Abstract

Reliable quantifications of brominated flame retardants (BFRs) not only ensure compliance with laws and regulations on the use of BFRs in commercial products, but also is key for accurate risk assessments of BFRs. Acetone is a common solvent widely used in the analytical procedure of BFRs, but our recent study found that acetone can react with some BFRs. It is highly likely that such reactions can negatively affect the quantifications of BFRs in environmental samples. In this study, the effects of acetone on the extraction yields of three representative BFRs [i.e., decabrominated diphenyl ether (decaBDE), hexabromocyclododecane (HBCD) and tetrabromobisphenol A (TBBPA)] were evaluated in the Soxhlet extraction (SE) system. The results showed that acetone-based SE procedure had no measureable effect for the recovery efficiencies of decaBDE but could substantially lower the extraction yields for both TBBPA and HBCD. After 24 h of extraction, the recovery efficiencies of TBBPA and HBCD by SE were 93 and 78% with acetone, 47 and 70% with 3:1 acetone:n-hexane, and 82 and 94% with 1:1 acetone:n-hexane, respectively. After 72 h of extraction, the extraction efficiencies of TBBPA and HBCD decreased to 68 and 55% with acetone, 0 and 5% with 3:1 acetone/n-hexane mixtures, and 0 and 13% with 1:1 acetone/n-hexane mixtures, respectively. The study suggested that the use of acetone alone or acetone-based mixtures should be restricted in the quantitative analysis of HBCD and TBBPA. We further evaluated nine alternative solvents for the extraction of the three BFRs. The result showed that diethyl ether might be reactive with HBCD and may not be considered as the alternative to acetone used solvents for the extraction of HBCD.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Brominated flame retardants (BFRs) are widely used in the plastics, electronic equipment, and household products to improve their flammability resistance. The most commonly used BFRs are tetrabromobisphenol A (TBBPA), polybrominated diphenyl ethers (PBDEs) and hexabromocyclododecane (HBCD) (Hyotylainen and Hartonen 2002). These BFRs have proved to persist and accumulate in the environment and have adverse effects on human health and the environment (de Wit 2002; Birnbaum and Staskal 2004). A global ban on these BFRs is currently performed or being considered (Kemmlein et al. 2009). For example, the use of PBDEs has been restricted since 2004 in electronics and electrical applications according to the RoHS Directive. HBCD has been identified as a substance of very high concern (SVHC) in EU and was listed in Stockholm Convention on persistent organic pollutants (POPs) subject to an eventual ban. Although TBBPA has not been included in the list of priority substances established by EU or other countries, the globe risk assessment of TBBPA is already undertaken (Kemmlein et al. 2009).

In order to comply with regulations such as of RoHS Directive, the determination of BFRs in the polymeric materials has become increasingly important during production of electric and electronic equipment and recycling of electronic wastes (Kemmlein et al. 2009). Furthermore, the analysis of BFRs in various environmental samples is also needed urgently (Covaci et al. 2003, 2007; An et al. 2011), because the information on the BFR contaminated levels in environments is essential for characterizing their occurrence, environmental behavior, and potential risks to the human health and environment of BFRs. Therefore, the analytic methods for quantifying BFRs in polymer and environmental samples have been developed rapidly in the past decades (de Wit 2002; Covaci et al. 2003, 2007; Morris et al. 2006; Abdallah et al. 2008). A large number of research articles have been published annually about the determination of BFRs in the products and environments (Web of Science electronic database).

Extraction of BFRs from matrices is the first and the most important step in the quantitative determinations of BFRs. The Soxhlet extraction (SE) is widely employed as a traditional and robust method for extracting BFRs from abiotic and biotic samples (van Leeuwen and de Boer 2008; Covaci et al. 2009). Its extraction efficiency is mainly dictated by both the solubility of BFRs in the extraction solvents and the accessibility of the extraction solvent to the matrix. Figure 1 summarizes the relevant data on the solvents used in the SE of TBBPA and HBCD according to the references included in Web of Science electronic database (2002–2016). Over half of the published research articles reported the use of the acetone/n-hexane mixtures in the SE of TBBPA or HBCD, which was far more frequently used than toluene or DCM in the research articles surveyed (Fig. 1). This finding is consistent with a review by Covaci et al. (2003) who reported that acetone/n-hexane mixtures are the preferred solvents for the determination of PBDEs.

