Abstract

Many load-bearing applications of hydrogels, such as human tissue replacements, require extremely high stiffness, strength and fracture energy, which are rarely achieved simultaneously. Here, we report cellulose nanofiber-based nanocomposite hydrogels, exhibiting highly increased stretchability but with no sacrifice in stiffness when compared with pure rehydrated cellulose nanofiber networks. The simple processes include suffusing a cellulose nanofiber cake with poly(vinyl alcohol) solution, drying at room temperature, annealing at 80 °C and 120 °C, and rehydration in water. During the drying and annealing processes, strong interactions (hydrogen bonds) between cellulose nanofiber and poly(vinyl alcohol) are formed instead of interfibrillar hydrogen bonds, resulting in more stretchable cellulose nanofiber networks. Thus, the optimized sample reaches an elastic modulus of 47.92 ± 0.99 MPa, a fracture strength of 15.91 ± 0.48 MPa and a fracture energy of 2302.9 ± 42.0 J/m2, which are almost equal to some human tissues. In addition, it contains high water content (66.8%), which is also close to the values of skin and cartilage. This article provides a simple method for preparation of load-bearing hydrogels from nanocelluloses.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogels, highly hydrated polymer networks, are being increasingly explored owing to the similar wet properties with human tissues (Wang et al. 2017; Zhang and Khademhosseini 2017). Most human tissues, such as skin and cartilage, comprise wet materials, which usually contain more than 60% water (Dubinskaya et al. 2007). However, human tissues usually have stiff (large elastic modulus), strong (high fracture strength) and tough (high fracture energy) mechanical properties: the modulus and strength of skin are more than 10 MPa, and the fracture energy is around 10 kJ/m2 (Wegst and Ashby 2004). Thus, various hydrogels with good mechanical properties under an equivalently swollen state have been developed, for example typical double-network hydrogels (Gong et al. 2003), physically cross-linked hydrogels (Luo et al. 2015; Zhang et al. 2016), physically and covalently hybrid cross-linked hydrogels (Li et al. 2014b; Lin et al. 2015; Zhao et al. 2016), mineralized hydrogels (Rauner et al. 2017) and stiff long fiber reinforced hydrogels (Huang et al. 2017; Illeperuma et al. 2014). However, it remains a challenge to develop hydrogels with the modulus of skin while maintaining a high strength and fracture energy. This is a desired goal because the three parameters, to a certain extent, are interrelated (Li et al. 2014a; Zhao 2017). For example, ultra-stiff mineralized hydrogels, with a modulus over 150 MPa, exhibit strength only around 1 MPa, mainly owing to poor stretchability (Rauner et al. 2017). On the other hand, many highly stretchable and tough hydrogels show a relatively low modulus and strength (Haraguchi and Takehisa 2002; Sun et al. 2014). Therefore, it is supposed that if the stretchability of stiff networks is maintained, hydrogels would show stiff, strong and tough properties.

Nanocelluloses, with extremely high stiffness and strength, have been widely explored (Klemm et al. 2011). Cellulose nanofibers (CNFs), cellulose nanocrystals and bacterial cellulose are widely used to reinforce hydrogels (De France et al. 2017). Usually, nanocellulose is dispersed in monomer solution, then incorporated into polymer networks (Chen et al. 2017; Liu et al. 2016; Yang et al. 2013). Though both modulus and fracture energy of hydrogels can be improved by adding a small amount of nanocellulose, the hydrogels are still very soft and weak compared with human tissues (De France et al. 2017; Wegst and Ashby 2004). This is because the polymer networks of hydrogels are usually soft and the content of nanocellulose is low (Yang et al. 2013, 2016), restraining further reinforcement. On the other hand, nanocellulose-based nanopaper shows extremely stiff and strong properties (Henriksson et al. 2008; Sehaqui et al. 2011), which may be used to fabricate hydrogels with excellent mechanical properties. Nevertheless, when nanopaper is immersed in water and hydrated, the strength and stiffness is lost because of disengagement of interfibrillar hydrogen bonds (Torres-Rendon et al. 2014).

