Abstract

Transient gene expression (TGE) bioprocesses have been difficult to scale up in large stirred tank bioreactors with volumes of more than 1.5 L. Low production levels are often observed, but the causes have not been investigated (Gutierrez-Granados et al. in Crit Rev Biotechnol 38:918–940, 2018). Chikungunya Virus-like particle (VLP), expressed by DNA–PEI transient transfection, is a representative case study for these difficulties. Clinical materials were produced in shake flasks, but the process suffered when transferred to large stirred tank bioreactors. The resulting process was not operationally friendly nor cost effective. In this study, a systematic approach was used to investigate the root causes of the poor scale up performance. The transfection conditions were first screened in ambr® 15 high throughput mini bioreactors then examined in 3 L stirred-tank systems. The studies found that production level was negatively correlated with inoculum cell growth status (P < 0.05). The pH range, DNA and PEI levels, order of the reagent addition, and gas-sparging systems were also studied and found to affect process performance. Further hydromechanical characterizations (Re, energy dissipation rates, and P/V, etc.) of shake flasks, ambr® 15, and 3-L stirred tank systems were performed. Overall, the study discovered that the shear stress (caused by a microsparger) and PEI toxicity together were the root causes of scale-up failure. Once the microsparger was replaced by a macrosparger, the scale-up was successful.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chikungunya virus (CHIKV) is a mosquito-borne alphavirus that has infected millions of people worldwide. CHIKV has been recognized as a severe public health threat since it was first isolated in 1953 (Simon et al. 2011). In Americas alone, more than 621,000 suspected and confirmed cases have been reported since its appearance in late 2013. The typical symptoms include rash, fever, headache, and joint pain. Vaccination is the most effective treatment to prevent the infections. Approaches include live attenuated, inactivated virus, and recombinant subunit candidates (Akahata et al. 2010; Smalley et al. 2016); however, no licensed vaccine has yet been made available to the public. Recently, the Vaccine Research Center (VRC) at the National Health Institute (NIH) constructed a virus-like particle (VLP) based CHIKV vaccine. The CHIKV VLP produced high neutralizing antibodies during a Phase I clinical trial (ClinicalTrials.gov, NCT01489358). The vaccine was found to have adequate efficacy, safety, and tolerability in human trials (Chang et al. 2014). The CHIKV VLP Vaccine is currently undergoing a phase II clinical trial (ClinicalTrials.gov, NCT02562482.).

The CHIKV VLP used for these clinical trials was expressed via transient gene expression (TGE) technology using plasmid DNA and PEI (polyethylenimine) in host HEK293 cells (Akahata et al. 2010). PEI is the most popular gene delivery vehicle due to its advantages in cost and transfection efficiency (Boussif et al. 1995; Gutierrez-Granados et al. 2018). DNA and PEI can be added either directly or indirectly to the cells. The indirect approach is the most cited method and involves a pre-mixing step of the two reagents (Cervera et al. 2013; Rajendra et al. 2015; Tuvesson et al. 2008; Venereo-Sanchez et al. 2016). Since DNA is anionic and PEI is cationic, a stable complex is formed when mixed. The complex attaches to the anionic cell surface and enters the host cells through endocytosis. The plasmid does not permanently integrate into the cellular genome; thus, the foreign gene can be lost during cell replication (Kim and Eberwine 2010; Kroll and Rathert 2018; Recillas-Targa 2006). Further, PEI is toxic to cells (Breunig et al. 2007; Florea et al. 2002; Kafil and Omidi 2011). Therefore, the concentrations and ratios of plasmid DNA and PEI need to be optimized to balance expression and toxicity.

The optimal conditions for a TGE system are typically identified in small scale studies. Large size flasks or wave bags are usually used for scale-up at next step (Bollin et al. 2011; Gutierrez-Granados et al. 2018; Raymond et al. 2011; Tait et al. 2004). Alternatively, large stirred tank bioreactors could provide better process control (dissolved oxygen and pH), process robustness, and cost of goods. Various bioreactor sizes from 1.5 to 100 L have been evaluated; however, lower expressions have been uniformly observed (Fliedl and Kaisermayer 2011; Rosser et al. 2005; Schlaeger and Christensen 1999). The root causes for the poor performance are not understood (Gutierrez-Granados et al. 2018).

The expressions of CHIKV VLP faced the same challenges. The clinical materials were only able to be produced in lab scale shake flasks at VRC, and not in large stirred tank bioreactors with volumes of more than 1.5 L. This study here is to investigate the root causes hindering the scale-up. The inoculum cell source, pH range, DNA and PEI levels, order of the reagent addition, impeller speed, and gas-sparging systems were studied. A systematic approach was used for the purpose.

Materials and methods

VRC HEK293 cells (NIH VRC, Bethesda, MD, Lot No. B087-179) were used for the transient transfection. Cells were thawed and expanded in shake flasks (Corning, Oneonta, NY) in a Multitron Pro Incubator (Infors USA, Laurel, MD). The incubator was controlled at 37 °C, 6% CO2, 140 rpm, and 80% relative humidity. Growth medium was 1X CDM4HEK293 (Hyclone, Logan, Utah) supplemented with 6 mM Glutamine (J.T. Baker, Japan) during reconstitution. Inocula were from 3-L shake flasks. To prepare cells for transfection, cells were centrifuged in a J6-MI Centrifuge (Beckman Coulter, Fullerton, CA) at room temperature at 1300 rpm for 5 min. The supernatant was aspirated off and the cell pellets were washed twice with same amount of transfection medium FreeStyle293 (GIBCO, Grand Island, NY). After the second wash, cells were resuspended into calculated amount of transfection medium with a target cell density of 20 million cells/mL. This cell density was used to inoculate each testing condition across various systems (1-L shake flask, ambr® 15 bioreactor, and 3-L Applikon bioreactor) in this study.