In our prior study, we have reported that HBCD and TBBPA were unstable in acetone (Zhong et al. 2010, 2012). They can react with acetone to form other brominated products, and their reaction pathways and mechanisms have been elucidated (Zhong et al. 2010, 2012). These findings have raised such important questions as whether and to what extent the reactions between BFRs and acetone affect the quantitative determinations of BFRs during the SE procedure. If acetone has negative impacts on the quantitative determinations of BFRs, the well perceived and widely accepted pre-assumption that acetone would be an appropriate solvent for the extraction of BFRs should be challenged. Furthermore, the published data on the concentrations of BFRs in the environments that were quantified with the acetone-based SE procedure should be analyzed retrospectively, and the environmental impacts and human health risk of BFRs may be reevaluated also.

To date, however, the effects of acetone or acetone/n-hexane mixtures on the quantitative determinations of HBCD and TBBPA have not been studied (Covaci et al. 2003; Morris et al. 2006). For instance, it is not clear how SE conditions, such as the extraction time and, ratio of hexane in acetone, and the presence of Cu powders, may affect the extraction efficiency of HBCD and TBBPA. In standard SE procedure, Cu powder is often added to the extraction solvents for removing elemental sulfur (Mechlińska et al. 2012) as sulfur, a major constituent interfering instrumental quantifications for BFRs, can be co-extracted with BFRs from sediment, soil, and sewage sludge. Systematic studies for quantifying such potential effects and for evaluating alternative solutions to such an issue are needed.

The first objective of this study was to address the above research needs by examining the effects of acetone on the extraction efficiency of decabromodiphenyl ether (decaBDE), HBCD and TBBPA during SE procedure under various SE conditions. In an effort to search alternative solvents for solving the acetone issue, we also evaluated the reactivities of decaBDE, HBCD, and TBBPA with a spectrum of organic solvent candidates including dichloromethane (DCM), toluene, diethyl ether, n-hexane, methanol, ethyl acetate, methyl tert-butyl ether, cyclohexane, 1-propanol. These solvents were used in the literature in the extraction of TBBPA and HBCD from various environmental matrices (Fig. 1). The results obtained in this study may not only help understand the environmental behavior and potential risks of these BFRs to human health, but also should provide a foundation for developing robust analytic method for BFRs that can be implemented as a standard method in environmental risk assessment and regulation establishment on the use of BFRs in electronic products.

Materials and methods

Chemicals

DecaBDE (99%) and TBBPA (97%) were purchased from Alfa Aesar (Lancaster, England). The technical HBCD mixture (>95%) was purchased from Tokyo Chemical Industry (Tokyo, Japan). Acetone, toluene, and n-hexane (ACS certified grade) were obtained from Honeywell Burdick & Jackson (Morristown, NJ, USA). The HPLC-grade DCM, methanol, and methyl tert-butyl ether were obtained from J.T. Baker (Philianapolis, NJ, USA), Merck (Darmstadt, Germany) and Tedia Company Inc. (Fairfield, Ohio, USA), respectively. Analytical grade ethyl acetate, cyclohexane, and 1-propanol were redistilled using a glass system. Analytical grade diethyl ether was purchased from Guangzhou Chemical Reagents Factory (Guangzhou, China) and used as received without further purification. Cu powders (<100 mesh; 0.05 mm) were purchased from Fuchen Chemical Reagents Factory (Tianjin, China) and washed with 1 M HCl and acetone prior to use.

Extraction yields of BFRs by SE with acetone or acetone/n-hexane mixture

A standard SE method was conducted by adding BFRs into the extraction thimbles and extracted with 200 mL solvents at the approximate rate of 3–4 cycles/h. In order to avoid the interference of matrices like adsorption, the standard soil or sediment was not added into the extraction thimbles. Only 20 µL of standard solutions of BFRs (1000 mg L−1) dissolved in toluene were added into extraction thimbles. The amounts of BFRs added were consistent with the contaminated levels of BFRs in soils and sediments reported in the literature (Sellström and Jansson 1995; Law et al. 2008; Abb et al. 2011). The extraction solvents selected were acetone, acetone/n-hexane mixture (3:1, v/v), and acetone/n-hexane mixture (1:1, v/v). In addition, according to the method described by Zhang et al. (2009), 1 g of Cu powders was added to the extraction flasks to investigate the effect of Cu on the extraction efficiency of BFRs by SE. Triplicate was used for each setup, and a total of eighteen setups were tested. After extraction of 24, 48, and 72 h, the extracts and the rinses of the Soxhlet extractor components were combined. Each sample was concentrated into a volume of 10 mL by rotary evaporation and then subjected to the instrumental analysis.

