Abstract

Novel Cu(II) ion-imprinted polymers (Cu-IIP) nanoparticles were prepared by using Cu(II) ion-thiosemicarbazide complex as the template molecule and methacrylic acid, ethylene glycol dimethacrylate (EGDMA), and 2,2′azobisisobutyronitrile (AIBN) as the functional monomer, cross-linker, and the radical initiator, respectively. The synthesized polymer nanoparticles were characterized by using infrared spectroscopy (IR), thermo gravimetric analysis (TGA), X-ray diffraction (XRD), and scanning electron microscopic (SEM) techniques. Some parameters such as pH, weight of the polymer, adsorption time, elution time, eluent type, and eluent volume which affect the extraction efficiency of the polymer were studied. In the proposed method, the maximum sorbent capacity of the ion-imprinted polymer was calculated to be 38.8 mg g−1. The preconcentration factor, relative standard deviation, and limit of detection of the method were found to be 80, 1.7 %, and 0.003 μg mL−1, respectively. The prepared ion-imprinted polymer nanoparticles have an increased selectivity toward Cu (II) ions over a range of competing metal ions with the same charge and similar ionic radius. The method was applied to the determination of ultra trace levels of Cu2+ in environmental water samples with satisfactory results.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Copper is the third essential heavy metal (after Fe3+ and Zn2+) in the human body and plays an important role in various physiologic processes. Its deficiency is a symptom of anemia, but at higher concentration levels, it is toxic and may cause various diseases. Genetically determined disorders of copper homeostasis have been associated with neurodegenerative diseases, such as Menkes disease, Wilson disease, and hereditary aceruloplasminemia (Sun et al. 2012). Copper is also an important element that is present in animals, plants, and microorganisms. It is both vital and toxic to many biological systems, depending on the level of concentration (Abbasi et al. 2010). The maximum tolerable daily intake for copper is 0.5 mg kg−1 (WHO, Technical Report Series, No. 683, 1982) body weight (Shams et al. 2004). The concentration of copper in various samples is low, so sensitive, and requires selective methods for determination of copper in food, environmental water, and biological samples.

In recent years, ion-imprinted polymers (IIPs), as selective sorbents for a particular chemical form of the given element, have received much attention. The high selectivity of IIPs can be explained by the polymer memory effect toward the metal ion interaction with a specific ligand, coordination geometry, metal ion coordination number, charge, and size (Dakova et al. 2009).

In this study, a novel nano structure Cu (II) ion-imprinted polymer has been synthesized for faster extraction of Cu (II) ions from various matrixes using methacrylic acid (MAA) as a monomer, ethyleneglycoldimethacrylate (EGDMA) as a cross-linking agent, and thiosemicarbazide (TSC) as a specific ligand for Cu (II). The extraction characteristics of the non-imprinted (blank P (B)), treated with thiosemicarbazide alone (control P (thiosemicarbazide)), and imprinted with Cu (II) - thiosemicarbazide complex (P (thiosemicarbazide -Cu)) polymer nanobeads have been compared. The adsorption and desorption characteristics have been investigated using batch procedures. Also the Cu (II) selectivity versus other interfering metal ions has been studied.

Experimental

Materials

MAA, EGDMA, and 2,2′-azobisisobutyronitrile (AIBN) were obtained from Aldrich (Milwaukee, WI, USA). Ethanol was of reagent grade from Merck Chemical Company and was used as received. Thiosemicarbazide, reagent grade Cu (NO3)2. 3H2O and nitrate or chloride salts of other cations (all from Merck) were used without any further purification. A stock standard solution of Cu2+ (1,000 μg mL−1) was prepared by dissolving 0.4589 g of copper nitrate Cu (NO3)2 · 3H2O in distilled-deionized water containing a few drops of concentrated nitric acid. The solution was made up to the mark in a 100-mL volumetric flask. This stock solution was diluted further, when necessary.

