Abstract

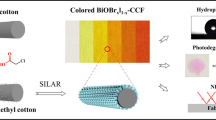

Cotton fabrics have been used in a variety of applications due to its attractive properties of softness, comfort, warmth, biodegradability and breathability. Coating cotton fabrics with photocatalytic materials can extend their use as self-cleaning and other practical applications. In this study, coating of cotton fabrics with dye sensitized/TiO2 for self-cleaning and UV blocking properties has been reported. Phthalocyanine based reactive dye, Reactive Blue-25 (RB-25), has been used as a visible light scavenger for TiO2. RB-25/TiO2 hybrid sol was prepared by sol–gel method and coated on the cotton fabrics via dip-pad-dry-cure method. The coated cotton fabric was characterized by FTIR-ATR, UV–Visible absorption, XRD, SEM and reflectance measurements. The surface studies confirmed the stable attachment of RB-25/TiO2 on the cotton fabric while photocatalytic and UV absorption studies shown that the RB-25/TiO2 coated cotton fabric exhibit substantial visible light driven self-cleaning and UV blocking properties. Rhodamine B (RhB) dye was used as to examine the photocatalytic efficiency of the coated cotton fabric. 91% RhB was degraded in 180 min when exposed to visible light in the presence of RB-25/TiO2 coated cotton fabric.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, effort has been made to bring innovations in the fabrication of textile materials. Along with growth of conventional textiles, the market growth of multifunctional textiles in last few years has opened new gateways of research and development in the textile industry. Among all textile materials, cotton has been preferred over other textile materials due to its porosity, absorbency, biodegradability and wear comfort. The surface functionalization of cotton fabrics with nano materials is an emerging research field to develop functional cotton fabrics with multiple functionalities and wide ranges of practical applications (Ahmad and Kan 2016; Li et al. 2017). Functional coatings on the cotton fabrics impart tailored properties to the cotton regarding performance and durability. Self-cleaning (Zhu et al. 2017a), antibacterial (Xu et al. 2018), antifouling (Zhang et al. 2018), UV-blocking (Chen et al. 2018; Gao et al. 2017), biosensing (Malon et al. 2014), oil–water separation (Huang et al. 2015) and many more smart cotton fabrics have been developed by coating with metals, non-metals, metal oxides, and some organic compounds (Afzal et al. 2013a, b). Imparting self-cleaning properties to cotton fabrics by coating with anatase TiO2 was reported for the first time in 2004 (Daoud and Xin 2004). Strong oxidizing power, chemical and photostability, cost-effective and environmentally friendly nature are the inherent characteristics of TiO2 which extend its versatile applications when coated on cotton fabrics. However, limited light absorption in the UV region of solar spectrum and short life of electron hole pair in the excited state of TiO2 due to high recombination rate of electron hole pair reduce its practical applications as a photocatalyst for self-cleaning coating on cotton fabrics (Zhang and Yates 2010). To overcome these limitations, TiO2 has been doped with metals (Wang et al. 2009), non-metals (Wu and Long 2011) and metal oxides (Pakdel and Daoud 2013). This doping technique enhances the photocatalytic properties of TiO2 under visible light, however, the coating stability of these doped TiO2 sols on cotton fabrics remains an issue. It has been reported (Afzal et al. 2012) that the problem can be overcome by attachment of some visible light scavengers on the TiO2 surface which can inject electrons into the conduction band of TiO2 after excitation with visible light. Porphyrin, a structural analogue of chlorophyll, has been used as a visible light scavenger for TiO2 (Afzal et al. 2012). The synthesis and purification process of porphyrin is an expensive and complex process which reduces its practical industrial applications. In this study, we report the coating of cotton fabric with a visible light active dye/TiO2 hybrid to impart self-cleaning and UV blocking properties. A phthalocyanine dye, Reactive Blue-25 (RB-25), has been used as a visible light scavenger for TiO2. This dye is commercially available and has been used in the dyeing of textiles on industrial scale.

