Abstract

In the present study, novel cellulose and chitosan composite hydrogels and films were constructed by directly dissolving cellulose and chitosan in alkali/urea aqueous solutions followed by a facile blending method and a mild coagulation process in an ethyl acetate gaseous phase. The structure and properties of the cellulose/chitosan composite materials were characterized by Field emission scanning electron microscopy, FTIR, wide angle X-ray diffraction, mechanical test and antibacterial experiment etc. The results indicated that there is strong hydrogen bonding interaction between cellulose and chitosan. The composite hydrogels exhibited homogeneous porous structure and the resultant films exhibited relative high light transmittance, indicating good miscibility between cellulose and chitosan due to their structure similarity. The mechanical strength increased with the cellulose content for the composite films, while the equilibrium swelling ratio, antibacterial activity and biocompatibility increased with the chitosan content. Facial mask shaped composite hydrogels with heavy metal ion adsorbability could be prepared facilely by using glass molds. Thus, the composite materials showed potential applications in the facial mask, antimicrobial packaging and water treatment fields.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recently, research of renewable resources has been listed as one of the 24 international frontiers due to global energy and sustainable development issues, and the utilization of natural polymers related materials has attracted much attention (Murugan and Ramakrishna, 2004; Saito et al. 2014; Anitha et al. 2014). Cellulose is the most abundant biopolymer in nature and can be dissolved and converted into regenerated functional materials with various shapes such as films, hydrogels, microspheres and fibers etc. (Cai et al. 2007; He et al. 2014a; Duan et al. 2014; Zhao et al. 2016; Wendler et al. 2009; Jedvert and Heinze 2017). Due to the intransigent nature of cellulose, materials made from it usually exhibit good mechanical properties, supporting their applications in various fields such as packaging and clothing manufacture (Mokhothu and John 2015). However, cellulose has poor bioactivity and no antimicrobial activity, which restricts its applications as biomaterials and antibacterial packaging. To solve this problem and make full use of cellulose, cellulose has usually been blended or modified with other polymers such as chitosan (Cao et al. 2016), collagen hydrolysate (Pei et al. 2013) and soy protein isolate (SPI) (Li et al. 2016a). Among these biopolymers, chitosan is the deacetylation product of chitin, the second most abundant biopolymer widely available from seafood processing waste (Chen et al. 2017; Rejinold et al. 2011). Chitosan exhibits good biocompatibility, hemostasis, antimicrobial activity and adsorptive property, which has been widely used in the biomedical, cosmetic and water treatment fields (Yang et al. 2016; He et al. 2017b; Yan et al. 2017). The poor mechanical property of chitosan greatly restricts its application, which is urgently needed to be improved to broaden the range of application. Thus, a worthwhile endeavor would be to blend chitosan with cellulose to realize the complement of each other’s advantages. The reported common solvents for cellulose and chitosan were N-methylmorpholine-N-oxide (NMMO), ionic liquids and ethylene diamine/potassium thiocyanate (Isogai and Atalla 1992; Hasegawa et al. 1994; Fink et al. 2001; Chaoming et al. 2009; Zhou et al. 2015), obviously, these solvents are usually expensive and hard to remove after the composite materials fabrication. Although cellulose and chitosan could be dissolved in NaOH/thiourea after chain depolymerization (Morgado et al. 2011), the exploiting of novel green solvents for directly dissolving cellulose and chitosan is still a challenge. Luckily, novel aqueous solvents such as LiOH/urea and KOH/LiOH/urea solutions were developed for cellulose and chitosan dissolution without depolymerization, respectively (Duan et al. 2015; Cai and Zhang 2005), and the regenerated cellulose and chitosan based materials were fabricated accordingly, which exhibited fascinating properties such as high strength, good biocompatibility and stimuli responsive (He et al. 2014b; Duan et al. 2016). However, as far as we know, bulk homogeneous cellulose/chitosan composite materials such as hydrogels or films from these novel alkali/urea aqueous solutions have never been reported.