Apparatus

The determination of copper and other metal ions was performed using a Chem Tech flame atomic absorption spectrometer (CTA, 2000, UK) equipped with a CTA 2000 single-element hollow cathode lamp, and a deuterium background corrector at respective wavelengths (resonance line) using an air-acetylene flame, while the instrumental parameters were those recommended by the manufacturer. A 780 pH Meter (Metrohm), equipped with a combined Ag/AgCl glass electrode, was used for pH measurement. Scanning electron micrographs were recorded using a Philips XL30 series instrument using a gold film for loading the dried nanoparticles on the instrument. Gold films were prepared by a Sputter Coater model SCD005 made by BAL-TEC (Switzerland). A Varian model 300 Bio equipped with 10 mm quartz cell was used for recording the UV-Vis spectra at 25.0 ± 0.1 °C. The FTIR spectra (4,000–400 cm−1) were recorded on a Bruker (Germany) FTIR Vertex 70 spectrometer. Thermogravimetery analysis (TGA) and differential thermal analysis (DTA) were carried out using a Stanton Redcroft, STA–780 series with an aluminum crucible, applying heating rate of 10 °C/min in a temperature range of 50–600 °C, under air atmosphere with the flow rate of 50 mL min−1. The sample mass used was about 3.0 mg. Eppendorf Varied-Pipettes (10–100, 100–1,000 μl) were used to deliver accurate volumes. All glassware and storage bottles were soaked in 10 % HNO3 overnight and thoroughly rinsed with deionized water prior to use.

Preparation of Cu2+-ion-imprinted polymeric nanoparticles

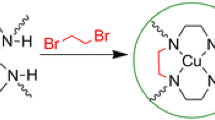

The copper ion-imprinted nanobeads were prepared by precipitation polymerization technique (Shamsipur and Besharati-Seidani 2011). For this purpose, 2.0 mmol of thiosemicarbazide was added into 25.0 mL of ethanol as porogen solvent, and then treated with 1.0 mmol of Cu (NO3)2 · 3H2O as imprint metal ion, at room temperature with continuous stirring for 30 min. In the polymerization procedure, MAA (4.0 mmol), EGDMA (30.0 mmol), and 0.4 mmol of AIBN were added as functional monomer, cross-linker, and free radical initiator, respectively, to the first step solution and stirred at room temperature. The polymerization mixture was purged with N2 gas for 10 min to remove the molecular oxygen, since it traps the radicals and retards the polymerization. Then, the reaction vial was sealed and heated in an oil bath at 60 °C for 24 h under magnetic stirring at 400 rpm to complete the thermal polymerization. After polymerization, the excess amount of solvent was removed by centrifugation of the resulting suspension solution. The imprint ion, i.e., Cu2+ ion was leached from the above polymer material by stirring 2 × 50 mL with HCl (50 %; v/v) for about 18 h (Shamsipur and Rajabi 2012) and, after centrifugation, the copper contents of the supernatant solutions were determined by atomic absorption spectrometer. This step was carried out several times until the supernatant solution was free from Cu2+ ions. The nanoparticles were then washed with ethanol and the sorbent repeatedly washed with doubly distilled-deionized water until neutral pH. The resulting nanoparticles were dried under a vacuum oven at 50 °C to obtain IIP nanoparticles for possible preconcentrative separation of Cu2+ ion from aqueous solutions. In the same way, the control non-imprinted polymeric (NIP) nanomaterials were similarly prepared using an identical procedure but without the addition of the imprint ion (i.e., Cu2+ ion). Powder nanoparticles of 100–200 nm in diameter were achieved and then applied for future adsorption and desorption studies. Scheme 1 shows the synthesis of ion-imprinted polymer.

Extraction procedure

Batch experiments were used for investigation of factors in adsorption and desorption steps. Extraction of Cu (II) ions from modeling solutions and real samples is followed by two steps: adsorption and desorption. In adsorption step, the pH of sample solution was adjusted to 10.0 by addition of 0.1 M sodium hydroxide or hydrochloric acid solutions. Then, 25 mg of dried polymer was suspended in aqueous solution containing 1.00 μg mL−1 concentration of Cu (II) and stirred for 20 min with a magnetic stirrer and then centrifuged (5 min, 6,000 rpm) and the supernatant solution removed. The Cu (II) ions preconcentrated onto IIP nanoparticles were eluted using 5.0 mL of HCl (1.0 M), while stirring for 10 min. The suspensions were then centrifuged and eluent solutions containing Cu (II) ions were removed from the nanoparticles. The resulting solutions were centrifuged and the copper contents of the solutions were determined by flame atomic absorption spectrometry (FAAS). Extraction percent of copper was calculated by the following equation:

C i and C f are the concentrations of copper ion before and after extraction in the solution.

