Abstract

Assessing the health risk from lead (Pb) in potable water requires accurate quantification of the Pb concentration. Under worst-case scenarios of highly contaminated water samples, representative of public health concerns, up to 71–98 % of the total Pb was not quantified if water samples were not mixed thoroughly after standard preservation (i.e., addition of 0.15 % (v/v) HNO3). Thorough mixing after standard preservation improved recovery in all samples, but 35–81 % of the total Pb was still un-quantified in some samples. Transfer of samples from one bottle to another also created high errors (40–100 % of the total Pb was un-quantified in transferred samples). Although the United States Environmental Protection Agency’s standard protocol avoids most of these errors, certain methods considered EPA-equivalent allow these errors for regulatory compliance sampling. Moreover, routine monitoring for assessment of human Pb exposure in the USA has no standardized protocols for water sample handling and pre-treatment. Overall, while there is no reason to believe that sample handling and pre-treatment dramatically skew regulatory compliance with the US Pb action level, slight variations from one approved protocol to another may cause Pb-in-water health risks to be significantly underestimated, especially for unusual situations of “worst case” individual exposure to highly contaminated water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

After implementation of modern corrosion control and an action level (AL) of 15 parts per billion (ppb) through the federally mandated EPA Lead and Copper Rule (LCR; United States Environmental Protection Agency (US EPA) 1991), it was believed that lead (Pb) in water had been addressed as a significant human health threat in the USA (CDC 2002). Assessments of a massive Pb contamination incident in Washington, DC tap water during 2001–2004 initially created some speculation that Pb-in-water levels much higher than the AL would be necessary to elevate Pb in children’s blood over the 10 μg/dL level of concern (CDC 2004; Guidotti et al. 2007). However, later and more detailed analysis of the Washington, DC experience revealed correlations between incidence of elevated blood Pb (EBL, ≥10 μg/dL) and the higher Pb in water (Edwards et al. 2009), or presence of Pb service lines (Brown et al. 2010). Brown et al. (2010) also determined that the risk from Pb service lines (and presumably Pb in water) extended to time periods when Washington, DC was meeting the 15 ppb Pb AL. This reinforced concerns (Levin et al. 2008; Edwards et al. 2009) that there is still a significant risk of EBL from potable water sources.

A recent literature review of other epidemiological studies in the USA, the UK, Germany, France, and Canada reaffirmed that Pb in water can be a significant contributor to Pb in blood, especially for infants and children (Triantafyllidou and Edwards 2011a). For example, a study by Galke et al. (2006) determined that the more glasses of tap water consumed by children, the greater the risk of elevated blood Pb in Milwaukee and in New York. Oddly, the actual water Pb levels quantified during that study did not strongly correlate with the risk of elevated blood Pb, whereas the act of drinking tap water did. It is possible that this apparent contradiction in Galke et al. (2006) might be due to a failure of typical sampling protocols to quantify Pb-in-water risks, even when present. This could occur, for example, if in some situations the actual Pb in water was much higher than the level quantified in collected water samples.

There is no current accepted protocol for collection and preparation/pre-treatment of tap water samples for Pb monitoring that is universally followed (Cartier et al. 2011). The interpretation of results when using different protocols for monitoring, coupled with the inherent variability of Pb in water, remain big challenges (Schock and Lemieux 2010; Schock 1990). In general, three categories of protocols can be identified in the US, including: (1) EPA Method 200.8 and 200.9 as supplemented by details in the Federal Register (henceforth termed “EPA standard protocol”), (2) other published methods explicitly deemed acceptable by the EPA, including Palintest Ltd. Method 1001 and Standard Method 3113 B, as supplemented by the Federal Register, and (3) methods developed on an “ad hoc” basis for targeted monitoring or for environmental assessments in homes of at-risk children. Only protocols from categories 1 and 2 can be used for compliance sampling under the EPA LCR, whereas any method can be followed for environmental assessments or targeted monitoring. For each protocol, there are three types of potential deficiencies which can “miss” Pb in water, either alone or in combination:

-

1.

