Abstract

Flexible fabrics with excellent photothermal conversion performance are highly demanded in developing smart textiles. This work reports the deposition of copper sulfide@polydopamine (CuS@PDA) nanocomposites on the surface of cotton fabrics. The morphology and structure of CuS@PDA coated cotton fabrics were characterized by scanning electron microscopy, transmission electron microscopy, X-ray photoelectron spectroscopy, X-ray diffraction (XRD) and thermogravimetric analysis. The mechanism of the deposition and bonding of CuS@PDA on the surface of cotton fabrics was discussed. It was found that PDA coating resulted in a uniform dispersion of CuS@PDA on cotton fabrics with enhanced bonding fastness between the nanocomposites and fibrous matrix. Due to the unique encapsulation structure of CuS@PDA nanocomposites, the coated cotton fabrics were used as efficient photocatalysts for photodegradation of methylene blue. In addition, the CuS@PDA coated cotton fabrics exhibited excellent photothermal conversion and thermal imaging properties. The photocatalysis and photothermal conversion performance of CuS@PDA coated cotton fabrics endows the potential in smart textile applications.

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Semiconductor compounds are promising candidates for photothermal conversion applications (Zhang et al. 2014; Jia et al. 2015). Among various gold semiconductor compound nanoparticles, copper chalcogenides (Cu2-xE, E = S, Se, Te) nanoparticles exhibit many advantages including fine-tuned localized surface plasmon resonance, broad absorption in the near infrared (NIR) region, good biocompatibility and low cost (Zhang et al. 2012; Huang et al. 2017; Bi et al., 2016). Copper sulfide (CuS) as a member of copper chalcogenides has drawn increasing attention due to its numerous copper vacancies in the crystallization process. These copper vacancies can promote the formation of hole carriers with good mobility, leading to strong localized surface plasmon resonance effects ideal for modification treatment (Wang et al. 2020; Zhang et al. 2017a, 2019).

Recently, various CuS based nanocomposites have been developed to further improve the performance of CuS with broader applications. Zheng et al. fabricated CuS nanocomposite hydrogels for chemo-photothermal therapy, and the multifunctional drug delivery system was developed by decorating graphene oxide and polyethylene glycol on the as-developed CuS nanocomposites (Zheng et al. 2018). According to Jia et al. hepatitis B core protein modified CuS exhibited high efficient photothermal conversion efficiency, and the modified CuS was used as nano-reactor to recruit metal ions into the cavity due to the affinity of copper ions (Jia et al. 2019). CuS-apoferritin was also fabricated through biomimetic synthesis approach, and then it was bound with water-soluble near infrared dye (MBA) to form nanocomposites (CuS-apoferritin-MBA) with enhanced photothermal conversion efficiency (He et al. 2018). In addition, a series of CuS nanocomposites were developed, such as CuS@nanogel-DOX nanocomposites (Meng et al. 2016), CuS@Au with a core–shell nanostructure (Lv et al. 2018), CuS@Cu2S@Au nanohybrid composites (Deng et al. 2017), CuS macroporous polyacrylamide hydrogel (Sun et al. 2019), magnetic Gd-doping CuS nanoparticles (Shi et al. 2019) and iron oxide nanoflowers@CuS hybrids (Curcio et al. 2019). These CuS nanocomposites were widely used in different fields including biomedical and energy devices.

Dopamine a functional element of adhesive proteins comprises alkylamine and catechol functional groups for secondary reactions when adhering on almost all types of surface (Zhang et al. 2017b; Oroujeni et al. 2018; Lu et al. 2015; Cao et al. 2018; Qiu et al. 2018). Dopamine plays the role of template for functional modification in textile finishing, and it has been used to modify the surface of textile materials with enhanced adhesive strength between functional coating and fibers. According to reported studies, dopamine was used to modify the textiles including polyester (PET) fabric (Xu et al. 2013), carbon fiber (Yan et al. 2015), cotton fabric (Sadi et al. 2019), and aramid fiber (Sa et al. 2014). The excellent crosslinking and adhesion performance of dopamine is attributed to its unique catechol structure (Sedõ et al. 2013). Polydopamine (PDA) is widely used as a binder through covalent binding with some specific substrates that have amine/thiol groups, or through noncovalent binding including metal coordination, π-π stacking, and hydrogen bonding effects. With PDA as the templates, functional nanocomponents can be immobilized on flexible textiles toward multi-functional applications (Cheng et al. 2018a, 2019a; Ran et al. 2019a).

