Abstract

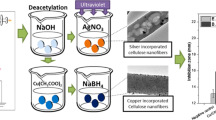

The AlOOH/Cu modified cellulose acetate fibres were prepared by a facile one-step method. First, the cellulose acetate fibres were treated in an aqueous suspension with the bimetallic Al/Cu nanoparticles, followed by their oxidation. Copper and copper intermetallides do not react with water, while the aluminum does with boehmite formation. During this process AlOOH/Cu particles consisting of boehmite nanosheets self-assembled into flower-like agglomerates, and copper-rich fragments with size of 2 nm were formed. These inclusions could be spread uniformly through the whole volume of nanosheets or form a solid spherical copper-rich core in the center of AlOOH/Cu particles. The AlOOH nanosheets provide an adhesive attachment of the particles on the surface of the cellulose acetate fibres, and the slow migration of copper ions through the shell into the surrounding medium. The morphology, physical and chemical properties of the materials were characterized by transmission electron microscopy, scanning electron microscopy, X-ray diffraction, energy dispersive X-ray spectroscopy, adsorption of nitrogen (BET method), Fourier transform infrared spectroscopy and electrophoretic mobility (ζ-potential measurement). The antibacterial activity of the hybrid fibrous sorbent prepared against Escherichia Coli and Staphylococcus Aureus was studied. Reduction of the concentration viable bacteria reached 100 % after exposure of the bacteria for 1 h to the hybrid fibrous absorbent.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Currently, problems with the microbiological safety of medical products continue, leading to the spread of hospital-acquired infections (Banach et al. 2015). This results in a significant threat to both patients and healthcare workers. To fight nosocomial infections it is proposed to use medical garments, wound dressing materials and bedding with antimicrobial properties (Qin 2016). The creation of an antibacterial effect is currently achieved by using a wide range of nanoparticles having various chemical nature (Zhang et al. 2016), structure (Huo et al. 2016), interfacial potential (Arakha et al. 2015) and morphology (Xiong et al. 2015). Commonly silver nanoparticles (Marin et al. 2015), zinc (Salem et al. 2015) and zinc oxide (Zhang et al. 2013), copper and copper oxide (Khan et al. 2017), titanium dioxide (Arora et al. 2015) are used for this purpose.

Copper and its compounds are used for disinfection for a long time (Grass et al. 2011). Copper is widely used as algaecides (Bishop and Rodgers 2012), fungicides (Tegenaw et al. 2015). There is a low human dermatological sensitivity to the copper particles (Borkow and del Carmen Elías 2016), at the same time they have a high antibacterial and antiviral activity (Palza 2015).

Impregnation of cellulose textiles with copper salt (Li et al. 2014), Cu-alginate nanoparticles (Heliopoulos et al. 2013) or CuO nanoparticles (El-Nahhal et al. 2012) has been studied extensively in recent years. The impregnation of textile materials with colloidal solutions (Zhang et al. 2009) or salt solutions followed by metal reduction (Liu et al. 2014) is the simplest and most common approach to immobilize nanoparticles on their surface. For strong adhesive attachment of nanoparticles a surface of textile fibres is activated, for example, using ultrasound or microwave radiation (Perelshtein et al. 2013).

Earlier, we have produced nanostructures having a high antibacterial activity by the oxidation of the Al/Cu bimetallic nanoparticles with water (Svarovskaya et al. 2015). In this work the cellulose acetate fibres were modified with AlOOH/Cu particles by a simple method, namely, the oxidation of Al/Cu bimetallic nanoparticles with water in the presence of cellulose acetate fibres, and physico-chemical and antibacterial activity of the obtained material were studied.