In the present work, both chitosan and cellulose were dissolved in alkali/urea aqueous solutions, and then blended together in ice bath with different ratios to prepare homogeneous mixed solutions, which were coagulated in an ethyl acetate gaseous phase to prepare chitosan/cellulose composite hydrogels (CCG). The composite hydrogels were air-dried to obtain the corresponding films (CCF). The structure and properties of CCG and CCF were characterized, the results indicated that there is strong hydrogen bonding interaction between cellulose and chitosan. CCG exhibited homogeneous structure, indicating good miscibility. The mechanical strength of CCF increased with the cellulose content, while the equilibrium swelling ratio of CCG and antibacterial activity of CCF increased with the chitosan content. Therefore, CCG and CCF showed potential applications in the facial mask, antimicrobial packaging and water treatment fields.

Experimental section

Materials

Chitosan (viscosity, 100–200 mPa s) with deacetylation degree of above 95% was purchased from Aladdin Reagent Company. The cellulose sample (cotton linter pulp) was supplied by Hubei Chemical Fiber Co. Ltd. (Xiangfan, China). Its weight-average molecular weight (Mw) was determined by static laser light scattering (DAWN DSP, Wyatt Technology Co., US) to be 10.9 × 104 (Cai et al. 2006). The NaOH, KOH, LiOH·H2O, ethyl acetate, ethanol and urea (Shanghai Chemical Reagent Co. Ltd., China) were used as received. All the chemical reagents were of analytical grade and used without further purification.

Preparation process of CCG and CCF

As we reported in our previous work (He et al. 2014a), cotton linter pulp was completely dissolved in the pre-cooled 8 wt% LiOH·H2O/15 wt% urea aqueous solutions at − 12.8 °C to obtain 4 wt% cellulose solutions. Chitosan powder was dispersed into 7 wt% KOH/7 wt% LiOH·H2O/8 wt% urea aqueous solutions with stirring for 15 min and treated for 5 min through ultrasonic treatment (ultrasonic instrument KQ5200E). The resultant suspensions were completely frozen in a refrigerator at the temperature below − 30 °C, and then thawed at room temperature to get 4 wt% chitosan solutions. The cellulose and chitosan solutions were blended together in an ice bath under mechanical stirring with different weight ratios of 9:1, 7:3, 5:5, 3:7 and 1:9. The blended cellulose/chitosan solutions were centrifuged at 7000 rpm for 10 min at 0 °C to remove the bubbles. The resultant cellulose/chitosan solutions were cast on a glass plate with the solution layer thickness of about 0.2 mm, which was controlled by glass tubes with two loops wrapped around. They were immediately coagulated for 0.5 h in a closed container filled with an ethyl acetate gaseous phase. The blended solutions could be transformed into hydrogel sheets, which were rinsed thoroughly with running water, and then washed with deionized water to remove the excess residuals. The resultant hydrogel sheets were then fixed on a polymethyl methacrylate (PMMA) plate and dried in air at room temperature to obtain the composite films. The composite hydrogel sheets were coded as CCG-10, CCG-30, CCG-50, CCG-70 and CCG-90, according to the weight percentage of chitosan. The resultant composite films were coded as CCF-10, CCF-30, CCF-50, CCF-70 and CCF-90 accordingly.

Characterization

The CCG hydrogels were frozen in liquid nitrogen, immediately snapped and then freeze-dried for SEM observation (FESEM, Zeiss, SIGMA). The acceleration voltage for the FESEM observation was 5 kV. The cross-section of the freeze-dried hydrogels was sputtered with gold, and then observed. FT-IR spectra were carried out with a FT-IR spectrometer (1600, Perkin–Elmer Co., MA) in the wavelength range from 4000 to 400 cm−1. The powdered and vacuum-dried CCF was obtained, and the test specimens were prepared by using a KBr disk method. Wide angle X-ray diffraction measurements (WAXD) were carried out with a WAXD diffractometer (D8-Advance, Bruker, USA). The patterns with Cu Kα radiation (λ = 0.15405 nm) at 40 kV and 30 mA were recorded in the region of 2θ from 5 to 40°, scanning rate was 2°/min. The samples were cut into powder and dried in a vacuum oven for 48 h before testing.