The aim of this work is to contribute a strategy of fabricating CuS@PDA nanocomposites followed by adhering on textiles. Using cotton fabrics as the model textiles, CuS@PDA nanocomposites coated cotton fabrics were fabricated. The coated textiles were characterized by transmission electron microscope (TEM), Zeta potential, scanning electron microscopy (SEM), X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), and thermogravimetric analysis (TG). In addition, photocatalytic performance, photothermal conversion and photothermal imaging of CuS@PDA nanocomposites coated cotton fabric were evaluated.

Experimental

Materials

Plain cotton fabrics (135 g/m2, 570/10 cm and 280/10 cm for warp and weft density, respectively) were provided by Wuhan Yudahua Textile Co., Ltd. Copper chloride dihydrate (CuC12·2H2O), trisodium citrate (C6H5Na3O7·2H2O), sodium sulfide (Na2S·9H2O) and Trizma base were purchased from Sinopharm Group Chemical Reagent Co., Ltd (Shanghai, China). Hydroxytyramine hydrochloride (dopamine hydrochloride) was obtained from Aldrich Chemical Co. (Milwaukee, USA). 3-Chloro-2-hydroxypropyl trimethyl ammonium chloride (CHPTAC, 65% w/w) was purchased from TCI Chemical Industry Co. (Tokyo, Japan). All the chemicals were in analytic grade and were directly used without any further purification.

Preparation and fabrication

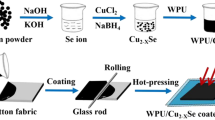

The preparation and deposition of CuS@PDA nanocomposites on cotton fabric are shown in Fig. 1.

Firstly, 40 mL of 50 mM Na2S·9H2O was dissolved in 500 mL solution of 4 mM CuC12·2H2O, then 0.9 g Na3C6H5O7·2H2O was added into the solution under magnetic stirring. CuS nanoparticles were obtained after water bath treatment of the mixture under 12,000 rpm centrifugation at 80 °C for 30 min.

Secondly, 1 g CuS nanoparticles were dispersed in the prepared dopamine-Tris solution (2 g/L, pH 8.5) under magnetic stirring. CuS@PDA nanocomposites were then obtained after vacuum filtration, drying and grinding treatment. CuS@PDA nanocomposites with different weights (0.5 g, 1 g, 1.5 g) were added to 100 mL deionized water under ultrasonic treatment for 10 min to prepare CuS@PDA suspension with different concentrations.

Thirdly, cotton fabrics were cleaned by acetone and deionized water followed by cationic modification by 50 g/L CHPTAC and 36 g/L NaOH mixed solution under 100% wet condition. The modified cotton fabric was sealed in a plastic bag for 24 h at room temperature. After washing and neutralization with 1% acetic acid, the modified cotton fabrics were immersed in the as-prepared CuS@PDA suspension in a constant temperature oscillator for 24 h at room temperature. The as-coated cotton fabrics were then washed with deionized water followed by vacuum drying to 60 °C.

Characterization and measurements

Structural studies of CuS@PDA nanocomposites were obtained from a transmission electron microscopy (TEM, Tecnai G220S-TWIN, FEI Co., US) at an accelerating voltage of 15 kV and 200 kV. The zeta potential of CuS@PDA suspension was obtained by Zetasizer Nano-ZS90 (Malvern). The surface morphology of fabrics was observed on a scanning electron microscope (SEM) (JSM-5600LV, JEOL, Japan). X-ray photoelectron spectroscopy (XPS) measurements were performed on a PHI 5000C ESCA system with a Mg Kα source at 14.0 kV and 25 mA (Perkin-Elmer, America). The crystal structure of CuS, CuS@PDA nanocomposites and CuS@PDA coated cotton fabrics was detected by X-Ray diffraction (XRD) (D/max 2500, Rigaku, Japan) using Cu K α radiation with the diffraction angle 2θ in the range of 10°–80°, at 40 kV and 200 mA. Thermal stability of fabrics was studied by thermal analyzer (TG, Netzsch TG209 F1) under N2 atmosphere with the heating rate of 10 °C/min.

The photocatalytic activities of CuS@PDA coated cotton fabrics were monitored through the degradation of Methylene blue (MB) under the irradiation of visible light. The experimental equipment was purpose-built as described in our previous work (Ran et al. 2019b). In the experiment, MB aqueous solution was taken out after different time intervals, and its concentration was calculated by recording its absorbance at 665 nm wavelength. The photocatalytic degradation efficiency of the MB solution was calculated as follows:

where Co and C are the initial and current concentrations of MB solution, respectively. Ao and A are the initial and current absorbance of MB solution at the 665 nm wavelength, respectively.

