Abstract

This study evaluated the filtration of engineered nanoparticles of fullerene and copper oxide (CuO) from water by using surface-modified microsized filters. The surfaces of microsized filters of cellulose acetate and glass fibers were coated with cationic and anionic surfactants to give them positively and negatively charged surfaces, respectively. Uncoated microfilters removed 30 % of a fullerene suspension, while no nanosized CuO suspension was removed. Cationic surfactant-coated filters enhanced the removal efficiency up to 70 % for the fullerene suspension, while the anionic surfactant-coated filters could not remove fullerene at all. The positively charged filters with cationic surfactant coating could easily adsorb negatively charged fullerenes on their surfaces. However, none of the surfactant-coated filters removed the CuO nanoparticles because the nanoparticles were not affected by the electrical charge of the filtration medium. The Hamaker constants of nanoparticles interacting with the filter materials in water were calculated to study these interactions. The Hamaker constant of fullerene interacting with cellulose acetate in water, 4.68E − 21 J, was higher than that of interacting with quartz in water, 2.59E − 21 J. However, the Hamaker constants of CuO interacting with quartz and cellulose acetate in water were both negative values, implying repulsive van der Waals interactions. The curves of potential energy of interaction between nanoparticles and the various filter media implied that the nanoparticles were very stable in water, and so, natural deposition of nanoparticles on the filters would not occur. Therefore, electrical bonding and hydrophobic interactions were the forces dominating fullerene removal by positively charged filters.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

A nanoparticle is normally defined as a particle having a diameter less than 100 nm. Artificial nanomaterials are normally called engineered nanomaterials to differentiate them from naturally occurring nanomaterials. Among engineered nanomaterials are fullerene, fullerol, single- and multi-walled nanotubes, quantum dots, and nanosized metal oxides. Nanoparticles can be released from nanomaterials. Manufacture and use of products based on nanotechnology have rapidly increased, and that has resulted in the continuous release of nanoparticles into the environment during the use of such products and upon their disposal.

Nanoparticles released from such products enter soil, air, and surface water and may affect both the human health and the ecosystem. One way humans are possibly exposed to such particles is by drinking water taken from surface water or groundwater. It is expected that nanoparticles pass through the traditional drinking water treatment processes. Environmental effects and the subsequent fates of nanoparticles are easily found in recent literature. However, only a few studies on recovery and removal of nanoparticles have been conducted, a majority of which are related to nanoparticle removal from the air stream. In addition, only a few studies on the removal of nanoparticles from the water can be found in literature. This study investigates the removal of engineered nanoparticles from water using microsized filters.

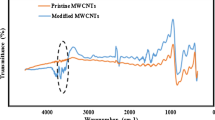

Holbrook et al. (2010) studied coagulation of nanoparticles during drinking water treatment processes. The average removal efficiency of multi-walled carbon nanotubes (MWCNTs) by a coagulation process on drinking water is 50 %. Zhang et al. (2008) also evaluated removal of nanoparticles through coagulation. They achieved a maximum of 80 % removal of quantum dots from water using an optimal alum dose. Kang and Shah (1997) investigated filtration efficiency of anionic nanoparticles through microporous filters. They increased the filtration efficiency of anionic nanoparticles from 10 to 95 % by coating the filters with a cationic surfactant, dimethyldioctadecylammonium bromide (DDAB). Lin et al. (2007) developed an electrical cross-flow filtration system to remove 60 % of nanosized aluminum oxide and silicon dioxide from an aqueous solution. Jassby et al. (2010) recently investigated filtration of fullerene nanoparticles by using a nanosized ceramic membrane. Hwang et al. (2012) practically used iron nanoparticles and membrane for recovery of ammonium salt from nitrate-containing water.