Experimental procedure

Al/Cu nanoparticles preparation

The Al/Cu nanoparticles were obtained by the electric explosion of twisted Cu and Al wires (EEW) in an argon atmosphere (The Company « Advanced Powder Technology LLC » , Tomsk, Russia). Aluminum to copper ratio was 50:50 wt%. The Cu and Al wires were bought from manufacturers and the label amount of metals in the wires was at least 98.0–99.9% wt. Before the experiment the wires were purified with an organic solvent to remove contaminants from the surface. To obtain Al/Cu nanoparticles, aluminum and copper wires were twisted together before EEW. Then a high-density current pulse (~ 107 A/cm2) was applied to the twisted wires; the current pulse was produced by the discharge of a capacitor bank. When the current pulse propagated through the wires, the explosive dispersion of metal and the fast expansion of explosion products (metal vapor and aerosol) into the atmospheric gas (argon) took place. Here, the explosion products were cooled and nanoparticles emerged. The productivity of the EEW assembly was 50 g/h, with the consumption of the electrical energy was 75 Kw h/kg. Al/Cu nanopowders are pyrophoric immediately after preparation; that is why they are passivated by slow air pass method before use.

Modification of cellulose acetate fibres with AlOOH/Cu particles

The Al/Cu nanoparticles were attached on cellulose acetate fibres by dip-coat method. For this, 100 mg of the Al/Cu nanoparticles were suspended in 100 mL of distilled water, 100 mg cellulose acetate fibres as a nonwoven material (FPA-15-2,0, Esfil Tehno, Estonia, Table 1) was immersed to the suspension. Then the suspension containing cellulose acetate fibres was put into a water bath reactor for the oxidation of the Al/Cu nanoparticles to form the AlOOH/Cu particles. The reactor was heated at 60 °C with continuous stirring for 1 h. Then treated nonwoven material was taken out, washed with distilled water and dried at 105 °C to constant mass for 3 h. At the end of the treatment, the color of the nonwoven material changed from white to brown (Fig. 1). The mass fraction of AlOOH/Cu particles fixed on the surface of cellulose acetate fibres were determined as the difference between nonwoven material mass before and after treatment, it was 5 wt%.

Characterization methods

The morphology of the Al/Cu nanoparticles and the AlOOH/Cu particles was characterized by transmission electron microscopy (JEOL-2100, JEM, Japan, operated at 200 kV), energy dispersive X-ray spectroscopy (X-Max Oxford Instruments, UK), and X-ray diffraction (XRD-6000, Cu Kα radiation, wavelength 1.54056 Å). The specific surface areas of the AlOOH/Cu particles were measured by nitrogen adsorption method using a Sorbtometer M (Catakon, Russia) nitrogen adsorption apparatus. The specific surface area was calculated by the BET method in the relative pressure range of 0.05 − 0.35. The morphology of the nonwoven material was characterized by scanning electron microscopy (LEO EVO 50, operated at 30 kV). FT-IR spectra were recorded using a Nikolet 5700 spectrometer (Thermo Electron, USA) at the wave-number range of 500–4000 cm−1 under ambient conditions. The ζ-potential of AlOOH/Cu particles was measured by their electrophoretic mobility (ZetaSizer Nano ZSP, Malvern Instruments, UK) at pH 7.4. 0.1 M HNO3 and 0.1 M NaOH were used to adjust the pH of the samples. The chemical composition of AlOOH/Cu particles we investigated by by voltammetric stripping analysis and spectrophothmetry. The concentration of Al3+ was measured in a UV spectrophotometer (PE-5400 V, PromEcoLab, Russia) at a wavelength of 535 nm using Eriochrome Cyanine R as the complexing agent. The content of the copper ions was determined by voltammetric stripping analysis (Voltammetric analyzer STA, Russia).

Antibacterial assay

The antibacterial effect was measured using AATCC test 100-2004, and agar diffusion test methods using bacteria Escherichia coli K-12 and Staphylococcus aureus ATCC 6538P (Russian National Collection of Industrial Microorganisms). We adjusted the bacterial suspension to achieve a turbidity equivalent to a 0.5 McFarland standard (Densilameter II, ERBA Lachema). This results in a suspension containing approximately 1.5 × 108 colony-forming units (CFU)/mL. The optical density (OD) of E. coli suspension was 0.3115, the (OD) of S. aureus suspension was 0.2656.

