Abstract

n the last years, much attention has been focused on the use of low-cost adsorbents for the removal of Cu(II) and Zn(II) from contaminated waters. In this context, we studied the sorption performances of two kinds of by-products resulted from the agriculture: soy bran and mustard husk. The effects of contact time, the initial metal ion concentration, pH, sorbent mass, and temperature on the adsorption capacity of the agricultural by-products as sorbents were investigated. The thermodynamic parameters associated with the adsorption process indicated that the process is spontaneous and endothermic. Modeling of experimental adsorption isotherm data showed that non-linear Langmuir isotherm fits better than other isotherms. The obtained values for the separation factor, R L were less than one which supports that the adsorption process was favorable. The obtained results indicated that the soy bran has a higher sorption capacity toward zinc ions (74.02 mg g−1) than mustard husk (63.69 mg g−1). Therefore, there is a great requirement for the search of biomaterials that are cheap and easily available for the removal of heavy metal ions from wastewater. The studied sorbents have the advantage of very low cost and great availability for simple operational experiments.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heavy metals get into our body in very small quantities with food, drinking water, and air. As essential elements, some heavy metals (e.g., copper, selenium, zinc) are vital in the maintenance of the human body metabolism. However, in high concentrations, they can be toxic.

As well known, heavy metals cannot be destroyed; the only way to prevent their release in the environment is their recovery and reuse. Nowadays, heavy metals are among the most significant pollutants in water and they are becoming a serious problem in terms of public health.

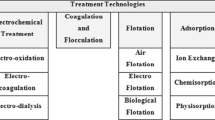

Generally, the removal of heavy metals from aqueous solutions has commonly been carried out through several processes: chemical precipitation, extraction with different solvents, ion exchange, reverse osmosis, or adsorption. Among these processes, adsorption with a suitable chosen adsorbent can be a simple but effective technique for removing heavy metals from wastewater.

The removal of heavy metal ions from water has become a major concern being regarded as a barrier to economic and social development, drawing attention to the fact that natural resources, materials, and energy are not inexhaustible.

Recently, the environmental pollution by heavy metals has attracted attention because of its complexity due to the fact that most heavy metals are not as soluble in water or, if they are, the chemical species are complexed with organic or inorganic ligands, which affects their toxicity.

Rapid industrialization has led to a huge increase in the use of heavy metals in recent decades and has inevitably led to an increased flow of heavy metals into the aquatic environment. Usually, heavy metals get into tissues through the food chain and accumulate in the human body. If these metals are ingested more than the maximum permitted, they can cause serious health problems. Therefore, it is necessary to clean wastewater contaminated with heavy metals before being discharged into the environment.

Copper is one of the heavy metals most used. Sources of copper waste include mining waste, copper-plating baths, fertilizer industry, paints, pigments, etc. Excessive doses of copper in humans cause severe irritation of the mucous membranes, affect the capillaries, and cause central nervous system irritations followed by depression and gastrointestinal irritation (Moore and Ramamoorthy 1984).

Zinc is present in the composition of the food and it is necessary for the growth and development of both animals and plants. An excess of zinc can produce undesirable responses such as anemia and serious damage to the reproductive capacity. In the body, it is attached to the red blood cells, skeletal muscles, and skin.

Conventional technologies to remove heavy metals include precipitation (Bratskaya et al. 2009; Huisman et al. 2006), ion exchange (Doula 2009; Inglezakis et al. 2007), chemical oxidation/reduction (Bojic et al. 2009), reverse osmosis (Chan and Dudeney 2008; Cséfalvay et al. 2009), electrodialysis, ultrafiltration (Kim et al. 2005; Korus and Loska 2009; Landaburu-Aguirre et al. 2009), etc. However, such technologies have some disadvantages such as high cost, sensitive conditions of application, and production of secondary sludge.

Recently, more attention was paid to cheap biomass such as rice husk, coconut shell, nut shell, cotton seed, oil cake, cane, and waste from tea manufacturing (Ajjabi and Chouba 2009; Babel and Kurniawan 2003; Jai et al. 2007; Mata et al. 2009; Oliveira and Franca 2008).