We recently developed a facile method to prepare CNF networks with high strength and water content by alkali treatment (Abe and Yano 2012). The interactions between hydrated CNFs are reinforced by partial mercerization of surface cellulose chains. However, the elongation is limited owing to the low stretchability of CNFs. In this study, we tried to combine CNFs with polymer to fabricate nanocomposite hydrogels, expecting to increase the stretchability and maintain the stiffness of the CNF networks in a hydrated state and thus achieve better mechanical performance. To this end, poly(vinyl alcohol) (PVA) is considered because good compatibility between CNFs and PVA has been proved (Qua et al. 2009; Yue et al. 2016; Zhou et al. 2014). In addition, PVA is a water soluble, crystallizable, biodegradable and nontoxic polymer with good mechanical properties, even in a hydrated state (Cha et al. 1996; Li et al. 2014b). The drying and annealing treatment of PVA, which may produce crystals, is widely used to prepare tough hydrogels (Cha et al. 1996; Li et al. 2014b). Crystalline region-based physical cross-linking of PVA requires only simple thermal treatment, avoiding the use of chemicals (Cha et al. 1996).

Hereby, we adopted CNFs and PVA to prepare nanocomposite hydrogels using a simple method. A wet CNF cake is immersed into PVA solution with various concentrations to absorb PVA chains, followed by a drying-annealing process. Then, the annealed CNF/PVA nanocomposite is rehydrated to form hydrogels. The mechanical properties of the CNF/PVA hydrogels are compared with some typical hydrogels and human tissues. The mechanism of uniaxial tensile behaviors is also proposed.

Experimental

Materials

Sodium chlorite (NaClO2, ≥ 75.0%) and potassium hydroxide (KOH, 85%) were purchased from Nacalai Tesque (Kyoto, Japan). Acetic acid (99%) was obtained from Wako Pure Chemicals (Osaka, Japan). 99 + % hydrolyzed poly(vinyl alcohol) with Mw = 146,000–186,000 was purchased from Sigma-Aldrich (Osaka, Japan). ADVANTEC® hydrophilic PTFE membrane with a pore size of 0.1 μm was used for vacuum filtration. All water mentioned is distilled.

CNFs were prepared according to our previous work (Abe et al. 2007; Abe and Yano 2012). Japanese cypress wood powder was treated with acidified NaClO2 and then KOH to remove lignin and hemicellulose, respectively. Briefly, 50 g of wood powder was dispersed in 1.5 L water and heated to 80 °C. 20 g NaClO2 and 4 mL acetic acid were added to the above dispersion every hour, which was repeated five times. The resulting white powder was washed by a large amount of water and then dispersed in 800 mL water. A total of 6 wt% KOH (56.5 g, 85% purity) was added and heated at 90 °C for 2 h. The resulting pulp powder was washed and diluted to a concentration of around 0.8 wt%. Finally, the dispersion was passed through a grinder (MKCA6-3; Masuko Sangyo Corp., Saitama, Japan) twice to obtain a cellulose nanofiber suspension.

Preparation of CNF/PVA hydrogels

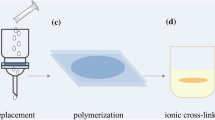

The CNF/PVA hydrogels were prepared in this study, as shown in Fig. 1. A total of 400 mL of CNF suspension with a concentration of 0.1 wt% was vacuum filtrated through a PTFE membrane to form a wet CNF cake with a water content of around 90 wt%. The wet CNF cake was peeled out of the filter and immersed into PVA solution with various concentrations from 2 to 10 wt% for 3 days. The wet CNF/PVA composite cake was treated by a drying-annealing process: it was dried at room temperature for 3 days and annealed at 80 °C for 3 h and 120 °C for 1 h. Finally, the dried CNF/PVA sheets were rehydrated in water for 3 days to form hydrogels which are named DAx based on the concentration of PVA. For example, DA2 is the hydrogel produced by immersing the wet CNF cake in 2 wt% PVA solution. For comparison, pure rehydrated CNF and PVA hydrogels were prepared as well. The rehydrated CNF hydrogel was prepared by drying the wet CNF cake at room temperature followed by rehydration in water for 3 days. Rehydrated PVA hydrogels were prepared by casting 10 wt% PVA solution followed by annealing and rehydration using the same method as for CNF/PVA hydrogels.