Sampling steps or instructions that fail to introduce the Pb-in-water hazards into the sampling bottle. Pb particulates present in water during normal household use, can be missed during sampling if low water flow rates are used to fill bottles (Triantafyllidou and Edwards 2011a), if plumbing lines have been flushed extensively before sampling (as sometimes instructed by utilities even though EPA instructions do not mention flushing), or if faucet aerators have been cleaned/removed (as is sometimes done even though EPA has officially discouraged the practice) (US EPA 2006; Triantafyllidou and Edwards 2011a). Likewise, only cold water samples are generally collected and analyzed for compliance with the EPA LCR or during environmental monitoring, even though it is believed that hot water sometimes contains much higher Pb and could contribute to EBL (Triantafyllidou and Edwards 2011a).

-

2.

Even if a water sample with high Pb is collected, specific steps of sample preparation/pre-treatment may fail to mobilize the Pb into an aliquot that will then be introduced to an appropriate Pb detector. The concentration of acid preservative added to the sample, the extent of sample mixing after preservation, and sample holding time after preservation and prior to analysis are all specified by the EPA, because they can affect Pb quantification. The only demonstrated limitation in the EPA standard protocol is the effectiveness of acid preservative, which created errors of up to 80 % if certain types of Pb particulates were present, because the acid was not sufficient to dissolve all the Pb and left particulates at the bottom or on the walls of sample containers (Triantafyllidou et al. 2007).

-

3.

Even if a water sample with high Pb is collected and pre-treated appropriately before it is introduced to an analytical detector, Pb is in a form that cannot always be quantified by the specific detector. For example, this could be a serious concern for the newly approved analytical method of Differential Pulse Anodic Stripping Voltammetry (DPASV), which measures dissolved Pb ions (i.e., Pb+2) but was shown to significantly underestimate particulate Pb (i.e., Pb+4) and colloidal Pb (Cartier et al. 2009).

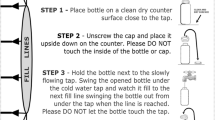

While all three categories of potential deficiencies deserve consideration, this work focuses on type 2 sample preparation techniques for the quantification of “total recoverable Pb” (termed “total Pb” henceforth for simplicity reasons). In relation to type 2 errors, water sample preparation under the federally mandated LCR (Fig. 1) typically involves: (1) Sample shipment to a certified lab after collection at the tap, (2) acidification of sample to pH <2.0 typically by addition of 0.15 % (v/v) concentrated nitric acid (HNO3) which is termed “standard preservation” in this work, (3) minimum holding time of 16 h, (4) turbidity measurement in aliquot, and additional heated acid digestion of an aliquot only if the turbidity is greater than 1 ntu (nephelometric turbidity unit), which is termed “aliquot digestion” henceforth in this work, and (5) analysis using an approved analytical method (either inductively coupled plasma mass spectrometry (ICP-MS) or flame atomic absorption). The EPA has also approved other analytical instruments which may use different sample pre-treatment methods for LCR compliance monitoring (Table 1).

Fig. 1 EPA standard protocol (i.e., sampling and analytical procedures) for total Pb quantification in drinking water samples in the USA, as described in EPA Methods 200.8 (ICP-MS) and 200.9 (STGFAA). A slightly different digestion (not shown) is recommended if the sample contains >1 % undissolved solids. Potential problems are emphasized in bold italics. This figure is a revised version of that published by Triantafyllidou et al. (2007) in Journal AWWA 99:6, and is included herein with permission

Table 1 EPA-approved analytical methods for LCR compliance monitoring of total lead in drinking water samples in the USA as listed in the Federal Register (US EPA 2009), and specific sample pre-treatment requirements for each method (US EPA 1994a, b, 2003; Palintest 1999; APHA 1998) If the Pb in water is dissolved, standard preservation adequately prohibits Pb from adhering to the sampling container at any step of the process (Fig. 1) so that it will be fully quantified. In addition to extensive testing by the authors which showed no problems in detecting dissolved Pb using the EPA standard preservation, Deshommes et al. (2010) found no difference in the measured Pb concentration of water samples, between the standard preservation and a more rigorous heated digestion (1 % (v/v) HNO3 + 0.5 % (v/v) HCl, 85°C) in cases where Pb was predominantly dissolved and did not exceed 32 ppb. Similarly, Lytle et al. (1993) found that standard preservation recovered 100 % of a very fine Pb solder powder which had been deliberately introduced to water samples.

