Abstract

Bacterial cellulose (BC) has great potential for use as a tissue scaffold due to its unique structure and properties including high tensile strength and good biocompatibility. However, poor biodegradability of BC in the human body may be a key disadvantage limiting its application in the field. In this paper, we developed a simple absorption method to prepare biodegradable cellulase/BC materials. The morphology, structure, degradation ratio and mechanical properties during the degradation process were characterized and investigated. In vitro studies reveal that the BC material degraded gradually in simulated body fluid within 24 weeks and the degradation rate could be adjusted by modulating the cellulase content. The mechanical properties indicate the cellulase/BC material could maintain tensile strength for as long as 24 days during the degradation process. Muscle-derived cells were seeded on the cellulase/BC material to evaluate the cytotoxicity, using LIVE/DEAD® viability/cytotoxicity assay and H&E staining. In vivo biocompatibility was evaluated by subcutaneous implantation using a dog model for 1, 2, 3 and 4 weeks. These results demonstrate that the cellulase/BC material had good in vitro and in vivo biocompatibility.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bacterial cellulose (BC), produced by Acetobacter xylinum, has attracted much attention and interest since first reported by Brown (1886). It exhibits many desirable properties, including excellent mechanical properties, high moisture permeability, biocompatibility, and has been used as electrical, magnetic, optical materials (Vitta et al. 2010; Hu et al. 2011; Müller et al. 2011). In particular, BC has become a promising material for wound care (Alvarez et al. 2004), artificial blood vessels (Bäckdahl et al. 2011) and tissue engineering applications in the bio-medical fields (Yin et al. 2015). Furthermore, the unique nanofibril network of BC, to some extent, mimics extracellular matrix (ECM), which makes BC very attractive as a scaffold for tissue engineering (Petersen and Gatenholm 2011). From a physical and a medical perspective, it is necessary for the ideal scaffolds to have good biocompatibility and mechanical strength (Nakanishi et al. 2003). Studies on mechanical properties of BC showed it had superior strength in wet state and was promising for use in tissue engineering materials (Svensson et al. 2005; Bäckdahl et al. 2006). In vivo biocompatibility of BC was studied by implanting subcutaneously in rats, pigs, dogs, mice (Helenius et al. 2006; Schumann et al. 2009; Pértile et al. 2012; Yang et al. 2014) and no macroscopic signs of inflammation around the implants and fibrotic capsule or giant cells were observed. The good biocompatibility of BC indicates that it has potential to be used as a scaffold in tissue engineering.

However, lack of biodegradability of BC may be one of the obstacles in hindering further application in human body, especially for bioresorbable matrix that can be replaced by natural tissue over time (Wang et al. 2011; Huang et al. 2014). BC is composed of glucose units linked with β-1,4 glucosidic bonds and can be degraded into glucose monomers by cellulases made by fungus, bacteria and insects in nature (Béguin and Aubert 1994; Scrivener et al. 1997). However, BC can not be biodegraded in the human body due to lack of chemical or enzymatic process that can hydrolyze the β-1,4-glucose linkages of cellulose. A few researches have been published focused on the development of bioabsorbable cellulose. Preparing oxidized BC or 2,3-dialdehyde BC (DABC) is an alternative method to improve the degradability of BC. However, chemical modification damages the mechanical properties of BC which might limit its application for specific tissue repair (Li et al. 2009; Peng et al. 2012). As we know, cellulases can degrade cellulose easily under appropriate conditions (Walker and Wilson 1991). BC degradation properties has been investigated by incorporating cellulases. The in vitro studies reveal that integration of cellulases makes BC into bioabsorbable materials which have extensibility similar to human skin (Hu and Catchmark 2011a, b). It is indicated that use of cellulases may be the most effective way to achieve the complete in-body degradation of cellulose and the degradation rate could be adjusted under the controllable preparation progress (Gusakov et al. 2007; Hu and Catchmark 2011a, b). The mechanical properties during the degradation process as well as the safety and toxicity of degradation product for human body are of great importance which should be further evaluated for BC applied in tissue engineering materials. In this work, we focused on the in vitro biodegradability of BC incorporating cellulase in simulated body fluid and in vivo biocompatibility of BC. The biodegradation rate to match the requirement of the tissue regeneration rate during healing can be achieved by changing the cellulase loading. The degradation behaviours including degradation ratio, crystal structure, micromorphology and the mechanical properties were characterized. Furthermore, the in vitro and in vivo biocompatibility of the composites were also evaluated.