The AATCC test method was used for the evaluation of the degree of antibacterial activity of textile materials. The materials and media were sterilized in autoclave at 121 °C for 20 min. An aliquot of the bacterial suspension was diluted 1500 times. The modified and untreated samples of 1 × 1 cm in size (0.01 g) were inoculated with 2 mL of inoculum 105 CFU/mL in separate 100 mL flasks. The total number of viable bacteria was counted after 1, 6 and 24 h incubation at 37 °C. For this, after incubation, the samples were diluted with 100 mL 0.1 M phosphate buffer solution (PBS). From each sample, 1 mL of solution was diluted to 10, 100, and 1000 mL and plated on a nutrient agar. All plates were incubated at 37 °C for 24 h. Antibacterial efficiency was calculated by Eq 1.

where R = reduction in percentage, A = CFU/test sample in blank, B = CFU/test sample for samples (modified/untreated). The flask with PBS and the bacterial suspension was used as blank.

For agar diffusion test for nanoparticles 20 mL of Mueller–Hinton agar was poured into sterile Petri dishes (diameter 90 mm) and left to solidify. The wells in agar were made on Petri dishes by using a sterile cork borer. Set amount of 100 μg/mL of nanoparticles water suspension was poured into these wells. Petri dishes were incubated at 37 °C for 48 h. According to Heliopoulos et al. (2013) the modified and untreated samples of fibres diameter of 25 ± 1 mm were placed on a double layer agar plate, where the bottom layer consisted of a meat-peptone agar without bacterial suspension, and the upper layer was inoculated with test bacteria (1 × 106 CFU/mL). An aliquot of the bacterial suspension was diluted 150 times. The plates were incubated for 24 h at 37 °C. The antibacterial activity was evaluated by the bacteria growth in the agar and the sample contact zone value.

Concentration of copper ions in aqueous extracts

To evaluate the concentration of copper ions in the aqueous extract the modified fibre material 1 × 1 cm in size (0.01 g) was placed into 100 mL of a 0.9% NaCl solution at 37 °C. The content of the copper ions in the solution was determined by voltammetric stripping analysis. Aliquots of the solution were taken through a membrane filter Sartorius 0.22 μm PTFE syringe (Goettingen, Germany), and the copper ion content therein was determined.

Results and discussion

Characteristics of the precursor

The Al/Cu nanoparticles are formed during the EEW of the twisted Al and Cu wires in argon atmosphere. The nanoparticles have a spherical form and the average size is approximately 85 nm (Fig. 2).

According to (Svarovskaya et al. 2015), during the electric explosion of monometallic wire the dispergation of metal to the liquid clusters having a few nanometers size takes place. The liquid clusters are combined together to form nanoparticles. Probably a similar process occurs when two wires of aluminum and copper are dispersed. During the electric explosion of two wires the clusters of aluminum and copper are formed, and then they collide with each other forming nanoparticles. According to TEM–EDX data (Fig. 3), aluminum and copper are uniformly distributed in a volume of the nanoparticles.

The particles have a complex phase structure corresponding to the phase diagram of the Al/Cu alloy (Lyakishev 1996). The XRD data (Fig. 4a) for the Al/Cu nanopowder indicate the presence of intermetallides Cu9Al4 and CuAl2, as well Al and Cu phases are present in the sample.

Structure and morphology of the AlOOH/Cu particles

When the bimetallic nanoparticles Al/Cu react with water the AlOOH/Cu nanoparticles, representing flower-like agglomerates of the boehmite nanosheets and copper-rich fragments are formed (Fig. 5). The nanosheet size is of 100-300 nm and a thickness is approximately 5-7 nm. Similar nanosheets are formed during the oxidation of electroexplosive Al and AlN/Al nanopowders in water (Bakina et al. 2015).