However, if larger Pb particles are present that can settle from solution or adhere to the walls of containers, several problems may arise in quantification and detection (Fig. 1). Such particles have been implicated in childhood Pb poisoning from water and thought to be present after partial Pb service line replacement (Triantafyllidou and Edwards 2011a), or presumably present in actual samples collected by Lytle et al. (1993) for which Pb was noted to rise with increased holding time. These potential problems depend upon the ability of standard preservation to render all the Pb soluble (Fig. 1). It is hypothesized that such problems may be exacerbated when coupled with lack of mixing of samples after standard preservation, the need for which is not explicitly mentioned in one EPA-approved protocol (Table 2). This work aims to examine the role of specific sample preparation steps in the quantification of Pb for worst-case situations; specifically, those in which highly contaminated water could pose a public health risk. Implications for regulatory compliance monitoring are considered as part of that evaluation.

Table 2 Comparison of two EPA-approved sample pre-treatment protocols, for quantification of metals in drinking water in the USA, with emphasis on total lead

Materials and methods

Water sample sources.

Potable water samples exposed to Pb pipe, leaded brass, or leaded solder plumbing were collected from four bench-scale experiments (Zhang et al. 2009; Hu et al. 2010; Triantafyllidou and Edwards 2011b; Nguyen et al. 2010) to examine specific limitations of various sample preparation procedures (Table 3). Collectively, these four sets of water samples represented worst-case extremes with high particulate Pb from all three major sources of Pb contamination (i.e., Pb pipe, Pb solder, and leaded brass) in potable water, and were used in four distinct tests in this work to evaluate specific sample preparation issues (Table 3).

Effect of sample mixing after standard preservation (tests 1 and 2).

For tests 1 and 2, unfiltered water samples were analyzed for total Pb after initial acidification with 0.15 % (v/v) concentrated HNO3 for at least 16 h at room temperature (~20°C), following instructions of standard preservation but without sample mixing (Table 3). For comparison, the samples were subsequently mixed and re-analyzed, as per the mixing specification of the EPA pre-treatment protocol (Table 3). As a final step, the samples were exposed to a very rigorous in-the-bottle digestion (addition of 2 % (v/v) HNO3 at room temperature) to potentially recover a greater fraction of the Pb compared with the standard preservation (Table 3).

Effect of sample transfer between sample bottles before analysis (Tests 3 and 4).

For tests 3 and 4, each unfiltered water sample was first divided into two portions after mixing. One portion remained in the original sampling container, while a second portion was poured into a new container. Each portion received either the same preservation treatment (Test 3) or different treatment in terms of acidification extent or temperature (Test 4), for the same amount of time prior to Pb analysis (Table 3). Unless otherwise stated (e.g., Tests 1 and 2, see Table 3) the samples from Tests 3 and 4 were always vigorously mixed following addition of HNO3.

Analytical methods.

Total Pb after each step of each test was measured in 10-mL sample aliquots with an ICP-MS in accordance with EPA method 200.8 (US EPA 1994a). Prior to analysis for total Pb, all sample aliquots were acidified, if needed, to reach 2 % (v/v) concentrated HNO3. In steps where the standard preservation protocol was followed, the pH of the water was confirmed to be <2.0 with an electrode according to Standard Method 4500-H+ (APHA 1998).

Results and discussion

Effect of sample mixing after standard preservation (Tests 1 and 2).