Studies on the interaction between surfactants and nanoparticles have shown that surfactants attach well to nanoparticle surfaces. Yang et al. (2010) investigated adsorption of a surfactant on the surface of a single-walled carbon nanotube (SWCNT) and also the surfactant’s effect on naphthalene adsorption on the SWCNT surface. They revealed that a cationic surfactant, cetylpyridinium chloride (CPC), competed with naphthalene to attach to the SWCNT surface. Similarly, other research showed that anionic surfactants coated on nanoparticles also affected adsorption of organic substances dissolved in water on a nanoparticle surface (Carrillo-Carrión et al. 2007).

The purpose of this study was to evaluate the possibility of nanoparticle filtration by surfactant-coated filters. This study first evaluated the filtration of fullerene and copper oxide nanoparticles through surfactant-coated microsized filters. No study of filtration of widely used nanoparticles by surfactant-coated filters has been done, although size-defined nanoparticles were used in an earlier study. The ultimate goal of this study was to suggest an economical filtering method to remove nanoparticles from water by using a less expensive filter and a surfactant. Furthermore, a less toxic surfactant would be suggested for coating the filter. This study evaluated a glass fiber filter and starch-based surfactant for a less expensive and less toxic filtration method to remove nanoparticles from water. The glass fiber filter was 20 % less expensive than a polypropylene filter, and the starch-based surfactant was less expensive and less toxic than DDAB. This study used widely known nanomaterials, fullerene and nanosized copper oxide.

Materials and methods

Surfactants used

This study used four different cationic surfactants and two anionic surfactants. The surfactants are shown in Table 1. The cationic surfactants used in this study were DDAB, CPC, cationic starch (CA-ST), and methyl triethanol ammonium methyl sulfate distearyl ester (CEQ90), while the anionic surfactants were sodium dodecyl sulfate (SDS) and alpha olefin sulfonate (AOS). DDAB and CPC were purchased from Sigma-Aldrich Co. CA-ST was obtained from Woojin Ind. Co., Korea. CEQ90 was obtained from Sunjin Chemical Co., Korea. AOS was obtained from Aekyung Chemical Co., Korea, and SDS was purchased from Junsei Chemical Co., Japan.

Filters used

Two different types of filters were used in this study. A cellulose acetate membrane filter and a glass fiber filter were used as shown in Table 2. The cellulose acetate membrane filter was purchased from Advantec Inc., and the glass fiber filter was purchased from Whatman Ltd. Pore sizes of the filters were 0.8 and 1.2 μm, respectively. Diameters of round-shaped filters used for this study were all 47 mm.

Surfactant-coated filters were prepared by placing a filter in 10-mM surfactant solution for 3 h and drying for 24 h at 30 °C after removal from the solution. The final steps were a 30-mL distilled water rinse and ambient drying.

Nanoparticle preparation

Copper oxide (CuO) nanopowder was purchased from Sigma-Aldrich. CuO nanopowder was placed in distilled water and sonicated for 24 h with a Sonics VCX500 ultrasonic processor. The CuO nanoparticle solution was then filtered through a 0.45 μm Nylon membrane filter to produce the suspensions of CuO nanoparticles in water for this study. The concentration of the CuO nanoparticle suspension was determined as 2.7 mg/L by using atomic absorption spectrophotometry (AAS) with acid-digestion pretreatment.

Fullerene-C60 was purchased from Sigma-Aldrich. Fullerene powder was placed in tetrahydrofuran. The powder solution was aerated with nitrogen gas for 30 min and then mixed for 24 h by a magnetic stirrer. After a 24-h settlement period, the solution was filtered through a 1.2-μm glass fiber filter. The filtered solution was placed in a rotary evaporator and evaporated while adding distilled water at a rate of 500 mL/min. These procedures, evaporation of solvent and replacing with water, were repeated three times to generate approximately 250 ml of solution in the evaporator. The solution in the evaporator was recovered and filtered again through a 0.45-μm Nylon membrane filter to produce the suspensions of fullerene nanoparticles in water for this study. The concentration of the fullerene suspension was determined as 7.2 mg/L total organic carbon (TOC) by TOC measurement.