The tensile strength (σb) and elongation at break (εb) of the CCF films in the dry state were measured on a universal tensile tester (CMT 6503, Shenzhen SANS Testing machine Co. Ltd., Shenzhen, China) according to ISO527-3-1995 (E) at a speed of 2 mm/min. The light transmittance of the CCF films was analyzed with a UV–Vis spectrophotometer over a wavelength range of 300–900 nm. The transmittance spectra were acquired using air as the background.

The heavy metal ion adsorbability of CCG-70 was also preliminarily studied, 3 cm × 6 cm CCG-70 hydrogel strip was immersed into a 50 mL 0.3 mol/L CuCl2 aqueous solution, and then soaked for 0.5 h, the adsorption process was photographed. The adsorption performance of CCG-70 was calculated by a gravimetric method accordingly.

Antibacterial test and L929 cell viability assay

The antibacterial test was performed similar to our previous work (Li et al. 2015). Briefly, culture medium, Petri dishes and others were sterilized in high-pressure steam for 20 min. Specimen, spirit lamp and test tube rack were sterilized for 30 min by UV in a clean bench. The culture medium was dumped into a Petri dish and UV sterilized for 30 min during solidification. Staphylococcus aureus or Echerichia coli colonies were scraped with inoculating loop, and then transferred to a centrifuge tube with 3 mL normal saline solution, which was vortexed to disperse bacteria evenly. 60 μL broth was added to the medium and then scratched. To test the anti-bacterial activities of the CCF films, implanted S. aureus and E. coli strains were placed in a Petri dish, thin disks of the CCF-10 and CCF-90 films with the diameter of 1 cm were stuck on the Petri dish to culture for 48 h at 60 °C in an incubator. The inhibition zones were then photographed.

To conduct cell viability assay, CCF films were cut into powder, sterilized by autoclaving, and then used to prepare the extract. According to ISO 10993-5, a cell line of L929 was re-suspended in the culture medium and plated (200 μL/well) into 96-well micrometer plates at 1 × 104 cells/well, which were incubated at 37 °C in a 5% CO2 atmosphere for 24 h. The medium was then replaced by 50 μL/well sterilized extract of CCF films, using the culture medium itself as a control. The cells were treated with 5 mg/mL MTT in PBS (20 μL/well) after incubating for 24, 48 and 72 h. A final concentration of 0.5 mg/mL MTT was obtained, and incubated for a further 4 h. At this stage, MTT was removed out and 150 μL dimethyl sulfoxide (DMSO) was added each well to dissolve the formazan crystals. The plates were placed in an incubator at 37 °C and shaken for 15 min. The absorbance values were measured in triplicate against a reagent blank at a test wavelength of 570 nm (Tecan GENios, Tecan Austria GmbH, Salzburg, Austria). Cell viability was calculated using Eq. 1:

where Atest and Acontrol corresponded to the absorbance values of the test and control groups, respectively.

Results and discussion

Appearance and structure of CCG and CCF

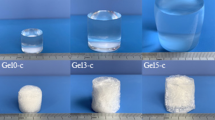

All the CCG-n hydrogels could be fabricated facilely, no obvious phase separation occurred during their preparation process. In our findings, an ethyl acetate gaseous phase could coagulate the cellulose/chitosan blend solutions homogeneously and slowly by continually providing acetic acid and ethanol as direct coagulants through hydrolysis in the blend solutions, which was much milder for the macromolecular aggregation than common aqueous coagulants such as an acetic acid or H2SO4 solution. Figure 1 shows the photographs of the CCG-10, CCG-30, CCG-50, CCG-70 and CCG-90 hydrogels. Obviously, all the CCG hydrogels were homogeneous, transparent and flexible, indicating good miscibility between chitosan and cellulose due to their structure similarity and the mild coagulation process. Moreover, the CCG hydrogels exhibited good skin affinity due to high hydrophilicity of cellulose and chitosan.