The distribution ratio (mL g−1) of Cu2+ ions between the IIP nanoparticles and aqueous solution was also determined by the following equation:

Where V is the volume of initial solution and m is the mass of IIP materials. Selectivity coefficients and relative selectivity coefficients (k′) for Cu2+ ions relative to foreign ions in the solution are defined as:

Where \( {k}_d^{C{u}^{2+}} \) and \( {k}_d^{M^{n+}} \) are the distribution ratios of copper and foreign ion, respectively. In order to obtain the reusability of the prepared ion-imprinted polymeric nanobeads, the adsorption experiments (adsorption-elution cycle) were repeatedly performed using the same nanoparticles.

Determination of copper in water samples

The water samples, such as Ilam city, river, and mineral water, were centrifuged, filtered, and subjected to UV digestion for 2 h. After adjusting the pH samples to 10.0, they were stored in a cool place and analyzed, following the procedure given in “Extraction procedure.”

Results and discussion

Preliminary complexation studies

Evidence for the formation of ternary complex Cu (II)-TSC was followed by the UV-Visible absorption spectra. The absorption spectrum of TSC (5.0 × 10−5 M) in ethanol solvent is illustrated in Fig. 1 (a), which showed a maximum at 270 nm. When Cu2+ was added with different concentrations (0.5 × 10−5, 2.0 × 10−5, 3.0 × 10−5, 5.0 × 10−5, 7.5 × 10−5, and 1.0 × 10−4 M), an absorbance peak was produced at 205 nm and absorbance increased with the increase in the concentration of copper (Fig. 1 (b)), while the absorbance of TSC at 270 nm decreased. These results clearly indicate that the ternary complex Cu (II)-TSC was readily formed in ethanol solvent. Furthermore, the stoichiometry of the complex was determined from the absorbance–mole ratio plot at maximum wavelength of the complex (205 nm). A distinct inflection point at mole ratio about 0.5 strongly supports the formation of a complex of mole ratio Cu (TSC)2 (Tada et al. 2011).

Characterization of Cu (II) ion-imprinted polymer

Colorimetry

After synthesis of unleached, leached IIP, and NIP, colorimetric studies were carried out to compare the changes in the color of prepared powders (Scheme 2). An obvious change in the color from dark yellow of unleached IIPs to white after leaching process clearly indicate the successful removal of copper ions from the polymeric matrix. Meanwhile, adsorption process caused an instant color change in the leached IIPs from white to the dark yellow due to fast extraction of copper ions into the imprinted polymeric matrix at desired pH.

FTIR spectra

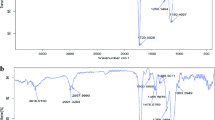

The resulting imprinted nanoparticles were characterized by FTIR spectroscopy. The FTIR spectra of unleached and leached ion-imprinted polymer (IIP) were recorded using KBr pellet method. Figure 2 shows the FTIR spectra of the un-leached and leached IIP nanoparticles. By comparing the infrared spectroscopy (IR) spectra of the polymers, it was observed that both the polymeric materials have a similar polymer backbone. Moreover, similarities between the IR spectra of these materials suggested that the leaching process does not affect the polymeric network (Daniel et al. 2005). In the IR spectra, the absorptions due to N-H (3,624.6 cm−1), C-N (1,150.5 cm−1) and C‗S (1,260.7 cm−1) were observed (Bindu and Kurup 1997). The N–H bands at 3,624.6 cm−1and C‗S band at 1,260.7 cm−1 in unleached IIP were shifted to 3,622.0 and 1,258.1 cm−1 in leached IIP. This amount of reduction in band frequencies indicates that the copper ions have been coordinated with non-bonding electron pairs of nitrogen in N–H and C‗S groups in TSC, and consequently the presence of Cu ions in unleached IIP structure is demonstrated. Moreover, the presence of C‗S, C-N, and N–H bands in the IR spectra of these materials indicated that thiosemicarbazide had been sufficiently immobilized in the polymer matrix.