Filtration procedure

A filtration apparatus consisting of a PYREX glass graduated funnel for use with a 47-mm microfiltration glass assembly with a fritted glass support base was used for this study. The prepared nanoparticle suspensions, 250 mL each, were filtered through uncoated or surfactant-coated filters that were already placed in the filtration apparatus. Filtrate concentrations of CuO nanoparticle suspensions were measured using AAS after acid digestion. Filtrate concentrations of fullerene nanoparticles were quantified by measuring the ultraviolet (UV) light absorbance of the filtrate using a UV spectrophotometer (Optizen 2120 UV, Mecasys Co., Ltd.). All experiments in this study were replicated.

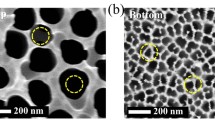

Particle size and zeta potential measurements

The size distribution of nanoparticles was measured using photon cross-correlation spectroscopy (NANOPHOX, Sympatec GmbH). Particle size distributions of fullerene and nano-CuO suspensions in water are shown in Fig. 1. Mean diameters of fullerene and CuO nanoparticle suspensions were 142 and 154 nm, respectively. The size distribution of fullerene nanoparticles was relatively wider than that of CuO nanoparticles.

The zeta potential of nanoparticles was measured using a zeta potential analyzer (ELS-6000, Otsuka Inc., Japan), while the zeta potential of surfactant-coated filters was measured using a different zeta potential analyzer (ELS-Z, Otsuka Inc., Japan). The zeta potential of CuO nanoparticles was 8.2 mV, and that of fullerene nanoparticles was −24.4 mV. This study found that the zero-charge point of CuO nanoparticles was pH 7.0 (data not shown here), while fullerene always showed negative zeta potential values regardless of pH. Figure 2 shows the zeta potential measurement results of surfactant-coated and non-coated filters. The cellulose acetate filter and the glass fiber filter showed negative zeta potential values. The negative zeta potential value of the glass fiber filter was higher than that of the cellulose acetate filter. The zeta potential measurement results clearly showed that the surface charge of cationic surfactant-coated filters were all positive, while those of the anionic surfactant-coated filters were all negatively charged.

Zeta potential measurement values of surfactant-coated and non-coated filters. Cellulose (0.8) indicates a cellulose filter having a pore size of 0.8 μm. GF/C (1.2) indicates a glass fiber filter having a pore size of 1.2 μm. Full names of abbreviated surfactant are described in Table 1

Results and discussion

Filtration efficiency of filters for nanoparticles

Figure 3 shows the filtration efficiencies of the surfactant-coated and non-coated filters for the fullerene suspension. The filtration results show that the cellulose acetate and glass fiber filters removed approximately 30 % of the fullerene suspension. Figure 3 clearly shows that cationic surfactant-coated filters removed about 70 % of the fullerene suspension, while the anionic surfactant-coated filters could not remove any fullerene. As already shown in Fig. 2, all cationic surfactant-coated filters showed positive zeta potential values. The positively charged filters with cationic surfactant coatings could easily adsorb negatively charged fullerenes on their surfaces. However, negatively charged filters with coated with anionic surfactants apparently repelled negatively charged fullerenes.

Pore diameters of the cellulose acetate filter and the glass fiber filter were 800 and 1,200 nm, respectively. As shown in Fig. 1, the sizes of fullerene and CuO nanoparticles were 78–266 and 111–230 nm, respectively. All nanoparticles used in this study were expected to penetrate those filters because the pore diameters were significantly larger than the nanoparticles. Thus, the removal of fullerene as shown in Fig. 3 was attributed to attachment of the negatively charged nanoparticles to the surface of the positively charged filters.

Upon repeated experiments, fullerene filtration results of non-coated filters were relatively similar to each other and showed little variance. However, surfactant-coated filters showed wide variations in removal results, implying that surfactant coating was not consistent every time. Also, the surfactant coatings were not homogeneous on the filters. The mechanism for fullerene removal by the non-coated filter seemed to progress by fullerene particles first placed on the filter attracting other fullerene particles to them. It is known that fullerene is very hydrophobic.