According to TEM data various copper distributions in these structures are observed. One of these structures can be characterized as core–shell particles. These particles have an electron dense spherical copper-rich core and a shell composed of AlOOH nanosheets (Fig. 6).

Another structure is characterized with more loose copper distribution. Copper-rich fragments with size of 2 nm are distributed throughout the whole volume in these structures (Fig. 7).

XRD data (Fig. 4b) show the main reflexes correspond to the AlOOH boehmite phase, as well copper and intermetallides are present. Copper and intermetallides Cu9Al4 and CuAl2 are found in the same ratios as in the Al/Cu nanoparticles. The specific surface area of the AlOOH/Cu particles is 140 m2/g, ζ- potential is 25 ± 3 mV at the pH 7.4

Coating mechanism

The surface morphology of the modified fibres was evaluated by SEM (Fig. 8).

The fibre surface is still smooth after modification and the AlOOH/Cu particles are uniformly distributed over the fibre surface. The content of AlOOH/Cu particles in the modified fibres is 5 wt%: 19,5 mg/g Cu and 21,2 mg/g Al.

Modifying of the cellulose acetate fibres involves firstly the Al/Cu nanoparticles adsorption onto the fibres surface followed by the oxidation of the metal particles with water to form the AlOOH/Cu particles in one-step process at 60 °C and atmospheric pressure. The bimetallic nanoparticles as well as the aluminum nanoparticles produced by EEW method usually are coated with a thin alumina layer (Bakina et al. 2015). The hydration of the surface oxide film occurs at the initial stage of the nanoparticles oxidation as reported by Bunker et al. 2002. OH− and H2O are reactive species, when they reach metal aluminum surface the oxidation reaction begins.

The nanoparticle Al/Cu can be represented as a galvanic cell, wherein an anode is aluminum, and a cathode—copper. In this case, the anode dissolution aluminum reaction is following (2):

While the electrolysis of water takes place at the cathode, and it is accompanied by the hydroxyl ions formation, pH of the suspension is increased, and hydrogen is released according to Eq. (3):

The reaction is accompanied by pH increase up to 8,0–8,5.

The reaction of the aluminum with water has been studied by Vedder and Vermilyea 1961. According the mechanism offered, the essential steps in the reaction are amorphous oxide formation; dissolution of the amorphous oxide; and precipitation of aluminum hydroxide. Alwitt has investigated boehmite film formation on the aluminum surface (Alwitt 1974). According to this work, the aluminum oxides are sparingly soluble. The surface hydrolysis is proceeding at a significant rate, and the critical supersaturation would be quickly reached adjacent to the surface and hydrous oxide would be precipitated on low energy surface sites. The pseudoboehmite plates formed firtstly are exceedingly thin and are attached to the substrate only along an edge. For some time then, the deposited material would occupy only a small fraction of the surface and probably would not interfere with the dissolution reaction.

Boehmite also precipitates on the cellulose acetate fibres surface at the adsorbed Al/Cu nanoparticles sites. Nanosheet or several nanosheets begin to grow between nanoparticle and fibre surface providing attachment of the hydrolyzed particle due to physical adsorption that is confirmed by FTIR data. Copper and intermetallides Cu9Al4 and CuAl2do not react with water at these conditions (60 °C and pH ~ 8) that is confirmed by XRD data. Resulting structures can be called AlOOH/Cu, where Cu is represented with Cu, Cu9Al4 and CuAl2 phases.

The FTIR spectra of pure AlOOH/Cu particles, untreated and modified fibres are shown in Fig. 9.