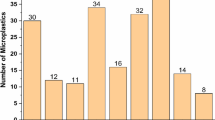

The recovery and quantification of Pb in water was dependent on sample mixing. Specifically, if the sample was not completely mixed immediately after adding 0.15 % acid per unit volume, four representative water samples from Pb pipes (Test 1) were determined to contain 369, 539, 58, and 1,903 ppb Pb after 17-h holding time (Fig. 2, top). When these samples were mixed at 17 h, Pb concentrations increased to 1,336, 13,680, 185, and 20,300 ppb, respectively (Fig. 2, top). Allowing an additional 7 h of holding time did not markedly increase the level of Pb, but when acid concentration was increased to 2 % (v/v), the resulting measurement of total leachable Pb was much higher in two of the four samples (Fig. 2, top). Practically, at least 71 (Pb pipe 3) to 97 % (Pb pipe 2) of the total leachable Pb was “missed” in the unmixed samples preserved with 0.15 % (v/v) HNO3, whereas 6 % (Pb pipe 4) to 81 % (Pb pipe 1) of the Pb was missed if the samples were mixed (Fig. 2, top). In the latter case (Pb pipe 1), standard preservation (0.15 % (v/v) HNO3) was typically not sufficient to dissolve all the Pb even if mixing was undertaken, compared with the more rigorous final acidification (2 % (v/v) HNO3). While the improved performance of stronger acid preservative (i.e., 2 % instead of 0.15 % (v/v) HNO3) needs to be further investigated, it was shown to recover more Pb compared with the standard preservation in some prior work (Triantafyllidou et al. 2007).

In the case of water samples containing particulates derived from Pb solder (Test 2), an even greater impact of sample mixing was apparent. The standard preservation without mixing after 17-h holding time missed 96 (solder 5, 6) to 98 % (solder 1, 2, and 3) of the Pb, when compared with a more rigorous 2 % acid exposure to recover total leachable Pb from the same sample after 65-h holding time (Fig. 2, bottom). In contrast, if standard preservation was conducted with mixing, only 1–5 % of the Pb would be missed, when compared with the total leachable Pb in the same sample (Fig. 2, bottom).

In summary, mixing a sample after adding 0.15 % (v/v) acid preservative greatly reduced (but not completely eliminated) errors in quantifying Pb in this work. Labs and utilities that do not mix samples immediately after standard preservation, as is allowed in one EPA-approved protocol (see Table 2), run the risk of “missing” serious Pb-in-water hazards. This, in theory at least, could allow utilities to comply with the EPA Pb AL when they otherwise would not, or result in under-estimation of human health risks from potable water consumption.

Effect of sample transfer between sample bottles before analysis (Tests 3 and 4).

When following instructions for home water customer sampling issued by a US water utility (Portland Water Bureau 2010) and in some other situations for environmental assessments of Pb-poisoned children, where samples are transferred from bottle to bottle before analysis (exemplar in Fig. 3, top left), relatively large white-colored Pb-containing particulates rapidly settled to the bottom of the original sampling container and were visually observed (Fig. 3, top right). When pouring off a portion of the sample to a smaller bottle, which is typically used for mailing and subsequent analysis (Portland Water Bureau 2010), the Pb particles remained at the bottom of the original container and were not transferred. In the experiments with Pb pipe (Test 3) when the two bottles were preserved and subjected to mixing, the water transferred to the smaller container only contained 58 (Pb pipe 4) to 97 % (Pb pipe 5) of the Pb detected in the original sampling container (Fig. 3, bottom). For these samples, subsequent determination of total leachable Pb even with very strong acid (2 % (v/v) HNO3 after 96 h) did not increase recovery of Pb (data not presented herein).

Illustrative tap water sampling instructions issued to customers of a large US city specify sample transfer to a smaller container for mailing and subsequent Pb quantification, after thorough mixing of original sample (top left). Pb-containing particles from laboratory experiment, which settled at the bottom of original sampling container (Test 3—Pb pipe 5), did not transfer to the smaller container for quantification and would have been discarded under these instructions (top right). Total Pb quantification in transferred samples (which would have been analyzed under the instructions) and in remaining water samples (which would have been discarded under the instructions), from a laboratory experiment utilizing Pb pipes on a logarithmic scale (Test 3, bottom). These samples can be considered “worst case” because they are highly contaminated

In a similar test with water samples collected from experiments of leaded brass (Test 4), a similar result was obtained, in that water samples in the original container always had more Pb. Specifically, water remaining in the original container had 50 (Brass 2) to 100 % (Brass 4) more Pb if the transferred portion received a relatively less rigorous preservation treatment (Test 4.a, Fig. 4, top). Water remaining in the original container had 42 (Brass 2) to 65 % (Brass 1) more Pb, even when the other transferred half received a more rigorous and heated preservation treatment (Test 4.b, Fig. 4, bottom). Similar trends were observed in Pb pipe samples from Test 4, although Pb concentrations were much higher in the Pb pipe water samples (up to 424 ppb for transferred samples and 2189 ppb for remaining samples), compared with those from brass materials (up to 30 ppb for transferred samples and up to 771 ppb for remaining samples) (Fig. 4).