These biomasses seem to be a viable option for heavy metal removal due to their economic and environmental characteristics, the chemical composition, availability, low price, and high efficiency in removal of heavy metals from dilute solutions, the possibility of regenerating the adsorbent, and metal recovery.

Tunali et al. (2006) and Deans and Dixon (1992) showed that biosorption of heavy metals are due to the electrostatic interaction between the metallic ions and negative-charged center (carboxyl, sulfate, hydroxyl, phosphate) on the sorbent surface.

An important requirement for an advantageous sorption is a sufficiently selective sorbent with a high sorption capacity. The aim of the present study is to analyze the behavior of the agriculture by-products in the presence of copper(II) and zinc(II) ions from the residual waters in different experimental conditions.

Material and methods

In order to remove Cu(II) and Zn(II) ions from synthetic residual waters, soy bran and mustard husk used in the milling and baking products were used as sorbents. Sorbents were collected from a local mill, ground, sieved, and were selected the particles of 0.9 μm. It was washed with deionized water, dried in an air circulating oven at 50 °C for 5 days and stored in a desiccator until use.

The characteristic of the soy bran and mustard husk are presented in Table 1. The sorption experiments were performed in a static system for each ion by stirring a suspension that contained heavy metal ion solution and sorbent.

The synthetic solution containing the heavy metal was prepared by dissolving the respective salts in distilled water, Cu(NO3)2°5H2O (Merck) and Zn(NO3)2°6H2O. The pH ranged between 2 and 7, the initial concentration of the solution ranged from 25 to 250 mg L−1, at a temperature of 298.15 to 318.15 K, and the sorbent mass varied from 0.0025 to 0.05 g. The pH of the solution was adjusted with 1 M NaOH or HNO3 solution.

When the equilibrium sorption was achieved, the sorbent has been separated by centrifugation and the concentration of the elements in solutions was measured by flame atomic absorption spectroscopy (FAAS). The measurements were performed on the continuum source atomic absorption spectrometer—contrAA® 300—equipped with an optimized high-resolution Echelle double monochromator.

The textural properties of all samples were investigated by nitrogen sorption on a NOVA 2200e (Quantachrome Instruments) automated gas adsorption system. The BET equation was used to estimate the specific surface area.

Microscopic investigation was performed on an environmental scanning electron microscope Quanta 200 coupled with an energy-dispersive x-ray spectroscope (ESEM/EDX). The dried powdered samples were covered with gold by cathodic evaporation and were examined in high vacuum, using an ETD detector.

The percentage of retained metal ion on the sorbent was calculated using the formula:

The amount of metal absorbed per unit mass by the sorbent was calculated by the Eq. (2)

where C 0 is the initial concentration of solution (mg L−1), C e is the equilibrium concentration (mg L−1), V is the volume of solution (L), and m is the sorbent mass (g).

The distribution coefficient K d is defined as the ratio of the concentration of metal in the sorbent and the one in the solution at equilibrium. It was calculated with Eq. (3).

where C 0 is the initial concentration of solution (mg L−1), C e is the equilibrium concentration (mg L−1), V is the volume of solution (mL), and m is the sorbent mass (g).

The following abbreviations have been used: mustard husk (M), soy bran (S), mustard husk after Cu(II) sorption (Cu-M), mustard husk after Zn(II) sorption (Zn-M), soy bran after Cu(II) sorption (Cu-S), and soy bran after Zn(II) sorption (Zn-S), respectively.

Results and discussion

Effect of contact time on the sorption process

The influence of the contact time on the adsorption process of copper and zinc ions on the two selected sorbents was studied varying the contact time in the range of 0–120 min. All experiments were carried out at a pH of 5 to 6.5 for both the copper and zinc ions at a temperature of 298.15 K and at a concentration of 100 mg L−1.

The results (Fig. 1) showed that the amount of the retained ions increases with increasing contact time and the equilibrium is reached in 60 min after which the sorption remains constant. It was found that the sorption has higher efficiency in the case of zinc ions, when the soy bran was used as sorbent.

Effect of initial concentration on the sorption process

The effect of the initial concentration on the adsorption process of copper and zinc ions were also investigated. These studies were carried out at room temperature. The concentration of copper and zinc ions in solutions range from 25 to 250 mg L−1, while all other parameters were maintained constant (pH 5 and 6.5, the 60-min contact time, 0.03-g sorbent mass).