To measure the photothermal conversion performance with different concentrations (0.5 g/100 mL, 1 g/100 mL and 1.5 g/100 mL) of CuS@PDA nanocomposites, the fabric samples were hanging to be irradiated by a laser power (1 W/cm2 power and 808 nm wavelength) from the distance of 20 cm, and the temperature was recorded by a digital thermometer. The effect of distance was studied by hanging fabrics at the distances of 10 cm, 20 cm, 30 cm and 40 cm, respectively. The laser power was also changed to 0.5 W/cm2, 1 W/cm2 and 1.5 W/cm2 to investigate its effects on the photothermal conversion. In addition, the cyclic photothermal conversion of the coated fabrics was also studied, in which the irradiating process was interrupted when the temperature of fabrics increased to its maximum, and then the irradiation was resumed once the temperature dropped to room temperature. The thermal imaging and photo-induced heating performance of CuS@PDA coated cotton fabrics were characterized by an Infrared thermal camera (FLIR ONE Pro), and both the surface temperature and thermal images were recorded.

Results and discussions

Characterization of PDA-coated CuS nanoparticles

The morphology of pure CuS nanoparticles and CuS@PDA nanocomposites were observed by TEM, as shown in Fig. 2a–c. The pure CuS nanoparticles show the coral-shaped structure (Fig. 2a). The polymerization of dopamine has formed a thin film on CuS nanoparticles, with PDA in a lighter color while CuS nanoparticles in a darker color (Fig. 2b). Apparently, the presence of PDA coating improved the uniform dispersion of CuS@PDA nanocomposites. It can be observed from Fig. 2c that the thickness of PDA coating is approximately 5 nm. The CuS@PDA nanocomposites exhibit a well-developed core–shell structure due to the formed thin and adhesive PDA layer. In Fig. 2d, the zeta potential of the CuS nanoparticles after PDA coating can be observed at the point of − 26.47 mV. The negative charges of CuS@PDA nanocomposites are crucial in maintaining a stable dispersion in solution and facilitating a uniform deposition onto the surface of cationized cotton fabrics.

Characterization of CuS@PDA-coated cotton fabrics

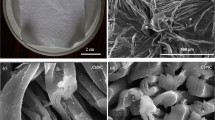

The surface morphology of the pristine cotton and CuS@PDA coated cotton fabrics was characterized by SEM, as shown in Fig. 3. The black CuS particles were covered on the fabric surface of the fabric, resulting in the change of color of cotton fabrics from white to black (Fig. 3a). Moreover, dopamine can self-polymerize to generate melanin-like (Lin et al. 2014), which also lead to the fabric turn into black. The surface of pristine cotton fabrics is smooth surface with longitudinal convolutions and grooves, as shown the SEM image in Fig. 3b. After coating CuS@PDA nanocomposites, the cotton fabric was covered by a dense film of CuS@PDA nanocomposites, as seen from the SEM image in Fig. 3c. Detailed view in Fig. 3d reveals that the nanocomposites are well distributed on the surface of fibers. It is evident that CuS@PDA nanocomposites have successfully deposited on the surface of cotton fabrics without significant aggregations. Dopamine was used to modify copper sulfide, which not only increase the active groups on the surface of copper sulfide, but also produce well-dispersed CuS@PDA nanoparticles. The strong adhesion of polydopamine can effectively anchor nanoparticles on fiber surface, thus improving the binding force between nanoparticles and fibers, which is beneficial to the reutilization of loaded fabrics.

The CuS@PDA nanocomposites have uniformly deposited on the surface of cotton fabrics, which is attributed to the presence of PDA. The effects of PDA on CuS@PDA nanocomposite coating on cotton fabrics can be classified into the following four categories: (1) PDA on CuS nanoparticles can inhibits the agglomeration of the nanoparticles, ensuring a uniform dispersion on the surface of fabrics; (2) Polydopamine layer was deposited on the surface of nanoparticles copper sulfide nanoparticles via polymerization, and the ester bond was formed through the dehydration between the phenolic hydroxyl active functional groups and hydroxyl groups in glucose-based macromolecular polysaccharides; (3) The strong adhesion of PDA itself effectively improves the fastness between CuS@PDA nanocomposites and fabrics; (4) The electrostatic effects between negatively charged CuS@PDA nanocomposites with positively charged cationized fabrics enhance the binding strength.