Tensile test and single edge crack test

The tensile test was performed on a universal testing machine (model 3365; Instron Corp., Canton, MA) equipped with a 2-kN cell at a stretch velocity 20 mm min−1 using dumbbell-shaped samples (width: 2 mm, length: 35 mm, gauge length: 20 mm). Five specimens were tested for each sample.

The single edge crack test was carried out on the same universal testing machine with the same stretch velocity, while rectangular species (width: 5 mm, length: 20 mm, gauge length: 10 mm) were used. Three unnotched specimens and three notched specimens with cut lengths of 1 mm at the middle edge were stretched until fracture to obtain stress–strain curves (Fig. S1). The elastic modulus was determined by the initial slope of the stress–strain curves of unnotched samples (0–2% strain). The fracture energy was calculated as follows (Long and Hui 2016; Mayumi et al. 2016):

where Γ is the fracture energy (J/m2), λc is critical value of stretch where the crack propagates, c is cut length (m), σ is the stress (Pa), ɛ is the strain, ɛc is the critical strain (λc = ɛc+ 1). Here, the stretch of the notched sample, where maximum stress is reached, is used as λc.

Water content

Hydrogels were dried in an oven at 110 °C overnight. The water content of hydrogels was determined by comparing the weight of equivalently swollen and thoroughly dried samples, which was calculated using the following equation:

where Ww is the weight of swollen hydrogel, and Wd is the weight of dried sample.

Structure characterizations

SEM images were obtained using a field-emission scanning electron microscope JSM-7800F Prime (JEOL, Tokyo) at an acceleration voltage of 1.5 kV. Samples were first freeze-dried and then coated with platinum by sputtering for 90 s. Thermogravimetric analysis (TGA) was determined on a TA-Q50 thermogravimetric analyzer (TA Instruments, Inc., New Castle, DE). PVA/CNF hydrogels were dried at room temperature for the TGA tests. Samples of 5-mg weight were maintained at 110 °C for 10 min to remove free water and heated under a nitrogen atmosphere from 110 to 600 °C at a heating rate of 10 °C min−1. X-ray diffraction (XRD) measurements were carried out on a Rigaku X-ray diffractometer (UltraX 18HF; Rigaku Corp., Tokyo) with CuKa radiation (40 kV and 300 mA) from 5° to 40° in reflection mode.

Results and discussion

Preparation of CNF/PVA hydrogels

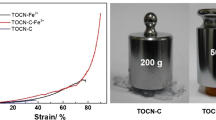

The CNF/PVA hydrogels were prepared by immersing a wet CNF cake in PVA aqueous solution followed by the treatment of drying, annealing and rehydration, which is illustrated in Fig. 1. A wet CNF cake was obtained by filtrating CNF suspension with a concentration of 0.1 wt%. Then, the wet CNF cake, with a water content of around 90 wt% and layered structure (Fig. 1b; Abe and Yano 2012), was carefully peeled from the PTFE filter membrane and immersed in PVA solution. PVA chains diffused into the layered CNF cake, resulting in a CNF/PVA composite cake (Fig. 1c). However, this wet nanocomposite was still soft because of the liquid-like property of the PVA chains. It was therefore necessary to induce crystallization of the PVA chains to form PVA networks, and it was necessary to reinforce the interactions between the PVA and CNFs as well. Hereby, a drying-annealing method was used (Li et al. 2014b). Both the crystalline and amorphous region of PVA separated the CNF layers (Fig. 1d). Hydrogen bonds may be formed between CNFs and PVA chains. Dried CNF/PVA nanocomposites were rehydrated in water for 3 days to form CNF/PVA hydrogels (Fig. 1e). The composition of the resulting hydrogels, calculated by the weighting method, is summarized in Table 1. The semi-transparent hydrogels, with a water content of 65–85%, were extremely strong, as shown in Fig. 1e. A small double-fold CNF/PVA hydrogel sheet with width of 5 mm and thickness of 0.25 mm could hold a 2-kg weight.