It was noticed that the sorption process enhances with the increasing concentration of the metal ions to an amount of 100 mg L−1 followed by a decrease in the adsorption process (Fig. 2). This variation could be explained by the fact that with the increasing concentration, the binding centers of sorbent are becoming saturated and no additional ions can be adsorbed. Another explanation could be that in dilute solutions, the metal ions have high mobility and, therefore, their interaction with the sorbent is high. In order to obtain effective removal of metal ions from the wastewater, the dilution of water containing metal ions at higher concentrations is recommended to be carried out prior to the adsorption operation.

Dependence of sorption process on the sorbent mass

An important factor influencing the effectiveness of the adsorption process from an economic point of view is the mass of sorbent to be used. The adsorption is inefficient if it requires a large amount of sorbent. The effect of the sorbent mass variation on the adsorption process was studied at a fixed concentration of 100 mg L−1 metal ion solution and pH of 5.0 (copper) and 6.5 (zinc), and at a temperature of 298.15 K.

Figure 3 shows that with the increase of sorbent mass ranging from 0.0025 to 0.05 g, the percentage of retained metal increases. The explanation could be that a larger mass of sorbent involves a larger number of available active centers on the surface. An increase in the weight of sorbent of more than 0.05 g leads to a decrease in the retention of metal ions.

Özer et al. (1997) have shown that the interaction of the particles at a greater concentration of the sorbent can contribute to the desorption of a part of the metal ions that is weakly bound to the surface of the sorbent. As a result, the removal of a certain amount of solute can be carried out with greater economy of sorbent if the solution is treated separately with low dosages of the sorbent, with filtration between each stage rather than in a single-step treatment with a higher dose.

pH dependence of sorption process

The pH is an important parameter influencing the chemistry of heavy metals in solution, namely: the hydrolysis process, the complexing by organic or inorganic ligands which may be present in solution, redox reactions, and precipitation reactions (Everett 1998). To assess the effect of the pH solution on the sorption process, the experiments were carried out over a range of pH between 2 and 7. In the case of copper ions at a pH greater than 5, and 6.5 for zinc, respectively, they start to precipitate, which makes it impossible to study the sorption process. Therefore, at such pH values of the removal of these ions, both processes by precipitation process as well as by adsorption could be carried out.

Ajjabi and Chouba (2009) denotes that the possible centers on these sorbents that could be responsible for the sorption include H+ ions from C6H5–OH and –COOH functional groups. These ions could be exchanged with the metallic ions in aqueous solutions:

where S means sorbent surface.

The decreased amount of the retained metal ion at the pH values greater than 5 and 6.5 may be due to the formation of anionic hydroxide complexes. Similar results were obtained using some species of peat (Ho and McKay 2004) and active carbon obtained from olive and peach stones (Alslaili et al. 2014; Ferro-Garcia et al. 1988).

At pH values lower that pH 5 and 6.5, the decreased removal efficiency may be due to the higher mobility of the H+ compared with that of metal ions. On the other hand, at pH values higher than pH 5 and 6.5, respectively, metal ions precipitate and sorption studies could not be performed (Mouni et al. 2010; Romera et al. 2007) (Fig. 4).

Effect of temperature on sorption process

The effect of temperature on the adsorption process of the two types of ions on the two selected sorbents was investigated at a chosen temperature range of 298.15–318.15 K and other parameters being kept constant, and the results are shown in Fig. 5.

The increasing percentage of adsorbed metal, when the temperature rises, indicates the endothermic nature of the process. This variation may be attributed to the increase of the number of active centers available for sorption on the surface of the sorbent or to the decrease of the thickness of the boundary layer surrounding the adsorbent so that the resistance of the adsorbent layer to the mass transfer drops. Also, another explanation could be that, as temperature increases, the diffusion speed of the sorbate molecules along the external layer as well as in the internal pores of the sorbent particles increases, too.

Thermodynamic studies

The thermodynamic parameters such as: the standard free energy (ΔG°), enthalpy (ΔH°), and entropy of the system (ΔS°) were estimated using Eqs. (4) and (5)

where K d is the distribution coefficient calculated with Eq. (3).