Total Pb quantification in transferred samples and in remaining water samples, from laboratory experiment utilizing brass coupons and Pb pipes (Test 4). These samples can be considered “worst-case” because they are highly contaminated with Pb. After one sampling event, the transferred samples were preserved with 2 % HNO3 under heated conditions while the remaining samples were preserved with 0.15 % HNO3 at room temperature (Test 4.a, top). In the subsequent sampling event, preservation procedures were switched between the transferred and the remaining water samples (Test 4.b, bottom). Regardless of preservation procedure, the original sample container always had more Pb quantified in water

Overall, the act of transferring water from one bottle to another created large errors in quantification of Pb, even if samples were transferred immediately upon collection. These errors potentially arose from very rapid sorption of soluble Pb ions to the walls of the original sampling containers, or from rapid settling of particulate Pb in the original containers (which was visually obvious in one instance, see Fig. 3).

Implications for AL monitoring and compliance under the LCR.

Limitations in Pb recovery, due to insufficient acid preservation and/or mixing (Tests 1, 2), might be causing Pb hazards in worst-case water samples to be underestimated, during routine utility monitoring under the LCR. Despite these noted limitations of the EPA standard protocol under the worst-case scenarios examined herein, the protocol is adequate for the majority of situations where Pb-in-water is present at lower levels and in the dissolved/colloidal form (Lytle et al. 1993; Triantafyllidou et al. 2007). In addition, even for the worst cases of high particulate Pb levels, potable water samples have yet to be collected that tested below the 15 ppb AL if bottles are mixed (Triantafyllidou et al. 2007). The AL therefore has usefulness in detecting hazardous taps, and compliance would only rarely be affected by the limitations discussed, as long as the bottles are completely mixed after adding the acid preservative. Furthermore, EPA instructions under the LCR mandate that samples are preserved inside the original sampling container, making any limitations by the act of transfer (Tests 3 and 4) irrelevant to AL monitoring and compliance.

Implications for customer sampling, environmental assessments of Pb-poisoned children, monitoring at schools and day care centers.

The above issues become more important for customer or school/day care sampling, and for environmental assessments of Pb-poisoned children, which do not fall under the LCR compliance sampling requirements. In those situations, often involving the most sensitive population groups at risk of worst-case exposure, application of the standard EPA protocol (or its modifications) after transfer, might miss the true extent of the Pb-in-water hazard, if present. Depending on the form (dissolved or particulate) and level of Pb contamination, sampling conducted with modified instructions involving transfer of part of the original water sample into a new container for quantification might “miss” a large percentage of the Pb present (Tests 3 and 4). Even though they are not employed for regulatory compliance purposes, assessment of human exposure threats using such protocols is a significant and under-appreciated concern.

Even more important is the monitoring of Pb in water at homes of Pb-poisoned children. In these worst-case situations, where a Pb hazard is likely present, rigorous sampling for Pb in water at multiple taps may be required. Health agencies typically follow some of the LCR instructions to conduct water sampling at the affected children’s homes. But if water is the dominant, or a contributing factor, to the children’s Pb exposure, standard sample preservation might not always be sufficient to quantify all the Pb in water. Indeed, many recent cases of childhood Pb poisoning in the US involved particulate Pb in water, ranging from hundreds to thousands of ppb (Triantafyllidou and Edwards 2011a). Those concentrations are not much different from the ones examined in this study, for which standard preservation in combination with insufficient sample mixing (Tests 1 and 2) or with sample transfer (Tests 3 and 4) “missed” much of the Pb present in water.

Other considerations.

Aside from the specific sample preparation techniques examined herein, other sample pre-treatment steps might also be contributing to underestimation of Pb hazards in water (Table 2). Those issues also deserve investigation, and are further complicated by certain inconsistencies between approved protocols, some of which are resolved by the mandates of the Code of Federal Register that takes precedence (Table 2).