Mechanical properties

Tensile tests of dried CNF nanopaper and rehydrated CNF hydrogel were performed (Fig. 2). The elastic modulus and fracture strength of the CNF nanopaper were as high as 11.0 ± 0.7 GPa and 130.2 ± 12.6 MPa, respectively, corresponding with reported values well (Torres-Rendon et al. 2014). As mentioned above, the rehydrated CNF hydrogel, produced from dried CNF nanopaper by rehydration, showed a remarkable decrease of mechanical properties (Fig. 2, red curve). The elastic modulus and fracture strength were reduced to 21.56 ± 1.85 MPa and 1.40 ± 0.35 MPa, while the elongation was slightly increased from 5.1 ± 0.4 to 12.9 ± 3.0%. The reason was the dissociation of the interfibrillar hydrogen bonds during hydration (Benítez and Walther 2017; Torres-Rendon et al. 2014; Walther et al. 2011).

Thus, the strong and tough polymer, PVA, was used to prepare the CNF/PVA nanocomposite hydrogels. The stress–strain curves of the CNF/PVA hydrogels are shown in Fig. 3, which is further summarized in Table 2. It was obvious that all the CNF/PVA hydrogels were much stiffer and stronger than the rehydrated CNF hydrogel (Fig. 3). When the PVA concentration was increased to no more than 7.5 wt%, the CNF/PVA hydrogels became stiffer, stronger and more stretchable, simultaneously. The largest elastic modulus of the CNF/PVA hydrogels, reached by DA7.5, was nearly 50 MPa (47.92 ± 0.99 MPa), which was higher than most stiff hydrogels (Wang et al. 2017), such as double-network hydrogels (Gong et al. 2003; Li et al. 2014b; Zhao et al. 2016) and polyelectrolytes hydrogels (Luo et al. 2015). The fracture strength of the DA7.5 was 15.91 ± 0.48 MPa, which is difficult to be reached by other methods (Zhang and Khademhosseini 2017). Furthermore, DA7.5 was very tough, reaching a fracture energy of 2302.9 ± 42.0 J/m2 (Table 2, Fig. S2). Though the water content of the CNF/PVA hydrogels reduced slightly from 73.3 to 66.8% (from DA2 to DA7.5, Table 1), it was higher than several typical hydrogels (Luo et al. 2015; Rauner et al. 2017; Zhang et al. 2016) and comparable to human tissue, such as skin and cartilage (Dubinskaya et al. 2007). When the concentration of PVA was further increased to 10 wt%, the composition of DA10 was quite similar to DA7.5, while its tensile properties were inferior to DA7.5 and roughly equal to DA5. This may have been due to the high viscosity of the 10 wt% PVA solution. The excellent mechanical properties of the CNF/PVA hydrogels were probably ascribed to a combination of the stiffness of CNFs and the toughness of PVA. First, PVA chains may coat the surface of the CNFs because of hydrogen bonds between the hydroxyl groups of PVA and cellulose, connecting the CNFs and acting as a cross-linker to the CNFs. It is noted that the CNF content of all CNF/PVA hydrogels are all similar (Table 1), which means that the decrease of water was replaced by the PVA chains. When more PVA was incorporated, the composite hydrogel became stiffer. Second, PVA can form its own networks owing to the physical cross-linking of the crystalline region, which is induced in the drying-annealing process. The PVA hydrogel treated by annealing was relatively strong, highly stretchable and very tough (Table 2). Thus, as PVA content increased, the stretchability was maintained. Therefore, the interesting phenomenon of a simultaneous increase of the elastic modulus, stretchability and fracture strength was observed.