In order to determine these thermodynamic parameters, the data obtained from the study of the influence of temperature on adsorption process were used. The values of ΔH° and ΔS° were calculated from the slope and intercept with the ordinate using the representation of ln K d versus 1/T. The obtained results are shown in Table 2.

The positive values obtained for ΔH° and ΔS° indicates the affinity sorbents for the two metal ions and the fact that the adsorption process is an endothermic one. The negative values of Gibbs energy indicate the spontaneity of the adsorption process.

Adsorption isotherms

The adsorption isotherms are important in understanding the mechanism of adsorption process, the interaction between sorbent and sorbate. In order to study the adsorption of copper and zinc ions on the two types of sorbents, Langmuir and Freundlich models were used.

The Langmuir adsorption isotherm characterizes a monolayer adsorption on a surface with a finite number of identical centers that are distributed homogeneously on the surface of the sorbent. In the present studies the linearized Langmuir isotherm was applied:

where q e is the amount of adsorbed metal per sorbent unit (mg g−1), C e is the metal ion concentration at equilibrium (mg L−1), q m is the parameter that denotes the maximum adsorption capacity (mg g−1), and K L is constantly referring to the adsorption energy (g L−1). K L and q m values were calculated from the intercept and the slope of the straight line obtained by plotting C e/q e versus C e (Fig. 6).

Langmuir isotherm characteristics can be expressed as a dimensionless constant named equilibrium parameter or separation factor (Weber and Chakkravorti 1974):

K L is the Langmuir constant and C 0 is the initial concentration of metal ions (mg L−1). For a favorable adsorption, the R L value must be between 0 and 1. In this sense, if R L > 1, adsorption is unfavorable; if R L = 1, adsorption is favorable; and if R L = 0, adsorption is irreversible. In our studies, R L obtained values were less than 1 (Table 2) which shows that the adsorption process was favorable.

Freundlich isotherm is another mathematical model widely used to describe the adsorption process of the metal ions from the solution on the solid surface. This model describes a heterogeneous surface adsorption. The linearized form was used for the model given by Eq. (8):

where q e is the equilibrium adsorption capacity (mg g−1), C e is the concentration of the metal ion in solution at equilibrium (mg L−1), K F (mg(1−1/n) L1/n g−1/n), and 1/n are the constants that relate the Freundlich adsorption capacity of the sorbent and the adsorption intensity, respectively.

The 1/n and K F values can be calculated from the slope and intercept of the linear representation of log q e versus C e (Fig. 7) and are presented in Table 3. The subunit values obtained for 1/n indicates a favorable sorption process. The obtained results indicate the fact that the adsorption capacity of the soy bran is higher than of the mustard husk.

In order to establish the efficiency of the sorbents, a comparison with the results from the literature for other sorbents was performed, and the results are presented in Table 4. The adsorption capacity of the investigated sorbents for the copper is higher as in the case of some other sorbents and its low cost and abundance make them as possible materials for the use in residual waters depollution.

The images shown in Fig. 8 represent the aspect of sorbent samples before and after sorption processes with enlargement of ×2500, scale 40 μm. For the analysis, we used electronic beam accelerating voltage of 20 kV.

Both soy bran and mustard husk have a granular structure. It can be noticed also that the presence of an amorphous matrix was slightly visible in soy bran sample. Samples Cu-S and Cu-M present a granular structure in a fibrillar matrix more visible in amorphous sample Cu-M. Pellets from samples Cu-S and Cu-M are lower than those observed in samples S and M (before the sorption process). Samples Zn-S and Zn-M present a completely different structure—more compact—fibers or pellets are not present.

Desorption of the retained ions

The desorption processes are important from two points of view: first, to recover the metal ion and its subsequent use in industrial field and, secondly, the reuse of the regenerated sorbent. The desorption was carried out using the static system by immersing the sorbent after sorption in different eluent solutions (EDTA, HNO3 and NaHCO3 0.1 M solutions) for 24 h with stirring at 250 rpm.

The metal ion concentration in the supernatant was determined using the AAS method. The percentage of desorbed metal ion was calculated using the following equation:

where amountdes represents the amount of desorbed metal ion and amountads is the amount of the retained metal ion. The obtained results are presented in Table 5.