The micro structure of the composites could reflect the miscibility between the components (Li et al. 2016b), which could be characterized by SEM. Figure 2 shows the SEM images of the freeze-dried CCG-n hydrogels (n = 10, 30, 50, 70 and 90). It was noted that all the CCG hydrogels exhibited homogeneous pores, further indicating the good miscibility between chitosan and cellulose. The pore size of CCG-10 was 0.44 μm, which increased with the chitosan content and reached 0.72 μm for CCG-90. The increase of the pore size for the CCG hydrogels with the increase of chitosan content was possibly due to the electrostatic repulsion of chitosan molecules, which was caused by a protonation of –NH2 groups on chitosan chains with acetic acid from ethyl acetate (Anitha et al. 2014; Duan et al. 2015). Figure 2f shows the swelling ratio of the CCG hydrogels. The swelling ratio of all the CCG hydrogels was above 12.5 g/g, indicating high hydrophilicity. Interestingly, the swelling ratio increased with the chitosan content, which was mainly caused by micro structure change through the electrostatic repulsion of chitosan molecules (Fig. 2a–e) (Qin et al. 2010; Duan et al. 2015).

The CCG hydrogels could be transformed into films by changing aggregation states of cellulose and chitosan through the inter and intra macromolecular chain rearrangement during the drying process (Wang et al. 2013; He et al. 2017a). Figure 3 shows the photographs of CCF and the corresponding light transmittance. The light transmittance value for CCF-10 was about 40% at 800 nm, which was lowest in CCF possibly due to the largest optical scattering and reflecting resulted from its relative heterogeneous structure caused by relative strong micro-phase separation (Fang et al. 2017). Other CCF films exhibited higher light transmittance (above 58% at 800 nm), indicating the formation of more homogeneous structures from inter-macromolecular rearrangement. It was noted that the light transmittance value of CCF-70 could reach 75% at 800 nm due to the formation of relative homogeneous structure, showing high light transparency. Therefore, all the CCF films exhibited relative high light transmittance, indicating good miscibility on the whole.

Figure 4 shows the FTIR spectra of the CCF-n films (n = 10, 50 and 90). The band at 3439 cm−1 was assigned to –OH or –NH of cellulose and chitosan in CCF-10, which shifted to 3432 and 3426 cm−1 for CCF-50 and CCF-90 respectively, indicating the formation of new inter-molecular hydrogen bonds between cellulose and chitosan (Xiong et al. 2010). The characteristic bands of amide-I and amide-II for chitosan appeared at 1663 and 1594 cm−1 for CCF-50 and CCF-90 respectively, whose intensity increased with the chitosan content. Those two bands weren’t found in CCF-10 because its chitosan content was quite low. The band at 1418 cm−1 was attributed to the –NH deformation vibration of chitosan. The strong peak at around 1065 cm−1 was attributed to the C–O–C stretching of the pyranose ring (Lima et al. 2005).

Figure 5 shows the WAXD patterns of the CCF-n films (n = 10, 50 and 90). There were three obvious crystal peaks at 2θ = 12.0°, 20.0° and 21.8° appeared in CCF-10, which were assigned to crystal planes (\(1\bar{1}0\)), (110) and (020) of cellulose II respectively (Isogai et al. 1989; French 2014). The new peak at 2θ of about 29.5° for CCF-50 and CCF-90 was attributed to the (130) crystal plane of chitosan, the peak intensity increased obviously with the chitosan content. Two peaks at 2θ = 20.0° and 21.8° for cellulose merged into one peak at 20.4° for CCF-50 and 20.2° for CCF-90 with the increase of chitosan content, and the peak at 12.0° for CCF-10 changed to 11.5° and 9.89° for CCF-50 and CCF-90 respectively, further indicating the formation of new inter-molecular hydrogen bonds between –OH and –NH2 groups.

