Abstract

Heavy metal accumulation and potential releases from loose deposits in drinking water distribution system (DWDS) can have critical impacts on drinking water safety, but the associated risks have not been sufficiently evaluated. In this work, the potential biological toxicity of heavy metals in loose deposits was calculated based on consensus-based sediment quality guidelines, and the effects of some of the main water quality parameters, such as the pH and bicarbonate and phosphate content, on the release behaviors of pre-accumulated heavy metals were investigated. The results showed that heavy metals (Cu, As, Cr, Pb, and Cd) significantly accumulated in all the samples, but the contents of the heavy metals were multiple magnitudes lower than the Fe and Mn contents. The potential biotoxicity of As and Cu was relatively high, but the biotoxicity of Cd was negligible. The water quality can significantly influence the release of heavy metals from loose deposits. As the pH increased from 7.0 to 9.0, the release of As and Cr obviously increased. The release of As, Cu, Pb, and Cr also accelerated with the addition of phosphate (from 1 to 5 mg/L). In contrast to the trends for the pH and phosphate, variations in the bicarbonate content did not have a significant influence on the release of As and Cr. The release ratios of heavy metals in the samples were very low, and there was not a correlation between the release rate of the heavy metals in the loose deposits and their potential biotoxicity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Deposited solids ubiquitously exist in drinking water distribution system (DWDS). The sources of the deposited solids include pipe corrosion by-products, residual particle deposition, dissolved substance precipitation, and/or adsorption. Iron (Fe), aluminum (Al), and manganese (Mn) are usually the main metal elements in the deposits (Liu et al. 2017). However, heavy metals, such as chromium (Cr), lead (Pb), copper (Cu), cadmium (Cd), nickel (Ni), and arsenic (As), can accumulate in DWDS deposited solids (Lytle et al. 2004; Sun et al. 2014).

The accumulation and release of heavy metals from deposited solids in DWDS has gradually attracted attention in recent years. For metallic pipes, the deposited solids can be divided into two categories: loose deposits on the top surface layer that can be easily re-suspended under a hydraulic disturbance and so-called corrosion scales, which are relatively hard and closely attached to the metallic pipe surface (Peng et al. 2010). For non-metallic pipes, no corrosion scales exist, and loose deposits are the only category of pipe-deposited solids. Generally, loose deposits are responsible for the deterioration of water quality in DWDS, such as the occurrence of water discoloration (Smedley and Kinniburgh 2002). More seriously, iron oxides (goethite, lepidocrocite, magnetite, etc.), manganese oxides, and silicates that are ubiquitously found in loose deposits have strong affinities for trace contaminants (Sarin et al. 2001, 2004). Although the concentrations of some heavy metals in treated water are extremely low or even undetectable, they can accumulate and concentrate in loose deposits over time. When the water quality conditions change (such as a water source switch), the heavy metals in the loose deposits could be released back into the bulk water at a significant concentration and place consumer health at a high risk (Li et al. 2016). A hydraulic disturbance of loose deposits can also result in increased heavy metal levels in bulk water while increasing the turbidity in DWDS (Carrière et al. 2005; McNeill and Edwards 2001; Nawrocki et al. 2010).

Heavy metals in deposited solids are non-degradable, and it is important to assess the potential biological toxicity of heavy metals due to their persistence and high toxicity that can seriously affect the water quality and endanger human health. To our knowledge, there is no research on the assessment of the potential biological toxicity of heavy metals in deposited solids. Consensus-based sediment quality guidelines (CBSQGs), a major evaluation tool for sediment quality assessment, have been extensively used for reliable prediction. Peña-Icart et al. used the CBSQGs method to assess sediment pollution of metals in Cienfuegos Bay (Peña-Icart et al. 2017). Liu et al. compared the metal concentrations in surface sediments of the Luanhe River Estuary with the threshold effect level and the probable effect level and discovered that Cu, Pb, Cr, Ni, and As occasionally had adverse biological effects on aquatic ecosystems (Liu et al. 2016). Studies have shown that the CBSQGs method has a high reliability for the evaluation of the potential biological toxicity of metal-contaminated sediments, and the method has been successfully used for the evaluation of sediment pollution in many countries, such as Cuba, China, America, Australia, and Portugal (Oliveira et al. 2011; Serafim et al. 2013). In this work, the CBSQGs method was used to assess the potential biological toxicity risk of heavy metals in the solid deposits of DWDS.