Each condition also used the same transfection and expression protocols unless otherwise specified. CHIKV VLP plasmid DNA was added first and PEI (linear, 25 kDa, PolySciences, Warrington, PA) second. At 3 h, 1.5× CDM4HEK293 production medium was added to the culture at 1:1 ratio for production purposes. Then the first sample was taken; cell density was expected to be approximately 10 million cells/mL after dilution. At 24 h, the culture was supplemented with 4 mM valproic acid (Sigma-Aldrich, St. Louis, MO). At 48 h, the culture was supplemented with post transfection feeds 5 g/L glucose (J.T. Baker, Japan) and 6 mM glutamine (GIBCO, Grand Island, NY). At 72 h, the culture was supplemented with additional 2 mM glutamine. At 96 h, the expression was completed.

Besides the direct addition of DNA–PEI (sequential order) stated above, other addition methods were also tested. These included reversed addition orders of DNA and PEI (PEI–DNA, PEI–DNA–PEI), and indirect addition via a pre-mixing step of the reagents. For the latter method, DNA and PEI were added into filtered Milli-Q water (Millipore, Darmstadt, Germany), mixed, and incubated at room temperature for 10 min before adding into culture.

An Advanced Micro Bioreactor ambr® 15 (Sartorius Stedim Biotech, Hertfordshire, UK) was used to screen the transfection conditions at small scale first. The utilizations of ambr® 15 have been well demonstrated (Delouvroy et al. 2015; Janakiraman et al. 2015; Velez-Suberbie et al. 2018). The ambr® 15 had two stations. Each station had 12 micro vessels, each with 15 mL maximum working volume. The vessels were controlled at 37 °C, 50% dissolved oxygen (DO) using air at 0.01 volume per liquid volume per minute (VVM) for background plus O2 supplement on cascade. Stirring was 800 RPM. CO2 and 0.25 M Na2CO3 were used to control pH at target values. All gases including air, O2, and CO2 were delivered through the sparge tube with an internal size of 1.0 mm. Each vessel was equilibrated with transfection medium overnight and calibrated before inoculation.

After the optimal transfection conditions were identified, Applikon 3-L bioreactors (Applikon Biotechnology, Schiedam, Netherlands) were used for the scale-up tests. Each 3-L bioreactor was equipped with two tier spargers for DO control. The first tier was an open tube (macrosparger, 1.6 mm) for background air; and the second tier was a microsparger (15 µm) for O2 supplement (CO2 for pH control as well). The second tier could also be the macrosparger solely. In this study, both types of spargers for tier 2 were tested. Temperature and DO were controlled the same as ambr® 15.

Cell densities were analyzed by Cedex Cell Counter (Roche Diagnostics, Indianapolis, IN). Cellular metabolites were analyzed by Bioprofile Chemistry Analyzer 100 (Nova Biomedical, Waltham, MA). Titer samples were centrifuged and filtered through 0.2 µm filters and stored in 2–8 °C refrigerators. Titers were analyzed by an in-house developed tandem chromatographic method combining ion-exchange (IEX) and size-exclusion (SEC) columns (Shaddeau et al. 2019). Toxicities of DNA and PEI were measured by cell growths and viabilities. Statistical analysis was conducted by JMP (SAS Institute, North Caroline). Hydrodynamics (whichever applicable) for ambr® 15, 3-L bioreactor, and shake flask are calculated as below.

Power input (\(\frac{P}{V}\))

Impeller tip speed (\(u_{tip}\))

Reynolds Number (\(Re\))

Average energy dissipation rate (EDR) for flask (\(\varepsilon_{\varphi }\))

with \(N_{e} = 75Re^{ - 1} + 25Re^{ - 0.6} + 1.5Re^{ - 0.2}\)

Maximum local EDR for bioreactors (\(\varepsilon_{max } )\) (Peter et al. 2006)

Results

Condition screening in ambr® 15 bioreactors

The first effort was to investigate the effects of inoculum cell source, pH, and DNA–PEI concentration on CHIKV VLP transfection in an ambr® 15 bioreactor (Table 1). To study the effect of inoculum cell source, HEK293 cells grown at four stages including early exponential (at a cell density of 2.3 million cells/mL), middle exponential (4.6 million cells/mL), late exponential (6.0 million cells/mL), and stationary (8.1 million cells/mL) phases (cell growth data not shown) were investigated. The pH was tested at 7.3 ± 0.2 (Station 1) and 6.9 ± 0.2 (Station 2). DNA (mg/L)–PEI (mg/L) were tested at concentrations of 20–40, 30–60, and 40–80 respectively.

The second effort was to further investigate the impact of pH and DNA–PEI concentration in an ambr® 15 bioreactor based on the first evaluation (Table 2). pH was maintained at 7.2 ± 0.1 and 6.8 ± 0.1 respectively to avoid overlap. A full factorial design of DNA (20, 30, 40 mg/L) and PEI (20, 40 mg/L) concentrations was tested. Condition DNA 20 mg/L–PEI 40 mg/L was used as a control.

The next effort was to test the toxicity of DNA and PEI, reversed addition order, and pre-mixed complex in an ambr® 15 bioreactor (Table 3). The toxicities of DNA and PEI via direct addition in sequential order were examined in Condition 1–3. The toxicities of DNA alone without PEI additions (DNA-0), or PEI alone without DNA additions (0-PEI) were examined in Condition 4–9. The reversed addition orders of DNA and PEI were examined in Condition 10–11. The indirect addition via a pre-mixing step of the reagents was examined in Condition 12.

Effect of inoculum cell source

The normalized titers are shown in Fig. 1. At each pH condition 6.9 ± 0.2 or 7.3 ± 0.2, the patterns of product expressions were the same. Specifically, inoculum cells at early exponential growth phase produced the highest titer expression; the inoculum cells at middle exponential growth phase produced the second highest titer expression; the inoculum cells at late exponential and stationary growth phases produced the lowest titer expression. Further bivariate fit model analysis indicated that the product titers were negatively correlated to inoculum cell growth status (P < 0.05 for each pH control condition, data not shown). Therefore, the study indicated the ideal cell source for transfection should be at early exponential growth phase.