We compared CNF/PVA hydrogels with some typical hydrogels that have good mechanical properties, taking stiffness, strength, equilibrium water content and fracture energy into account (Figs. 4, S3). Though recently developed mineralized hydrogels were extremely stiff, the CNF/PVA hydrogels were much stronger and tougher (Rauner et al. 2017). In addition, the CNF/PVA hydrogels were much stiffer and stronger than polyelectrolyte hydrogels (Luo et al. 2015) and physical double-network hydrogels (Zhang et al. 2016), which contained even less water. Compared with skin and cartilage, the CNF/PVA hydrogels showed comparable modulus, strength and water content (Dubinskaya et al. 2007; Wegst and Ashby 2004). The fracture energy of the CNF/PVA hydrogels was lower than that of skin but similar to that of cartilage (Fig. S3b). In contrast to aramid nanofiber/PVA nanocomposite hydrogels (Xu et al. 2018), showing simultaneous increasing of elastic modulus, stretchability and fracture strength as well, the water content of CNF/PVA hydrogels was less while the stiffness and strength were much higher. We concluded that CNF/PVA hydrogels have very stiff and strong properties and relatively high fracture energy.

Comparison of CNF/PVA hydrogel with several stiff and strong hydrogels and tissues. a Elastic modulus versus equilibrium water content. b Fracture strength versus equilibrium water content. The data of other hydrogels are summarized from the literature: 1. mineralized hydrogel (Rauner et al. 2017); 2. polyelectrolytes hydrogel (Luo et al. 2015); 3. physical double-network hydrogel (Zhang et al. 2016); 4–5. skin and cartilage (Dubinskaya et al. 2007; Wegst and Ashby 2004); 6. PVA/AM hydrogel (Li et al. 2014b); 7. aramid nanofiber hydrogels (Xu et al. 2018)

Structure characterization

To investigate the micro structure of the CNF/PVA hydrogels, samples were freeze-dried and then observed using SEM. For the rehydrated CNF hydrogel, nanofibers with diameter around 15 nm and a layered structure were observed on the surface and in cross section (Fig. 5a, e), which is similar to ground CNFs (Abe et al. 2007) and filtrated CNF wet cake (Abe and Yano 2012). On the surface of DA2 (Fig. 5b), the diameter of the nanofibers seemed to become thicker (around 30 nm) and part of the nanofibers were aligned or combined. At the end of the fibers or junction points, knot-like small particles were observed. Thus, the proposal that PVA may coat the surface of the CNFs and connect the CNFs is reasonable. The layered structure was maintained and nanofibers were observed in cross section, though the layer became thicker compared with the rehydrated CNF hydrogel (Fig. 5f). When the concentration of PVA was increased to 7.5 wt%, it became difficult to find nanofibers on the surface of DA7.5 (Fig. 5c). Instead, a porous structure, produced after the sublimation of ice crystals during the freeze-drying process, was observed (Fig. 5c). The layered structure became indistinct in cross section (Fig. 5g). For PVA hydrogels, small particles existed on the surface while the layered structure was lost in cross section (Fig. 5d, h).

TGA was carried out to confirm the interactions between the CNFs and PVA chains (Fig. S4). The composition of composite hydrogels was calculated according to the residue at 595 °C and the assumption that no interactions happened between the CNFs and PVA chains. Compared with the composition by the weighting method (Table 1), the TGA method showed less PVA content (Table S1). This was probably because interactions between the CNFs and PVA chains (hydrogen bonds) increased the final residue.