X-ray diffraction

The X-ray diffraction (XRD) patterns of the unleached (a), leached (b), and NIP (c) nanosized ion-imprinted polymer are shown in Fig. 3. In un-leached IIP, the corresponding peak to the 2θ values of 18.7402, 28.2112, 31.6208, and 33.1892 (which attributed to copper ions) disappeared after leaching, leaving vacant sites in the matrix while the rest of the polymer backbone remained unaffected. This behavior confirms complete removal of the copper from the material during leaching process. In all of the above cases, the XRD of leached IIPs was similar to the corresponding XRD patterns of control polymers.

Scanning electron microscopy

The surface morphology of the leached and unleached polymers was observed by scanning electron microscopic (SEM). The SEM image was obtained in order to account for the effect of Cu (II) removal from the polymer as depicted in Fig. 4a (unleached) and 4b (leached). Moreover, an enhanced surface area was also observed from the SEM image of the leached rather than unleached polymer. Thus, the ordered nano-pattern observed in the SEM image of leached polymer is probably due to the metal ion imprinting of Cu (II) on the polymer. Also, it is clear that the pore size in the imprinted polymer is in the nano-range, corresponding to the size of the Cu ion.

Results of thermal analysis for the polymer samples

Thermal behaviors of the prepared NIP and Cu-IIP nanoparticles before and after leaching were studied under identical conditions using TGA and DTA techniques. Figure 5 represents TGA/DTA curves for the NIP nanoparticles. As seen in Fig. 5a, an endothermic event was observed in the DTA curve of the NIP sample. This peak is observed due to the starting thermal decomposition of the ligand around 304 °C. This peak is followed by three continuous exothermic peaks which are responsible for the main decomposition of complex. On the other hand, TGA thermogram of this sample showed a main mass loss step for the decomposition of nanoparticles. This step was started at about 250 °C and continued until 420 °C. The TGA curve indicates about 95 % total mass loss for the thermal decomposition of this sample in this temperature range. Furthermore, DTA curve reveal another exothermic peak at higher temperature which is compatible with 5 % mass loss in the TGA curve of sample.

Thermal behavior of the Cu-IIP sample is studied and the results are shown in Fig. 5b. As seen in TGA/DTA curves, thermal stability of this sample is significantly different from NIP nanoparticles. A mild exothermic event was observed on the DTA curve of the sample which is followed by a sharp exothermic peak. This sharp peak is along with another small exothermic phenomenon. TGA thermogram of this sample shows a main decomposition step with about 82 % loss in the mass of sample. This mass loss step is started at about 220 °C and continued until temperature of 400 °C.

Thermal behavior of the polymer sample after leaching was also investigated and the results are presented in Fig. 5c. TGA/DTA curves for this sample are relatively comparable with the NIP nanoparticles. A small exothermic event was observed in the DTA curve of this sample which was followed by three continuous exothermic phenomena. TGA thermogram for this sample shows that main decomposition of the compound is started at about 250 °C and continuous until about 550 °C. On the other hand, the TGA curve indicates about 98 % mass loss for thermal decomposition of the sample in this temperature range.

These results suggest that the thermal decomposition of the leached polymer (in the absence of metallic copper ions) is approximately complete and during its decomposition in the temperature range of 250–550 °C, the whole of hydrocarbon compositions of the nanoparticles changed to the gaseous products. A comparison between thermal behaviors of the leached and un-leached samples shows that nanoparticles in both samples decompose exothermally during a single step; however, the mass loss for both samples is considerably different. This observed difference in mass loss of the samples is due to the presence and absence of the copper ion, respectively, in the Cu-IIP nanoparticles and leached samples.