The effect of pH, inoculum source, and DNA–PEI concentration on CHIKV VLP production in the first ambr® 15 bioreactor study. Product titer was normalized to that of Vessel 1 condition (DNA 20 mg/L–PEI 40 mg/L at pH 7.3 ± 0.2) on Day 4. Vessel 16 had a control issue during the study and its data was not included. E: early exponential; M: middle exponential; L: late exponential; S: stationary

Effect of pH condition

CHIKV VLP product expressions were not affected by the pH condition when tested at 7.3 ± 0.2 or 6.9 ± 0.2 (P > 0.0783 for Day 3; P > 0.0794 for Day 4, t Test, data not shown). A close look at both pH profiles indicated that pH in the high pH (7.3 ± 0.2) condition decreased from 7.5 to 7.1 during the first 36 h and maintained at 7.1 afterwards; and pH in the low pH (6.9 ± 0.2) condition maintained at 7.1 throughout the run (data not shown). The pH profiles were not differentiated as expected most likely due to the media buffer capacity. Therefore, the effect of pH condition was not conclusive and further study was needed.

In the subsequent test, pH parameters were set apart without overlap, i.e., 7.2 ± 0.1 and 6.8 ± 0.1. Inoculum cell sources tested in this section were from middle exponential growth phase only. Although the first study found that early exponential growth phase produced the highest product titer, its cell density was too low (only ~ 2 million cells/mL) to realistically meet the demand of high cell density 20 million cells/mL for transfection. As a result, only inoculum at mid-exponential growth phase was used going forward.

The non-overlapping pH differentiated the cell growth profiles (Fig. 2). The high pH 7.2 ± 0.1 condition produced higher peak cell densities (14–16 million cells/mL) than that of the low pH 6.8 ± 0.1 condition (12 million cells/mL) when PEI was tested at 20 mg/L. However, pH did not affect cell growth substantially when PEI was tested at 40 mg/L. Both pH conditions produced peak cell densities around 10 million cells/mL. Therefore, the pH effect on cell growth was dependent on PEI levels.

The non-overlapping pH also affected the CHIKV VLP product expressions (Fig. 3). Specifically, when PEI was tested at 40 mg/L concentration, the high pH 7.2 ± 0.1 produced 4–5 fold higher product levels than that of the low pH controlled at 6.8 ± 0.1. When PEI was tested at 20 mg/L concentration, the titer expression was quite low at both pH conditions. Therefore, the effect on titer expression by pH was opposite from its effect on cell growth.

In summary, the first two ambr® 15 studies suggested that the pH control in bioreactor was a critical parameter for CHIKV VLP transient transfection and expression. The optimal pH should be within 7.5–7.1. Such pH range in general accorded to that of shake flasks when incubated with 6% CO2 (data not shown) for successful transfection.

Effect of DNA/PEI

DNA and PEI concentrations

The first two ambr® 15 studies showed the best DNA and PEI concentrations were 20 and 40 mg/L respectively. In the first study, a common titer expression pattern occurred across four different cell growth stages at each pH condition (Fig. 1): the highest titer expression came from DNA 20 mg/L–PEI 40 mg/L, the second highest titer expression came from DNA 30 mg/L–PEI 60 mg/L, and the lowest titer expression came from DNA 40 mg/L–PEI 80 mg/L. The study implied that either the higher concentration of DNA or PEI was responsible for the loss of titers. To better understand this phenomenon, a lower concentration of PEI (20 mg/L) was tested in the second study while maintaining the DNA levels the same (Table 2). The study found that the titer expressions were not dramatically impacted by variations of DNA concentrations, but dramatically reduced to less than one-tenth that of Control (DNA 20 mg/L–PEI 40 mg/L) by the change of PEI to 20 mg/L (Fig. 3, pH 7.2 ± 0.1 condition). Taken together, the data indicated that the transient transfection was more sensitive to PEI than DNA. PEI conditions should be well defined.

The sensitivity could be attributed to the toxicity of PEI. PEI 20 mg/L concentration group resulted in higher peak cell densities than PEI 40 mg/L group at pH 7.2 ± 0.1 condition (Fig. 2). This implied that PEI could be more toxic to cells at high concentrations. To confirm this, DNA alone, PEI alone, and combinations of DNA–PEI were tested respectively at various concentrations (Table 3 Conditions 1–9). DNA alone did not affect the viabilities regardless of concentration. But PEI inversely affected the viabilities: the higher the concentrations of PEI, the lower the viabilities. DNA–PEI combinations had better viabilities than that of PEI alone (Fig. 4). This indicated that the toxicity of PEI could be remedied with the addition of DNA.

DNA and PEI addition order

The studies discussed above both used direct addition methods, and the DNA and PEI were added to the cells sequentially. In this part of the investigation, three different addition methods were tested for the selected concentration of DNA 20 mg/L–PEI 40 mg/L (Table 3, Conditions 10–12). These three methods included a divided dose of PEI (20 mg/L each), PEI first DNA second, and a pre-mixed indirect addition. The purpose was to investigate if alternative addition methods could improve the transient expressions.

Cell growths were affected by different addition methods. First, cells grew in each condition and reached similar peak cell densities by day 2. Afterwards, cells in the Control condition (DNA 20 mg/L–PEI 40 mg/L) gradually died and cell density was less than the other conditions by day 4. In comparison, cell density in the pre-mixed complex condition was the highest (data not shown). According to our experience, a mild cell growth increase followed by some viable cell loss usually indicated successful transfections. This hypothesis was confirmed by the titer expressions (Fig. 5). The control had the highest titers and pre-mixed complex had the lowest. The lowest titer can be explained by the precipitation of DNA and PEI during pre-mixing step. Precipitation immediately occurred when DNA and PEI were mixed, regardless of the addition order. Because of the precipitation, the effective DNA and PEI concentrations used for the transfection were less than the expected target 20 and 40 mg/L. This was confirmed by NanoDrop™ absorbance at 260 nm that only 6.9 mg/L of DNA was left in solution (data not shown). As a result, the PEI toxicity was reduced as well, and cells had better growth. This trend was consistent with the test of PEI 20 mg/L condition in Fig. 2. Taken together, the direct sequential addition of DNA and PEI was confirmed to be the best method over others for CHIKV VLP transfection.