Experimental section

Materials and instruments

All chemicals were purchased from SinopharmChemical Reagent Co., Ltd. (China). Cellulases were obtained from solarbiolife sciences (Cellulases are composed of endoglucanases, exoglucanases and beta-glucosidases from Trichoderma viride, 3 units/mg at pH 5, 37 °C. In this paper, the pH 7.4 and the temperature 37 °C were adopted to degrade BC which is intended to simulate the pH and the temperature of human body fluids). BC was prepared in our laboratory (Li et al. 2015). The basal medium is as followed: 5.0 wt% d-glucose, 0.5 wt% peptone, 0.5 wt% yeast extract, 0.2 wt% disodium hydrogen phosphate, 0.1 wt% monopotassium phosphate and 0.1 wt% citric acid, the pH was adjusted to 5.0 with NaOH. BC pellicles were purified in 2 % sodium hydroxide solution for 30 min in order to remove cells and medium, then rinsed in deionized water to pH = 7. The BC pellicles were stored at 4 °C in deionized water for further use. The FE-SEM images were observed on a Hitachi S-4800 and the lyophilized samples were coated with a thin layer of evaporated gold. The cellulase content in BC composites was obtained using a BCA Protein Assay Kit (the detailed procedure can be seen in Supporting Information). X-ray diffraction (XRD) patterns were obtained using a Rigaku D/max-2000 PC XRD with the CuKα radiation ranging from 5° to 80° (2θ angle). The degree of crystallinity (Crystallinity index, CrI) was calculated from the ration of the area of all crystalline peaks to the total area described by previous researchers (Park et al. 2010). The mechanical properties of cellulase/BC materials during degradation process were measured using a WDW 3020 universal testing machine at room temperature. The in vitro biodegradation studies were performed in simulated body fluid (SBF) which is a physiologically relevant environmental buffer (Kokubo and Takadama 2006). Degradation ratio was used to evaluate the degradation states of cellulase/BC materials prepared by different concentrations of cellulase and absorption time. The degradation ratio was calculated by the following equation:

where glucose content was measured by DNS (3,5-dinitrosalicylic acid) method.

Preparation of cellulase and SBF solutions

Cellulases solutions of different concentrations (3, 5, 7, 10 mg/mL) were prepared by desolving cellulases in deionized water. SBF solution was prepared by dissolving NaCl, NaHCO3, KCl, K2HPO4·3H2O, MgCl2·6H2O, CaCl2 and Na2SO4 into deionized water, and buffered to pH 7.4 at 37 °C with trishydroxymethyl aminomethane and HCl (Kokubo et al. 1990; Ni and Wang 2002).

Fabrication of the cellulase/BC composites

The purified BC pellicles were cut into 3 × 3 cm sheet with the same thickness (about 2 mm) and placed under a Xlb (Extra load brick) load to remove free water. Then the BC pellicles (about 0.35 mm) were put into flasks containing cellulase solutions with certain concentration. The BC membranes absorbed cellulases under magnetic stirring and the absorption time was 10, 20, 30, 40, 50, 60 min. The cellulase/BC composites were rinsed with water to remove cellulases unbounded to BC. And the rinsed process was repeated for five times.

In vitro biocompatibility tests

A LIVE/DEAD viability/cytotoxicity assay was utilized to evaluate the cytotoxicity of the pure BC and cellulase/BC materials. The isolation and culture of muscle cells obtained from healthy dog lingual tissue were performed as previously described (Yang et al. 2014). We seeded a 600 µL suspension of 1 × 104 cells/mL on each scaffold (1 × 1 cm), then added 2 mL of culture medium on the top of substrates. After cultivation for 1 day, 3 days and 7 days, we rinsed the scaffolds twice with phosphate buffered saline (PBS). 500 µL LIVE/DEAD assay reagents (4 μM of EthD-1 and 2 μM of calcein AM in DPBS) was added on the scaffold surfaces, incubated for 45 min at 25 °C and imaged the labeled cells using a Nikon Eclipse TE2000 inverted fluorescence microscope (Nikon Instrument Inc.). Viable cells labeled with calcein AM were detected at an excitation wavelength of 494 nm. Dead cells labeled with EthD-1 were detected at an excitation wavelength of 528 nm. Cell viability and the total percentage of viable cells were determined by counting live and dead cells for each growth condition. To compare the differences of cell viability on the materials with and without cellulase, we performed Chi squared tests. We considered a P value <0.05 to indicate statistically significant data.

To evaluate cellular proliferation on pure BC and cellulase/BC materials, they were seeded with muscle cells obtained from healthy dog lingual tissue. Before cell seeding, the cellulase/BC materials were sterilized with 75 % ethanol for 2 h, washed three times in sterilized PBS and then filled with 5 mL of DMEM with 10 % FBS for 24 h at 37 °C. The lingual muscle cells (1 × 104 cells) were seeded onto the surface of pure BC and cellulase/BC materials (1 × 1 cm). Then all cells-seeded samples were incubated in static conditions at 37 °C in a humidified atmosphere with 5 % CO2. The medium was changed every day. The cells-seeded samples were fixed and embedded in paraffin after incubating for 1, 2, 3 and 4 weeks. Routine hematoxylin and eosin staining (H&E staining) was used for each section.