The factors influencing heavy metal release from deposited solids have been reported (Gerke et al. 2016; Lytle et al. 2010). Water quality parameters, such as the pH, alkalinity, and phosphate (which serves as an inhibitor of corrosion) and chlorine contents, are considered important factors for the release of iron and heavy metals (Antelo et al. 2005; Xie and Giammar 2011). In addition, the temperature, redox potential, dissolved oxygen, and natural organic matter also influence the adsorption-release balance of heavy metals in deposited solids (Gheju et al. 2016; Hsu et al. 2008; Jain and Loeppert 2000). Yang et al. found that a significant increase in the sulfate concentration can cause a high iron release and even a red water occurrence (Yang et al. 2014). Sun et al. found that changes in the water chemistry can trigger the release of heavy metals from iron corrosion scales. With an increase in the sulfate concentration, the release of Mn, Ni, Cu, Pb, Cr, and As increases (Sun et al. 2017). Peng et al. found that the water quality parameters that influence the release of iron can also result in a high heavy metal release (Peng and Korshin 2011). However, the previous studies mainly focused on the release of iron or trace contaminants from hard corrosion scales, and heavy metal releases from loose deposits have rarely been reported.

In this work, loose deposits in real DWDS were characterized, and the potential biological toxicity of the heavy metals in the loose deposits was evaluated by referencing the CBSQGs method. The release behaviors of heavy metals under the influence of some main water quality parameters, including the pH and bicarbonate and phosphate contents, were investigated. The findings of this work could provide a basis for a risk assessment of heavy metals that originate from loose deposits in DWDS.

Materials and methods

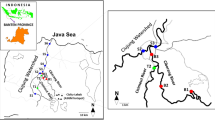

Sample collection

Loose deposits were collected from 11 different DWDS sites in a metropolitan city in northern China. The whole pipe network length is approximately 10,000 km and serves an area of approximately 7.3 million km2. The main pipe materials were unlined cast iron pipes and cement-lined ductile iron pipes, which accounted for nearly 70% of the pipes. In this work, the samples were only collected from areas with relatively high pipe ages (15–20 years old or more), and pipe materials were mainly old unlined cast iron pipes, which could be representative areas with relatively high loose deposit-related risks.

Sampling process

Loose deposits were obtained by unbolting fire hydrants at the chosen sample locations, and the suspended solids were captured from the discharge stream in a customized net assembly. The assembly was a fine (50 μm pore size, 380 mm length, and 105 mm diameter) synthetic nylon mesh net. The assembly was joined with the hydrant, and the hydrant was fully opened for 5 to 7 min to ensure enough deposits were retained. Once the net was removed from the hydrant, the net was placed into a large plastic bag with a seal and brought back to the laboratory as soon as possible. Each sample was vacuum freeze-dried for 18 h. The specimens were marked, Nos. 1 to 11. For comparison, a corrosion scale sample obtained from an iron pipe was included (sample No. 12). All of the dried samples were crushed using an agate mortar and pestle in an anaerobic chamber and passed through a number 90 sieve (160-μm mesh).