Experimental

Materials

Plain woven cotton fabric (100% scoured and bleached) having areal density of 119 g/m2 with 40/1 yarn in both warp and weft direction was used. The warp and weft density of cotton fabric was 52 cm−1 and 28 cm−1 respectively. Titanium tetraisopropoxide (TTIP, Aldrich 97%) was used as precursor for TiO2. All other chemicals such as hydrochloric acid, absolute ethanol and glacial acetic acid were used as received from the suppliers to prepare TiO2 nano-sol. A phthalocyanine-based reactive dye, C.I. Reactive Blue 25 (RB-25) dye was provided by Avani Dye Chem Industries, India. It was used without further purification. The chemical structure of RB-25 is given in the Fig. 1.

Preparation of RB-25/TiO2 nano-sol

TiO2 nano-sol with composition H2O (70%), absolute ethanol (20%), TTIP (5%), glacial acetic acid (4%) and hydrochloric acid (1%) was prepared. To prepare the TiO2 nano-sol, the precursor TTIP (15 mL) was dissolved in absolute ethanol (60 mL). This TTIP solution was added dropwise to the acidified water (225 mL). The mixture was stirred at 70 °C for 16 h. To prepare the RB-25/TiO2 nano-sol, 3 mL, 5 mL and 7 mL of RB-25 solution (0.05 g/100 mL) were added separately during the TiO2 nano-sol preparation.

Coating of cotton fabric with RB-25/TiO2 nano-sol

The cotton fabric, before coating process, was completely washed with non-ionic detergent, C-13 oxoalcoholethoxylate (1 g/L) to remove the impurities and dried at 80 °C for 30 min. The dried cotton fabrics were coated with already prepared TiO2 and RB-25/TiO2 sols by dip-pad-dry-cure method as reported in previous study (Ahmad and Kan 2017). In detail, the pre-cleaned cotton fabrics were dipped in the TiO2 and RB-25/TiO2 sols for 5 min and pressed with a padding machine (Rapid Labortex Co., Ltd., Taipei, Taiwan). The nip pressure of the padder was kept at 2.5 kg/cm2 to get the homogeneous coating of TiO2 and RB-25/TiO2 on each of the cotton fabric pieces. The wet pick up of TiO2 and RB-25/TiO2 sol was measured by weighing the cotton fabric pieces before and after padding. The wet pick up of all padded samples was about 77–80%. Aqueous solution of Na2CO3 was sprayed thoroughly by conventional spraying method to neutralize the fabric to pH 7. The TiO2 coated and RB-25/TiO2 coated cotton fabrics were dried in a preheated oven at 80 °C for 5–8 min and finally cured at 120 °C in a preheated curing machine (Mathis Lab dryer Labor-Trockner Type LTE, Werner Mathis AG Co., Oberhasli, Switzerland) for 5 min.

The resulting RB-25/TiO2 coated fabrics were washed with de-ionized water to remove the unattached TiO2 and RB-25 dye molecules. The coated fabric samples were dried at standard atmospheric conditions for further characterization. The coating process is summarized in the Fig. 2.

Fourier transform infrared spectroscopy analysis

Fourier transform infrared (FTIR) spectrophotometer equipped with an attenuated total reflection (ATR) accessory (Spectrum 100, Perkin Elmer Ltd., Thane, India) was used to get transmittance spectra of pristine cotton fabric and RB-25/TiO2 coated cotton fabrics. The FTIT-ATR spectra were obtained in the scanning range of 650–4000 cm−1 with an average of 64 scans of each fabric at 16 cm−1 resolution.

UV–visible absorption studies

The UV–visible absorption of RB-25 dissolved in water was measured by using a UV–visible UH5300 spectrophotometer (Hitachi, Tokyo, Japan). The UV–visible absorption of pristine cotton fabric, TiO2 coated and RB-25/TiO2 coated cotton fabrics were measured with Cary 300 spectrophotometer.