In vivo biocompatibility tests

All animal procedures were approved by the Institutional Animal Care and Use Committee of Shanghai Jiaotong University Affiliated 6th People’s Hospital. General anesthesia was induced by intravenous injection of pentobarbital. The skin on the backs of the 1-year-old female dogs (n = 4) was shaved and disinfected with 75 % ethanol. A 2 cm long incision was made on the back of the animals. The pure BC and cellulase/BC composites were then implanted subcutaneously into dogs. The skin was sutured with silk sutures fixed in each corner as the operative marker. The grafts were harvested 1, 2, 3, 4 weeks after implantation, fixed in 10 % neutral buffered formalin, dehydrated and embedded in paraffin. Cross sections (5 μm) were cut and stained with H&E for cellular infiltration and inflammatory response.

Results and discussion

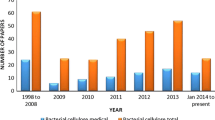

Analysis of cellulase content

BCA Protein Assay Kit was used to assess concentration of unbound protein to deduce the cellulase absorbed into BC. The effects of absorption time and cellulase concentration on cellulase quantity were also investigated. As shown in Fig. 1, with the increase of absorption time and the concentration of cellulase, the content of cellulase absorbed in BC increased in the 0–20 min timeframe. It is a relatively a fast absorption process. There are many hydroxyl groups on the large specific surface area of BC, which can interact with the amine groups and carboxyl groups in cellulase by formation of hydrogen bonds. However, the absorption would reach saturation after 20 min. Subsequently, there is little change observed for the absorption amount which just indicates the diffusion of the cellulase into a dense BC nanofibers or the cellulase release from the BC. Therefore, the cellulase content can be controlled by changing the cellulase concentration and absorption time for meeting degradation demands of different tissues.

FE-SEM characterization of cellulase/BC composites

As shown in Fig. 2, the lyophilized samples incorporating cellulases were observed by FE-SEM. As seen from Fig. 2a, the nanofibrillar network structure of BC consists of continuous nanofibers with a diameter in the range from 30 to 100 nm. There is no obvious difference between pure BC and cellulase/BC composites except the cellulose fibrils decrease in size and some collapse into bundles which indicates the existence of cellulase in BC and the BC degradation during the process of absorption (Fig. 2b–e). Compared to cellulase/BC composites prepared via freeze-dried method (Fig. S2 in Supporting Information), we can realize homogeneous distribution of cellulase in BC using this absorption method by selecting appropriate concentration of cellulase and the absorption time. This is because that the naked hydroxyl groups on the surface of BC nanofibers can freely interact with the amine groups and carboxyl groups in cellulase in the cellulase solution.

The degradation of cellulase/BC composites in SBF

In order to investigate the degradation of BC, we used DNS (3,5-dinitrosalicylic acid) method to measure the glucose content (the degradation product). Figure 3 shows the degradation curves of BC under different cellulase concentration and absorption time. It was observed that all samples were degraded with time and the samples with more cellulases had a higher degradation rate. When the cellulase concentration (3 mg/mL) and the absorption time (<60 min) is less, the BC can not be degraded completely even after 24 weeks due to lower cellulase content (Fig. 3a1, a2). When the cellulases concentration increased to 5 mg/mL or greater, cellulose with less absorption time could be degraded completely in 24 weeks, and the complete degradation time can be adjusted to 15 weeks for sample c and d (Fig. 3c, d) by changing the cellulase content in BC. Moreover, it is found that more glucose was released in the first 8 weeks and the degradation rate became slow in the last few weeks as a result of the reduced activity of cellulase in SBF or cellulases diffusion away from the materials (Endo et al. 2001; Liu et al. 2008).

The degradation ratio of cellulase/BC composites made by absorption method in SBF. The cellulase concentration and absorption time: a 3 mg/mL, a1 10 min, a2 30 min, a3 60 min, b 5 mg/mL, b1 10 min, b2 30 min, b3 60 min, c 7 mg/mL, c1 10 min, c2 30 min, c3 60 min, d 10 mg/mL, d1 10 min, d2 30 min, d3 60 min

Macroscopic pictures

Macroscopic pictures of the prepared cellulase/BC composites during degradation process are shown in Fig. 4. As seen from the pictures, the cellulase/BC composites gradually became thin and transparent, then fragments and finally almost completely invisible. It is known that the more cellulases, accompanied with the faster degradation rate of BC. The BC membranes initially became fragments and then became invisible. Combining Figs. 3 and 5, both sample a and b could maintain tensile strength to provide physical support for cells for 2 weeks. It is the least time to repair inflammation of tissue damage as Tanaka et al. (2006) reported. We believe that it is controllable to adjust the degradation rate of BC by changing the content of cellulases.