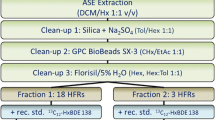

The stability of BFRs in other organic solvents

According to Fig. 1, in addition to acetone, nine solvents were also used for the extraction of BFRs, including DCM, toluene, diethyl ether, methanol, ethyl acetate, methyl tert-butyl ether, cyclohexane, 1-propanol, and hexane. The objective of this test was to search for alternative candidate solvents which should be nonreactive with the targeted BFRs and thus could be used to replace acetone in the SE procedure if acetone was not appropriate due to its reactions with BFRs. Three BFRs (decaBDE, TBBPA or HBCD) were dissolved in each of these nine solvents to prepare twenty-seven types of work solutions, each containing 2 mg L−1 of a target BFR. A aliquot (2 mL) of a given work solution was added to a brown bottle capped with a Teflon-lined serum cap. The bottles so prepared were immediately placed on an end-over-end rotator shaker preset in dark and at room temperature. After 72 h of mixing, three bottles were taken from the shaker for the analysis of residual BFR concentrations. Any loss of BFR beyond the statistical deviations of the method was considered as the result of its reaction with the solvent.

Chemical analysis

Quantification of TBBPA was performed on a HPLC equipped with an UV detector (HPLC–UV) (Model LC-20AB; Shimadzu, Kyoto, Japan) and an Inertsil ODS-SP column (dimensions 150 mm × 4.6 mm, particle size 5 µm). The 0.2% of ammonium acetate buffer-methanol (1:4, v/v) was used as an isocratic eluent at a flow rate of 0.8 mL min−1, and the wavelength of the UV detector was set at 210 nm. The concentrations of decaBDE and HBCD were analyzed by a Shimazu QP2010 GC (Kyoto, Japan) equipped with an DB-5 fused silica capillary column (15 m × 0.25 mm × 0.1 µm) and ECD. The oven temperature was programmed to maintain at 60 °C for 1 min, be ramped at 20 °C min−1–300 °C, and be held at 300 °C for 15 min. The inlet and ECD was held isothermally at 260 and 310 °C, respectively. Helium was used as the carrier gas at a flow rate of 1 mL min−1. Quantification of decaBDE, TBBPA, and HBCD was performed by external calibration, using six-point calibration curves obtained by the injection of standard solutions containing 0.1–5 mg L−1 of the technical BFRs.

The transformation products of BFRs, if any, were identified by a Shimazu QP2010 plus GC–MS (Kyoto, Japan) with a DB-5MS fused silica capillary column (15 m × 0.25 mm × 0.1 µm). The GC column temperature programmed from 60 to 300 °C at 5 °C min−1 heating rate and held at 300 °C for 15 min. The inlet was held isothermally at 260 °C. Helium was used as the carrier gas at a flow rate of 1 mL min−1. The MS was operated in electron impact ionization mode with electron energy of 70 eV, and scan ranged from 50 to 750 amu. The ion source and GC–MS interface temperatures were held at 250 and 280 °C, respectively.

Results and discussion

Extraction efficiency of decaBDE by SE with acetone or acetone/n-hexane mixture

The high extraction efficiency of BFRs is a prerequisite for the reliable analysis of BFRs. Figure 2 shows that recovery efficiencies of decaBDE by SE with acetone or acetone/n-hexane mixtures under different operational conditions (solvent ratio, extraction time, and the addition of Cu powders). The recovery efficiencies for decaBDE were between 95 and 106% (RSD < 5%) after 24 h of SE. A separate study also showed that 105 ± 8% of decaBDE was recovered after decaBDE dissolved in acetone for 72 h. Meanwhile, the recovery efficiencies were not affected by Cu powders consistently in all tests with SE times of 24 and 72 h. The results indicated that extraction with acetone or acetone/n-hexane mixtures allowed complete recovery efficiency of decaBDE during the SE procedure. It suggested that decaBDE was stable or nonreactive in the acetone-based solvents.

According to the above results, we recommended that acetone or acetone/n-hexane mixtures could be applied in the SE of decaBDE from various matrices. Prior studies have shown that the use of acetone/n-hexane mixtures provided low recovery efficiencies of decaBDE in sediments and biota (Dodder et al. 2002; Hoh and Hites 2005). Such low recovery efficiencies should not be attributed to its reaction with the solvent matrix. Instead, it may be caused by decaBDE evaporation, inefficient separation of decaBDE from lipid fraction during clean-up procedures after extraction, UV/light degradation in the laboratory, and/or by thermal degradation in the chromatographic system (Strandberg et al. 2001; Dodder et al. 2002).