Color yield measurements

Reflectance studies of coated fabrics were conducted by a reflectance spectrophotometer (Macbeth Color-Eye 7000A, Grand Rapids, Michigan, USA) by using a D65 illuminant and 10° standard observer. The reflectance measurements were taken for each sample three times from 400 to 700 nm with 10 nm intervals. K/S values were obtained by using the Kubelka–Munk equation (Eq. 1).

where K is the absorption coefficient of the colorant, S is the scattering coefficient of the colored substrate and R is the reflectance of the colored sample. The higher the K/S value, the greater the dye uptake is, resulting in a better color yield.

XRD and SEM analysis

Crystal structures of pristine cotton fabric, TiO2 coated and RB-25/TiO2 coated cotton fabric were examined by high power X-ray diffractometer (Rigaku Smartlab, USA). SEM images were recorded by Scanning Electron Microscope (Tescan VEGA3, Czech Republic) to observe the surface morphologies of the pristine cotton fabric, TiO2 coated and RB-25/TiO2 coated cotton fabrics.

Photocatalytic activity measurements

Rhodamine B (RhB) was selected as probe dye to evaluate the photocatalytic efficiency of TiO2 coated and RB-25/TiO2 coated cotton fabrics. 3 g of the cotton fabric (each from pristine cotton, TiO2 coated and RB-25/TiO2 coated cotton fabrics) were cut into pieces of 1 cm × 1 cm dimension. The pristine and coated cotton fabric pieces were soaked in 100 mL of the RhB dye aqueous solution (18 mg/L) in a 250 mL glass beaker. The cotton fabric pieces were shaken well in the dye solution and kept in the dark for 2 h to achieve the absorption–desorption equilibrium. The beakers with a test specimen were exposed to visible light under Philip fluorescent lamps with light intensity of 5.2–5.3 mW cm−2 on the top of samples while vigorously shaking. To measure the concentration of RhB in the presence of pristine and coated cotton fabrics, a total of 10 mL of the target dye solution was taken out from each beaker after regular time intervals for 3 h and the UV–Visible absorption spectra were recorded on a UV–Visible UH5300 spectrophotometer (Hitachi, Tokyo, Japan). The concentration of RhB, at 555 nm (λmax of RhB), after visible light irradiation at regular time intervals was compared with the initial concentration of RhB. The relative decrease in the concentration of RhB was examined by plotting C/Co where C is concentration of RhB at any specific time and Co is initial concentration of RhB. The dye degradation efficiency was calculated by using Eq. 2.

UV-protection factor analysis

UV-protection factor of the RB-25/TiO2 coated cotton fabric was evaluated by Cary 300 spectrophotometer at wavelength range of 280–400 nm with scanning speed of 300 nm/min. The results were calculated by Cary 300 using the methods described in the Australian/New Zealand Standard AS/NZS 4399:1996). The coated cotton fabrics were washed five times at room temperature in a laundry machine for 40 min without any detergent and UV protection factor was also measured after five washings.

Self-cleaning study

For self-cleaning studies, the RB-25/TiO2 coated cotton fabric (5 × 2.5 cm) was dipped in aqueous solution of Rhodamine B (RhB) (7.5 mg/L). The stained fabric samples were dried in dark and the stained fabrics were exposed to light (8 W lamp) for 6 h. Also, these stained samples were placed in open environment under sunlight.

Results and discussion

Fourier transform infrared spectroscopy

To study the surface modifications of the cotton fabric by the coating with RB-25/TiO2, the FTIR-ATR transmittance spectra of pristine cotton fabric and RB-25/TiO2 coated cotton fabrics were recorded as shown in the Fig. 3. Figure 3a represents the FTIR transmittance spectrum of pristine cotton fabric. The broad peak at around 3300 cm−1 is due to the surface hydroxyl groups (–OH) present on the cellulose chains of the cotton fabrics. The peaks at 2900 cm−1, 1320 cm−1 and 1038 cm−1 are due to C–H stretching vibrations of the cellulose alkyl chains, C–O, C–H bending vibrations, and C–O, O–H stretching vibrations of the polysaccharide in the cotton fabrics respectively. The peak at 1638 cm−1 is associated with the water adsorbed in the cellulose chains.