Adsorption/desorption experiments

Effect of pH

For metal, ionic complexation with ligands is highly dependent on the equilibrium pH of the medium, and the pH value of the solution is an important parameter for adsorbing metal ions. To evaluate the effect of pH on the extraction efficiency, the pH of 20 mL of sample solutions containing 1.00 μg mL−1 of copper ion was adjusted in the range of 1.0–13.0. The results obtained for the influence of pH on the Cu (II) extraction efficiency are presented in Fig. 6. The Cu (II) adsorption of Cu (II)-imprinted polymer increased from pH 1.0 to 10.0 but decreased from pH 10.0 to 13.0. Therefore, the maximum binding capacity was obtained at pH 10.0. As expected, due to the presence of nitrogen and sulfur donor atoms in TSC and functional monomers (MAA), the complex formation with metal ion is highly dependent on the pH of solution. At low pH, the donor nitrogen and sulfur atoms in the TSC-MAA network may be protonated and therefore, negligible amounts of copper ions can be adsorbed to the polymeric network. When the pH is increased, the protonation of ligand is suppressed and the condition becomes more favorable for complex formation and adsorption of Cu (II) ions to the imprinted sorbent. Also, the adsorption amount of copper ions on the IIP nanobeads is decreased at pH > 10 possibly due to formation of hydroxide species of Cu (II). So, pH 10.0 was chosen as the optimum pH for the next experiments.

Effect of type and concentration of eluent

As the ions are not removed from the sorbent completely with an inappropriate eluent, the eluent solution is an important factor for elution efficiency and recovery. To elute the copper ions from these synthesized IIP nanoparticles, a variety of selected eluent solutions, including HCl, H2SO4, and HNO3 were used. After leaching of bounded copper using 5.0 mL of 1.0 M of each acid on the IIPs nanoparticles, the amount effluent copper was determined by atomic absorption spectrometer. It was found that 5.0 mL of hydrochloric acid 1.0 M can accomplish the quantitative elution of the copper ion from the IIP nanobeads. High efficiency of HCl for leaching of copper is probably due to the strong exchange of the specific binding Cu2+ ion with the nitrogen and sulfur atoms in the TSC structure. Thus, 1.0 M HCl was selected as eluent for future studies.

After selection of the proper eluent, several 5.0 mL portions of hydrochloric acid solutions with different concentrations (i.e., 0. 1, 0.5, 1.0, and 2.0 M) were used for leaching of copper ions from the imprinted sites in the polymer network in order to study the optimum eluent concentration. It was found that desorption of adsorbed Cu (II) ions increased with increasing hydrochloric acid concentration. This is most probably due to increased protonation of the nitrogen and sulfur atoms as the donor atoms in the TSC structure of imprinted polymer. Thus, 5.0 mL of 1.0 M hydrochloric acid was selected as optimal eluent solution.

Effect of IIP weights

The percentage of preconcentration of copper ions with different weights of IIP was also investigated. Twenty milliliters of aqueous solution containing 1.0 μg mL−1 copper ion at pH 10.0 was used and other conditions were the same as above. The results indicate no difference between 25.0 and 50.0 mg of IIP nanoparticles in enrichment of copper ions and specific binding of copper ions onto active sites in the IIP. Consequently, 25.0 mg of IIP nanoparticles were used for further studies.

Effect of adsorption and desorption times

The effect of adsorption and desorption times on the binding quantity of Cu (II) ion was investigated in a batch system. In a typical uptake kinetics test, 25.0 mg of the sorbent was added to 20.0 mL of a 1.0 μg mL−1 solution of Cu (II) at pH 10.0. The resulting suspension was stirred for different periods of time (i.e., from 5 to 30 min) under magnetic stirring. After centrifugation, the supernatant solution was removed and the Cu (II) ions were determined by atomic absorption spectrometer. Time dependence of the adsorption of Cu (II) onto the imprinted polymeric nanoparticles is plotted in Fig. 7 (a). The results indicated that quantitative adsorption of Cu (II) can be achieved over a period of 20 min. Therefore, the optimum adsorption time of 20 min was selected and used in all subsequent studies.