The surface element of cotton fabrics before and after coating were characterized by XPS analysis. As shown in Fig. 4a, the XPS scanning spectra of both fabrics exhibit the binding energy (BE) of 284.83 eV and 531.78 eV corresponding to C 1 s and O 1 s, respectively. A new signal at 401.91 eV of N 1 s due to the amino groups of dopamine can be observed from Fig. 4b (Lee et al. 2017; Cheng et al. 2020), suggesting that the PDA layer has been successfully deposited on the surface of the cotton fabrics. In Fig. 4c, the high-resolution XPS spectrum of Cu 2p consists of two peaks at 932.47 eV and 943.10 eV due to the binding energy of Cu 2p3/2 electrons of copper, and it contains another two peaks at 953.50 eV and 961.80 eV attributing to the binding energy of Cu 2p1/2 electrons of copper element (Ludwig et al. 2015; Karikalan et al. 2017). In Fig. 4d, the binding energy of S 2p at 168.02 eV can be observed. These results confirm that both CuS and PDA have deposited on the coated cotton fabrics.

The crystal structure and preferred crystal orientation of both CuS@PDA nanocomposites and CuS@PDA cotton fabric were characterized by the X-ray diffraction analysis. As shown in Fig. 5a, CuS@PDA nanoparticles exhibit polycrystalline structure with obvious high intensity diffraction peaks at 2θ = 28.8° (101), 33.9° (103) and 47.74° (107) attributing to the lattice planes of the hexagonal phase of CuS covellite structure (PDF 06–0464) (Li et al. 2013). The other weak diffraction peak at 2θ = 59.08° is also due to the hexagonal phase (116) of CuS (Chaki et al. 2014). In the XRD pattern of the CuS@PDA coated cotton fabrics, the observed diffraction peaks are at 2θ = 15.06°, 16.62°, 22.48° and 34.48°, which can be attributed to (1–10), (110), (200) and (004) planes of cotton fibers, respectively (Cheng et al. 2018b). In addition, two weak diffraction peaks at 2θ = 28.8° and 47.74° are also observed due to the existence of CuS nanoparticles. The broaden diffraction peaks in XRD pattern indicate the formation of CuS@PDA nanocomposites (Gupta et al. 2012).

As shown the TG curves in Fig. 5b, the onset and endset decomposition temperature for pristine cotton fabrics is 407 °C and 456 °C, respectively. The weight residue is 9.32 wt% at 800 °C, suggesting that cotton fabrics can almost completely decompose. Whereas the onset and endset decomposition temperature for coated cotton fabrics is 327 °C and 372 °C, respectively. This may be due to a large amount of CuS@PDA nanocomposites on the fiber surface to promote the carbonization of cellulose chain. In addition, the weight residue is 16.42 wt% at 800 °C, which can be calculated and deduce the mass fraction of CuS nanoparticles deposited on the surface of the cotton was 7.1%.

Photocatalytic activities

The CuS@PDA nanocomposite coated cotton fabrics can be used to degrade MB under visible light irradiation. The visible light driven photocatalysis performance of CuS@PDA coated cotton fabrics is shown in Fig. 6. In Fig. 6a, the absorption peak of residual MB aqueous solution at 665 nm decreases rapidly with the increase in irradiation time, indicating the effective photocatalysis behavior of CuS@PDA coated cotton fabrics. When the irradiation time up to 330 min, the absorbance of MB solution has no obvious absorption peak, which indicates that solution was almost completely decomposed. The residual relative concentration of MB solution decreases gradually with increasing irradiation time as shown in Fig. 6b. It can be calculated that 97.3% of MB was degraded after irradiation for 330 min in the presence of CuS@PDA coated cotton fabrics. According to reported studies (Lai et al. 2019), CuS nanoparticles exhibit weak photocatalytic performance, and the catalytic efficiency is as low as 10% for 90 min treatment. In this work, polydopamine layer was deposited on the surface of CuS nanoparticles, thus improve the well dispersion of CuS nanoparticles. Followed by the fabrication of CuS@PDA catalyst with shell-core structure, which can not only increase the contact area between the catalyst and dye molecules, but also improve the energy transfer from polydopamine to CuS nanoparticles during illumination, thus effectively promoting the catalytic reaction.