Characterization of loose deposits

The inorganic contaminants in all the samples were measured as follows: after the microwave digestion and dilution, the pH was adjusted to 2 or lower by adding nitric acid (HNO3). The high levels of metals were analyzed using inductively coupled plasma atomic emission spectrometry (ICP-OES, OPTIMA 2000, PerkinElmer, USA), and low levels of metals were determined using inductively coupled plasma mass spectrometry (ICP-MS, NexION 300X, PerkinElmer, USA). Five representative samples, namely samples 1–4 (loose deposits) and sample 12 (corrosion scales), were selected for X-ray diffraction (XRD) characterization. The XRD (PANalytical X’Pert PRO MPD) was performed to obtain the crystalline phases of the samples, and the operation parameters were Ni0-filtered Cu-Kα radiation (λ of 1.5406 A) and a 2θ value range of 3°–70° with a 0.02° step size. The quantification method for XRD was the same as that previously reported (Yang et al. 2012). Furthermore, the apparent morphologies of sample 1 (loose deposit) and sample 12 (corrosion scale) were observed using scanning electron microscopy (SEM, Zeiss, German), and the elemental composition in a local area was measured using energy dispersive X-ray spectroscopy (EDS).

Risk assessment method of the potential biological toxicity of heavy metals

CBSQGs include two thresholds, the threshold effect concentration (TEC) and the potential effect concentration (PEC). The former indicates that the harmful biological effect is negligible when the pollutant concentration is lower than the TEC, and the latter indicates that harmful biological effects are more likely to occur when the pollutant concentration is higher than the PEC (MacDonald et al. 2000). Table 1 shows the guideline values for the heavy metals, and the data are from MacDonald (MacDonald and Ingersoll 2010).

Heavy metal release experiments

Influence of the water quality parameters

In this work, release refers to the element migrating into bulk water in a dissolved form via either dissolution or desorption. All the metal release experiments were conducted using background water prepared using deionized water with the addition of NaNO3 as the supporting electrolyte (20 mmol/L). The pH was adjusted to predetermined values using 0.1 M HCl and 0.1 M NaOH solutions.

For the pH effect experiments, 0.03 g of the deposit samples was transferred to a 250-mL conical flask, and 100 mL of background water was added. The pH values tested were 7.0, 8.0, and 9.0. The solutions were placed on a constant temperature shaker at 150 rpm and maintained at 25 ± 1 °C for 168 h. The release dynamics were investigated by collecting samples at pre-settled time intervals. All the samples were digested by adding HNO3 (pH < 2) and filtered through a 0.45-μm membrane filter using a polypropylene syringe filter before the analysis. For the bicarbonate and phosphate effect experiments, a series of PO43− (1, 2, 3, 4, and 5 mg PO43−/L) and HCO3− (1, 2, 3, 4, and 5 mg HCO3−/L) concentrations were selected based on potential actual concentrations in DWDS. The remaining experimental steps were the same as the pH effect experiments.

Blank tests without samples were performed. The amount of metal released (mg/kg) and the release ratio (%) were calculated. All the release data were averages of duplicate determinations, and the relative errors were approximately ± 5%.

Heavy metal release ratio calculation method

The following equation was utilized to calculate the release ratio of heavy metals from loose deposits.

where A (μg/L) is the average concentration of heavy metal released, B (mg/kg) the initial heavy metal content in the loose deposits, 0.1 L the volume of water, and 0.03 g the amount of loose deposits.

Results and discussion

Characterization of loose deposits

SEM-EDS analysis

To observe the microstructure of the loose deposits (sample 1) and corrosion scales (sample 12), two typical SEM images are shown in Fig. 1a, d. Both solids clearly have a porous structure that is favorable for adsorbing and accommodating heavy metals. The EDS analysis (Fig. 1c, d) showed that the dominant chemical elements in both the loose deposits and corrosion scales were Fe and O. In addition, Si, Mg, F, and other elements were observed on the surface of the loose deposits.

XRD analysis

Four loose deposit samples and the corrosion scale sample, which had relatively higher contents of Mn, As, and Cr, were selected to analyze their crystalline characteristics (Fig. 2). Figure 3 summarizes the main crystalline substances and their contents in the five samples. Goethite and lepidocrocite were observed in most samples as the iron minerals, but magnetite was not frequently observed. Next, due to the erosion of the cement linings of the cast iron pipes and the existence of residual gravel, quartz had a larger proportion in the samples. As seen, two types of aluminum silicate were detected in most samples, which might be due to the reaction between the residual aluminum and silica or come from the source waters. These minerals could accommodate heavy metals via adsorption, complexation, and other combinations. The crystal compositions of the loose deposits and corrosion scales were not obviously different.

