Qiaoqin, X., & Yubing, S. (2008). Leaching experiments of experimental pollution caused by heavy metals of waste rocks in the copper mine: a case study of Yaoyuanshan ore deposit in the Fenghuangshan Copper Ore Field, Anhui, China. Chinese Acta Geoscientica Sinica, 29(2), 247–252.

Ye, M., Yan, P., Sun, S., et al. (2017). Bioleaching combined brine leaching of heavy metals from lead-zinc mine tailings: Transformations during the leaching process. Chemosphere, 168, 1115–1125.

Yin, S. H., Wang, L. M., et al. (2018). Copper recycle from sulfide tailings using combined leaching of ammonia solution and alkaline bacteria. Journal of Cleaner Production, 189, 746–753.

Yuebing, S., Qixing, Z., & Guanlin, G. (2007). Phytoremediation and strengthening measures for soil contaminated by heavy metals. Chinese Journal of Environmental Engineering, 1(3), 103–110.

Zhang, G. Y., Lin, Y. Q., & Wang, M. K. (2011). Remediation of copper polluted red soils with clay materials. Journal of Environmental Sciences, 23(3), 461–467. https://doi.org/10.1016/s1001-0742(10)60431-7.

Zhang, L., Zhang, D. W., Wei, Y., Luo, L., & Dai, T. (2014). Risk assessment of trace elements in cultured freshwater fishes from Jiangxi province, China. Environmental Monitoring and Assessment, 186(4), 2185–2194. https://doi.org/10.1007/s10661-013-3528-1.

Funding

This study was financially supported by the MIN-NORTH project funded by Interreg Nord Program: Development, Evaluation and Optimization of Measures to Reduce the Impact on the Environment from Mining Activities in Northern Regions; China’s Post-doctoral Science Foundation (2017M612161), Jiangxi postdoctoral research project (2017KY05).

Author information

Authors and Affiliations

Contributions

Shuai Fu and Jinmei Lu: conception and design, acquisition of data, analysis and interpretation of data, drafting the article, and revised and approved the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fu, S., Lu, J. Temperature-driven variation in the removal of heavy metals from contaminated tailings leaching in northern Norway. Environ Monit Assess 191, 123 (2019). https://doi.org/10.1007/s10661-019-7244-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-019-7244-3