X-ray diffraction was performed to check whether the differences in crystallinity affected the mechanical properties. The CNF sample showed typical cellulose I peaks (Fig. S5). CNF/PVA hydrogels showed high crystallinity, indicating that the crystallinity of CNFs was maintained and that the PVA also crystallized. The results of the DA2 was similar to that of the CNFs, while the DA7.5 showed both cellulose I and PVA peaks. Though a slight peak shift was detected, we considered that slight difference of crystallinity was not the main cause of the different mechanical behaviors. However, it should be noted that all the samples were tested after drying at room temperature, which may have increased the PVA crystallization.

Proposed mechanism

The structure of the CNF/PVA hydrogels is proposed (Fig. 1), which is based on the compositions, tensile tests, single edge tests and other characterizations. For the rehydrated CNF hydrogel, because most interfibrillar hydrogen bonds dissociate in wet conditions, it became relatively weak and brittle. For the CNF/PVA hydrogels, in the drying and annealing process, strong interactions (hydrogen bonds) between the CNFs and PVA were formed instead of interfibrillar hydrogen bonds. That is, nanofibers were separated but connected by PVA chains. The interactions between the CNFs and PVA were maintained well in the hydrated state owing to the strong hydrogen bonds and the entanglement of the PVA chains. Meanwhile, PVA networks were formed through physical cross-linking of the crystalline region, which was also maintained well in the hydrated state. Because the PVA chains are strong, tough and highly stretchable, the PVA chains probably acted as cross-linker and contributed to the stiffness of the composite hydrogels. When the composite hydrogels were stretched, the fracture of the PVA chains and disintegration of the hydrogen bonds may have dissipated much energy, which maintained the stretchability. For the CNF/PVA hydrogels with different amounts of PVA incorporated, the CNF content was almost the same (Table 1). As more PVA was incorporated, we believed that more water was replaced by the PVA, making the hydrogels stiffer, stronger and tougher, simultaneously. Therefore, the excellent mechanical properties of the CNF/PVA hydrogels resulted from the enhanced stiffness in the hydrated state and the maintained stretchability. We expected that other strong and tough polymer networks, which interact with CNFs well, will also result in nanocomposite hydrogels with excellent mechanical properties.

Conclusion

In the current study, we developed stiff and strong CNF/PVA nanocomposite hydrogels. The maximum elastic modulus and fracture strength reached by the DA7.5 hydrogel were 47.92 ± 0.99 MPa and 15.91 ± 0.48 MPa, respectively, which were almost comparable to skin and cartilage. In addition, the CNF/PVA hydrogels had a high water content and showed high fracture energy. It was revealed that both the PVA networks and the interactions between the CNFs and PVA were maintained well in the hydrated state. Because the PVA chains are strong, tough and highly stretchable, the PVA chains probably acted as cross-linker, contributing to the stiffness. When the hydrogels were stretched, the fracture of the PVA chains and disintegration of the hydrogen bonds may have dissipated much energy, maintaining the stretchability. The enhanced stiffness and maintained stretchability resulted in nanocomposite hydrogels with excellent mechanical properties. Given that stiffness, strength and fracture energy are very important for hydrogels while they are rarely achieved simultaneously, this study may suggest a simple and versatile method for preparation of load-bearing hydrogels from nanocelluloses.

References

Abe K, Yano H (2012) Cellulose nanofiber-based hydrogels with high mechanical strength. Cellulose 19:1907–1912. https://doi.org/10.1007/s10570-012-9784-3

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromol 8:3276–3278

Benítez AJ, Walther A (2017) Cellulose nanofibril nanopapers and bioinspired nanocomposites: a review to understand the mechanical property space. J Mater Chem A 5:16003–16024. https://doi.org/10.1039/c7ta02006f

Cha WI, Hyon SH, Oka M, Ikada Y (1996) Mechanical and wear properties of poly(vinyl alcohol) hydrogels. In: Macromolecular symposia, vol 1. Wiley, pp 115–126

Chen C, Wang H, Li S, Fang L, Li D (2017) Reinforcement of cellulose nanofibers in polyacrylamide gels. Cellulose. https://doi.org/10.1007/s10570-017-1512-6