Figure 3b spectrum represents the RB-25/TiO2 coated cotton fabric. The peak intensity at 3300 cm−1 and 1038 cm−1 has decreased with the coating of RB-25/TiO2 on the surface of cotton fabric which confirms the chemical attachment of the RB-25/TiO2 via surface hydroxyl groups (–OH) of the cotton fabric. Peak at 1638 cm−1 has disappeared after coating with the photocatalyst which also indicates that the adsorbed water molecules are removed by the attachment of RB-25/TiO2. TiO2 has strong electrostatic attachment with RB-25 and cotton fabrics. The schematic diagram of attachment of RB-25/TiO2 on the cotton fabric is given in the Fig. 4.

UV–visible absorption measurements

Binding of RB-25/TiO2 with the cotton fabric was studied by UV–visible absorption measurements. Figure 5 presents the UV–visible absorption spectra of RB-25 in water, TiO2 coated, and RB-25/TiO2 coated cotton fabric. The absorption peak at 662 nm shown in the spectrum of RB-25 in water belongs to inherent Q band of the phthalocyanine core structures. When RB-25/TiO2 was coated on the cotton fabric, this absorption peak (Q band) shifted to 675 nm as shown in Fig. 5b. This bathochromic shift (red shift) of 13 nm can be attributed to the strong binding of RB-25/TiO2 with the fabric (Afzal et al. 2013a, b).

The Fig. 6 presents the UV–visible absorption spectrum of RB-25/TiO2 coated cotton fabric with different concentrations of RB-25. 3 mL of RB-solution (0.05 mg/100 mL), 5 mL of RB-solution and 7 mL of RB-25 solution were added in the TiO2 mixture during sol preparation in sample 1, 2 and 3 respectively. The Q-band peak intensity is higher in the sample 3 representing the higher uptake of the dye by the fabric.

Color yield measurements

To confirm the presence of RB-25 on the coated cotton fabric, color yield measurements were done by reflectance spectrophotometer. The K/S values of the RB-25/TiO2 coated cotton fabrics calculated by using the Kubelka–Munk equation are given in the Table 1. The sum of K/S values are according to the dye concentration in each of the coated samples. The K/S values increased as the dye amount increased within the photocatalyst hybrid sols. The increasing value of K/S by increasing dye concentration in the RB-25/TiO2 sol indicates the greater uptake of the dye on the cotton fabric during the coating process. This can also be confirmed from the UV visible absorption spectrum given in the Fig. 5.

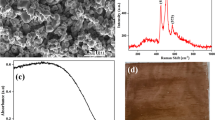

X-ray diffraction analysis

Crystal structures of pristine cotton fabric, TiO2 coated and RB-25/TiO2 coated cotton fabric were studied by high power X-ray diffractometer. XRD pattern of pristine cotton, TiO2 coated cotton and RB-25/TiO2 coated cotton are given in the Fig. 7. The sharp diffraction peaks at 14.7°, 16.4°, 22.6° and 34.4° shown in the XRD pattern of pristine cotton fabric are characteristics peaks for cellulose I crystalline structure (Kafle et al. 2014). After coating with TiO2 and RB-25/TiO2, the characteristic peaks intensity of the cellulose substrate structure is not changed which confirms that the crystalline phase of cellulose I does not alter with TiO2 and RB-25/TiO2 coating. However, sharp diffraction peaks at 25.4°, 38.1° and 48° appeared in XRD pattern of TiO2 coated and RB-25/TiO2 coated cotton fabrics. These characteristic peaks correspond the crystalline anatase phase of TiO2 which confirm the successful coating of anatase TiO2 on the fabrics (Afzal et al. 2014). Moreover, the peaks of anatase TiO2 do not change in RB-25/TiO2 coated cotton fabrics which indicates that RB-25 has no effect on the crystalline structure of the TiO2.