Figure 4 shows the filtration efficiency of the surfactant-coated filter and non-coated filter for the CuO nanoparticle suspension. The filtration results show that the cellulose acetate filter and glass fiber filter could not remove the CuO particles. Furthermore, surfactant-coated filters also were unable to remove the CuO particles. As mentioned earlier, the zeta potential of the CuO particles was 8.2 mV, which is close to zero charge. This implies that CuO nanoparticles were not affected by the electrical charge of the filtration medium.

Interactions between nanoparticles and filter medium

In this investigation, nanoparticles suspended in water are interacting with filters. The Hamaker constants of nanoparticles interacting with the filter material in water were calculated to study their interactions. The Hamaker constant is a key parameter to describe van der Waals forces between two surfaces. The overall Hamaker constant for nanoparticles (p) interacting with a surface of composition (s) in the water (w), A pws , can be obtained by aggregating the Hamaker constants of the homogeneous materials (Petosa et al. 2010; Ma et al. 2010):

Table 3 shows the Hamaker constants of interacting systems used in this study. The Hamaker constant of cellulose acetate was calculated from the Lifshitz-van der Waals component of the surface tension, 44.9 mJ/m2 (van Oss 2006). The Hamaker constant values for which references are not given in Table 3 were all calculated in this study.

The Hamaker constant of fullerene interacting with cellulose acetate in water, 4.68E − 21 J, was higher than that of quartz, 2.59E − 21 J. The values imply that fullerene was a little more attracted to the cellulose acetate filter than the glass filter. As already shown in Fig. 3, the cellulose acetate filter removed slightly more fullerene from the water than the glass fiber filter. The Hamaker constants of CuO interacting with quartz and cellulose acetate in water were all negative values. Negative Hamaker constants indicate a repulsive van der Waals interaction (Bergstrom 1997). As already shown in Fig. 4, CuO nanoparticles were not retained on either the cellulose acetate or the glass fiber filters. This suggests that there was no attractive van der Waals force between the surfaces of the nano-CuO particles and the filters.

The stability of nanoparticles suspended in water is also described by the classical Derjaguin−Landau−Verwey−Overbeek (DLVO) theory (Petosa et al. 2010). Deposition of nanoparticles on the collector surface can be also evaluated by the total interaction energy, that is, the sum of the van der Waals and electrical double-layer interactions. The electrical double-layer interaction energy between the nanoparticles and the plate surface (V EDL ) is expressed as

where ε 0 is the dielectric permittivity of vacuum (8.85E − 12 C2/J m), ε r is the relative dielectric permittivity of water (78.54 at 25 °C), a p is the particle radius, k B is the Boltzmann constant (1.38E − 23 J/K), T is the absolute temperature, z is the counterion valence, e is the electron charge (1.6E − 19 C), Γ is the dimensionless surface potential for particle or collector, κ is the inverse Debye length, and h is the separation distance. Γ is the dimensionless surface potential for particle or collector and is a function of the surface potential of the nanoparticles or the filter material. The surface potential values of the nanoparticles and the filter surface were estimated by the Nernst equation (Hiemenz and Rajagopalan 1997). The van der Waals interaction energy between the nanoparticles and the plate surface (V VDW ) are expressed as

where λ is the characteristic length.

Figure 5 shows interaction energies as a function of distance between nanoparticles and uncoated filters. For interaction between nanoparticles and filters, the electrical double-layer interaction energy was significantly larger than the van der Waals interaction energy. The attractive van der Waals interaction energies were negligible, and the repulsive forces were dominant in the nanoparticle filter system. The potential energy curves imply that the nanoparticles were very stable in the water, and natural deposition of nanoparticles on the filters would not occur. Therefore, the interaction force analysis explains the penetration of CuO nanoparticles through filters.

Removal of fullerene by cationic surfactant-coated filters can be explained by electrical bonding between positively charged filters and negatively charged fullerene. Furthermore, the hydrophobic interaction acted between the fullerene and surfactant coated filters. Fullerene is hydrophobic (Ma et al. 2010). Surfactants also have hydrophobic components. It is known that the hydrophobic interaction force is much stronger than the van der Waals force (Elimelech et al. 1995). Therefore, although fullerene displayed repulsive interactions with filter surface, electrical bonding and hydrophobic interactions were the dominant forces for fullerene removal by positively charged filters.