Elemental composition analysis

The XRD results showed a large number of substances in the samples with heavy metal adsorption capacity, such as Fe3O4. The metal elements in the samples were tested by ICP-OES/MS, and the potential biotoxicity was analyzed.

Table 2 summarizes the contents of the major inorganic elements in the samples. Similar to previous studies, the loose deposits and corrosion scales were mainly composed of Fe and Mn. The Fe in the samples was mainly derived from the corrosion of a ferrous metal pipe (Benson et al. 2012), and Mn mainly came from the presence of soluble ions in the water sources, which were released from iron pipes or from the use of manganese oxidants (KMnO4) in water treatment processes (Cerrato et al. 2006). Heavy metals, Cu, As, Cr, Cd, and Pb, were also detected, and they may be from the pipe materials (Veschetti et al. 2010).

The Fe content was 31,700 to 94,000 mg/kg (mg element/kg sample). The second most prominent metal found in the DWDS samples was Mn, and the highest concentration of Mn was 10,950 mg/kg. Cu was the most prominent heavy metal found in the DWDS samples. The highest concentration in the samples was 1408 mg/kg, which is harmful (see below). Cr, As, Pb, and Cd were found in all the samples, but their concentrations were significantly lower compared with those of Fe and Mn, especially Cd.

It should be noted that the contents of heavy metals in loose deposits can be affected by the levels of heavy metals in the finished water. However, the finished water before entering the distribution system can sufficiently meet the regulation limits, and the heavy metals are routinely monitored by the water supply company. The heavy metal levels of the finished water are as follows based on a 1-year monitoring report (unit mg/L): Cr < 0.007, Cd < 0.0005, Cu < 0.002, As < 0.001, Pb < 0.001.

Potential biological toxicity risk of heavy metals

The elemental composition results showed that heavy metals (As, Cd, Pb, and Cr) were detected in all the samples. The potential biotoxicity risk of the five heavy metals was evaluated. The accumulated concentration of Cd in the samples was very low, and there was no biotoxicity, which is not listed in this paper. As seen from Fig. 4, some samples had toxic heavy metal concentrations that exceeded the corresponding PEC concentration, indicating that the other four heavy metals will produce harmful biological effects.

The concentrations of the heavy metals (As, Cd, Cu, Pb, and Cr) in the corrosion scale (sample 12) were below the TEC. The concentration of As in all the loose deposits was higher than the TEC of 9.79 mg/kg, and five of the loose deposit samples had concentrations higher than the PEC. There were six samples with Cu concentrations between the TEC and PEC, and five samples have concentrations above the PEC. The Pb concentration in most samples was less than the TEC, and two sample concentrations were higher than the PEC. The Cr concentration in nine samples was between the TEC and PEC, and one sample was higher than the PEC. The potential biotoxicity of As and Cu in the samples was relatively large.

The enrichment of heavy metals with potential biological toxicity in pipe scale may have an effect on the microbial community structure that exists in pipes. This may possibly interfere with the diversity of the microbes and cause the dissolution and release of trace contaminants from the scale, leading to unsafe water.

Effect of the water quality parameters on heavy metal release

The potential biological toxicity risk assessment results showed that 4 of the 11 loose deposits had a biological toxicity, especially for As, which had a high level of potential biotoxicity. Heavy metals in loose deposits can enter bulk water either via hydraulic re-suspension in a particulate form or dissolution/desorption in a dissolved form. The dissolution/desorption processes can be affected by the water quality conditions. Here, the effects of the pH and bicarbonate and phosphate contents on the heavy metal release from loose deposits were investigated.

Effect of the pH on heavy metal release

The effects of the pH on the release of As, Cu, Pb, and Cr are shown in Fig. 5. The concentration of As and Cr noticeably increased as the time and pH increased. The release of Cu and Pb from the loose deposits had the same trend with the change in the pH, and the highest release was at pH 8.