Scale-up test in 3-L bioreactors

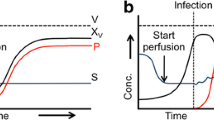

ambr® 15 mini bioreactors were only equipped with a sparge tube where all three gases including air, oxygen, and CO2 shared the same tube. Conventional large stirred tank bioreactors typically use two tier sparger systems to achieve high cell densities. The first tier is open tube (macrosparger) for background air, and the second tier is microsparger for oxygen and CO2. Such set up was used for the high cell density transfection during the first scale up study in 3-L bioreactors as well.

To identify the optimal hydromechanical environment for transfection, impeller agitation (RPM) and tier one open tube air flow rate (VVM) were tested at hi–hi (250RPM-0.05VVM), mid–mid (170RPM-0.025VVM), and lo–lo (90RPM-0.0125VVM) respectively (Table 4). Hi–hi combination provided the best mass transfer coefficient kla ~ 3 h−1 (data not shown); however, it was only able to sustain a cell density of ~ 2 million cells/mL, not the high cell density of 20 million cells/mL. To maintain DO, O2 was immediately cascaded through tier 2 microsparger system. The lower the impeller speed (RPM), the higher the demand of O2 (CO2 for pH as well). Taken together, lower agitation speeds and lower background gas flow rates via open tube would result in higher gas flow rates through microspargers. It has been well reported that the hydrodynamic stress generated by a microsparger (smaller bubbles) is several orders higher than that of a macrosparger (larger bubbles) and mechanical mixing (Kioukia et al. 1996; Ma et al. 2004; Nienow 2006; Varley and Birch 1999). Therefore, the hydrodynamic environments were totally differentiated by such design.

Cell growth in 3-L bioreactors using microspargers is shown in Fig. 6. All conditions started with the same target cell densities of 20 million cells/mL for transfection. The cells in control flask had moderate growth. However, cells died in hi–hi condition. The situation was even worse for mid–mid condition, in which only 2 million cells/mL remained with the poor viability by the first cell count. Titer levels were also significantly lower compared with the control (Fig. 6). Hi–hi condition produced about 50% less than the control, and mid–mid condition produced ~ 70% less.

At the next study, microspargers were replaced with macrospargers (Table 4). Cell growth patterns were different compared with the first run. All conditions had similar growth patterns. i.e., moderate cell growth increases followed by viable cell losses (Fig. 7). Such trends implied good titer expressions. Titer levels were comparable for all tested conditions and the control flask (Fig. 7). In contrast to 50–70% loss in the first test using microspargers, the improvement was significant. The data suggest the impeller agitation speeds were not a critical factor for the transfection, nor the macrosparger and its gas flow rates. The results were repeated in another set of experiment with hi–hi condition (data not shown). Overall, the study suggested that transient transfection can be implemented in 3-L bioreactors using macrospargers with similar titer expression as the control flask.

The transient transfection was successful in shake flasks, ambr® 15, and 3-L bioreactors using open tube spargers, but not in the 3-L bioreactors using microspargers. It is of great interest to understand the shear and hydromechanical environment for each system. The calculations are shown in Table 5. The control flask had a Re number nearly 50,000, four times that of the 3-L bioreactor running at the highest 250 RPM speed, and twenty times that of the ambr® 15. The control flask had an average energy dissipation rate nearly 0.14 w/kg, eight times that of the ambr® 15, and fourteen times that of the 3-L bioreactor at 250 RPM. The ambr® 15 had 16.7 w/m3 power input, 1.6 times of the 3-L bioreactor at 250 RPM. The ambr® 15 had maximum energy dissipation rate 0.92 w/kg, two times that of the 3-L bioreactor at 250 RPM. The ambr® 15 had similar tip speed as 3-L bioreactors at 250 and 170 RPM. Taken together, the control flask and ambr® 15 had higher shear and hydromechanical stress by most measurements but still provided good titer expressions. This indicated that mechanical mixing could be ruled out as a critical factor hindering transfection and expression. Instead, microsparger and associated shear stress were most likely the root causes (discussed below).

Discussion

Transient gene expression (TGE) techniques for VLP, recombinant proteins, and viral vectors using mammalian cells are widely reported, but the titer expressions are generally lower, less predictable, and reproducible compared to stable transfections (de los Milagros Bassani Molinas et al. 2014; Gutierrez-Granados et al. 2018; Rajendra et al. 2015; Tuvesson et al. 2008). CHIKV VLP in this case were not exceptional and the historical productions at VRC had up to four-fold variations when transfected and expressed in shake flasks (internal data not shown). Many hypotheses have been proposed to explain the phenomena. The difficulties of DNA–PEI complex entry into the nucleus either via active or passive transport are considered one of the bottlenecks (Carpentier et al. 2007; Grosse et al. 2006; Han et al. 2009; Won et al. 2009). Another bottleneck is that the vectors are not integrated into host cell genome like stable transfection. The foreign genes can be lost due to cell division or degradation over time (Kim and Eberwine 2010; Kroll and Rathert 2018; Recillas-Targa 2006). While these challenges still exist today, the studies here mainly focused on how extracellular parameters and environments made impacts on TGE performance, particularly at high cell density conditions. High cell density transfection has been used to improve titer expressions (Ansorge et al. 2009; Backliwal et al. 2008a; Sun et al. 2008).

The study indicated that the transfection productions were directly correlated to inoculum cell growth, i.e., the earlier the cell growth phase and more robust the actual growth rate, the higher the titer production. This finding is in line with literature reports that the best cell status for transfections should be at exponential growth phase (Cervera et al. 2013; Park et al. 2006; Segura et al. 2007). At this stage, cells are actively growing with rapid host gene replications. This probably facilitates the plasmid DNA uptake into the cell nucleus.