Extraction efficiency of HBCD by SE with acetone or acetone/n-hexane mixture

Figure 3 shows that, unlike decaBDE, HBCD was not completely recovered by SE using acetone or acetone/n-hexane mixtures. After 24 h of extraction, the recovery efficiencies of HBCD by SE were 78 ± 1% with acetone, 70 ± 15% with 3:1 acetone:n-hexane, and 94 ± 4% with 1:1 acetone:n-hexane, respectively. When the extraction time was increased to 72 h, the recovery efficiencies of HBCD decreased dramatically to 55 ± 3% with acetone, 5 ± 1% with 3:1 acetone:n-hexane, and 13 ± 2% with 1:1 acetone:n-hexane, respectively. It indicated that the reactivity of HBCD with acetone or acetone/n-hexane had caused significant decreases in extraction yield for HBCD after 24 h of SE and that increasing extraction time had rapidly decreased the extraction efficiencies. As HBCD terms to be bound very tightly to sample matrix such as soil, sediments, and biota samples, the extraction of HBCD in the laboratory often requires longer extraction times (i.e., ≥48 h) to ensure full penetration of the solvent to the sample matrix (Wu et al. 2008; Gao et al. 2011; Meng et al. 2011). According to our results summarized above, it could be expected that a significant amount of HBCD could be lost due to its reaction with acetone during long periods of SE under long extraction period. Such a huge loss could not be corrected using the spiking of internal standards that were not reactive with acetone. The data generated in these previous studies using other internal standards rather than 13C12-HBCD should be evaluated retrospectively.

The results shown in Fig. 3 indicated that Cu powder had no apparent further effect on the recovery efficiencies of HBCD. For instance, in the presence of Cu, the recovery efficiencies of HBCD by SE after 24 h of extraction were 95 ± 1% with acetone, 76 ± 10% with 3:1 acetone:n-hexane, and 95 ± 2% with 1:1 acetone:n-hexane, respectively. When the extraction time increased up to 72 h, the recovery efficiencies of HBCD also dramatically decreased to 63 ± 8% with acetone, 12 ± 4% with 3:1 acetone:n-hexane, and 21 ± 5% with 1:1 acetone:n-hexane, respectively. These data had no statistically significant difference from the extraction yields of HBCD with acetone in the absence of Cu. It is likely that Cu has no catalytic effect on the degradation of HBCD by acetone as suggested by Zhong et al. (2010).

In previous studies, the acetone/n-hexane mixtures have been considered as ideal solvents and commonly used in the extraction of BFRs (Fig. 1), due to their polar and nonpolar properties favored for accelerating the extraction of target compound from complex matrix. However, this study demonstrated that the mixtures of acetone:n-hexane resulted in much lower extraction yields of HBCD compared to pure acetone after 72 h of extraction (Fig. 3). This might be due to the fact that the viscosity of the solvent mixtures was lowered with addition of n-hexane (Johari 1968). Bai et al. (2003) have reported that the solvent viscosity was inversely related to the rate constant observed for electron transfer reactions. Therefore, it could be hypothesized that the mixtures of acetone/n-hexane with low viscosity probably promoted the electron transfer reactions between acetone and HBCD, leading to faster degradation of HBCD and its lower recovery efficiencies.

In addition, a high peak corresponded to pentabromocyclododecene (PBCDe) was detected in the extracts during SE of HBCD with acetone/n-hexane mixtures (Fig. 4), but no product was detected with pure acetone (data not shown). It is known that PBCDe is the key intermediate of microbial degradation, photolytical degradation, thermal degradation, and biological metabolism of HBCD. It was also detected in various environmental samples including indoor dust, chicken eggs, fish, sludge, and sediments (Davis et al. 2006; Hiebl and Vetter 2007; Abdallah and Harrad 2009). When acetone/n-hexane mixtures were used in the extraction of HBCD, it is likely that the so measured concentration of PBCDe may be artificially higher and environmental processes may be incorrectly accounted for the formation of all the detected PBCDe, thus resulting in incorrect estimation on the environmental fate of HBCD.

Extraction efficiency of TBBPA by SE with acetone or acetone/n-hexane mixture

Figure 5 indicates that the acetone-based SE procedures could strongly affect the quantifications of TBBPA. The extraction recovery efficiencies of TBBPA were 93 ± 1% with acetone, 47 ± 5% with 3:1 acetone/n-hexane mixtures, and 82 ± 3% with 1:1 acetone/n-hexane mixtures during 24 h of SE, respectively. The loss of TBBPA followed the order of 3:1 acetone/n-hexane > 1:1 acetone/n-hexane > acetone, which was similar to that for HBCD (Figs. 2 and 5). As explained above, the lower solvent viscosity due to addition of n-hexane may have enhanced the rates of electron transfer reactions with TBBPA, hence resulted in increased loss and lowered extraction yields of TBBPA when compared to pure acetone (Johari 1968).