In ion-imprinted polymer technique, after the adsorption of analyte on IIP, a time interval is necessary to break the bonding between ligand and metal ions. In order to investigate the optimum desorption time, various times were examined in the range of 3–15 min, while other parameters were kept in optimum condition. As shown in Fig. 7b, extraction recovery was increased up to 10 min and it remained constant at in longer times. Therefore, 10 min is the best quantitative time for the elution of metal ions from the imprinted polymer.

Effect of sample volume

In the analysis of real samples, the sample volume is one of the important parameters influencing the preconcentration factor. Therefore, the effect of sample volume on quantitative adsorption of Cu (II) ion was investigated. For this purpose, 25.0 mg of IIP was suspended in different sample volumes (25.0, 50.0, 100.0, 200.0, 300.0, 400.0, 500.0, 600.0, 700.0, and 800.0 mL), and the total amount of loaded Cu (II) was kept constant in 1.00 μg. All solutions were extracted under the optimum condition by the proposed method. The results demonstrated that the dilution effect was not significant for sample volumes of copper ions up to 400.0 mL. However, at higher sample volumes, the recovery decreased significantly. Thus, a high preconcentration factor of 80 was obtained in which the quantitative extraction of copper by the prepared IIP is possible.

The adsorption capacity

The adsorption capacity (maximum amount of copper ion adsorbed for 1.00 g of IIP nanoparticles) is an important factor to evaluate the IIPs (Rajabi et al. 2013). To measure the adsorption capacity, imprinted or non-imprinted polymers (50.0 mg) were equilibrated with Cu2+ solutions (20.0 mL) within the concentration range of 1.00–100.00 μg mL−1 at pH 10.0. The adsorption value increased with the increase of concentration of Cu2+ (1.00–50.00 μg mL−1), and a saturation value was achieved in the concentration range of 50.00–100.00 μg mL−1. The adsorption capacity of the imprinted and non-imprinted polymers was calculated to be 37.36 and 15.11 mg g−1, respectively. The resulting plot of Q vs. initial concentration of copper ion is shown in Fig. 8. The capacity of imprinted nanoparticles is larger than that of non-imprinted ones. This difference indicates that the imprinting plays an important role in the adsorbent behavior. During the preparation of the imprinted adsorbent, the presence of Cu2+ encouraged an orderly ligand arrangement. After removal of Cu2+, the imprinted cavities and specific binding sites of functional groups in a predetermined orientation are formed; however, no such specificity is found in non-imprinted polymers (He et al. 2008). Thereby the memory effect owned by imprinted materials to the template metal ion allows them to possess a shorter response time and higher adsorption capacity to metal ions than NIP.

Regeneration and reusability

The stability and reusability of Cu (II)-IIP were investigated. The regenerated Cu (II)-IIP was reused for up to 14 adsorption-desorption cycles. The results showed that Cu (II) imprinted nanoparticles could be repeatedly used without any significant loss in the initial binding affinity. The operating capacity was calculated from the loading and elution tests. Cu (II)-ion-imprinted polymer has a superior reusability, which can be repeated for use in 10 cycles with not less than 95 % recovery. These studies clearly indicate the availability of reversible nature of binding sites for picking Cu (II) ions using copper-IIP nanoparticles. This stability of the sorbent without any evidence for polymer destruction is most likely due to the strong hydrogen bonding attachment of polymer chains to the monomers in the polymer network (Rajabi et al. 2013). It can be concluded that the IIP nanobeads can be used many times without decreasing their adsorption capacities significantly.