This study further indicated that the optimal pH for TGE should be in the range of 7.5–7.1. pH lower than 6.9 was not suitable for high titer expressions. Gutierrez-Granados et al. (2018) reviewed that the majority of the transfection work published so far were conducted either in a pH above 7.0 for bioreactors, or with 5% CO2 injection for flasks or wave bags. The lower pH condition is not ideal for transient transfection since it negatively affects the intracellular conditions (Brunner et al. 2000; Grosjean et al. 2002; Tait et al. 2004) and the formation and size of DNA–PEI polyplex (van Gaal et al. 2011).

The optimal DNA and PEI concentrations for CHIKV transfection were found to be DNA 20 mg/L and PEI 40 mg/L, at a ratio of 1:2. Such ratios have also been well reported (Derouazi et al. 2004; Durocher et al. 2002; Grieger et al. 2016; Pham et al. 2003; Tait et al. 2004). Interestingly, if DNA and PEI were still added with the same ratio but at DNA 30 mg/L–PEI 60 mg/L or DNA 40 mg/L–PEI 80 mg/L level, the titer expressions decreased. Also, the higher the concentration of PEI used, the more toxic effect (measured by viable cell densities and viabilities) it had on cells. Such observations were in line with the previous reports. High amount of PEI (> 3 mg/L/1 million cells/mL) and polyplex could negatively inhibit the transfection due to its excessive toxicity and cytostatic effect on cells (Carpentier et al. 2007; Tuvesson et al. 2008).

However, decreasing PEI concentration to 20 mg/L was not an option either. The low concentration resulted in more robust cell growth but dramatically decreased the titers. One can believe that low PEI concentration did not form enough DNA–PEI polyplexes for high cell density transfection, nor had enough free PEI residue left in the solution after the formation of DNA–PEI polyplex. The presence of free PEI residue is important to increase the transfection efficiency (Gutierrez-Granados et al. 2018). On the other hand, increasing DNA concentrations to 30 and 40 mg/L while maintaining PEI at 40 mg/L did not affect the titers dramatically. Together, these data indicate that CHIKV VLP expressions were more sensitive to the concentrations of PEI than DNA. The use of PEI should be fine-tuned.

Addition methods of DNA and PEI were important as well. Two addition methods, direct and indirect, have been reported for transfection (Backliwal et al. 2008b; Bos et al. 2014; Rajendra et al. 2015; Raymond et al. 2011). Direct method added DNA and PEI sequentially, and indirect method added pre-mixed DNA and PEI complex. Although the indirect method using the preformed DNA–PEI complexes are reported to improve the transfection efficiencies, no consistent results have been shown that one method is superior to another one (Gutierrez-Granados et al. 2018). In this study, both methods were tested. The indirect method only produced product titer one tenth that of the direct method. This was most likely due to the precipitation of DNA and PEI during the pre-mixing step. The precipitation was immediately formed regardless of the addition order of DNA and PEI. As a result, the DNA and PEI left over for the transfection were less than the optimal target 20 and 40 mg/L. Interestingly, no precipitation was reported in the literature using the indirect method, most likely due to the much lower concentrations DNA or PEI used (Gutierrez-Granados et al. 2018). Therefore, the indirect method could face challenges when high concentrations of reagents must be used (e.g.—when using high inoculation cell densities). The direct method was more suitable in this case.

A reversed order of direct addition, i.e., PEI–DNA or PEI–DNA–PEI instead of DNA–PEI was also tested. PEI is positively charged. DNA and cellular surfaces are negatively charged. The thought is that PEI and cells will form electrostatic interactions before the DNA bonds to PEI. As such, a sandwich structure (cell–PEI–DNA) might form, and endocytosis may be facilitated. However, only about 50% of product titers were measured compared with that of DNA–PEI sequential addition. Similar observations are also reported that DNA–PEI sequential addition is preferred over other additions (Boussif et al. 1995; Gebhart and Kabanov 2001). The underlying reasons are most likely due to the complexation structures and charges formed under such conditions (van Gaal et al. 2011).

In addition to the transfection conditions identified above, impeller speed and gas sparging strategy are critical parameters for bioreactor scale-up. The hydrodynamic stress generated by impeller mixing has been well reported. For instance, impeller tip speed above 1.5 m/s is generally considered to trigger cell damage (Varley and Birch 1999). The average energy dissipation rate (EDR) levels caused by impeller agitation alone are typically in the range of 0.01–1 w/kg; while the maximum EDR at which various mammalian cell types begin to experience damage are approximately 2–4 orders of magnitude higher (Hu et al. 2011; Ma et al. 2002). In this 3-L scale-up study, the impeller tip speeds, as well as the average and maximum EDRs caused by impeller mixing were well within these limits. Therefore, these impeller speeds were not expected to cause cell death.

The burst of gas bubbles could be more detrimental to mammalian cells than the mechanical mixing (Kioukia et al. 1996; Ma et al. 2004; Nienow 2006). A burst air bubble (1.7 mm in diameter) could generate EDR 1.66 × 104 to 4 × 105 w/kg (Boulton-Stone and Blake 1993; Garcia-Briones and Chalmers 1994), several orders of magnitude higher than that of mechanical agitation. The lethal damage increases with the decrease of bubble size (Varley and Birch, 1999). It has been reported that shear stress impacts cell physiology, cellular uptake of DNA cargo, and transfection efficiency (Mennesson et al. 2006; Shin et al. 2009). Therefore, the microspargers used in the first scale-up test were most likely the root cause for cellular damage and transfection. The higher the microsparger gas flow rate, and the worse the cellular damage. In contrast, the tube spargers in the second test had much larger bubble size and shear stress was believed not strong enough to damage the cells and inhibit the transfection. As a result, cells had slight growth before lysis. Such trend was usually a good sign of transfections according to our experience.