Figure 5 shows that the loss of TBBPA was a function of the SE time. When the extraction time increased to 48 h, the recovery efficiencies of TBBPA decreased to 75% with acetone, 0.2% with 3:1 acetone/n-hexane mixtures, and 0.5% 1:1 acetone/n-hexane mixtures, respectively. After 72 h of extraction, no TBBPA was detected with two acetone/n-hexane-based SE procedures. It is apparent that the SE procedure with acetone/n-hexane mixtures over extended extraction times may cause massive loss of TBBPA. Gerecke et al. (2006) showed that acetone/n-hexane mixtures yielded low extraction recovery efficiencies (40–90%) when TBBPA was extracted for 6 h in Soxhlet apparatus. The yields would be much lower if the extraction time were longer.

The data presented in Figs. 3 and 5 showed that, compared to HBCD, TBBPA exhibited even more loss during SE procedure with acetone/n-hexane mixtures. It is likely that the reactivity of TBBPA with acetone is stronger than HBCD. Our previous study evaluated the degradation rates of TBBPA and HBCD in acetone using the amber bottles as the reactors (Zhong et al. 2010, 2012). The rate constant for the degradation of TBBPA in acetone was approximately eight times faster than that for HBCD. Furthermore, the mechanism underlying the reaction between acetone and TBBPA is likely different from that for HBCD. It was proposed in our prior study that TBBPA was firstly degraded via β-scission to form two different radicals in the presence of acetone, which were then coupled to form high molecular weight products (Zhong et al. 2012). The observed faster rate of TBBPA degradation may be fundamentally related to its radical reaction, compared to the dehydrobromination of HBCD in which no radical was involved.

Another feature of our results (Fig. 5) is that Cu powder could dramatically increase the loss of TBBPA during the SE procedure. After 72 h of SE, the recovery efficiencies of TBBPA with acetone were at 0.5% in the presence of Cu powder, compared to 68% without Cu powder (Fig. 5). This may be due to the fact that Cu could catalyze the degradation of TBBPA in acetone (Zhong et al. 2012). Therefore, it is even worse to use activated Cu powders for removal of sulfur during SE of TBBPA with acetone or acetone/n-hexane mixtures. Compared to HBCD, the losses of TBBPA during SE with acetone/n-hexane mixtures were more dramatic over longer extraction time and with the addition of Cu powders. If both conditions of longer extraction time and addition of Cu powder are applied simultaneously in the quantitative analysis of TBBPA, its concentrations may be substantially underestimated.

The stability of BFRs in other organic solvents

It is highly necessary to find alternative solvents for the extraction of BFRs from various environmental samples. Indeed other solvents have been used for the extraction of decaBDE, TBBPA or HBCD in the literature. For example, toluene is an excellent solvent for dissolving many BFRs and is commonly used for the extraction of BFRs from abiotic sample such as sediments, air sample, and electronic products (Evenset et al. 2007; Takigami et al. 2009; Kajiwara et al. 2011). The binary solvent systems DCM/n-hexane mixtures can facilitate penetration of the solvent in the sample matrix, improving the extraction yields of BFRs from tissues of biotic samples such as fishes, human adipose, and dolphins (Pulkrabová et al. 2007; Johnson-Restrepo et al. 2008). Ethyl acetate was less commonly applied for the extraction of BFRs, but Han et al. (2010) had demonstrated that ethyl acetate yielded better extraction efficiency for HBCD than acetone/n-hexane (1:1, v/v). They proposed that ethyl acetate was the most appropriate solvent for the extraction of HBCD from seaweed. Methyl tert-butyl ether and cyclohexane are compatible solvents for extraction of TBBPA and HBCD from sediments (Chu et al. 2005; Haukås et al. 2009). The polar solvents of 1-propanol and methanol were useful for the rupture of BFRs–matrix interactions to increase the extraction yields of BFRs by other solvents. However, whether decaBDE, TBBPA or HBCD may be reactive in these extraction solvents has not been evaluated experimentally.

Figure 6 shows the extraction efficiencies for the three BFRs using nine different organic solvents including toluene, DCM, methanol, ethyl acetate, methyl tert-butyl ether, cyclohexane, 1-propanol, hexane, and diethyl ether. The results indicated that all but diethyl ether had the high recovery efficiencies for all three BFRs (ranging from 94 to 111%) and that diethyl ether exhibited lower recovery efficiency (82%) for HBCD. It suggested that the eight solvents can be considered as the alternative solvents for the extraction of BFRs, whereas diethyl ether may not be suitable. Whether temperature and/or addition of Cu could trickle reactions between the three BFRs and other solvents, which should be investigated in future study.