Properties and applications of CCG and CCF

Figure 6 shows the stress–strain (σ–ε) curves of the CCF-n films (n = 10, 30, 50, 70 and 90). The tensile strength values of all the CCF films were above 48 (MPa) and much higher than pure chitosan films reported in the previous work (Rubentheren et al. 2015; Xu et al. 2010; Tang et al. 2008), showing good mechanical strength due to strong hydrogen bonding interaction between cellulose and chitosan. The mechanical strength increased gradually with the cellulose content in the CCF films, indicating that cellulose could be used effectively to strengthen chitosan. The tensile strength value of CCF-10 could reach about 90.0 (MPa), which was even higher than those of pure cellulose films reported in other work (Qi et al. 2009; He et al. 2011, 2013). Interestingly, the elongation at break increased with the chitosan content (≤ 30%) firstly and decreased obviously with further increase of chitosan content (> 30%). The Young’s modulus values for CCF-90, CCF-70, CCF-50, CCF-30 and CCF-10 were 3518.7, 4015.0, 4577.2, 4725.0, and 5035.1 (MPa) respectively, which increased obviously with the cellulose content. Therefore, compared with CCF-90, the mechanical strength, Young’s modulus and elongations at break were improved significantly with the increase of cellulose content in CCF, so cellulose could be used to improve the mechanical property of chitosan.

The antibacterial activity of CCF-10 and CCF-90 was evaluated using E. coli and Staphyoccocus aureus. Figure 7 shows the photographs of antibacterial test for CCF-10 and CCF-90. E. coli bacteria colonies appeared on both CCF-10 and CCF-90, the number of bacteria colonies was much smaller for CCF-90 than that of CCF-10 (Fig. 7a, c), indicating better antibacterial activity of CCF-90 against E. coli. There was one Staphyoccocus aureus bacteria colony appeared on CCF-10, nearly no bacteria colony appeared on CCF-90, indicating better antibacterial activity of CCF-10 and CCF-90 against Staphyoccocus aureus than E. coli (Fig. 7b, d). Thus, the antibacterial activity increased with the chitosan content, so chitosan could be used to improve the antibacterial activity of cellulose. Figure 7e shows the experimental results of the cytotoxicity of the CCF films by MTT assay. The cell viability value for the CCF-10 film could reach 93% at 24 h, which increased obviously with the incubation time and reached 109% at 72 h, indicating no cytotoxicity to the L929 cells. The cell viability value increased obviously with the chitosan content (Fig. 7e) because the presence of –NH2 groups on chitosan is beneficial for cell proliferation (Dash et al. 2011; He et al. 2017b), which reached above 125% for CCF-90, showing high biocompatibility. Thus, chitosan could be used to improve the antibacterial activity and biocompatibility of cellulose (Fig. 7).

As we all know, chitosan could be used as a facial mask because it exhibits good moisture absorbability and moisture retentivity, heavy metal ion and dye adsorbability, antibacterial activity and nontoxicity (Crini and Badot 2008; Dash et al. 2011). As we mentioned above, the CCG hydrogels exhibited good flexibility, processibility, light transmittance and skin affinity (Fig. 1), so we managed to prepare cellulose/chitosan facial masks. Figure 8 shows the photographs of a glass mold for the fabrication of facial masks and the CCG-70 facial mask. As we expected, the CCG-70 facial mask could be facilely fabricated according to the mold shapes. It was noted that the fabrication process for the CCG hydrogels was mainly physical, so the CCG hydrogels could retain the intrinsic properties of cellulose and chitosan. Moreover, the addition of a little edible vinegar could improve the antibacterial activity of CCG significantly by protonation of the –NH2 groups of chitosan (Anitha et al. 2014), showing wide potential as antibacterial facial masks.