Further, PEI cytotoxicity could make the cellular damage associated with microsparger shear stress even worse. Rawat and Gadgil (Rawat and Gadgil 2016) reported that the combined effects of Lipofectamine 2000 and shear stress increased the toxicity of the lipoplex and accounted for the extensive cell growth inhibitions and transfection efficiency reductions. Since PEI is also toxic, such synergistic effects could have existed for DNA–PEI system as well. The PEI cytoxicity weakened the cells and made them vulnerable; the microsparging shear stress magnified the effects.

It must be pointed out that TGE using large stirred tank bioreactors has been reported in literature. Some studies achieve comparable titers during scale-up and some have significant loss. In neither case have the scale-up challenges and root causes been discussed in detail (Gutierrez-Granados et al. 2018). Further literature review indicates a few different strategies are used to overcome the scale-up issues to achieve comparable protein productions. One strategy is to use surface aeration instead of sparging for DO control (same method as shake flasks) (Ansorge et al. 2009; Durocher et al. 2002; Pham et al. 2003; Venereo-Sanchez et al. 2016). Other strategies include low cell density for transfection (0.5–2.0 million cells/mL), or low DO control (20%), or Pluronic supplementation as shear protectant (Derouazi et al. 2004; Muller et al. 2007; Tuvesson et al. 2008). The former strategy eliminates gas sparging and associated hydrodynamic stress; the latter strategies minimize gas sparging and shear damage. These strategies together imply that shear stress is the root cause for TGE failure in large stirred tank bioreactors as well.

Conclusion

In summary, a systematic approach was used to troubleshoot the CHIKV VLP transient expression challenge in large stirred tank bioreactors. The transfection parameters were first optimized at small scale. Parameters including the optimal inoculum cell source, optimal pH range, best DNA and PEI concentrations, and addition method were identified. The scale-up challenge came from the microsparging and associated hydrodynamic stress, under the effect of PEI toxicity. To resolve the issue, replacing the microsparger with the macrosparger was the solution.

References

Akahata W et al (2010) A VLP vaccine for epidemic chikungunya virus protects non-human primates against infection. Nat Med 16:334–338. https://doi.org/10.1038/nm.2105

Ansorge S, Lanthier S, Transfiguracion J, Durocher Y, Henry O, Kamen A (2009) Development of a scalable process for high-yield lentiviral vector production by transient transfection of HEK293 suspension cultures. J Gene Med 11:868–876. https://doi.org/10.1002/jgm.1370

Backliwal G, Hildinger M, Chenuet S, Wulhfard S, De Jesus M, Wurm FM (2008a) Rational vector design and multi-pathway modulation of HEK 293E cells yield recombinant antibody titers exceeding 1 g/l by transient transfection under serum-free conditions. Nucleic Acids Res 36:e96. https://doi.org/10.1093/nar/gkn423

Backliwal G, Hildinger M, Hasija V, Wurm FM (2008b) High-density transfection with HEK-293 cells allows doubling of transient titers and removes need for a priori DNA complex formation with PEI. Biotechnol Bioeng 99:721–727. https://doi.org/10.1002/bit.21596

Bollin F, Dechavanne V, Chevalet L (2011) Design of experiment in CHO and HEK transient transfection condition optimization. Protein Expr Purif 78:61–68. https://doi.org/10.1016/j.pep.2011.02.008

Bos AB et al (2014) Development of a semi-automated high throughput transient transfection system. J Biotechnol 180:10–16. https://doi.org/10.1016/j.jbiotec.2014.03.027

Boulton-Stone JM, Blake JR (1993) Gas bubbles bursting at a free surface. J Fluid Mech 254:437–466. https://doi.org/10.1017/S0022112093002216

Boussif O, Lezoualc’h F, Zanta MA, Mergny MD, Scherman D, Demeneix B, Behr JP (1995) A versatile vector for gene and oligonucleotide transfer into cells in culture and in vivo: polyethylenimine. Proc Natl Acad Sci USA 92:7297–7301

Breunig M, Lungwitz U, Liebl R, Goepferich A (2007) Breaking up the correlation between efficacy and toxicity for nonviral gene delivery. Proc Natl Acad Sci USA 104:14454–14459. https://doi.org/10.1073/pnas.0703882104

Brunner S, Sauer T, Carotta S, Cotten M, Saltik M, Wagner E (2000) Cell cycle dependence of gene transfer by lipoplex, polyplex and recombinant adenovirus. Gene Ther 7:401–407. https://doi.org/10.1038/sj.gt.3301102

Carpentier E, Paris S, Kamen AA, Durocher Y (2007) Limiting factors governing protein expression following polyethylenimine-mediated gene transfer in HEK293-EBNA1 cells. J Biotechnol 128:268–280. https://doi.org/10.1016/j.jbiotec.2006.10.014

Cervera L, Gutiérrez-Granados S, Martínez M, Blanco J, Gòdia F, Segura MM (2013) Generation of HIV-1 Gag VLPs by transient transfection of HEK 293 suspension cell cultures using an optimized animal-derived component free medium. J Biotechnol 166:152–165. https://doi.org/10.1016/j.jbiotec.2013.05.001

Chang LJ et al (2014) Safety and tolerability of chikungunya virus-like particle vaccine in healthy adults: a phase 1 dose-escalation trial. Lancet 384:2046–2052. https://doi.org/10.1016/s0140-6736(14)61185-5

de los Milagros Bassani Molinas M, Beer C, Hesse F, Wirth M, Wagner R (2014) Optimizing the transient transfection process of HEK-293 suspension cells for protein production by nucleotide ratio monitoring. Cytotechnology 66:493–514. https://doi.org/10.1007/s10616-013-9601-3

Delouvroy F, Siriez G, Tran A-V, Mukankurayija L, Kochanowski N, Malphettes L (2015) ambr™ Mini-bioreactor as a high-throughput tool for culture process development to accelerate transfer to stainless steel manufacturing scale: comparability study from process performance to product quality attributes. BMC Proc 9:P78. https://doi.org/10.1186/1753-6561-9-s9-p78