Another area of concern is analytical instrument limitations (i.e., type 3 of potential deficiencies mentioned in the Introduction of this paper). For example, Pb quantification in water of US schools/daycares is voluntary, and does not fall under the umbrella of the federally mandated LCR. In the absence of explicit analytical requirements, schools and daycares may employ anodic stripping voltammetry for Pb quantification (Goebel et al. 2004) without performing sample acid digestion. The federally mandated LCR requires acid digestion (Table 1), acknowledging that DPASV only measures dissolved Pb and not particulate Pb, and that all Pb in the sample has to be first rendered soluble so that it can be quantified by DPASV. But even if a sample is completely digested and all the Pb solubilized, the EPA-approved DPASV method requires neutralization of the sample pH before analysis (Palintest 1999). There are certain circumstances in potable water, where neutralization of the sample pH may defeat the purpose of the original digestion, because certain Pb solids might re-precipitate through reactions with compounds such as phosphate, or Pb can sorb to the walls of the container. If precipitation and/or sorption were to occur, anodic stripping voltammetry is anticipated to be subject to a large error in quantifying Pb under EPA-approved procedures. Overall, the practicality and logic behind usage of DPASV on-site analyzers for total Pb determination (for compliance reasons or otherwise) warrants future investigation.

References

American Public Health Association (APHA), American Water Works Association, & Water Environment Federation. (1998). Standard methods for the examination of water and wastewater (20th ed.). Washington, DC: American Public Health Association.

Brown, M. J., Raymond, J., Homa, D., Kennedy, C., & Sinks, T. (2010). Association between children's blood lead levels, lead service lines, and water disinfection, Washington, DC, 1998–2006. Environ Research, 111(1), 67–74.

Cartier, C., Prévost, M., Nour, S., & Pirog, M. (2009). A rapid method for the detection of lead service lines. American Water Works Association Water Quality and Technology Conference (WQTC), Seattle, WA.

Cartier, C., Laroche, L., Deshommes, E., Nour, S., Richard, G., Edwards, M., & Prévost, M. (2011). Investigating dissolved lead at the tap using various sampling protocols. Journal of American Water Works Association, 103(3), 55–67.

Centers for Disease Control and Prevention (CDC). (2002). Managing elevated blood lead levels among young children. Recommendations from the Advisory Committee on Childhood Lead Poisoning Prevention.

Centers for Disease Control and Prevention (CDC). (2004). Blood lead levels in residents of homes with elevated lead in tap water—District of Columbia, 2004. Morbidity and Mortality Weekly Report, 53, 268–270.

Deshommes, E., Laroche, L., Nour, S., Cartier, C., & Prévost, M. (2010). Source and occurrence of particulate lead in tap water. Water Research, 44(12), 3734–3744.

Edwards, M., Triantafyllidou, S., & Best, D. (2009). Elevated blood lead in young children due to lead-contaminated drinking water: Washington, DC, 2001–2004. Environmental Science & Technology, 43(5), 1618–1623.

Galke, W., Dixon, S., McLaine, P., Wilson, J., & Ashley, P. (2006). US Department of Housing and Urban Development. Study of HUDs Risk Assessment Methodology in three U.S. Communities. Available from: http://www.nchh.org/LinkClick.aspx?fileticket=HZUenslvU/0=&tabid=217. Accessed 7/10/2010

Goebel, A., Vos, T., Louwagie, A., Lundbohm, L., & Brown, J. H. (2004). Lead-testing service to elementary and secondary schools using anodic stripping voltammetry. Journal of Chemical Education, 81, 214–217.

Guidotti, T. L., Calhoun, T., John, O., Davies-Cole, J. O., Knuckles, M. E., Stokes, L., Glymph, C., Lum, G., Moses, M. S., Goldsmith, D. F., & Ragain, L. (2007). Elevated lead in drinking water in Washington DC, 2003–2004: the public health response. Environmental Health Perspectives, 115, 695–701.

Hu, J., Gan, F., Nguyen, C., & Edwards, M. (2010). Galvanic corrosion of lead pipe after partial lead line replacements. Proceedings of the European Corrosion Congress Moscow, Russia, 13–17 September

Levin, R., Brown, M. J., Kashtock, M. E., Jacobs, D. E., Whelan, E. A., Rodman, J., Schock, M. R., Padilla, A., & Sinks, T. (2008). Lead exposures in U.S. children, 2008: implications for prevention. Environmental Health Perspectives, 116(10), 1285–1293.