Generally, if the adsorbed ions could be desorbed using distilled water, the binding of the sorbent and metal ions are established through weak links. If it is carried out with acid or alkaline solutions, the sorption is done through ion exchange adsorption. The desorption results are an indication that most of Cu(II) and Zn(II) ions are retained on sorbent surface through chemisorption or ion exchange type of binding. The results show that the sorption process is reversible and also, there is the possibility to reuse chosen sorbents taking into account the high recovery level of both cations.

Conclusions

The results obtained in this study established the possible use of mustard husk and soy bran as sorbents for Cu (II) and Zn(II) ions from aqueous solutions. The positive value of enthalpy (ΔH°) confirmed the endothermic nature of the sorption interaction while the negative value of free energy (ΔG°) indicated the possibility and the spontaneous nature for the sorption of copper and zinc ions onto investigated sorbents.

The sorption of Cu(II) and Zn(II) onto mustard husk and soy bran was fitted well with Langmuir isotherm. The obtained results demonstrate that mustard husk and soy bran are promising sorbents for the removal of copper and zinc ions from residual waters.

References

Ajjabi, L. C., & Chouba, L. (2009). Biosorption of Cu2+ and Zn2+ from aqueous solutions by dried marine green macroalga Chaetomorpha linum. Journal of Environmental Management, 90, 3485–3489.

Aksu, Z., & Isoglu, I. A. (2005). Removal of copper(II) ions from aqueous solution by biosorption onto agricultural waste sugar beet pulp. Process Biochemistry, 40, 3031–3044.

Alslaili, T. M., Abustan, I., Ahmad, M. A., & Foul, A. A. (2014). Kinetics and equilibrium adsorption of iron (II), lead (II), and copper(II) onto activated carbon prepared from olive stone waste. Desalination and Water Treatment, 52, 7887–7897.

Babel, S., & Kurniawan, T. A. (2003). Low-cost adsorbents for heavy metals uptake from contaminated water: a review. Journal of Hazardous Materials, 97, 219–243.

Banu, I. (2008). Potential of maize cobs for removal Zn(II) and Ni(II) in aqueous system. Revista de Chimie Bucharest, 59, 1375–1377.

Bojic, A. L., Bojic, D., & Andjelkovic, T. (2009). Removal of Cu2+ and Zn2+ from model wastewaters by spontaneous reduction-coagulation process in flow conditions. Journal of Hazardous Materials, 168, 813–819.

Bratskaya, S. Y., Pestov, A. V., Yatluk, Y. G., & Avramenko, V. A. (2009). Heavy metals removal by flocculation/precipitation using N-(2-carboxyethyl)chitosans. Colloid Surface, 339, 140–144.

Brown, P., Atly Jefcoat, I., Parrish, D., Gill, S., & Graham, E. (2000). Evaluation of the adsorptive capacity of peanut hull pellets for heavy metals in solution. Advances in Environmental Research, 4, 19–29.

Chan, B. K. C., & Dudeney, A. W. L. (2008). Reverse osmosis removal of arsenic residues from bioleaching of refractory gold concentrates. Minerals Engineering, 21, 272–278.

Cséfalvay, E., Pauer, V., & Mizsey, P. (2009). Recovery of copper from process waters by nanofiltration and reverse osmosis. Desalination, 240, 132–142.

Das, Nilanjana, Karthika, P., Vimala, R., Vinodhini, V. (2008). Use of natural products as biosorbent of heavy metals. An overview. Natural Product Radiance, 7, 133–138.

Deans, J. R., & Dixon, B. G. (1992). Uptake of Pb2+ and Cu2+ by novel biopolymers. Water Research, 26, 469–472.

Doula, M. K. (2009). Simultaneous removal of Cu, Mn and Zn from drinking water with the use of clinoptilolite and its Fe-modified form. Water Research, 43, 3659–3672.

Everett, A. J. (1998). Adsorption of metals by geomedia. California: Academic.

Ferro-Garcia, M. A., Rivera-Ultrilla, J., Rodriguez-Gordillo, J., & Bautista-Toledo, I. (1988). Adsorption of zinc, cadmium and copper on activated carbons obtained from agricultural by-products. Carbon, 26, 363–373.