The maximum concentrations of As during the experimental period were 0.12 μg/L at pH 7, 0.20 μg/L at pH 8, and 0.60 μg/L at pH 9, respectively. The effect of the pH can be attributed to adsorption site competition behavior between arsenate anions and hydroxyl ions. At a higher pH, more hydroxyl ions adsorbed on the loose deposits, and more arsenate anions were displaced from the adsorption sites into the bulk water (Copeland et al. 2007). In addition, the As adsorbed on Al minerals was released in a dissolved form when the amphoteric Al compounds dissolved under the higher pH conditions. The released Cu and Pb concentrations increased when the pH increased from 7 to 8, and the concentrations decreased as the pH increased to 9. The maximum release concentrations of Cu and Pb were 1.02 and 0.67 μg/L, respectively. Under acidic conditions, the surface of the loose deposits had a more positive charge, which led to stronger electrostatic adsorption with anions (CrO42−, HCrO4−, and Cr2O72−). The positive charge on the surface of the loose deposits decreased as the pH increased. Therefore, the adsorption capacity of Cr decreased, and the release concentration increased. Generally, the loose deposits had a strong adsorption effect on anions within a neutral pH range (Turgut et al. 2005).

Effect of bicarbonate on the release of heavy metals

In a series of release experiments, bicarbonate was added into the aqueous system. The results indicated that the presence or absence of bicarbonate did not have a significant influence on the release of As and Cr from the loose deposits, but bicarbonate had a slight influence on the release of Pb and Cu (Fig. 6). Stachowicz and Williams et al. observed a slight effect or no effect on the release of As(V) from different goethite materials with bicarbonate, but they observed a clear effect on As(III) (Stachowicz et al. 2007).

Effect of phosphate on the release of heavy metals

Figure 7 shows the release of As, Cu, Pb, and Cr as the phosphate concentration changes. When the concentration of phosphate approached 5 mg/L, the maximum concentrations for the metals were As 1.8 μg/L, Pb 2.5 μg/L, and Cr and Cu approximately 1.0 μg/L. Clearly, as higher concentrations of phosphate were added, more heavy metals were released from the DWDS loose deposits. This was in accordance with previous studies that showed phosphate had a higher affinity for iron hydroxide sites in the loose deposits than the heavy metals. Therefore, phosphate competes for adsorption sites with the anions in the loose deposits, causing the high mobility of the heavy metals (Morillo et al. 2015).

The results showed that changes in the water quality parameters have a remarkable effect on the release of heavy metals. Within the study scope, the maximum concentrations of As, Cu, Pb, and Cr released from the loose deposits were 1.80, 1.02, 2.50, and 1.04 μg/L, respectively. A comparison of the heavy metal release concentrations with the drinking water regulations (Table 3) showed that the As, Cu, Pb, and Cr release concentrations were far less than the drinking water standards of China, the USA, Japan, and the EU.

Relationship between the release concentrations of different inorganic elements

Aluminiferous loose deposits can effectively accumulate various heavy metals under the action of adsorption and coprecipitation. As and Cr, which are biologically toxic and high release, were selected to study their correlation with Al in the release process. Figure 8 shows that the correlations between the release concentrations of Al and Cr (R2 > 0.93), As and Cr (R2 = 0.9172), and As and Mn (R2 = 0.9041) in the studied pH range were significant. Under a pH of 9, there was a high correlation (R2 = 0.9375) between the release concentrations of Al and As. The release of As and Cr may occur with the release of Al and Mn compounds. Mn decreased as the pH increased, which explained the negative correlation between Mn and As (Silva et al. 2012).

Release ratio of the heavy metals from the loose deposits

The heavy metal release concentrations in samples 1–5 (Table 4) were different and consistent with the total content in the original loose deposits (Table 2). The release ratio of the heavy metals in the different samples did not have a trend as the pH changed. In the study pH range, the highest release ratios of Cr, Mn, Cu, As, and Pb in the five samples were 5.12, 6.12, 3.78, 5.57, and 0.68%, respectively. The release experimental data illustrated that the release ratio of the heavy metals was quite low.