The characteristic peaks assignment of cellulose acetate fibres (Azzaoui et al. 2015) are as follows (Fig. 9a): 3481 cm−1 (O–H stretch); 1747 cm−1 (C=O carbonyl ester band); 1431 and 1371 cm−1 (CH3 group stretching vibrations); 1234 and 1049 cm−1(ν(C-O)ester vibration). Figure 9b displays the FTIR spectra of AlOOH/Cu. The strong, broad band at 3307 cm−1 is assigned to the νas (Al)O–H and νs (Al)O–H stretching vibrations (Zhang et al. 2012). The band at 1065 cm−1 is assigned to the δs Al-O–H mode of γ-AlOOH. The strong band at 742 cm−1 is ascribed to the vibration mode of AlO6. The FTIR spectra of the cellulose acetate fibres modified with AlOOH/Cu particles (Fig. 9c) are the superposition of FTIR spectra of cellulose acetate fibres and AlOOH/Cu particles regard to the number of bands and their positions. Thus, the AlOOH/Cu particles do not form chemical bonds with fibres surfaces and the adhesion of AlOOH/Cu particles on cellulose acetate fibres caused by physical adsorption.

Moreover, ζ-potential of AlOOH/Cu particles is positive + 27.0 mV (pH 7.4) while cellulose fibres are negatively charged and ζ-potential of them is − 35.5 mV (pH 7.4). Therefore, electrostatic interaction of positively charged AlOOH/Cu particles and negatively charged cellulose acetate fibres confirms the AlOOH/Cu particles attachment on the fibres’ surface.

Antibacterial activity

According to agar well diffusion method, the copper-containing nanoparticles exhibit antibacterial activity (Table 2).

Sadiq et al. (2009) showed a mild antibacterial activity of the alumina nanoparticles only at very high concentrations, which might be due to charge interactions between the particles surface and cells.

The authors (Perelshtein et al. 2009) have obtained hybrid material by precipitation of the copper hydroxide with smooth plate form on the cellulose surface and have shown its antibacterial activity against E. coli (Gram-negative bacteria) and S. aureus (Gram-positive bacteria). Wang et al. 2007 have shown on nanotubes as an example that individual irregular-shaped crystals have more opened surface to contact than smooth spherical and tubular particles that can promote antibacterial effect.

The cellulose acetate fibres (FPA15-2,0 Esfil Techno) modified with boehmite nanosheets (AlOOH-modified fibres) have been reported in our previous work (Svarovskaya at al. 2017). The AlOOH nanosheets were prepared by the reaction of composite AlN/Al nanoparticles with water at 60 °C. The AlOOH modified cellulose acetate fibres had high adsorption capacity for E. coli. The bacterial adsorption data fitted well by the Langmuir equation. We attributed this to the electrostatic interaction of positively charged boehmite nanostructures (ξ = + 35 mV, pH 7.4) and negatively charged bacterial cells (ξ = − 36 mV, pH 7.4). Therefore, we expect more pronounced antibacterial activity of the modified fibers.

The antibacterial activity of the untreated, AlOOH- modified and AlOOH/Cu modified fibres was tested against the E. coli and S. aureus. The reduction of bacterial viability (R, %) reached 100% with modified fibres. As shown in Fig. 10, exposure of bacteria to the AlOOH/Cu modified fibres during 1 h results in complete inhibition of bacterial growth (R = 100%).

If an antibacterial agent is able to diffuse into agar, the inhibition zone becomes evident. Antibacterial activity investigation with agar diffusion shows small inhibition zones (Fig. 11), but there is no bacterial growth directly under the AlOOH/Cu modified fibres. In this case, antibacterial agent is fixed on the fibrous matrix that prevents its diffusion into agar.

Untreated cellulose acetate fibres Fig. 11 (1) and cellulose acetate fibres modified with AlOOH nanosheets Fig. 11 (2) did not show any inhibitory effects on bacteria due to lack of copper which was responsible for the antibacterial activity.

The main factor affecting the antibacterial activity of the AlOOH/Cu modified fibres is the release of the copper ions into the surrounding medium. The minimal inhibitory concentration of copper ions in solution which has been reported in (Du et al. 2009) was 257 μg/mL (257 ppm). According to Li et al. 2015, the content of copper ions of 10 ppm decreased E. coli growth at 90% after 3 h exposure. The concentration of Cu2+ ions in the solution during the exposure time of modified fibers in distilled water from 30 min to 24 h did not exceed 6 ppm (Fig. 12).