Derouazi M, Girard P, Van Tilborgh F, Iglesias K, Muller N, Bertschinger M, Wurm FM (2004) Serum-free large-scale transient transfection of CHO cells. Biotechnol Bioeng 87:537–545. https://doi.org/10.1002/bit.20161

Durocher Y, Perret S, Kamen A (2002) High-level and high-throughput recombinant protein production by transient transfection of suspension-growing human 293-EBNA1 cells. Nucleic Acids Res 30:E9

Fliedl L, Kaisermayer C (2011) Transient gene expression in HEK293 and vero cells immobilised on microcarriers. J Biotechnol 153:15–21. https://doi.org/10.1016/j.jbiotec.2011.02.007

Florea B, Meaney C, Junginger HE, Borchard G (2002) Transfection efficiency and toxicity of polyethylenimine in differentiated Calu-3 and nondifferentiated COS-1 cell cultures. AAPS PharmSci 4:4. https://doi.org/10.1208/ps040312

Garcia-Briones MA, Chalmers JJ (1994) Flow parameters associated with hydrodynamic cell injury. Biotechnol Bioeng 44:1089–1098. https://doi.org/10.1002/bit.260440910

Gebhart CL, Kabanov AV (2001) Evaluation of polyplexes as gene transfer agents. J Control Release 73:401–416

Grieger JC, Soltys SM, Samulski RJ (2016) Production of recombinant adeno-associated virus vectors using suspension HEK293 cells and continuous harvest of vector from the culture media for GMP FIX and FLT1. Clin Vector Mol Ther 24:287–297. https://doi.org/10.1038/mt.2015.187

Grosjean F, Batard P, Jordan M, Wurm FM (2002) S-phase synchronized CHO cells show elevated transfection efficiency and expression using CaPi. Cytotechnology 38:57–62. https://doi.org/10.1023/A:1021197830091

Grosse S, Thevenot G, Monsigny M, Fajac I (2006) Which mechanism for nuclear import of plasmid DNA complexed with polyethylenimine derivatives? J Gene Med 8:845–851. https://doi.org/10.1002/jgm.915

Gutierrez-Granados S, Cervera L, Kamen AA, Godia F (2018) Advancements in mammalian cell transient gene expression (TGE) technology for accelerated production of biologics. Crit Rev Biotechnol 38:918–940. https://doi.org/10.1080/07388551.2017.1419459

Han X, Fang Q, Yao F, Wang X, Wang J, Yang S, Shen BQ (2009) The heterogeneous nature of polyethylenimine-DNA complex formation affects transient gene expression. Cytotechnology 60:63. https://doi.org/10.1007/s10616-009-9215-y

Hu W, Berdugo C, Chalmers JJ (2011) The potential of hydrodynamic damage to animal cells of industrial relevance: current understanding. Cytotechnology 63:445–460. https://doi.org/10.1007/s10616-011-9368-3

Janakiraman V, Kwiatkowski C, Kshirsagar R, Ryll T, Huang YM (2015) Application of high-throughput mini-bioreactor system for systematic scale-down modeling, process characterization, and control strategy development. Biotechnol Prog 31:1623–1632. https://doi.org/10.1002/btpr.2162

Kafil V, Omidi Y (2011) Cytotoxic impacts of linear and branched polyethylenimine nanostructures in A431. Cells Bioimpacts 1:23–30. https://doi.org/10.5681/bi.2011.004

Kim TK, Eberwine JH (2010) Mammalian cell transfection: the present and the future. Anal Bioanal Chem 397:3173–3178. https://doi.org/10.1007/s00216-010-3821-6

Kioukia N, Nienow AW, Al-Rubeai M, Emery AN (1996) Influence of agitation and sparging on the growth rate and infection of insect cells in bioreactors and a comparison with hybridoma culture. Biotechnol Prog 12:779–785. https://doi.org/10.1021/bp9600703

Kroll C, Rathert P (2018) Stable expression of epigenome editors via viral delivery and genomic integration. Methods Mol Biol 1767:215–225. https://doi.org/10.1007/978-1-4939-7774-1_11

Ma N, Koelling KW, Chalmers JJ (2002) Fabrication and use of a transient contractional flow device to quantify the sensitivity of mammalian and insect cells to hydrodynamic forces. Biotechnol Bioeng 80:428–437. https://doi.org/10.1002/bit.10387

Ma N, Chalmers JJ, Aunins JG, Zhou W, Xie L (2004) Quantitative studies of cell-bubble interactions and cell damage at different pluronic F-68 and cell concentrations. Biotechnol Prog 20:1183–1191. https://doi.org/10.1021/bp0342405

Mennesson E, Erbacher P, Kuzak M, Kieda C, Midoux P, Pichon C (2006) DNA/cationic polymer complex attachment on a human vascular endothelial cell monolayer exposed to a steady laminar flow. J Control Release 114:389–397. https://doi.org/10.1016/j.jconrel.2006.06.006

Muller N, Derouazi M, Van Tilborgh F, Wulhfard S, Hacker DL, Jordan M, Wurm FM (2007) Scalable transient gene expression in Chinese hamster ovary cells in instrumented and non-instrumented cultivation systems. Biotechnol Lett 29:703–711. https://doi.org/10.1007/s10529-006-9298-x

Nienow AW (2006) Reactor engineering in large scale animal cell culture. Cytotechnology 50:9–33. https://doi.org/10.1007/s10616-006-9005-8

Park JY, Lim BP, Lee K, Kim YG, Jo EC (2006) Scalable production of adeno-associated virus type 2 vectors via suspension transfection. Biotechnol Bioeng 94:416–430. https://doi.org/10.1002/bit.20776

Peter CP, Suzuki Y, Buchs J (2006) Hydromechanical stress in shake flasks: correlation for the maximum local energy dissipation rate. Biotechnol Bioeng 93:1164–1176. https://doi.org/10.1002/bit.20827