As we all know, there are some heavy metal ions left in the cosmetic, which threatens human health. So the adsorbability of heavy metal ions is a critical factor to evaluate the function of facial masks. The preliminary heavy metal ion adsorbability of CCG was evaluated. CCG-70 was soaked into the CuCl2 solution to study the Cu2+ adsorbability. Figure 9 shows the photographs of Cu2+ adsorption process by CCG-70. Obviously, CCG-70 exhibited good Cu2+ adsorbability, and the Cu2+ adsorption amount reached 2.98 mmol/g after 0.5 h adsorption, so the CCG-70 hydrogels could be used as a facial mask to remove the residual heavy metal ions left on the face or as portable water treatment adsorbents.

Conclusions

Novel flexible cellulose and chitosan composite hydrogels and films were successfully constructed by using a facile blending and gaseous coagulation method. The composite hydrogels exhibited homogeneous porous structures and the resultant films exhibited relative high light transmittance (above 40% at 800 nm), indicating good miscibility between cellulose and chitosan due to their structure similarity. The mechanical strength and Young’s modulus for CCF increased obviously with the cellulose content, which could reach about 90.0 and 5035.1 MPa, respectively. The equilibrium swelling ratio, antibacterial activity and biocompatibility increased with the chitosan content. The Cu2+ adsorption amount for CCG-70 reached 2.98 mmol/g after 0.5 h adsorption, CCG-70 facial mask could be facilely fabricated by using glass molds. Thus, the cellulose/chitosan composite materials showed potential applications in the facial mask, antimicrobial packaging and water treatment fields.

References

Anitha A, Sowmya S, Kumar P, Deepthi S, Chennazhi K, Ehrlich H, Tsurkan M, Jayakumar R (2014) Chitin and chitosan in selected biomedical applications. Prog Polym Sci 39:1644–1667

Cai J, Zhang L (2005) Rapid dissolution of cellulose in LiOH/urea and NaOH/urea aqueous solutions. Macromol Biosci 5:539

Cai J, Liu Y, Zhang L (2006) Dilute solution properties of cellulose in LiOH/urea aqueous system. J Polym Sci Polym Phys 44:3093–3101

Cai J, Zhang L, Zhou J, Qi H, Chen H, Kondo T, Chen X, Chu B (2007) Multifilament fibers based on dissolution of cellulose in NaOH/urea aqueous solution: structure and properties. Adv Mater 19:821–825

Cao Z, Luo X, Zhang H, Fu Z, Shen Z, Cai N, Xue Y, Yu F (2016) A facile and green strategy for the preparation of porous chitosan-coated cellulose composite membranes for potential applications as wound dressing. Cellulose 23:1349–1361

Chaoming S, Yeongtarng S, Yawokuo T (2009) Preparation and characterization of cellulose/chitosan blend films. Carbohydr Polym 78:169–174

Chen X, Yang H, Zhong Z, Yan N (2017) Base-catalysed, one-step mechanochemical conversion of chitin and shrimp shells into low molecular weight chitosan. Green Chem 19:2783–2792

Crini G, Badot PM (2008) Application of chitosan, a natural aminopolysaccharide, for dye removal from aqueous solutions by adsorption processes using batch studies: a review of recent literature. Prog Polym Sci 33:399–447

Dash M, Chiellini F, Ottenbrite RM, Chiellini E (2011) Chitosan—a versatile semi-synthetic polymer in biomedical applications. Prog Polym Sci 36:981–1014

Duan J, He X, Zhang L (2014) Magnetic cellulose–TiO2 nanocomposite microspheres for highly selective enrichment of phosphopeptides. Chem Commun 51:338–341