Selectivity study

The imprinted polymers are also characterized by a uniform distribution of chelating sites (Molochnikov et al. 2003). In IIPs, the cavities created after removal of the template are complementary to the imprint ion in size and coordination geometries. Furthermore, the unique shape of the copper ion may be expected to lead to much greater selectivity for the copper ion by ion imprinting. In comparison with other metal ions, in the case of non-ion-imprinted sorbent, the random distribution of ligand functionalities in the polymeric network results in no specificity in rebinding affinities. Ni2+, Fe3+, Pb2+, Al3+, Cd2+, Zn2+, Ca2+, Mg2+, and Co2+ are chosen as the competitor ions as they have the same charge and similar size Both the imprinted and non-imprinted polymers were used to obtain 2 sets of experimental data. Polymer material (25.0 mg) was added to 20 mL aqueous solutions containing 1.00 μg mL−1 Cu2+/M n+. The pH was then adjusted accordingly to pH 10.0. After the adsorption-equilibrium, the mixtures were filtered and the concentration of each ion in the remaining solution was measured by atomic absorption spectroscopy. The measured values gave the concentrations of the unextracted ions, from which extraction efficiency was evaluated. Table 1 summarizes the distribution ratios (K d), selectivity coefficients (k) and relative selectively coefficients (k) calculated using Eqs. (2, 3 and 4), respectively. From the data in Table 1, the following can be observed: (1) the selectivity coefficients of NIP for Cu (II) with respect to foreign ions are very low; (2) the selectivity coefficients of Cu (II)-IIP for Cu (II) with respect to foreign ions are very high; (3) the relative selectivity coefficients indicate adsorption affinity and selectivity of imprinting material for the template with respect to non-imprinting material. The above results imply that the imprinted cavities and specific binding sites in a predetermined orientation were formed in the Cu (II)-IIP, and the size of foreign ions does not match well with the cavity imprinted by Cu (II), resulting in high recognition ability and high selectivity of Cu (II)-IIP for Cu (II) ions.

Analytical figures of merit

The analytical performance data for the batch preconcentration procedure are given in Table 2. Under the optimized conditions described above, the calibration curve for Cu2+ was linear over the concentration range of 0.001 to 0.100 μg mL−1 with the correlation coefficient (R2) of 0.999. According to the IUPAC definition, for a sample volume of 200 mL the detection limit (3 s of the blank signal intensity divided by slope of the calibration curve) of this method was 0.0002 μg mL−1 with the preconcentration step. The relative standard deviation (RSD) was 1.7 % for 1.00 μg mL−1 copper level (n = 8), indicating favorable precision of the proposed method. A comparison of the proposed method with other literature (Shamsipour et al. 2013; Shamsipur et al. 2010; Yılmaz et al. 2013; Ebrahimzadeh et al. 2013; Lopes Pinheiro et al. 2012; Luo et al. 2012) is given in Table 3.

Real sample analysis

The applicability of the ion-imprinted polymer for preconcentration of trace levels of Cu (II) was tested using Ilam city, river and mineral water, samples. The mentioned samples were prepared according to the real samples preparation Section. For the preconcentration procedure, pH of real samples was adjusted to 10 spiked with copper ions and used in the extraction procedure. The concentration of sorbed Cu (II) ions was determined based on standard addition method and recovery tests (Table 4). It was found that the quantitative extraction of copper ions was performed successfully by the Cu (II)-IIP even in the presence of various diverse ions.

Conclusion

The ion-imprinted polymer method is a useful technique for the preparation of sorbent for preconcentration of metal ions, such as copper from aqueous solutions. In this study, a Cu (II) ion-imprinted polymer with exceedingly large performance, as marked by the fast equilibration-adsorption kinetics, the very large relative selectivity coefficients, high extraction efficiency percentages of the targeted ion (Cu2+), even in the presence of other closely related ions, was successfully prepared. The polymer was simple and relatively easy to prepare. The Cu (II)-imprinted nanoparticles can be used repeatedly with no significant decrease in binding affinities. Due to relatively high preconcentration factor, trace copper ions at ng mL−1 levels in high volume samples can be determined and separated by ion-imprinted polymers.

References

Abbasi, S., Khani, H., & Tabaraki, R. (2010). Determination of ultra trace levels of copper in food samples by a highly sensitive adsorptive stripping voltammetric method. Food Chemistry, 123, 507–512.

Bindu, P., & Kurup, M. R. P. (1997). E.s.r. and electrochemical studies of four- and five-coordinate copper (II) complexes containing mixed ligands. Transition Metal Chemistry, 22, 578–582.

Dakova, I., Karadjova, I., Georgieva, V., & Georgiev, G. (2009). Ion-imprinted polymethacrylic microbeads as new sorbent for preconcentration and speciation of mercury. Talanta, 78, 523–529.