Scanning electron microscope (SEM) analysis

The deposition of the RB-25/TiO2 coating on the surface of cotton fabric was confirm by the scanning electron microscopic (SEM) analysis of the coated cotton fabrics. SEM images of pristine cotton fabric and RB-25/TiO2 coated cotton fabric are given in the Fig. 8.

The smooth surface has been observed for the pristine fabric as shown in the image 8a. However, the deposition of RB-25/TiO2 on the cotton fabric can easily be seen in the image 8b. In addition, surface elemental analysis was conducted by EDX data. The EDX data has been given in the Table 2 and the EDX spectrum is given in the Fig. 9.

Photocatalytic activity measurements

RhB (C28H31N2O3Cl) is a toxic dye which have hazardous effects on human and animal skin. It is widely used as a basic dye in textile industries and its large amount is being released to the waste water resulting in the water pollution. To evaluate the photocatalytic efficiency of RB-25/TiO2 coated cotton fabric, this dye was used as a target probe. The degradation curves (C/Co plots) of the RhB with pristine cotton, TiO2-coated and RB-25/TiO2 coated cotton fabrics are presented in Fig. 10. The curve 10a represent the degradation of RhB when only pristine cotton was used and the curve 10b corresponds to the degradation of RhB by the TiO2 coated fabric as a photocatalyst. The degradation of RhB was 25% and 30% for pristine cotton fabric and TiO2 coated cotton fabric after 180 min of light irradiation. However, the RhB degradation efficiency for RB-25/TiO2 coated cotton was 91% after 180 mint of light irradiation. The degradation curves 10c–e correspond to RB-25/TiO2 coated cotton fabrics when 3 mL, 5 mL and 7 mL of the dye solution of RB-25 were used respectively. The degradation curves show that the photocatalytic activity of RB-25/TiO2 coated cotton fabric increased as the dye concentration was increased in the TiO2 nano-sol. The degradation efficiency increased from 52 to 91% as the dye concentration was increased from 3 to 7 mL in the photocatalyst hybrid. This indicates that the ratio of RB-25 and TiO2 plays an important role in the photocatalytic efficacy of the RB-25/TiO2 photocatalyst.

The mechanism for the visible light driven photocatalytic efficiency of the RB-25/TiO2 hybrid can be attributed to the electron injection from excited state of the dye molecule to the conduction band of the TiO2. Thus, electron density in the conduction band of TiO2 increases which results in increase in the photocatalytic performance of TiO2 under visible light source. The schematic explanation of photocatalytic phenomenon of RB-25/TiO2 is given in the Fig. 11.

The energy gaps were measured from the absorption wavelength using a simple energy equation as given in the Table 3.

UV-protection factor analysis

UV-protection factor (UPF) is the measure of how much of the UV radiations coming from the sun are absorbed by the fabric. UPF measurements of the RB-25/TiO2 coated cotton fabrics were tested by Cary 300 spectrophotometer at wavelength range of 280–400 nm with scanning speed of 300 nm/min. UPF values and average (%) transmission of UV-A (315–400 nm) and UV-B (290–315 nm) radiations for the RB-25/TiO2 coated cotton fabric are presented in the Table 4.

According to the Australian/New Zealand Standard AS/NZS 4399:1996, the fabrics having the value of UPF above 50 show excellent protection against UV light coming from sun (Mishra and Butola 2018). The RB-25/TiO2 coated cotton fabrics have shown the UPF values more than 100 which reflects excellent UV protection. The high energy UV radiations, UV-B ranging 290–315 nm are more than 99% absorbed by the fabric. The graphical representation of UV transmission from the coated fabric is given in the Fig. 12.