Implications

The acetone/n-hexane mixtures are the typical solvents for the SE of BFRs from different environmental matrices such as sediments and biota samples. This study indicated that such acetone-based extraction procedure had no measureable effect on the recovery efficiencies for decaBDE and could be used as a standard procedure for its quantification in environmental samples. However, the same extraction procedures yielded artificially lowered extraction yields for both HBCD and TBBPA due to their reactions during extraction. It is particularly alarming that the SE with the acetone/n-hexane mixtures (1:1 or 3:1; v/v) did not recover TBBPA after 72-h extraction (Figs. 3 and 5). Such abnormally low extraction yield was primarily caused by chemical reactions of the analytes with acetone. The result was quite opposite to the conventional practice in analytical laboratories that acetone/n-hexane mixtures would offer quantitative yields for BFRs. According to our results, such practice could be fundamentally flawed even with much shorter extraction periods (<24 h) when target BFRs are HBCD and TBBPA. It is highly recommended that acetone or acetone/n-hexane mixtures not be used as the solvents in the standard analytical procedure for quantifying these two BFRs in environmental samples.

Our study calls attention that the occurrence, behavior, and fate of these two BFRs in the environment based on analytical data obtained using acetone-based SE procedures may be inaccurate and should be reevaluated with new data obtained with alternative solvent extractions. TBBPA is the most commonly used BFRs, accounting for approximately 60% of the total BFRs market (Covaci et al. 2009). However, the concentrations of TBBPA in various environmental samples reported in previous studies were much lower than other BFRs (Morris et al. 2004; Law et al. 2006). Prior studies hypothesized that the reported lower concentrations of TBBPA were due to its lowered extractability because it might be tightly bound to polymeric matrix of the electronic products and soil/sediment particles. Our data demonstrated that TBBPA is readily degraded during SE with acetone/n-hexane mixtures and such degradation increased as a function of extraction time and in the presence of Cu powders. It is highly possible that the reported much lower concentrations of TBBPA in environmental samples could be primarily due to artificially lowered recovery efficiencies of the chemical during laboratory extraction, instead of presumed low levels of TBBPA in environments or low extractability of TBBPA in environmental samples. Apparently, the concentrations of TBBPA in environments may be substantially underestimated in the literature when acetone was applied in analytic procedure.

Our study also calls attention to other extraction techniques, such as pressurized liquid extraction, sonication extraction, and microwave-assisted extraction which use acetone as the extraction medium for quantification of TBBPA and HBCD in environmental samples. These extraction methods are often performed under extreme conditions such as high pressures and high temperatures. Such extreme conditions might even increase the reaction rates between acetone and two BFRs. It is certainly true when these extraction methods are acetone based. Careful measures such as shortened extraction times should be considered (Xiong et al. 2015, 2016).

References

Abb, M., Stahl, B., & Lorenz, W. (2011). Analysis of brominated flame retardants in house dust. Chemosphere, 85(11), 1657–1663.

Abdallah, M. A.-E., & Harrad, S. (2009). Personal exposure to HBCDs and its degradation products via ingestion of indoor dust. Environment International, 35(6), 870–876.

Abdallah, M. A.-E., Ibarra, C., Neels, H., Harrad, S., & Covaci, A. (2008). Comparative evaluation of liquid chromatography-mass spectrometry versus gas chromatography-mass spectrometry for the determination of hexabromocyclododecanes and their degradation products in indoor dust. Journal of Chromatography A, 1190(1–2), 333–341.

An, T., Zhang, D., Li, G., Mai, B., & Fu, J. (2011). On-site and off-site atmospheric PBDEs in an electronic dismantling workshop in south China: Gas-particle partitioning and human exposure assessment. Environmental Pollution, 159(12), 3529–3535.

Bai, Y. M., Sun, P., Zhang, M. Q., Zhao, G., Yang, Z. Y., & Shao, Y. H. (2003). Effects of solution viscosity on heterogeneous electron transfer across a liquid/liquid interface. Electrochimica Acta, 48(23), 3447–3453.

Birnbaum, L. S., & Staskal, D. F. (2004). Brominated flame retardants: Cause for concern? Environmental Health Perspectives, 112(1), 9–17.

Chu, S., Haffner, G. D., & Letcher, R. J. (2005). Simultaneous determination of tetrabromobisphenol A, tetrachlorobisphenol A, bisphenol A and other halogenated analogues in sediment and sludge by high performance liquid chromatography-electrospray tandem mass spectrometry. Journal of Chromatography A, 1097(1–2), 25–32.

Covaci, A., Voorspoels, S., Abdallah, M. A.-E., Geens, T., Harrad, S., & Law, R. J. (2009). Analytical and environmental aspects of the flame retardant tetrabromobisphenol-A and its derivatives. Journal of Chromatography A, 1216(3), 346–363.

Covaci, A., Voorspoels, S., & de Boer, J. (2003). Determination of brominated flame retardants, with emphasis on polybrominated diphenyl ethers (PBDEs) in environmental and human samples—a review. Environment International, 29(6), 735–756.