The photocatalytic activity of CuS@PDA coated cotton fabrics is attributed to the presence of CuS@PDA nanocomposites on the fiber surface. The mechanism of photocatalysis of CuS@PDA coated cotton fabrics in MB photodegradation under visible light irradiation is proposed in Fig. 7. When CuS@PDA nanocomposites was irradiated by light with energy greater than the band gap energy, conduction-band (CB) electrons (e−) and valence-band (VB) holes (h+) would be generated on its surface, as shown in Eq.①. The released electrons can be captured by the adsorbed O2 molecules to produce superoxide anion radical (·O2−), and the holes can be reacted with water molecules to form highly reactive hydroxyl radicals (·OH), as shown in Eqs.② and ③. The dyes MB can be degraded into CO2 and H2O by the generated ·O2− and ·OH radicals. Meanwhile, the holes (h+) can directly react with MB molecules to produce CO2 and H2O, as shown in Eq.④ (Moafi et al. 2011; Wang et al. 2018).

Photothermal conversion

Considering the absorption of CuS@PDA nanocomposite materials mainly occur at the near-Infrared region, the photothermal conversion performance at the wavelength of 808 nm of the CuS@PDA coated cotton fabrics was investigated. As shown in Fig. 8a, the surface temperature of the CuS@PDA coated cotton fabrics increases quickly with the irradiation of laser power, and the temperature reaches to its maximum after 40 s. The power of 0.5 W/cm2 is too weak to generate photothermal transfer of the fabric, as the heating curve is not obvious. With the increase of power, however, the heating rate increases dramatically, and less time is required to reach to the maximum temperature. Besides, the higher the laser power, the higher the surface temperature of the coated fabrics can reach.

The temperature increase-irradiation duration curves of different irradiation of laser power (0.5–2.0 W power) (a); The temperature increase-irradiation duration curves of different irradiation distance (10–40 cm) (b); The temperature increase-irradiation duration curves of different concentrations of CuS@PDA nanocomposites (0.5 g/100 mL, 1 g/100 mL and 1.5 g/100 mL) (c); The temperature increase-irradiation duration curves under cyclic irradiation/non-irradiation (d)

In order to explore the effects of the irradiation distance on the photothermal conversion, the distance between 10 and 40 cm were chosen to perform the experiments in which the wavelength was 808 nm and the power was 1 W/cm2. As shown the curves in Fig. 8b, the shorter the irradiation distance, the higher heating rate and the shorter time required to reach the maximum temperature. Furthermore, the surface temperature is evidently higher with the decrease of the irradiation distance. The rapid heating process can be mainly attributed to the strong absorbency of CuS in near infrared region, which can be used as ideal photothermal conversion materials. After the addition of copper sulfide modified by dopamine, the loaded fabric with shell-core structure CuS@PDA nanoparticles exhibit efficient photothermal effects due to strong near-infrared light absorption, thus rapid heating process was obtained under the action of small irradiation power (1 W).

Cotton fabrics coated with different concentrations (0.5 g/100 mL, 1 g/100 mL and 1.5 g/100 mL) of CuS@PDA nanocomposites were irradiated at the distance of 20 cm by 1 W/cm2 808 nm wavelength laser. As shown in Fig. 8c, the influence of the concentration is not obvious. This is mainly due to the transition between CuS energy bands, which lead to the good absorption in the near infrared region and photo-thermal conversion efficiency. In addition, PDA is a melanin-like mimic of mussel adhesive protein (Cheng et al. 2019b), which can also absorb near infrared light. Therefore, the surface temperature of the fabric can quickly reach 60 °C even at a lower concentration (0.5 g/100 mL).

Cyclic irradiation/non-irradiation experiment was also carried out to study the stability of the photothermal conversion. As shown in Fig. 8d, the CuS@PDA coated cotton fabrics was irradiated with 1 W/cm2 power at a 20 cm irradiation distance. The temperature of the coated cotton fabrics after irradiation for 50 s is 71.2 °C. After the termination of irradiation, the cotton fabrics cool down to the initial temperature after 2 min. The temperature will rise to 70 °C again when the laser power is back on, and the heating/cooling process can be repeated (Fig. 8d). The results indicate that the CuS@PDA coated cotton fabrics exhibit good photothermal conversion performance with photothermal stability. The transition between CuS energy bands provide robust absorption in the near-infrared region. The CuS@PDA loaded fabric exhibits efficient photothermal properties when irradiated by 808 nm laser. As natural melanin, polydopamine can absorb light in the near-infrared region and CuS exhibits superior photothermal conversion efficiency, thus the loaded cotton fabrics have excellent photothermal properties due to the synergistic effects between CuS nanoparticles and PDA layer.