It can be observed from the UV transmittance spectra that all the UV region of radiations has been absorbed by the coated fabrics with negligible transmittance which shows that the RB-25/TiO2 coated cotton fabrics possess excellent UV protective properties (Zhu et al. 2017b).

Self-cleaning studies

For self-cleaning studies, the RB-25/TiO2 coated cotton fabric was dipped in aqueous solution of Rhodamine B (RhB) (7.5 mg/L). The stained fabric samples were dried in dark and the stained fabrics were exposed to light (8 W lamp = 464 lm) for 4 h. Also, these stained samples were placed in open environment under sunlight for 1 h. The stains of RhB were removed from the RB-25/TiO2 coated cotton fabrics in 4 h under lamp exposure and in open environment sunlight exposure the stains were removed in 1 h. However, the stains of RhB remained same on the pristine cotton fabric. The stained pristine cotton fabric and RB-25/TiO2 coated cotton fabrics before and after light irradiation are shown in the Fig. 13.

Conclusions

In this study, preparation and coating of RB-25/TiO2 nano-sol on the cotton fabric and structural, morphological and photocatalytic studies of the coated cotton fabric have been reported. In detail, TiO2 and RB-25/TiO2 sols were prepared by the sol–gel method. The TiO2 and RB-25/TiO2 sols were coated on the pre-cleaned cotton fabric by dip-pad-cure-dry method. The wet pick up of TiO2 and RB-25/TiO2 on the cotton fabric was measured by weighing the cotton fabric before and after padding. It was calculated from the weight gain of cotton fabric which was about 77%. After coating the cotton fabrics were washed with deionized water to completely remove the unattached TiO2 and RB-25 molecules from the fabric. The resulting coated cotton fabrics were dried at standard atmospheric conditions for structural, morphological and photocatalytic evaluations. Studies of structural properties of the coated cotton fabric were conducted by FTIR and UV–visible absorption measurements. FTIR and UV–visible absorption spectra confirmed the attachment of RB-25/TiO2 on the cotton fabric. The maximum absorption peak of the RB-25 had a red shift of 13 nm by after coating on the cotton fabric which indicates its strong binding.

Morphological studies were conducted by the XRD, SEM and EDX analysis. XRD, SEM and EDX studies confirmed the deposition of RB-25 and anatase TiO2 layer on the cotton fabric surface. Photocatalytic efficiency of the resulting cotton fabric was evaluated by the degradation of RhB dye. The coated cotton fabrics shown remarkable photocatalytic and self-cleaning properties. The UV transmittance spectra of the coated fabrics shown the remarkable UV blocking properties.

References

Afzal S, Daoud WA, Langford SJ (2012) Self-cleaning cotton by porphyrin-sensitized visible-light photocatalysis. J Mater Chem 22(9):4083–4088

Afzal S, Daoud WA, Langford SJ (2013a) Photostable self-cleaning cotton by a copper (II) porphyrin/TiO2 visible-light photocatalytic system. ACS Appl Mater Interfaces 5(11):4753–4759

Afzal S, Daoud WA, Langford SJ (2013b) Visible-light self-cleaning cotton by metalloporphyrin-sensitized photocatalysis. Appl Surf Sci 275:36–42

Afzal S, Daoud WA, Langford SJ (2014) Superhydrophobic and photocatalytic self-cleaning cotton. J Mater Chem A 2(42):18005–18011

Ahmad I, Kan CW (2016) A Review on development and applications of bio-inspired superhydrophobic textiles. Materials 9(11): Article Number 892

Ahmad I, Kan CW (2017). Visible-light-driven, dye-sensitized TiO2 photo-catalyst for self-cleaning cotton fabrics. Coatings 7(11): Article Number 192

Chen D, Mai Z, Liu X, Ye D, Zhang H, Yin X, Zhou Y, Liu M, Xu W (2018) UV-blocking, superhydrophobic and robust cotton fabrics fabricated using polyvinylsilsesquioxane and nano-TiO2. Cellulose 25(6):3635–3647