Effect of nanoparticle suspension concentration on filtration efficiency

Figures 3 and 4 show that fullerene was retained by the positively charged microsized filter, while CuO nanoparticles were not removed by any filters. Note that the suspension concentration of fullerene (2.5 mg/L as TOC) and CuO nanoparticles (2.7 mg/L) used in the experiments were similar. It is well known that suspension concentration affects filtration efficiency (Tian et al. 2013). This study also evaluated filtration of fullerene under a higher suspension concentration (7.2 mg/L as TOC) and filtration of a CuO nanoparticle suspension under a lower concentration (1.0 mg/L).

Figure 6 shows the effect of fullerene suspension concentration on filtration efficiency of surfactant-coated filters. Two different fullerene concentrations, 2.5 and 7.5 mg/L, were evaluated. In non-coated filters, fullerene removal efficiency was reduced as fullerene concentration increased from 2.5 to 7.5 mg/L. For four cationic surfactant-coated filters, the fullerene removal of two filters, DDAB and CPC coated, were reduced as the fullerene concentration increased, while those of two other filters, CA-ST and CEQ-90 coated, were increased as the fullerene concentration increased. The results show again that cationic surfactant-coated filters were able to remove fullerene regardless of fullerene concentration, and anionic surfactant-coated filters were unable to remove fullerene from the water.

Figure 7 shows that effect of CuO nanoparticle suspension concentration on filtration efficiency of the surfactant-coated filters. Two different fullerene concentrations, 1.0 and 2.7 mg/L, were evaluated. Lower CuO nanoparticle concentration, 1.0 mg/L, was evaluated because no filters removed CuO nanoparticles at the 2.7 mg/L concentration. The CuO nanoparticle concentration did not show significant differences in filtration efficiency between non-coated and surfactant-coated filters. This result confirms that CuO nanoparticles could not be removed by either cationic surfactant-coated or anionic surfactant-coated filters.

This study used four different cationic surfactants to modify the surface of microsized filters. The filtration results of the four cationic surfactants showed similar fullerene removal efficiencies. Potential health effects of the surfactants are a future consideration for development of a nanoparticle removal system. No adverse health effects from exposure to cationic starch are known to exist. Cationic starch is a promising surface modifier for further development of a nanoparticle removal system.

Conclusions

This study evaluated the filtration of engineered nanoparticles, fullerene and copper oxide, from water by using surface-modified microfilters, since nanoparticles would otherwise be expected to penetrate the micron-sized pores. This study obtained the following conclusions from filtration results of nanoparticles by non-coated filters and surfactant-coated filters. Cationic and anionic surfactants were used for coating the surface of the microsized filters.

In general, microsized filters cannot remove nanoparticles. The various microfilters in this study removed some of the fullerene nanoparticles, while CuO nanoparticles were not removed at all. The cationic surfactant-coated filters enhanced the removal efficiency up to 70 % for the fullerene suspension, while the anionic surfactant-coated filters could not remove fullerene. The zeta potential measurement results clearly showed that the surface charges of cationic surfactant-coated filters were all positive, and the surfaces of fullerene nanoparticles were negatively charged. The positively charged filters with cationic surfactant coatings could easily adsorb negatively charged fullerenes on their surfaces. However, the surfactant-coated filters were unable to remove the nano-CuO particles. CuO nanoparticles were not affected by the electrical charge of the filtration medium.

The Hamaker constant of fullerene interacting with cellulose acetate in water, 4.68E − 21 J, was higher than that of quartz, 2.59E − 21 J. This implied that fullerene was a little more attracted to the cellulose acetate filter than the glass filter. However, the Hamaker constants of CuO interacting with quartz and cellulose acetate in water were both negative values, implying repulsive van der Waals interactions. The interaction potential energy curves implied that the nanoparticles were very stable in water, and natural deposition of nanoparticles on the filters would not occur. Therefore, electrical bonding and hydrophobic interactions were the dominant forces for fullerene removal by positively charged filters.