Covaci, A., Voorspoels, S., Ramos, L., Neels, H., & Blust, R. (2007). Recent developments in the analysis of brominated flame retardants and brominated natural compounds. Journal of Chromatography A, 1153(1–2), 145–171.

Davis, J. W., Gonsior, S. J., Markham, D. A., Friederich, U., Hunziker, R. W., & Ariano, J. M. (2006). Biodegradation and product identification of [C-14]hexabromocyclododecane in wastewater sludge and freshwater aquatic sediment. Environmental Science and Technology, 40(17), 5395–5401.

de Wit, C. A. (2002). An overview of brominated flame retardants in the environment. Chemosphere, 46(5), 583–624.

Dodder, N. G., Strandberg, B., & Hites, R. A. (2002). Concentrations and spatial variations of polybrominated diphenyl ethers and several organochlorine compounds in fishes from the northeastern United States. Environmental Science and Technology, 36(2), 146–151.

Evenset, A., Christensen, G. N., Carroll, J., Zaborska, A., Berger, U., Herzke, D., et al. (2007). Historical trends in persistent organic pollutants and metals recorded in sediment from Lake Ellasjoen, Bjornoya, Norwegian Arctic. Environmental Pollution, 146(1), 196–205.

Gao, S. T., Wang, J. Z., Yu, Z. Q., Guo, Q. R., Sheng, G. Y., & Fu, J. M. (2011). Hexabromocyclododecanes in surface soils from e-waste recycling areas and industrial areas in South China: Concentrations, diastereoisomer- and enantiomer-specific profiles, and inventory. Environmental Science and Technology, 45(6), 2093–2099.

Gerecke, A. C., Giger, W., Hartmann, P. C., Heeb, N. V., Kohler, H.-P. E., Schmid, P., et al. (2006). Anaerobic degradation of brominated flame retardants in sewage sludge. Chemosphere, 64(2), 311–317.

Han, C., Chen, X., Xie, W., Zhu, Z., Liu, C., Chen, F., et al. (2010). Determination of hexabromocyclododecane diastereoisomers in Sargassum fusiforme and comparison of the extraction efficiency of ultrasonication, microwave-assisted extraction, Soxhlet extraction and pressurised liquid extraction. Journal of Separation Science, 33(21), 3319–3325.

Haukås, M., Hylland, K., Berge, J. A., Nygård, T., & Mariussen, E. (2009). Spatial diastereomer patterns of hexabromocyclododecane (HBCD) in a Norwegian fjord. Science of the Total Environment, 407(22), 5907–5913.

Hiebl, J., & Vetter, W. (2007). Detection of hexabromocyclododecane and its metabolite pentabromocyclododecene in chicken egg and fish from the official food control. Journal of Agricultural and Food Chemistry, 55(9), 3319–3324.

Hoh, E., & Hites, R. A. (2005). Brominated flame retardants in the atmosphere of the east-central United States. Environmental Science and Technology, 39(20), 7794–7802.

Hyotylainen, T., & Hartonen, K. (2002). Determination of brominated flame retardants in environmental samples. TrAC Trends in Analytical Chemistry, 21(1), 13–30.

Johari, G. P. (1968). Dielectric constants, densities, and viscosities of acetone-1-propanol and acetone-n-hexane mixtures at 25 °C. Journal of Chemical and Engineering Data, 13(4), 541–543.

Johnson-Restrepo, B., Adams, D. H., & Kannan, K. (2008). Tetrabromobisphenol A (TBBPA) and hexabromocyclododecanes (HBCDs) in tissues of humans, dolphins, and sharks from the United States. Chemosphere, 70(11), 1935–1944.

Kajiwara, N., Noma, Y., & Takigami, H. (2011). Brominated and organophosphate flame retardants in selected consumer products on the Japanese market in 2008. Journal of Hazardous Materials, 192(3), 1250–1259.

Kemmlein, S., Herzke, D., & Law, R. J. (2009). Brominated flame retardants in the European chemicals policy of REACH-Regulation and determination in materials. Journal of Chromatography A, 1216(3), 320–333.

Law, R. J., Bersuder, P., Allchin, C. R., & Barry, J. (2006). Levels of the flame retardants hexabromocyclododecane and tetrabromobisphenol A in the blubber of harbor porpoises (Phocoena phocoena) stranded or bycaught in the UK, with evidence for an increase in HBCD concentrations in recent years. Environmental Science and Technology, 40(7), 2177–2183.