Daoud WA, Xin JH (2004) Nucleation and growth of anatase crystallites on cotton fabrics at low temperatures. J Am Ceram Soc 87(5):953–955

Gao S, Huang J, Li S, Liu H, Li F, Li Y, Chen G, Lai Y (2017) Facile construction of robust fluorine-free superhydrophobic TiO2@fabrics with excellent anti-fouling, water-oil separation and UV-protective properties. Mater Des 128:1–8

Huang JY, Li SH, Ge MZ, Wang LN, Xing TL, Chen GQ, Liu XF, Al-Deyab SS, Zhang KQ, Chen T, Lai YK (2015) Robust superhydrophobic TiO2@fabrics for UV shielding, self-cleaning and oil–water separation. J Mater Chem A 3(6):2825–2832

Kafle K, Greeson K, Lee C, Kim SH (2014) Cellulose polymorphs and physical properties of cotton fabrics processed with commercial textile mills for mercerization and liquid ammonia treatments. Text Res J 84(16):1692–1699

Li S, Huang J, Chen Z, Chen G, Lai Y (2017) A review on special wettability textiles: theoretical models, fabrication technologies and multifunctional applications. J Mater Chem A 5(1):31–55

Malon RS, Chua K, Wicaksono DH, Córcoles EP (2014) Cotton fabric-based electrochemical device for lactate measurement in saliva. Analyst 139(12):3009–3016

Mishra A, Butola BS (2018) Development of cotton fabrics with durable UV protective and self-cleaning property by deposition of low TiO2 levels through sol–gel process. Photochem Photobiol 94(3):503–511

Pakdel E, Daoud WA (2013) Self-cleaning cotton functionalized with TiO2/SiO2: focus on the role of silica. J Colloid Interface Sci 401:1–7

Wang RH, Wang XW, Xin JH (2009) Advanced visible-light-driven self-cleaning cotton by Au/TiO2/SiO2 photocatalysts. ACS Appl Mater Interfaces 2(1):82–85

Wu D, Long M (2011) Realizing visible-light-induced self-cleaning property of cotton through coating N-TiO2 film and loading AgI particles. ACS Appl Mater Interfaces 3(12):4770–4774

Xu QB, Ke XT, Cai DR, Zhang YY, Fu FY, Endo T, Liu X (2018) Silver-based, single-sided antibacterial cotton fabrics with improved durability via an l-cysteine binding effect. Cellulose 25(3):2129–2141

Zhang Z, Yates JT (2010) Direct observation of surface-mediated electron–hole pair recombination in TiO2(110). J Phys Chem C 114(7):3098–3101

Zhang S, Yang X, Tang B, Yuan L, Wang K, Liu X, Zhu X, Li J, Ge Z, Chen S (2018) New insights into synergistic antimicrobial and antifouling cotton fabrics via dually finished with quaternary ammonium salt and zwitterionic sulfobetaine. Chem Eng J 336:123–132

Zhu C, Shi J, Xu S, Ishimori M, Sui J, Morikawa H (2017a) Design and characterization of self-cleaning cotton fabrics exploiting zinc oxide nanoparticle-triggered photocatalytic degradation. Cellulose 24(6):2657–2667

Zhu T, Li S, Huang J, Mihailiasa M, Lai Y (2017b) Rational design of multi-layered superhydrophobic coating on cotton fabrics for UV shielding, self-cleaning and oil-water separation. Mater Des 134:342–351

Acknowledgments

This research study was supported by The Hong Kong Polytechnic University (Project code: account code: RTKV) which is greatly acknowledged, and we would also thank the Materials Research Centre, The Hong Kong Polytechnic University for providing the characterization facilities for this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahmad, I., Kan, Cw. & Yao, Z. Reactive Blue-25 dye/TiO2 coated cotton fabrics with self-cleaning and UV blocking properties. Cellulose 26, 2821–2832 (2019). https://doi.org/10.1007/s10570-019-02279-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-019-02279-2