Photo-induced heating performance

The excellent photothermal conversion performance of CuS@PDA coated cotton fabrics grants the potential of the coated fabrics as photothermal device. The CuS@PDA coated cotton fabrics were sewn on waist band and glove for thermal therapy applications, as shown in Fig. 9. It can be seen that after being irradiated for 40 s, the temperature of the fabric heater can rise to 62.1 °C and 63.9 °C for the coated fabrics on the waist band and the glove, respectively. Besides, within 20 s the temperature of the coated fabrics on the glove can rapidly rise to 52.4 °C. These experimental results indicate that the CuS@PDA coated cotton fabrics are promising candidates for photothermal therapy devices. The photothermal heating mechanism of coated fabrics can be explained as the excellent photothermal conversion performance of CuS@PDA nanoparticles.

Evolution of thermal imaging and heating temperature of the CuS@PDA coated cotton fabrics as therapy heaters (irradiated by 1 W/cm2 808 nm laser at the distance of 20 cm). Photo of the coated fabrics on a waist band (a) and its thermal images after irradiation for 0 s (b) and 40 s (c). Photo of the coated fabrics on a glove (d) and its thermal images after irradiation for 0 s (e), 20 s (f) and 40 s (g)

Conclusions

In summary, CuS@PDA nanocomposites were successfully prepared and deposited on the surface of cotton fabrics. The coated functional layer was bonded firmly with cotton fabric substrate owing to the bonding mechanism of hydrogen bonding, electrostatic effects, and adhesion of dopamine. The structural characterizations results showed the uniform dispersion of both CuS nanoparticles and CuS@PDA nanocomposites. The CuS@PDA nanoparticles showed core-sheath structure and were evenly deposited on the surface of cotton fabrics. The existence of the coated CuS@PDA was further confirmed by XPS analysis and XRD diffraction. The coated cotton fabrics exhibited high photocatalysis efficiency to degrade methylene blue within 330 min. Furthermore, CuS@PDA coated cotton fabrics showed superior photothermal conversion performance. Cyclic photothermal conversion experiment suggested the good photothermal stability of the coated fabrics. CuS@PDA coated cotton fabrics were demonstrated in photo-induced heating applications.

References

Bi H, Dai Y, Xu J, Lv R, He F, Gai S, Yang D, Yang P (2016) CuS-Pt(IV)-PEG-FA nanoparticles for targeted photothermal and chemotherapy. J Mater Chem B 4:5938–5946

Cao N, Miao Y, Zhang D, Boukherroub R, Lin X, Ju H, Li H (2018) Preparation of mussel-inspired perfluorinated polydopamine film on brass substrates: Superhydrophobic and anti-corrosion application. Prog Org Coat 125:109–118

Chaki SH, Deshpande MP, Tailor JP (2014) Characterization of CuS nanocrystalline thin films synthesized by chemical bath deposition and dip coating techniques. Thin Solid Films 550:291–297

Cheng D, He M, Ran J, Cai G, Wu J, Wang X (2018a) In situ reduction of TiO2 nanoparticles on cotton fabrics through polydopamine templates for photocatalysis and UV protection. Cellulose 25:1413–1424

Cheng D, He M, Ran J, Cai G, Wu J, Wang X (2018b) Depositing a flexible substrate of triangular silver nanoplates onto cotton fabrics for sensitive SERS detection. Sensor Actuat B-Chem 270:508–517

Cheng D, Bai X, He M, Wu J, Yang H, Ran J, Cai G, Wang X (2019a) Polydopamine-assisted immobilization of Ag@Au NPs on cotton fabrics for sensitive and responsive SERS detection. Cellulose 26:4191–4204

Cheng W, Zeng X, Chen H, Li Z, Zhao Y (2019b) Versatile polydopamine platforms: synthesis and promising applications for surface modification and advanced nanomedicine. ACS Nano 13(8):8537–8565

Cheng D, Bai X, Pan J, Wu J, Ran J, Cai G, Wang X (2020) In situ hydrothermal growth of Cu NPs on knitted fabrics through polydopamine templates for heating and sensing. Chem Eng J 382:123036–123045

Curcio A, Silva AKA, Cabana S, Espinosa A, Baptiste B, Menguy N, Wilhelm C, Abou-Hassan A (2019) Iron oxide nanoflowers@CuS hybrids for cancer tri-therapy: interplay of photothermal therapy, magnetic hyperthermia and photodynamic therapy. Theranostics 9:1288–1302

Deng X, Li K, Cai X, Liu B, Wei Y, Deng K, Xie Z, Wu Z, Ma P, Hou Z, Cheng Z, Lin J (2017) A hollow-structured CuS@Cu2S@Au nanohybrid: synergistically enhanced photothermal efficiency and photoswitchable targeting effect for cancer theranostics. Adv Mater 29:1701266–1701274