Duan J, Liang X, Cao Y, Wang S, Zhang L (2015) High strength chitosan hydrogels with biocompatibility via new avenue based on constructing nanofibrous architecture. Macromolecules 48:2706–2714

Duan J, Liang X, Zhu K, Guo J, Zhang L (2016) Bilayer hydrogel actuators with tight interfacial adhesion fully constructed from natural polysaccharides. Soft Matter 13:345–354

Fang Y, Zhang R, Duan B, Liu M, Lu A, Zhang L (2017) Recyclable universal solvents for chitin to chitosan with various degree of acetylation and construction of robust hydrogels. ACS Sustain Chem Eng 5:2725–2733

Fink HP, Weigel P, Purz H, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO-solutions. Prog Polym Sci 26:1473–1524

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Hasegawa M, Isogai A, Kuga S, Onabe F (1994) Preparation of cellulose–chitosan blend film using chloral/dimethylformamide. Polymer 35:983–987

He M, Chang C, Peng N, Zhang L (2011) Structure and properties of hydroxyapatite/cellulose nanocomposite films. Carbohydr Polym 87:2512–2518

He M, Xu M, Zhang L (2013) Controllable stearic acid crystal induced high hydrophobicity on cellulose film surface. ACS Appl Mater Interfaces 5:585–591

He M, Kwok RTK, Wang Z, Duan B, Tang BZ, Zhang L (2014a) Hair-inspired crystal growth of HOA in cavities of cellulose matrix via hydrophobic–hydrophilic interface interaction. ACS Appl Mater Interfaces 6:9508–9516

He M, Zhao Y, Duan J, Wang Z, Chen Y, Zhang L (2014b) Fast contact of solid-liquid interface created high strength multi-layered cellulose hydrogels with controllable size. ACS Appl Mater Interfaces 6:1872–1878

He M, Wang X, Wang Z, Chen L, Lu Y, Zhang X, Li M, Liu Z, Zhang Y, Xia H, Zhang L (2017a) Biocompatible and biodegradable bioplastics constructed from chitin via a “green” pathway for bone repair. ACS Sustain Chem Eng 5:9126–9135

He M, Zhang X, Yao W, Wang C, Shi L, Zhou P (2017b) Construction of alternate layered chitosan/alginate composite hydrogels and their properties. Mater Lett 200:43–46

Isogai A, Atalla RH (1992) Preparation of cellulose–chitosan polymer blends. Carbohydr Polym 19:25–28

Isogai A, Usuda M, Kato T, Uryu T, Atalla RH (1989) Solid-state CP/MAS carbon-13 NMR study of cellulose polymorphs. Macromolecules 22:3168–3172

Jedvert K, Heinze T (2017) Cellulose modification and shaping—a review. J Polym Eng 37:845–860

Li R, He M, Li T, Zhang L (2015) Preparation and properties of cellulose/silver nanocomposite fibers. Carbohydr Polym 115:269–275

Li C, He M, Tong Z, Li Y, Sheng W, Luo L, Tong Y, Yu H, Huselstein C, Chen Y (2016a) Construction of biocompatible regenerated cellulose/SPI composite beads using high-voltage electrostatic technique. RSC Adv 6:52528–52538

Li S, Cui Z, Zhang L, He B, Li J (2016b) The effect of sulfonated polysulfone on the compatibility and structure of polyethersulfone-based blend membranes. J Membr Sci 513:1–11

Lima IS, Lazarin AM, Airoldi C (2005) Favorable chitosan/cellulose film combinations for copper removal from aqueous solutions. Int J Biol Macromol 36:79–83

Mokhothu TH, John MJ (2015) Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr Polym 131:337–354

Morgado DL, Frollini E, Castellan A, Rosa DS, Coma V (2011) Biobased films prepared from NaOH/thiourea aqueous solution of chitosan and linter cellulose. Cellulose 18:699–712

Murugan R, Ramakrishna S (2004) Bioresorbable composite bone paste using polysaccharide based nano hydroxyapatite. Biomaterials 25:3829–3835