Daniel, S., Prabhakara Rao, P., & Prasada Rao, T. (2005). Investigation of different polymerization methods on the analytical performance of palladium (II) ion imprinted polymer materials. Analytica Chimica Acta, 536, 197–206.

Ebrahimzadeh, H., Behbahani, M., Yamini, Y., Adlnasab, L., & Asgharinezhad, A. A. (2013). Optimization of Cu(II)-ion imprinted nanoparticles for trace monitoring of copper in water and fish samples using a Box–Behnken design. Reactive and Functional Polymers, 73, 23–29.

He, Q., Chang, X. J., Zheng, H., Jiang, N., Hu, Z., & Wang, X. Y. (2008). Determination of chromium(III) and total chromium in natural waters using a surface ion-imprinted silica gel as selective adsorbent. International Journal of Environmental Analytical Chemistry, 88, 373–384.

Lopes Pinheiro, S. C., Descalzo, A. B., Raimundo, I. M., Jr., Orellana, G., & Moreno-Bondi, M. C. (2012). Fluorescent ion-imprinted polymers for selective Cu(II) optosensing. Analytical and Bioanalytical Chemistry, 402, 3253–3260.

Luo, X., Huang, Y., Deng, F., Luo, S., Zhan, Y., Shu, H., & Tu, X. (2012). A magnetic copper(II)-imprinted polymer for the selective enrichment of trace copper(II) ions in environmental water. Microchimica Acta, 179, 283–289.

Molochnikov, L. S., Kovalyova, E. G., Zagorodni, A. A., Muhammed, M., Sultanov, Y. M., & Efendiev, A. A. (2003). Coordination of Cu(II) and Ni(II) in polymers imprinted so as to optimize amine chelate formation. Polymer, 44, 4805–4815.

Rajabi, H. R., Shamsipur, M., & Pourmortazavi, S. M. (2013). Preparation of a novel potassium ion imprinted polymeric nanoparticles based on dicyclohexyl 18C6 for selective determination of K+ ion in different water samples. Materials and Science Engineering C, 33, 3374–3381.

Shams, E., Babaei, A., & Soltanizadeh, M. (2004). Simultaneous determination of copper, zinc and lead by adsorptive stripping voltammetry in the presence of morin. Analytica Chimica Acta, 501, 119–124.

Shamsipur, M., & Rajabi, H. R. (2012). Flame photometric determination of cesium ion after its preconcentration with nanoparticles imprinted with the cesium-dibenzo-24-crown-8 complex. Microchimica Acta, 180, 243–252.

Shamsipur, M., & Besharati-Seidani, A. (2011). Synthesis of a novel nanostructured ion-imprinted polymer for very fast and highly selective recognition of copper (II) ions in aqueous media. Reactive and Functional Polymers, 71, 131–139.

Shamsipur, M., Besharati-Seidani, A., Fasihi, J., & Sharghi, H. (2010). Synthesis and characterization of novel ion-imprinted polymeric nanoparticles for very fast and highly selective recognition of copper(II) ions. Talanta, 83, 674–681.

Sun, L., Hao, D., Shen, W., Qian, Z., & Zhu, C. (2012). Highly sensitive fluorescent sensor for copper (II) based on amplified fluorescence quenching of a water-soluble NIR emitting conjugated polymer. Microchimica Acta, 177, 357–364.

Tada, R., Chavda, N., & Shah, M. K. (2011). Synthesis and characterization of some new thiosemicarbazide derivatives and their transition metal complexes. Journal of Chemical and Pharmaceutical Research, 3, 290–297.

Yılmaz, V., Hazer, O., & Kartal, Ş. (2013). Synthesis, characterization and application of a novel ion-imprinted polymer for selective solid phase extraction of copper(II) ions from high salt matrices prior to its determination by FAAS. Talanta, 116, 322–329.

Acknowledgments

The authors are grateful to the Ilam University Research Council for financing the project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roushani, M., Abbasi, S. & Khani, H. Synthesis and application of ion-imprinted polymer nanoparticles for the extraction and preconcentration of copper ions in environmental water samples. Environ Monit Assess 187, 219 (2015). https://doi.org/10.1007/s10661-015-4468-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-015-4468-8