Pham PL, Perret S, Doan HC, Cass B, St-Laurent G, Kamen A, Durocher Y (2003) Large-scale transient transfection of serum-free suspension-growing HEK293 EBNA1 cells: peptone additives improve cell growth and transfection efficiency. Biotechnol Bioeng 84:332–342. https://doi.org/10.1002/bit.10774

Rajendra Y, Hougland MD, Alam R, Morehead TA, Barnard GC (2015) A high cell density transient transfection system for therapeutic protein expression based on a CHO GS-knockout cell line: process development and product quality assessment. Biotechnol Bioeng 112:977–986. https://doi.org/10.1002/bit.25514

Rawat J, Gadgil M (2016) Shear stress increases cytotoxicity and reduces transfection efficiency of liposomal gene delivery to CHO-S cells. Cytotechnology 68:2529–2538. https://doi.org/10.1007/s10616-016-9974-1

Raymond C, Tom R, Perret S, Moussouami P, L’Abbe D, St-Laurent G, Durocher Y (2011) A simplified polyethylenimine-mediated transfection process for large-scale and high-throughput applications. Methods 55:44–51. https://doi.org/10.1016/j.ymeth.2011.04.002

Recillas-Targa F (2006) Multiple strategies for gene transfer, expression, knockdown, and chromatin influence in mammalian cell lines and transgenic animals. Mol Biotechnol 34:337–354. https://doi.org/10.1385/mb:34:3:337

Rosser MP et al (2005) Transient transfection of CHO-K1-S using serum-free medium in suspension: a rapid mammalian protein expression system. Protein Expr Purif 40:237–243. https://doi.org/10.1016/j.pep.2004.07.015

Schlaeger EJ, Christensen K (1999) Transient gene expression in mammalian cells grown in serum-free suspension culture. Cytotechnology 30:71–83. https://doi.org/10.1023/a:1008000327766

Segura MM, Garnier A, Durocher Y, Coelho H, Kamen A (2007) Production of lentiviral vectors by large-scale transient transfection of suspension cultures and affinity chromatography purification. Biotechnol Bioeng 98:789–799. https://doi.org/10.1002/bit.21467

Shaddeau AW, Schneck NA, Li Y, Ivleva VB, Arnold FJ, Cooper JW, Lei QP (2019) Development of a new tandem ion exchange and size exclusion chromatography method to monitor vaccine particle titer in cell culture media. Anal Chem 91:6430–6434. https://doi.org/10.1021/acs.analchem.9b00095

Shin HS, Kim HJ, Sim SJ, Jeon NL (2009) Shear stress effect on transfection of neurons cultured in microfluidic devices. J Nanosci Nanotechnol 9:7330–7335. https://doi.org/10.1166/jnn.2009.1769

Simon F, Javelle E, Oliver M, Leparc-Goffart I, Marimoutou C (2011) Chikungunya virus infection current infectious disease reports 13:218–228. https://doi.org/10.1007/s11908-011-0180-1

Smalley C, Erasmus JH, Chesson CB, Beasley DWC (2016) Status of research and development of vaccines for chikungunya. Vaccine 34:2976–2981. https://doi.org/10.1016/j.vaccine.2016.03.076

Sun X, Hia HC, Goh PE, Yap MGS (2008) High-density transient gene expression in suspension-adapted 293 EBNA1 cells. Biotechnol Bioeng 99:108–116. https://doi.org/10.1002/bit.21537

Tait AS, Brown CJ, Galbraith DJ, Hines MJ, Hoare M, Birch JR, James DC (2004) Transient production of recombinant proteins by Chinese hamster ovary cells using polyethyleneimine/DNA complexes in combination with microtubule disrupting anti-mitotic agents. Biotechnol Bioeng 88:707–721. https://doi.org/10.1002/bit.20265

Tuvesson O, Uhe C, Rozkov A, Lüllau E (2008) Development of a generic transient transfection process at 100 L scale. Cytotechnology 56:123–136. https://doi.org/10.1007/s10616-008-9135-2

van Gaal EV, van Eijk R, Oosting RS, Kok RJ, Hennink WE, Crommelin DJ, Mastrobattista E (2011) How to screen non-viral gene delivery systems in vitro? J Control Release 154:218–232. https://doi.org/10.1016/j.jconrel.2011.05.001

Varley J, Birch J (1999) Reactor design for large scale suspension animal cell culture. Cytotechnology 29:177–205. https://doi.org/10.1023/a:1008008021481

Velez-Suberbie ML, Betts JPJ, Walker KL, Robinson C, Zoro B, Keshavarz-Moore E (2018) High throughput automated microbial bioreactor system used for clone selection and rapid scale-down process optimization. Biotechnol Prog 34:58–68. https://doi.org/10.1002/btpr.2534

Venereo-Sanchez A et al (2016) Hemagglutinin and neuraminidase containing virus-like particles produced in HEK-293 suspension culture: an effective influenza vaccine candidate. Vaccine 34:3371–3380. https://doi.org/10.1016/j.vaccine.2016.04.089

Won Y-Y, Sharma R, Konieczny SF (2009) Missing pieces in understanding the intracellular trafficking of polycation/DNA complexes. J Control Release 139:88–93. https://doi.org/10.1016/j.jconrel.2009.06.031

Acknowledgments

We thank Robin Luedtke and Diane Wycuff (VPP/VRC/NIH) for reviewing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author contributions

PC designed the study, performed the experiments, analyzed the data, and wrote the manuscript. JD assisted part of the experiments. VBI performed the product titer analysis. JH, RS, and FA reviewed the manuscript/played management roles.

Rights and permissions

About this article

Cite this article

Chen, P., Demirji, J., Ivleva, V.B. et al. The transient expression of CHIKV VLP in large stirred tank bioreactors. Cytotechnology 71, 1079–1093 (2019). https://doi.org/10.1007/s10616-019-00346-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10616-019-00346-x