Pei Y, Yang J, Liu P, Xu M, Zhang X, Zhang L (2013) Fabrication, properties and bioapplications of cellulose/collagen hydrolysate composite films. Carbohydr Polym 92:1752–1760

Qi H, Cai J, Zhang L, Kuga S (2009) Properties of films composed of cellulose nanowhiskers and a cellulose matrix regenerated from alkali/urea solution. Biomacromol 10:1597–1602

Qin Y, Lu X, Sun N, Rogers RD (2010) Dissolution or extraction of crustacean shells using ionic liquids to obtain high molecular weight purified chitin and direct production of chitin films and fibers. Green Chem 12:968–971

Rejinold NS, Chennazhi KP, Tamura H, Nair SV, Rangasamy J (2011) Multifunctional chitin nanogels for simultaneous drug delivery, bioimaging, and biosensing. ACS Appl Mater Interfaces 3:3654–3665

Rubentheren V, Ward TA, Chee CY, Nair P (2015) Physical and chemical reinforcement of chitosan film using nanocrystalline cellulose and tannic acid. Cellulose 22:2529–2541

Saito T, Oaki Y, Nishimura T, Isogai A, Kato T (2014) Bioinspired stiff and flexible composites of nanocellulose-reinforced amorphous CaCO3. Mater Horiz 1:321–325

Tang C, Xiang L, Su J, Wang K, Yang C, Zhang Q, Fu Q (2008) Largely improved tensile properties of chitosan film via unique synergistic reinforcing effect of carbon nanotube and clay. J Phys Chem B 112:3876–3881

Wang Q, Cai J, Zhang L, Xu M, Cheng H, Han CC, Kuga S, Xiao J, Xiao R (2013) A bioplastic with high strength constructed from a cellulose hydrogel by changing the aggregated structure. J Mater Chem A 1:6678–6686

Wendler F, Kosan B, Krieg M, Meister F (2009) Possibilities for the physical modification of cellulose shapes using ionic liquids. Macromol Symp 280:112–122

Xiong X, Duan J, Zou W, He X, Zheng W (2010) A pH-sensitive regenerated cellulose membrane. J Membr Sci 363:96–102

Xu Y, Ren X, Hanna MA (2010) Chitosan/clay nanocomposite film preparation and characterization. J Appl Polym Sci 99:1684–1691

Yan T, Cheng F, Wei X, Huang Y, He J (2017) Biodegradable collagen sponge reinforced with chitosan/calcium pyrophosphate nanoflowers for rapid hemostasis. Carbohydr Polym 170:271–280

Yang R, Li H, Huang M, Yang H, Li A (2016) A review on chitosan-based flocculants and their applications in water treatment. Water Res 95:59–89

Zhao D, Huang J, Zhong Y, Li K, Zhang L, Cai J (2016) High-strength and high-toughness double-cross-linked cellulose hydrogels: a new strategy using sequential chemical and physical cross-linking. Adv Funct Mater 26:6279–6287

Zhou Y, Luo X, Huang L, Lin S, Chen L (2015) Development of ionic liquid-mediated antibacterial cellulose–chitosan films. J Biobased Mater Bio 9:389–395

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 51503177, 81501921), the Natural Science Foundation of Jiangsu Province (Grant No. BK20160440), Talent Introduction Project of Yancheng Institute of Technology (Grant No. XJ201526), A Project Funded by the Flagship Major Development of Jiangsu Higher Education Institutions (PPZY2015A025) and Research Fund of Jiangsu Collaborative Innovation Center for Ecological Building Materials and Environmental Protection Equipments.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

He, M., Chen, H., Zhang, X. et al. Construction of novel cellulose/chitosan composite hydrogels and films and their applications. Cellulose 25, 1987–1996 (2018). https://doi.org/10.1007/s10570-018-1683-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1683-9