Gupta VK, Pathania D, Agarwal S, Singh P (2012) Adsorptional photocatalytic degradation of methylene blue onto pectin-CuS nanocomposite under solar light. J Hazar Mater 243:179–186

He Y, Shen Y, Zhou S, Wu Y, Yuan Z, Wei C, Gui L, Chen Y, Gu Y, Chen H (2018) Near infrared dye loaded copper sulfide-apoferritin for tumor imaging and photothermal therapy. RSC Adv 8:14268–14279

Huang X, Zhang W, Guan G, Song G, Zou R, Hu J (2017) Design and functionalization of the NIR-responsive photothermal semiconductor nanomaterials for cancer theranostics. Accounts Chem Res 50:2529–2538

Jia GZ, Lou WK, Cheng F, Wang XL, Yao JH, Dai N, Chang K (2015) Excellent photothermal conversion of core/shell CdSe/Bi2Se3 quantum dots. Nano Res 8:1443–1453

Jia Q, Li D, Zhang Q, Ye S, Xi Z, Wang X, Shan W, Ren L (2019) Biomineralization synthesis of HBc-CuS nanoparticles for near-infrared light-guided photothermal therapy. J Mater Sci 54:13255–13264

Karikalan N, Karthik R, Chen SM, Karuppiah C, Elangovan A (2017) Sonochemical synthesis of sulfur doped reduced graphene oxide supported CuS nanoparticles for the non-enzymatic glucose sensor applications. Sci Rep 7(1):2494–2503

Lai C, Zhang M, Li B, Huang D, Zeng G, Qin L, Liu X, Yi H, Cheng M, Li L, Chen Z, Chen L (2019) Fabrication of CuS/BiVO4 binary heterojunction photocatalysts with enhanced photocatalytic activity for Ciproflfloxacin degradation and mechanism insight. Chem Eng J 358:891–902

Lee M, Lee SH, Oh IK, Lee H (2017) Microwave-accelerated rapid, chemical oxidant-free, material-independent surface chemistry of Poly(dopamine). Small 13:1600443–1600448

Li Y, Hu J, Liu G, Zhang G, Zou H, Shi J (2013) Amylose-directed synthesis of CuS composite nanowires and microspheres. Carbohydr Polym 92:555–563

Lin LS, Cong ZX, Cao JB, Ke KM, Chen X (2014) Multifunctional Fe3O4@polydopamine core-shell nanocomposites for intracellular mRNA detection and imaging-guided photothermal therapy. ACS Nano 8(4):3876–3883

Lu Z, Xiao J, Wang Y, Meng M (2015) In situ synthesis of silver nanoparticles uniformly distributed on polydopamine-coated silk fibers for antibacterial application. J Colloid Interf Sci 452:8–14

Ludwig J, An L, Pattengale B, Kong Q, Zhang X, Xi P (2015) Ultrafast hole trapping and relaxation dynamics in p-type cus nanodisks. J Phys Chem Lett 6(14):2671–2675

Lv Q, Gao MY, Cheng ZH, Chen Q, Shen AG, Hu JM (2018) Rational synthesis of hollow cubic CuS@Spiky Au core-shell nanoparticles for enhanced photothermal and SERS effects. Chem Commun 54:13399–13402

Meng Z, Wei F, Wang R, Xia M, Chen Z, Wang H, Zhu M (2016) NIR-laser-switched in vivo smart nanocapsules for synergic photothermal and chemotherapy of tumors. Adv Mater 28:245–253

Moafi HF, Shojaie AF, Zanjanchi MA (2011) Photocatalytic self-cleaning properties of cellulosic fibers modified by nano-sized zinc oxide. Thin Solid Films 519(11):3641–3646

Oroujeni M, Kaboudin B, Xia W, Jönsson P, Ossipov DA (2018) Conjugation of cyclodextrin to magnetic Fe3O4 nanoparticles via polydopamine coating for drug delivery. Prog Org Coat 114:154–161

Qiu WZ, Yang HC, Xu ZK (2018) Dopamine-assisted co-deposition: an emerging and promising strategy for surface modification. Adv Colloid Interfac 256:111–125

Ran J, Bi S, Jiang H, Telegin F, Bai X, Yang H, Cheng D, Cai G, Wang X (2019a) Core-shell BiVO4@PDA composite photocatalysts on cotton fabrics for highly efficient photodegradation under visible light. Cellulose 26:6259–6273