Thus, there are not enough free copper ions beyond the AlOOH/Cu modified fibres for fast inactivation of bacteria. It can be assumed that the antibacterial effect of the AlOOH/Cu modified fibres is realized via adsorption of bacteria on AlOOH nanosheets and their subsequent inactivation by copper ions that are present in AlOOH/Cu modified fibres. Cell viability depends mainly on their surface negative electric charge. Evidently positive charge of the AlOOH nanosheets surface is of great importance in the bacterial adhesion. Thus, we suggest the two-stage mechanism of the interaction between AlOOH/Cu modified fibres and bacterial cells:

-

1.

During the first stage the fast bacterial adhesion proceeds on the boehmite nanosheets surface mainly due to electrostatic interaction followed by stronger van der Waals interactions and hydrogen bonds formation.

-

2.

During the second stage the interaction proceeds between bacterial cells and copper nanoparticles by direct contact due to the depolarization of the cell membrane (Chatterjee et al. 2014).

Conclusion

The cellulose acetate fibres modified with AlOOH/Cu nanoparticles were produced by a simple one-step route. The excellent bactericidal effect of the material was demonstrated. Thus, the inactivation of adhered bacteria occurs without substantial release of copper ions to the solution that reduces probability for the formation resistant strains of microorganisms, and on the other hand, prevents secondary contamination with copper ions. This approach enables to reduce content of the antibacterial component and hence to decrease the material toxicity. The modified fibres has potential applications as a wound dressing.

References

Alwitt RS (1974) The growth of hydrous oxide films on aluminum. J Electrochem Soc 121:1322–1328. https://doi.org/10.1149/1.2401679

Arakha M, Saleem M, Mallick BC, Jha S (2015) The effects of interfacial potential on antibacterial propensity of ZnO nanoparticle. Sci Rep 5:9578. https://doi.org/10.1038/srep09578

Arora B, Murar M, Dhumale V (2015) Antibacterial potential of TiO2 nanoparticles against MDR Pseudomonas aeruginosa. J Exp Nanosci 10:819–827. https://doi.org/10.1080/17458080.2014.902544

Azzaoui K, Mejdoubi E, Lamhamdi L, Zaoui S, Berrabah M, Elidrissi A, Hammouti B, Fouda MMG, Al–Deyab SS (2015) Structure and properties of hydroxyapatite/hydroxyethyl cellulose acetate composite films. Carbohydr Polym 115:170–176. https://doi.org/10.1016/j.carbpol.2014.08.089

Bakina OV, Svarovskaya NV, Glazkova EA, Lozhkomoev AS, Khorobraya EG, Lerner MI (2015) Flower-shaped AlOOH nanostructures synthesized by the reaction of an AlN/Al composite nanopowder in water. Adv Powder Technol 26:1512–1519. https://doi.org/10.1016/j.apt.2015.08.007

Banach DB, Bearman GM, Morgan DJ, Munoz-Price LS (2015) Infection control precautions for visitors to healthcare facilities. Expert Rev Anti Infect Ther 13:1047–1050. https://doi.org/10.1586/14787210.2015.1068119

Bishop WM, Rodgers JHJ (2012) Responses of Lyngbya wollei to exposures of copper-based algaecides: the critical burden concept. Arch Environ Contam Toxicol 62:403–410. https://doi.org/10.1007/s00244-011-9711-x

Borkow G, del Carmen Elías A (2016) Facial skin lifting and brightening following sleep on copper oxide containing pillowcases. Cosmetics 3:24. https://doi.org/10.3390/cosmetics3030024

Bunker BC, Nelson GC, Zavadil KR, Barbour JC, Wall FD, Sullivan JP, Windisch CF Jr, Engelhardt MH, Baer DR (2002) Hydration of passive oxide films on aluminum. J Phys Chem B 106:4705–4713. https://doi.org/10.1021/jp013246e