Law, R. J., Bersuder, P., Barry, J., Wilford, B. H., Allchin, C. R., & Jepson, P. D. (2008). A significant downturn in levels of hexabromocyclododecane in the blubber of harbor porpoises (Phocoena phocoena) stranded or bycaught in the UK: An update to 2006. Environmental Science and Technology, 42(24), 9104–9109.

Mechlińska, A., Wolska, L., & Namiesńik, J. (2012). Removal of sulfur from a solvent extract. TrAC Trends in Analytical Chemistry, 31, 129–133.

Meng, X. Z., Duan, Y. P., Yang, C., Pan, Z. Y., Wen, Z. H., & Chen, L. (2011). Occurrence, sources, and inventory of hexabromocyclododecanes (HBCDs) in soils from Chongming Island, the Yangtze River Delta (YRD). Chemosphere, 82(5), 725–731.

Morris, S., Allchin, C. R., Zegers, B. N., Haftka, J. H., Boon, J. P., Belpaire, C., et al. (2004). Distribution and fate of HBCD and TBBPA brominated flame retardants in north sea estuaries and aquatic food webs. Environmental Science and Technology, 38(21), 5497–5504.

Morris, S., Bersuder, P., Allchin, C. R., Zegers, B., Boon, J. P., Leonards, P. E. G., et al. (2006). Determination of the brominated flame retardant, hexabromocyclodocane, in sediments and biota by liquid chromatography-electrospray ionisation mass spectrometry. TrAC Trends in Analytical Chemistry, 25(4), 343–349.

Pulkrabová, J., Hajšlová, J., Poustka, J., & Kazda, R. (2007). Fish as biomonitors of polybrominated diphenyl ethers and hexabromocyclododecane in Czech aquatic ecosystems: pollution of the Elbe river basin. Environmental Health Perspectives, 115(Suppl 1), 28–34.

Sellström, U., & Jansson, B. (1995). Analysis of tetrabromobisphenol A in a product and environmental-samples. Chemosphere, 31(4), 3085–3092.

Strandberg, B., Dodder, N. G., Basu, I., & Hites, R. A. (2001). Concentrations and spatial variations of polybrominated diphenyl ethers and other organohalogen compounds in Great Lakes air. Environmental Science and Technology, 35(35), 1078–1083.

Takigami, H., Suzuki, G., Hirai, Y., & Sakai, S. (2009). Brominated flame retardants and other polyhalogenated compounds in indoor air and dust from two houses in Japan. Chemosphere, 76(2), 270–277.

van Leeuwen, S. P. J., & de Boer, J. (2008). Advances in the gas chromatographic determination of persistent organic pollutants in the aquatic environment. Journal of Chromatography A, 1186(1–2), 161–182.

Wu, J. P., Luo, X. J., Zhang, Y., Luo, Y., Chen, S. J., Mai, B. X., et al. (2008). Bioaccumulation of polybrominated diphenyl ethers (PBDEs) and polychlorinated biphenyls (PCBs) in wild aquatic species from an electronic waste (e-waste) recycling site in South China. Environment International, 34(8), 1109–1113.

Xiong, J., An, T., Zhang, C., & Li, G. (2015). Pollution profiles and risk assessment of PBDEs and phenolic brominated flame retardants in water environments within a typical electronic waste dismantling region. Environmental Geochemistry and Health, 37(3), 457–473.

Xiong, J., Li, G., An, T., Zhang, C., & Wei, C. (2016). Emission patterns and risk assessment of polybrominated diphenyl ethers and bromophenols in water and sediments from the Beijiang River, South China. Environmental Pollution, 219, 596–603.

Zhang, X. L., Luo, X. J., Chen, S. J., Wu, J. P., & Mai, B. X. (2009). Spatial distribution and vertical profile of polybrominated diphenyl ethers, tetrabromobisphenol A, and decabromodiphenylethane in river sediment from an industrialized region of South China. Environmental Pollution, 157(6), 1917–1923.

Zhong, Y., Peng, P. A., & Huang, W. L. (2012). Transformation of tetrabromobisphenol A in the presence of different solvents and metals. Chemosphere, 87(10), 1141–1148.

Zhong, Y., Peng, P. A., Yu, Z. Q., & Deng, H. P. (2010). Effects of metals on the transformation of hexabromocyclododecane (HBCD) in solvents: Implications for solvent-based recycling of brominated flame retardants. Chemosphere, 81(1), 72–78.

Acknowledgements

This study was supported financially by National Natural Science Foundation of China (Nos. 41120134006 and 41473107). This is contribution No. IS-2392 from GIGCAS.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, Y., Li, D., Zhu, X. et al. Solvent effects on quantitative analysis of brominated flame retardants with Soxhlet extraction. Environ Geochem Health 40, 1955–1964 (2018). https://doi.org/10.1007/s10653-017-9979-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10653-017-9979-5