The evaluation results showed that the potential biotoxicity of As and Cu in the samples was relatively high. However, the release results found that the release ratio of the heavy metals in the samples was very low; there was no correlation between the release rate of the heavy metals in the loose deposits and their potential biotoxicity. The release rate was influenced by the form of the heavy metals in the loose deposits (Peng et al. 2012).

The maximum amount of the heavy metals could reach 3 mg/L for As, 34 mg/L for Cu, 19 mg/L for Pb, and 1 mg/L for Cr if the metals were completely released to the pipe system under extreme conditions, concentrations much higher than the regulation limits of 0.01, 0.05, 1.0, and 0.01 mg/L for As, Cr, Cu, and Pb, respectively (taking China’s regulation limits as example). Although the heavy metals in loose deposits cannot be completely released from the DWDS in a short time, the potential release of heavy metals should not be ignored.

Conclusions

Due to changes in water quality parameters, heavy metals accumulated in loose deposits and corrosion scales may be released into DWDS, affecting the water quality. In this study, the potential biotoxicity risk of loose deposits was evaluated, and the effects of the water quality parameters on the release of heavy metals in loose deposits were studied by batch experiments. The main conclusions are as follows:

The accumulation of Fe and Mn in the loose deposits can reach up to 94,000 and 10,950 mg/kg, respectively. Cu was the most prominent heavy metal found in the DWDS solids, and Cu can have a concentration of 1408 mg/kg. Cr, As, Pb, and Cd were found in all the samples. The evaluation results found that the potential biotoxicity of As and Cu in the samples was relatively large, and there was no biotoxicity for Cd. Therefore, the release risks of heavy metals cannot be ignored.

The maximum concentrations of As, Cu, Pb, and Cr released into the aqueous system from the loose deposits were 0.60, 1.02, 0.67, and 1.04 μg/L, respectively, under different pH conditions. With an increase in the phosphate concentration, the release of As, Cu, Pb, and Cr progressively increased. In addition, bicarbonate had a weak competitive power with other competing ions for the adsorption sites, and it did not have a significant effect on the release of heavy metals from the loose deposits. The correlations between the release concentrations of Al and Cr (R2 > 0.93), As and Cr (R2 = 0.9172), and As and Mn (R2 = 0.9041) were significant in the studied pH range.

Although the release ratio of the heavy metals in the loose deposits was small within the water quality parameter study scope, subsequent investigations should be conducted to further elucidate the effect of other water quality parameters on heavy metal release, such as natural organic matter and oxidation-reduction potential.

References

Antelo, J., Avena, M., Fiol, S., López, R., & Arce, F. (2005). Effects of pH and ionic strength on the adsorption of phosphate and arsenate at the goethite-water interface. Journal of Colloid and Interface Science, 285(2), 476–486.

Benson, A. S., Dietrich, A. M., & Gallagher, D. L. (2012). Evaluation of iron release models for water distribution systems. Critical Reviews in Environmental Science and Technology, 42(1), 44–97.

Carrière, A., Gauthier, V., Desjardins, R., & Barbeau, B. (2005). Evaluation of loose deposits in distribution systems through unidirectional flushing. Journal/American Water Works Association, 97(9), 82-92.

Cerrato, J. M., Reyes, L. P., Alvarado, C. N., & Dietrich, A. M. (2006). Effect of PVC and iron materials on Mn(II) deposition in drinking water distribution systems. Water Research, 40(14), 2720–2726.

Copeland, R. C., Lytle, D. A., & Dionysious, D. D. (2007). Desorption of arsenic from drinking water distribution system solids. Environmental Monitoring and Assessment, 127(1–3), 523–535.

Gerke, T. L., Little, B. J., & Barry Maynard, J. (2016). Manganese deposition in drinking water distribution systems. Science of the Total Environment, 541, 184–193.