Ran J, Chen B, Bai X, Bi S, Jiang H, Cai G, Cheng D, Wang X (2019b) Immobilizing CuO/BiVO4 nanocomposite on PDA-templated cotton fabric for visible light photocatalysis, antimicrobial activity and UV protection. Appl Surf Sci 493:1167–1176

Sa R, Yan Y, Wei Z, Zhang L, Wang W, Tian M (2014) Surface modification of aramid fibers by bio-inspired poly(dopamine) and epoxy functionalized silane grafting. ACS Appl Mater Inter 6:21730–21738

Sadi MS, Pan J, Xu A, Cheng D, Cai G, Wang X (2019) Direct dip-coating of carbon nanotubes onto polydopamine-templated cotton fabrics for wearable applications. Cellulose 26:7569–7579

Sedõ J, Saiz-Poseu J, Busqué F, Ruiz-Molina D (2013) Catechol-based biomimetic functional materials. Adv Mater 25:653–701

Shi H, Sun Y, Yan R, Liu S, Zhu L, Liu S, Feng Y, Wang P, He J, Zhou Z, Ye D (2019) Magnetic semiconductor Gd-doping CuS nanoparticles as activatable nanoprobes for bimodal imaging and targeted photothermal therapy of gastric tumors. Nano Lett 19:937–947

Sun Y, Gao J, Liu Y, Kang H, Xie M, Wu F, Qiu H (2019) Copper sulfide-macroporous polyacrylamide hydrogel for solar steam generation. Chem Eng Sci 207:516–526

Wang X, Li L, Fu Z, Cui F (2018) Carbon quantum dots decorated cus nanocomposite for effective degradation of methylene blue and antibacterial performance. J Mol Liq 268:578–586

Wang Z, Yu N, Li X, Yu W, Han S, Ren X, Yin S, Li M, Chen Z (2020) Galvanic exchange-induced growth of Au nanocrystals on CuS nanoplates for imaging guided photothermal ablation of tumors. Chem Eng J 381:122613–122623

Xu H, Shi X, Lv Y, Mao Z (2013) The preparation and antibacterial activity of polyester fabric loaded with silver nanoparticles. Text Res J 83:321–326

Yan J, Lu H, Huang Y, Fu J, Mo S, Wei C, Miao YE, Liu T (2015) Polydopamine-derived porous carbon fiber/cobalt composites for efficient oxygen reduction reactions. J Mater Chem A 3:23299–23306

Zhang B, Shan Y, Chen K (2017a) A facile approach to fabricate of photothermal functional Fe3O4@CuS microspheres. Mater Chem Phys 193:82–88

Zhang X, Huang Q, Deng F, Huang H, Wan Q, Liu M, Wei Y (2017b) Mussel-inspired fabrication of functional materials and their environmental applications: progress and prospects. Appl Mater Today 7:222–238

Zhang X, Wu J, Williams GR, Yang Y, Niu S, Qian Q, Zhu LM (2019) Dual-responsive molybdenum disulfide/copper sulfide-based delivery systems for enhanced chemo-photothermal therapy. J Colloid Interf Sci 539:433–441

Zhang Q, Zhou Y, Wang F, Dong F, Li W, Li HM, Patzke GR (2014) From semiconductors to semimetals: bismuth as a photocatalyst for NO oxidation in air. J Mater Chem A 2:11065–11072

Zhang YW, Tian JQ, Li HY, Wang L, Qin XY, Asiri AM, Al-Youbi AO, Sun XP (2012) Biomolecule-assisted, environmentally friendly, one-pot synthesis of CuS/reduced graphene oxide nanocomposites with enhanced photocatalytic performance. Langmuir 28:12893–12900

Zheng Y, Liang Y, Zhang D, Zhou Z, Li J, Sun X, Liu YN (2018) Fabrication of injectable CuS nanocomposite hydrogels based on UCST-type polysaccharides for NIR-triggered chemo-photothermal therapy. Chem Commun 54:13805–13808

Acknowledgments

This research was supported by Natural Science Foundation of Hubei Province (2018CFB679), Hubei Province Technical Innovation Special Project (2019AAA005) and Engineering Research Center of Environment-Friendly Functional Materials, Ministry of Education, Huaqiao University (EFFM-201902).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, D., Liu, Y., Zhang, Y. et al. Polydopamine-assisted deposition of CuS nanoparticles on cotton fabrics for photocatalytic and photothermal conversion performance. Cellulose 27, 8443–8455 (2020). https://doi.org/10.1007/s10570-020-03358-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03358-5