Chatterjee AK, Chakraborty R, Basu T (2014) Mechanism of antibacterial activity of copper nanoparticles. Nanotechnology 25:135101. https://doi.org/10.1088/0957-4484/25/13/135101

Du WL, Niu SS, Xu YL, Xu ZR, Fan CL (2009) Antibacterial activity of chitosan tripolyphosphate nanoparticles loaded with various metal ions. Carbohydr Polym 75:385–389. https://doi.org/10.1016/j.carbpol.2008.07.039

El-Nahhal IM, Zourab SM, Kodeh FS, Selmane M, Genois I, Babonneau F (2012) Nanostructured copper oxide-cotton fibers: synthesis, characterization, and applications. Int Nano Lett 2:14. https://doi.org/10.1186/2228-5326-2-14

Grass G, Rensing C, Solioz M (2011) Metallic copper as an antibacterial surface. Appl Environ Bacteriol 77:1541–1547. https://doi.org/10.1128/AEM.02766-10

Heliopoulos NS, Papageorgiou SK, Galeou A, Favvas EP, Katsaros FK, Stamatakis K (2013) Effect of copper and copper alginate treatment on wool fabric. Study of textile and antibacterial properties. Surf Coat Technol 235:24–31. https://doi.org/10.1016/j.surfcoat.2013.07.009

Huo S, Jiang Y, Gupta A, Jiang Z, Landis RF, Hou S, Liang XJ, Rotello VM (2016) Fully zwitterionic nanoparticle antibacterial agents through tuning of core size and ligand structure. ACS Nano 10:8732–8737. https://doi.org/10.1021/acsnano.6b04207

Khan SA, Shahid S, Sajid MR, Noreen F, Kanwal S (2017) Biogenic synthesis of CuO nanoparticles and their biomedical applications: a current review. Int J Adv Res 5(6):925–946. https://doi.org/10.21474/IJAR01/4495

Li YL, Deletic A, McCarthy DT (2014) Removal of E.coli from urban stormwater using antibacterial-modified filter media. J Hazard Mater 24:73–81. https://doi.org/10.1016/j.jhazmat.2014.01.057

Li HH, Chen QS, Zhao JW, Urmila K (2015) Enhancing the antibacterial activity of natural extraction using the synthetic ultrasmall metal nanoparticles. Sci Rep 5:11033. https://doi.org/10.1038/srep11033

Liu H, Lee YY, Norsten TB, Chong K (2014) In situ formation of anti-bacterial silver nanoparticles on cotton textiles. J Ind Text 44:198–210. https://doi.org/10.1177/1528083713481833

Lyakishev NP (1996) State Diagrams of Double Metallic Systems [in Russian], Moscow

Marin S, Vlasceanu GM, Tiplea RE, Bucur IR, Lemnaru M, Marin MM, Grumezescu AM (2015) Applications and toxicity of silver nanoparticles: a recent review. Curr Top Med Chem 15:1596–1604. https://doi.org/10.2174/1568026615666150414142209

Palza H (2015) Antibacterial polymers with metal nanoparticles. Int J Mol Sci 16:2099–2116. https://doi.org/10.3390/ijms16012099

Perelshtein I, Applerot G, Perkas N, Wehrschuetz-Sigl E, Hasmann A, Guebitz G, Gedanken A (2009) CuO–cotton nanocomposite: formation, morphology, and antibacterial activity. Surf Coat Technol 204:54–57. https://doi.org/10.1016/j.surfcoat.2009.06.028

Perelshtein I, Ruderman Y, Beddow J, Singh G, Vinatoru M, Joyce E, Mason TJ, Blanes M, Mollá K, Gedanken A (2013) The sonochemical coating of cotton withstands 65 washing cycles at hospital washing standards and retains its antibacterial properties. Cellulose 20:1215–1221. https://doi.org/10.1007/s10570-013-9929-z