Gheju, M., Balcu, I., & Mosoarca, G. (2016). Removal of Cr(VI) from aqueous solutions by adsorption on MnO2. Journal of Hazardous Materials, 310, 270–277.

Hsu, J.-C., Lin, C.-J., Liao, C.-H., & Chen, S.-T. (2008). Evaluation of the multiple-ion competition in the adsorption of As(V) onto reclaimed iron-oxide coated sands by fractional factorial design. Chemosphere, 72(7), 1049–1055.

Jain, A., & Loeppert, R. H. (2000). Effect of competing anions on the adsorption of arsenate and arsenite by ferrihydrite. Journal of Environment Quality, 29(5), 1422.

Li, M., Liu, Z., Chen, Y., & Hai, Y. (2016). Characteristics of iron corrosion scales and water quality variations in drinking water distribution systems of different pipe materials. Water Research, 106, 593–603.

Liu, J., Yin, P., Chen, B., Gao, F., Song, H., & Li, M. (2016). Distribution and contamination assessment of heavy metals in surface sediments of the Luanhe River Estuary, northwest of the Bohai Sea. Marine Pollution Bulletin, 109(1), 633–639.

Liu, G., Zhang, Y., Knibbe, W. J., Feng, C., Liu, W., Medema, G., & van der Meer, W. (2017). Potential impacts of changing supply-water quality on drinking water distribution: a review. Water Research, 116, 135-148.

Lytle, D. A., Sorg, T. J., & Frietch, C. (2004). Accumulation of arsenic in drinking water distribution systems. Environmental Science and Technology, 38(20), 5365–5372.

Lytle, D. A., Sorg, T. J., Christy, M., & Lili, W. (2010). Particulate arsenic release in a drinking water distribution system. Journal/American Water Works Association, 102(3), 87–98.

MacDonald, D. D., & Ingersoll, C. G. (2010). Tools for assessing contaminated sediments in freshwater, estuarine, and marine ecosystems. Sedimentology of Aqueous Systems, 171–199. https://doi.org/10.1002/9781444317114.ch7.

MacDonald, D., Ingersoll, C., & Berger, T. A. (2000). Development and evaluation of consensus-based sediment quality guidelines for freshwater ecosystems. Archives of Environmental Contamination and Toxicology, 39(2000), 20–31.

McNeill, L. S., & Edwards, M. (2001). Review of iron pipe corrosion in drinking water distribution systems. Journal AWWA, 93(7), 88–100.

Morillo, D., Pérez, G., & Valiente, M. (2015). Efficient arsenic(V) and arsenic(III) removal from acidic solutions with novel forager sponge-loaded superparamagnetic iron oxide nanoparticles. Journal of Colloid and Interface Science, 453, 132–141.

Nawrocki, J., Raczyk-Stanisławiak, U., Świetlik, J., Olejnik, A., & Sroka, M. J. (2010). Corrosion in a distribution system: Steady water and its composition. Water Research, 44(6), 1863–1872.

Oliveira, A., Palma, C., & Valença, M. (2011). Heavy metal distribution in surface sediments from the continental shelf adjacent to Nazaré canyon. Deep Sea Research Part II: Topical Studies in Oceanography, 58(23), 2420–2432.

Peña-Icart, M., Mendiguchía, C., Villanueva-Tagle, M., Bolaños-Alvarez, Y., Alonso-Hernandez, C., Moreno, C., & Pomares-Alfonso, M. S. (2017). Assessment of sediment pollution by metals. A case study from Cienfuegos Bay, Cuba. Marine Pollution Bulletin, 115(1–2), 534–538.

Peng, C.-Y., & Korshin, G. V. (2011). Speciation of trace inorganic contaminants in corrosion scales and deposits formed in drinking water distribution systems. Water Research, 45(17), 5553–5563.