De France KJ, Hoare T, Cranston ED (2017) A review of hydrogels and aerogels containing nanocellulose. Chem Mater 29:4609–4631. https://doi.org/10.1021/acs.chemmater.7b00531

Dubinskaya VA, Eng LS, Rebrow LB, Bykov VA (2007) Comparative study of the state of water in various human tissues. Bull Exp Biol Med 144:294–297. https://doi.org/10.1007/s10517-007-0314-5

Gong JP, Katsuyama Y, Kurokawa T, Osada Y (2003) Double-network hydrogels with extremely high mechanical strength. Adv Mater 15:1155–1158

Haraguchi K, Takehisa T (2002) Nanocomposite hydrogels: a unique organic-inorganic network structure with extraordinary mechanical, optical, and swelling/de-swelling properties. Adv Mater 14:1120

Henriksson M, Berglund LA, Isaksson P, Lindstrom T, Nishino T (2008) Cellulose nanopaper structures of high toughness. Biomacromolecules 9:1579–1585

Huang Y, King DR, Sun TL, Nonoyama T, Kurokawa T, Nakajima T, Gong JP (2017) Energy-dissipative matrices enable synergistic toughening in fiber reinforced soft composites. Adv Funct Mater 27:1605350. https://doi.org/10.1002/adfm.201605350

Illeperuma WRK, Sun J-Y, Suo Z, Vlassak JJ (2014) Fiber-reinforced tough hydrogels. Extreme Mech Lett 1:90–96. https://doi.org/10.1016/j.eml.2014.11.001

Klemm D, Kramer F, Moritz S, Lindstrom T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed Engl 50:5438–5466. https://doi.org/10.1002/anie.201001273

Li J, Illeperuma WRK, Suo Z, Vlassak JJ (2014a) Hybrid hydrogels with extremely high stiffness and toughness. ACS Macro Lett 3:520–523. https://doi.org/10.1021/mz5002355

Li J, Suo Z, Vlassak JJ (2014b) Stiff, strong, and tough hydrogels with good chemical stability. J Mater Chem B 2:6708–6713. https://doi.org/10.1039/c4tb01194e

Lin P, Ma S, Wang X, Zhou F (2015) Molecularly engineered dual-crosslinked hydrogel with ultrahigh mechanical strength, toughness, and good self-recovery. Adv Mater 27:2054–2059. https://doi.org/10.1002/adma.201405022

Liu L, Li L, Qing Y, Yan N, Wu Y, Li X, Tian C (2016) Mechanically strong and thermosensitive hydrogels reinforced with cellulose nanofibrils. Polym Chem 7:7142–7151. https://doi.org/10.1039/c6py01652a

Long R, Hui CY (2016) Fracture toughness of hydrogels: measurement and interpretation. Soft Matter 12:8069–8086. https://doi.org/10.1039/c6sm01694d

Luo F et al (2015) Oppositely charged polyelectrolytes form tough, self-healing, and rebuildable hydrogels. Adv Mater 27:2722–2727. https://doi.org/10.1002/adma.201500140

Mayumi K, Guo J, Narita T, Hui CY, Creton C (2016) Fracture of dual crosslink gels with permanent and transient crosslinks. Extreme Mech Lett 6:52–59. https://doi.org/10.1016/j.eml.2015.12.002

Qua EH, Hornsby PR, Sharma HSS, Lyons G, McCall RD (2009) Preparation and characterization of poly(vinyl alcohol) nanocomposites made from cellulose nanofibers. J Appl Polym Sci 113:2238–2247. https://doi.org/10.1002/app.30116

Rauner N, Meuris M, Zoric M, Tiller JC (2017) Enzymatic mineralization generates ultrastiff and tough hydrogels with tunable mechanics. Nature 543:407–410. https://doi.org/10.1038/nature21392