Qin Y (2016) Medical textile materials. Elsevier, UK

Sadiq IM, Chowdhury B, Chandrasekaran N, Mukherjee A (2009) Antimicrobial sensitivity of Escherichia coli to alumina nanoparticles. Nanomed 5:282–286. https://doi.org/10.1016/j.nano.2009.01.002

Salem W, Leitner DR, Zingl FG, Schratter G, Prassl R, Goessler W, Reidl J, Schild S (2015) Antibacterial activity of silver and zinc nanoparticles against Vibrio cholerae and enterotoxic Escherichia coli. Int J Med Bacteriol 305:85–95. https://doi.org/10.1016/j.ijmm.2014.11.005

Svarovskaya NV, Berenda AV, Bakina OV, Glazkova EA, Lozhkomoev AS, Khorobraya EG, Domashenko VV, Lerner MI, Fomenko AN (2015) Chemical behaviour of Al/Cu nanoparticles in water. Prog Nat Sci 25:1–5. https://doi.org/10.1016/j.pnsc.2015.01.001

Svarovskaya NV, Bakina OV, Glazkova EA, Fomenko AN (2017) Glass and cellulose acetate fibers-supported boehmite nanosheets for bacteria adsorption. Prog Nat Sci 27:274–286. https://doi.org/10.1016/j.pnsc.2017.02.006

Tegenaw A, Tolaymat T, Al-Abed S, El Badawy A, Luxton T, Sorial G, Genaidy A (2015) Characterization and potential environmental implications of select Cu-Based fungicides and bactericides employed in US markets. Environ Sci Technol 49:1294–1302. https://doi.org/10.1021/es504326n

Vedder W, Vermilyea DA (1961) Aluminum + water reaction. Trans Faraday Soc 65:561–584. https://doi.org/10.1039/TF9696500561

Wang J, Li L, Xiong D, Wang R, Zhao D, Min C, Yu Y, Ma L (2007) High spatially resolved morphological, structural and spectroscopical studies on copper oxide nanocrystals. Nanotechnology 18:075705. https://doi.org/10.1088/0957-4484/18/7/075705

Xiong L, Tong ZH, Chen JJ, Li LL, Yu HQ (2015) Morphology-dependent antibacterial activity of Cu/CuxO nanoparticles. Ecotoxicology 24:2067–2072. https://doi.org/10.1007/s10646-015-1554-1

Zhang F, Wu X, Chen Y, Lin H (2009) Application of silver nanoparticles to cotton fabric as an antibacterial textile finish. Fibers Polym 10:496–501. https://doi.org/10.1007/s12221-009-0496-8

Zhang YX, Jin YJZ, Yu XY, Xu WH, Luo T, Zhu BJ, Liu JH, Huang XJ (2012) Self-assembled, monodispersed, flowerlike γ-AlOOH hierarchical superstructures for greatly fast removal of heavy metal ions with high efficiency. Cryst Eng Comm 9:3005–3007. https://doi.org/10.1039/C2CE06545B

Zhang G, Liu Y, Morikawa H, Chen Y (2013) Application of ZnO nanoparticles to enhance the antibacterial activity and ultraviolet protective property of bamboo pulp fabric. Cellulose 20:1877–1884. https://doi.org/10.1007/s10570-013-9979-2

Zhang YY, Xu QB, Fu FY, Liu XD (2016) Durable antibacterial cotton textiles modified with inorganic nanoparticles. Cellulose 23:2791–2808. https://doi.org/10.1007/s10570-016-1012-0

Acknowledgments

The present work was financially supported of the Russian Science Foundation (Project No. 17-79-20382).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bakina, O.V., Glazkova, E.A., Lozhkomoev, A.S. et al. Cellulose acetate fibres surface modified with AlOOH/Cu particles: synthesis, characterization and antimicrobial activity. Cellulose 25, 4487–4497 (2018). https://doi.org/10.1007/s10570-018-1895-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1895-z