Peng, C. Y., Korshin, G. V., Valentine, R. L., Hill, A. S., Friedman, M. J., & Reiber, S. H. (2010). Characterization of elemental and structural composition of corrosion scales and deposits formed in drinking water distribution systems. Water Research, 44(15), 4570–4580.

Peng, C. Y., Hill, A. S., Friedman, M. J., Valentine, R. L., Larson, G. S., Romero, A. M. Y., et al. (2012). Occurrence of trace inorganic contaminants in drinking water distribution systems. Journal - American Water Works Association, 104(3), 53–54.

Sarin, P., Snoeyink, V. L., Bebee, J., Kriven, W. M., & Clement, J. A. (2001). Physico-chemical characteristics of corrosion scales in old iron pipes. Water Research, 35(12), 2961–2969.

Sarin, P., Snoeyink, V. L., Bebee, J., Jim, K. K., Beckett, M. A., Kriven, W. M., & Clement, J. A. (2004). Iron release from corroded iron pipes in drinking water distribution systems: Effect of dissolved oxygen. Water Research, 38(5), 1259–1269.

Serafim, A., Company, R., Lopes, B., Pereira, C., Cravo, A., Fonseca, V. F., França, S., Bebianno, M. J., & Cabral, H. N. (2013). Evaluation of sediment toxicity in different Portuguese estuaries: ecological impact of metals and polycyclic aromatic hydrocarbons. Estuarine, Coastal and Shelf Science, 130, 30–41.

Silva, J., De Mello, J. W. V., Gasparon, M., & Abrahão, W. A. P. (2012). Effects of competing anions and iron bioreduction on arsenic desorption. Water, Air, and Soil Pollution, 223(9), 5707–5717.

Smedley, P., & Kinniburgh, D. (2002). A review of the source, behaviour and distribution of arsenic in natural waters. Applied Geochemistry, 17(5), 517–568.

Stachowicz, M., Hiemstra, T., & Van Riemsdijk, W. H. (2007). Arsenic-bicarbonate interaction on goethite particles. Environmental Science and Technology, 41(16), 5620–5625.

Sun, H., Shi, B., Lytle, D. A., Bai, Y., & Wang, D. (2014). Formation and release behavior of iron corrosion products under the influence of bacterial communities in a simulated water distribution system. Environmental Science: Processes & Impacts, 16(3), 576–585.

Sun, H., Shi, B., Yang, F., & Wang, D. (2017). Effects of sulfate on heavy metal release from iron corrosion scales in drinking water distribution system. Water Research, 114, 69–77.

Turgut, C., Katie Pepe, M., & Cutright, T. J. (2005). The effect of EDTA on Helianthus annuus uptake, selectivity, and translocation of heavy metals when grown in Ohio, New Mexico and Colombia soils. Chemosphere, 58(8), 1087–1095.

Veschetti, E., Achene, L., Ferretti, E., Lucentini, L., Citti, G., & Ottaviani, M. (2010). Migration of trace metals in Italian drinking waters from distribution networks. Toxicological and Environmental Chemistry, 92(3), 521–535.

Xie, Y., & Giammar, D. E. (2011). Effects of flow and water chemistry on lead release rates from pipe scales. Water Research, 45(19), 6525–6534.

Yang, F., Shi, B., Gu, J., Wang, D., & Yang, M. (2012). Morphological and physicochemical characteristics of iron corrosion scales formed under different water source histories in a drinking water distribution system. Water Research, 46(16), 5423–5433.

Yang, F., Shi, B., Bai, Y., Sun, H., Lytle, D. A., & Wang, D. (2014). Effect of sulfate on the transformation of corrosion scale composition and bacterial community in cast iron water distribution pipes. Water Research, 59, 46–57.

Funding

This work was supported by the National Natural Science Foundation of China (51678558, 51378493) and the National Key R&D Program of China (2016YFC0400803).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Q., Han, W., Han, B. et al. Assessment of heavy metals in loose deposits in drinking water distribution system. Environ Monit Assess 190, 388 (2018). https://doi.org/10.1007/s10661-018-6761-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-018-6761-9