Sehaqui H, Zhou Q, Ikkala O, Berglund LA (2011) Strong and tough cellulose nanopaper with high specific surface area and porosity. Biomacromol 12:3638–3644. https://doi.org/10.1021/bm2008907

Sun Y-N, Gao G-R, Du G-L, Cheng Y-J, Fu J (2014) Super tough, ultrastretchable, and thermoresponsive hydrogels with functionalized triblock copolymer micelles as macro-cross-linkers. ACS Macro Lett 3:496–500. https://doi.org/10.1021/mz500221j

Torres-Rendon JG, Schacher FH, Ifuku S, Walther A (2014) Mechanical performance of macrofibers of cellulose and chitin nanofibrils aligned by wet-stretching: a critical comparison. Biomacromol 15:2709–2717. https://doi.org/10.1021/bm500566m

Walther A, Timonen JV, Diez I, Laukkanen A, Ikkala O (2011) Multifunctional high-performance biofibers based on wet-extrusion of renewable native cellulose nanofibrils. Adv Mater 23:2924–2928. https://doi.org/10.1002/adma.201100580

Wang W, Zhang Y, Liu W (2017) Bioinspired fabrication of high strength hydrogels from non-covalent interactions. Prog Polym Sci 71:1–25. https://doi.org/10.1016/j.progpolymsci.2017.04.001

Wegst UGK, Ashby MF (2004) The mechanical efficiency of natural materials. Phil Mag 84:2167–2186. https://doi.org/10.1080/14786430410001680935

Xu L, Zhao X, Xu C, Kotov NA (2018) Water-rich biomimetic composites with abiotic self-organizing nanofiber network. Adv Mater. https://doi.org/10.1002/adma.201703343

Yang J, Han CR, Duan JF, Xu F, Sun RC (2013) Mechanical and viscoelastic properties of cellulose nanocrystals reinforced poly(ethylene glycol) nanocomposite hydrogels. ACS Appl Mater Interfaces 5:3199–3207. https://doi.org/10.1021/am4001997

Yang J, Ma M, Zhang X, Xu F (2016) Elucidating dynamics of precoordinated ionic bridges as sacrificial bonds in interpenetrating network hydrogels. Macromolecules 49:4340–4348. https://doi.org/10.1021/acs.macromol.6b00874

Yue Y, Han J, Han G, French AD, Qi Y, Wu Q (2016) Cellulose nanofibers reinforced sodium alginate-polyvinyl alcohol hydrogels: core-shell structure formation and property characterization. Carbohydr Polym 147:155–164. https://doi.org/10.1016/j.carbpol.2016.04.005

Zhang YS, Khademhosseini A (2017) Advances in engineering hydrogels. Science. https://doi.org/10.1126/science.aaf3627

Zhang HJ et al (2016) Tough physical double-network hydrogels based on amphiphilic triblock copolymers. Adv Mater 28:4884–4890. https://doi.org/10.1002/adma.201600466

Zhao X (2017) Designing toughness and strength for soft materials. Proc Natl Acad Sci 114:8138–8140

Zhao D, Huang J, Zhong Y, Li K, Zhang L, Cai J (2016) High-strength and high-toughness double-cross-linked cellulose hydrogels: a new strategy using sequential chemical and physical cross-linking. Adv Funct Mater 26:6279–6287. https://doi.org/10.1002/adfm.201601645

Zhou Y, Fu S, Zhang L, Zhan H, Levit MV (2014) Use of carboxylated cellulose nanofibrils-filled magnetic chitosan hydrogel beads as adsorbents for Pb(II). Carbohydr Polym 101:75–82. https://doi.org/10.1016/j.carbpol.2013.08.055

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yang, X., Abe, K., Biswas, S.K. et al. Extremely stiff and strong nanocomposite hydrogels with stretchable cellulose nanofiber/poly(vinyl alcohol) networks. Cellulose 25, 6571–6580 (2018). https://doi.org/10.1007/s10570-018-2030-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-2030-x