References

Bergstrom, L. (1997). Hamaker constants of inorganic materials. Advances in Colloid and Interface Science, 70, 125–169.

Carrillo-Carrión, C., Lucena, R., Cárdenas, S., & Valcárcel, M. (2007). Surfactant-coated carbon nanotubes as pseudophases in liquid-liquid extraction. Analyst, 132, 551–559.

Elimelech, M., Gregory, J., Jia, X., & Williams, R. A. (1995). Particle deposition and aggregation: measurement, modelling and simulation. MA, USA: Butterworth-Heineman.

Hiemenz, P. C., & Rajagopalan, R. (1997). Principles of colloid and surface chemistry. New York: Marcel Dekker, Inc.

Holbrook, R. D., Kline, C. N., & Filliben, J. J. (2010). Impact of source water quality on multiwall carbon nanotube coagulation. Environmental Science and Technology, 44, 1386–1391. doi:10.1021/es902946j.

Hwang, Y., Kim, D., Ahn, Y. T., Moon, C. M., & Shin, H. S. (2012). Recovery of ammonium salt from nitrate-containing water by iron nanoparticles and membrane contactor. Environmental Engineering Research, 17, 111–116. doi:10.4491/eer.2012.17.2.111.

Jassby, D., Chae, S. R., Hendren, Z., & Wiesner, M. (2010). Membrane filtration of fullerene nanoparticle suspensions: effects of derivatization, pressure, electrolyte species and concentration. Journal of Colloid and Interface Science, 346, 296–302.

Kang, P. K., & Shah, D. O. (1997). Filtration of nanoparticles with dimethyldioctadecylammonium bromide treated microporous polypropylene filters. Langmuir, 13, 1820–1826.

Kim, S., Lee, K. S., Zachariah, M. R., & Lee, D. (2010). Three-dimensional off-lattice Monte Carlo simulations on a direct relation between experimental process parameters and fractal dimension of colloidal aggregates. Journal of Colloid and Interface Science, 344, 353–361. doi:10.1016/j.jcis.2010.01.008.

Lin, Y. T., Sung, M., Sanders, P. F., Marinucci, A., & Huang, C. P. (2007). Separation of nano-sized colloidal particles using cross-flow electro-filtration. Separation and Purification Technology, 58, 138–147.

Ma, X., Wigington, B., & Bouchard, D. (2010). Fullerene C60: surface energy and interfacial interactions in aqueous systems. Langmuir, 26, 11886–11893. doi:10.1021/la101109h.

Petosa, A. R., Jaisi, D. P., Quevedo, I. R., Elimelech, M., & Tufenkji, N. (2010). Aggregation and deposition of engineered nanomaterials in aquatic environments: role of physicochemical interactions. Environmental Science and Technology, 44, 6532–6549.

Tian, J. Y., Ernst, M., Cui, F., & Jekel, M. (2013). Effect of particle size and concentration on the synergistic UF membrane fouling by particles and NOM fractions. Journal of Membrane Science, 446, 1–9.

Van Oss, C. J. (2006). Interfacial forces in aqueous media. Boca Raton: CRC Press.

Yang, K., Jing, Q., Wu, W., Zhu, L., & Xing, B. (2010). Adsorption and conformation of a cationic surfactant on single-walled carbon nanotubes and their influence on naphthalene sorption. Environmental Science and Technology, 44, 681–687. doi:10.1021/es902173v.

Zhang, Y., Chen, Y., Westerhoff, P., & Crittenden, J. C. (2008). Stability and removal of water soluble CdTe quantum dots in water. Environmental Science and Technology, 42, 321–325.

Acknowledgments

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2010-0007799).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jeong, SW., Kim, H. Filtration of fullerene and copper oxide nanoparticles using surface-modified microfilters. Environ Monit Assess 186, 5855–5864 (2014). https://doi.org/10.1007/s10661-014-3824-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10661-014-3824-4