Lytle, D., Schock, M., Dues, N., & Clark, P. (1993). Investigating the preferential dissolution of lead from solder particulates. Journal of American Water Works Association, 85(7), 104–110.

Nguyen, C. K., Stone, K. R., Dudi, A., & Edwards, M. A. (2010). Corrosive microenvironments at lead solder surfaces arising from galvanic corrosion with copper pipe. Environmental Science & Technology, 44(18), 7076–7081.

Palintest. (1999). Method 1001: lead in drinking water by differential pulse anodic stripping voltametry. Erlanger: Palintest Ltd.

Portland, OR Water Bureau. Manual on “How to plan for, collect and return your water sample for lead testing”. Available from: http://web.multco.us/sites/default/files/health/documents/water_test_kit_instructions.pdf. Accessed 10/10/2010

Schock, M. R. (1990). Causes of temporal variability of lead in domestic plumbing systems. Environmental Monitoring and Assessment, 15(1), 59–82.

Schock, M. R., & Lemieux, F. G. (2010). Challenges in addressing variability of lead in domestic plumbing. Water Science & Technology: Water Supply-WSTWS, 10(5), 793–799.

Triantafyllidou, S., & Edwards, M. (2011a). Lead (Pb) in tap water and in blood: implications for lead exposure in the United States. Critical Reviews in Environmental Science and Technology. doi:10.1080/10643389.2011.556556.

Triantafyllidou, S., & Edwards, M. (2011b). Galvanic corrosion after simulated small-scale partial lead service line replacements. Journal of American Water Works Association, 103(9), 85–99.

Triantafyllidou, S., Parks, J., & Edwards, M. (2007). Particulate lead in drinking water. Journal of American Water Works Association, 99(6), 107–117.

US EPA (1991). Drinking water regulations: maximum contaminant level goals and national drinking water regulations for lead and copper. Federal Register, 56(110), 26460–26564.

US EPA (1994a). Method 200.8. Determination of Trace Elements in Waters and Wastes By Inductively Coupled Plasma - Mass Spectrometry Revision 5.4. Environmental Monitoring Systems Laboratory, Office of Research and Development, U.S. Environmental Protection Agency, Cincinnati, Ohio 45268.

US EPA (1994b). Method 200.9. Determination of Trace Elements by Stabilized Temperature Graphite Furnace Atomic Absorption Revision 2.2, Environmental Monitoring Systems Laboratory, Office of Research and Development, U.S. Environmental Protection Agency, Cincinnati, Ohio 45268.

US EPA (2003). Method 200.5. Determination of Trace Elements by Axially Viewed Inductively Coupled Plasma Atomic Emission Spectrometry Revision 4.2, Environmental Monitoring Systems Laboratory, Office of Research and Development, U.S. Environmental Protection Agency, Cincinnati, Ohio 45268.

US EPA (2009). Analytical Methods Approved for Drinking Water Compliance Monitoring of Inorganic Contaminants and Other Inorganic Constituents. Available from: at http://www.epa.gov/ogwdw/methods/pdfs/methods/methods_inorganic.pdf. Accessed 10/10/2010

US EPA, Office of Water. (2006). Memorandum on Management of Aerators during collection of tap samples to comply with the Lead and Copper Rule.

Zhang, Y., Griffin, A., Rahman, M., Camper, A., Baribeau, H., & Edwards, M. (2009). Lead contamination of potable water due to nitrification. Environmental Science & Technology, 43(6), 1890–1895.

Acknowledgments

The authors acknowledge the financial support of the National Science Foundation under grant CBET-0933246. Opinions and findings expressed herein are those of the authors and do not necessarily reflect the views of the National Science Foundation. The authors are grateful to John A. Consolvo of the Philadelphia Water Department (USA) for answering questions relevant to Pb-in-water quantification methods and for providing comments to improve the quality of this manuscript. The authors would also like to thank the anonymous reviewers for their valuable comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Triantafyllidou, S., Nguyen, C.K., Zhang, Y. et al. Lead (Pb) quantification in potable water samples: implications for regulatory compliance and assessment of human exposure. Environ Monit Assess 185, 1355–1365 (2013). https://doi.org/10.1007/s10661-012-2637-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10661-012-2637-6