Ho, Y. S., & McKay, G. (2004). Sorption of copper (II) from aqueous solution by peat. Water, Air, and Soil Pollution, 158, 77–97.

Huisman, J. L., Schouten, G., & Schultz, C. (2006). Biologically produced sulphide for purification of process streams, effluent treatment and recovery of metals in the metal and mining industry. Hydrometallurgy, 83, 106–113.

Inglezakis, V. J., Stylianou, M. A., Gkantzou, D., & Loizidou, M. D. (2007). Removal of Pb(II) from aqueous solutions by using clinoptilolite and bentonite as adsorbents. Desalination, 210, 248–256.

Jai, P. H., Wook, J. S., Kyu, Y. J., Gil, K. B., & Mok, L. S. (2007). Removal of heavy metals using waste eggshell. Journal of Environmental Science, 19, 1436–1441.

Kim, H. J., Baek, K., Kim, B. K., & Yang, J. W. (2005). Humic substance-enhanced ultrafiltration for removal of cobalt. Journal of Hazardous Materials, 122, 31–36.

Korus, I., & Loska, K. (2009). Removal of Cr(III) and Cr(VI) ions from aqueous solutions by means of polyelectrolyte-enhanced ultrafiltration. Desalination, 247, 390–395.

Landaburu-Aguirre, J., García, V., Pongrácz, E., & Keiski, R. L. (2009). The removal of zinc from synthetic wastewaters by micellar-enhanced ultrafiltration: statistical design of experiments. Desalination, 240, 262–269.

Larous, S., Meniai, A. H., & Lehocine, M. B. (2005). Experimental study of the removal of copper from aqueous solutions by adsorption using sawdust. Desalination, 18, 483–490.

Lee, S. H., & Yang, J. W. (1997). Removal of copper in aqueous solution by apple wastes. Separation Science Technology, 32, 1371–1387.

Mata, Y. N., Blázquez, M. L., Ballester, A., González, F., & Muñoz, J. A. (2009). Sugar-beet pulp pectin gels as biosorbent for heavy metals: preparation and determination of biosorption and desorption characteristics. Chemical Engineering Journal, 150, 289–301.

Moore, J., & Ramamoorthy, S. (1984). Heavy metals in natural waters: applied monitoring and impact assessment. New York: Springer.

Mouni, L., Merabet, D., Bouzaza, K., & Belkhiri, L. (2010). Removal of Pb2+ and Zn2+ from aqueous solutions by activated carbon prepared from Dates stones. Desalination and Water Treatment, 16, 66–73.

Oliveira, L.S., Franca, A.S. (2008). Low-cost adsorbents from agri-food wastes. Food Science and Technology New Research, 171–209.

Özer, A., Ekiz, H. I., Özer, D., Kutsal, T., & Çaglar, A. (1997). A staged purification process to remove heavy metal ions from wastewater using R. arrhizus. Process Biochemistry, 32, 319–326.

Ozsoy, H. D., & Kumbur, H. (2006). Adsorption of Cu(II) ions on cotton boll. Journal of Hazardous Materials, 136, 911–916.

Romera, E., Gonzalez, F., Ballester, A., Blazquez, M. L., & Munoz, J. A. (2007). Comparative study of biosorption of heavy metals using different types of algae. Bioresource Technology, 98, 3344–3353.

Tunali, S., Akar, T., Ozcan, A. S., Kiran, I., & Ozcan, A. (2006). Equilibrium and kinetics of biosorption of lead(II) from aqueous solutions by Cephalosporium aphidicola. Separation Purification Technology, 47, 105–112.

Wang, X., & Qin, Y. (2005). Equilibrium sorption isotherms for of Cu2+ on rice bran. Process Biochemistry, 40, 677–680.

Weber, T. W., & Chakkravorti, R. K. (1974). Pore and solid diffusion models for fixed-bed. AIChE Journal, 20, 228–232.

Acknowledgments

One of the authors (D. Humelnicu) would like to thank Dr. Mirela Suchea for her help in the SEM images discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Humelnicu, D., Ignat, M. & Doroftei, F. Agricultural by-products as low-cost sorbents for the removal of heavy metals from dilute wastewaters. Environ Monit Assess 187, 222 (2015). https://doi.org/10.1007/s10661-015-4454-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10661-015-4454-1