Mechanical properties of cellulase/BC composites during degradation process

The mechanical properties of the cellulase/BC composites were evaluated using tensile testing and the changes of tensile strength of samples are shown in Fig. 5. It is evident that the tensile strength of all samples decreased during degradation process in SBF. This is because the amorphous region and crystalline region were gradually degraded under the action of cellulases. The compact arrangement of BC nanofibers became loose, which made BC membrane easier to take deformation during tensile testing. As seen from the data of tensile strength, the rate of the degradation is faster for the higher cellulases than those of less cellulases amount. From Fig. 5a, when the cellulase concentration is 3 mg/mL, the stress at break can still maintain 6 Mpa after 8 days degradation. When the cellulase concentration increases to 10 mg/mL (Fig. 5d), the stress at break was about 0.24 Mpa after degradation for 8 days and only small fragments were observed. The result is consistent with the observed phenomenon from macroscopic images. It is demonstrated that the mechanical properties can be adjusted by control the cellulase concentration and the degradation time in order to satisfy requirement of skin (Maurel et al. 1998), porcine carotid artery (Bäckdahl et al. 2006) or other medical materials. Considering the mechanical property and degradation rate of BC, the cellulase/BC composite with the absorption for 30 min and cellulase concentration of 5 mg/mL was chosen as representative sample for tests as follows.

Surface morphology and crystal structure of cellulase/BC composites during degradation process

Figure 6 shows the FE-SEM images of cellulase/BC composites for different time during degradation process. During the first 2 weeks degradation in SBF solution, the 3D nanofibrous network is still maintained just along with some tiny holes on the surface of BC. It is demonstrated that the amorphous regions of BC were gradually degraded under the action of cellulase with the fracture of hydrogen bonds within and between molecular chains leading to a loose arrangement of molecular chains. As the extension of the degradation time from 2 to 8 weeks, shown in Fig. 6e, f, although the 3D nanofibrous network still can be observed, the degradation obviously increase and the hole become larger than those in the initial stage. After degradation for 8 weeks later (Fig. 6g), the 3D nanofibrous network of BC almost disappear with fracture of many fibrils and fall into pieces. It is indicated that the cellulose chains were randomly broken by cellulase and BC were gradually degraded. This kind of degradation is necessary for scaffold materials to provide interspace for growth of new tissue (Atala 1997). Meanwhile, BC was evenly degraded instead of collapsing block by block which provide skeleton and it is beneficial for tissue regeneration.

Figure 7 shows the X-ray diffraction patterns of BC and BC incorporating cellulases for different degradation time during degradation process. From Fig. 7a, three obvious peaks at 2θ = 14.2°, 16.5°, 22.7° are observed, corresponding to the (\(1\bar{1}0\)), (110) and (200) of cellulose I crystals (Watanabe et al. 1998; Yu et al. 2014). The crystallinity index is 69.5 %. When cellulases were introduced into cellulose, an obvious decrease for the three characteristic peaks intensities (Fig. 7b–d) was observed along with the degradation process. After 10 weeks degradation, only a broad peak is observed (Fig. 7f). The phenomenon indicates the obvious decrease of the degree of crystallinity. This is because that the cellulose chains were randomly broken by endo-1,4-β-d-glucanase and the crystalline region gradually transformed into amorphous region leading to the decrease of CrI and peak intensities (Jeffries et al. 1977). Peak at about 2θ = 16.5° disappeared 8 weeks later during degradation process (Fig. 7e) and the CrI of BC was only 20.60 % at that moment. It is reasonable to point out that cellulase/BC composite exhibited low mechanical properties, which was associated with low crystallinity.

In vitro incubation of muscle-derived cells on cellulase/BC composite scaffold

The viability/cytotoxicity of muscle cells in contact with the pure BC and cellulase/BC materials was measured using a LIVE/DEAD assay, as shown in Fig. 8. As shown in Fig. 8a, we can observe obvious proliferation and growth during the culture time after introduced cellulases in BC. Based on an analysis of microscopy, the cellulase/BC material induced cellular activity that was statistically equivalent to those of the BC group at 1, 3, 7 days (Fig. 8b). It is demonstrated that the incorporation of cellulases in BC has no effect on the compatibility of BC. To further evaluate the cellular proliferation of the materials, the cell propagation for 4 weeks were investigated after muscle-derived cells were seeded on the surface of pure BC and cellulase/BC composites scaffold and the H&E staining images are shown in Fig. 9. Good cell proliferation on the surface of samples was observed, which indicates good biocompatibility of samples (Fig. 9a–h). However, few cells migrated into pure BC due to its compact fibrous network and non-degradability (Fig. 9a–d). For cellulase/BC composites, along with the degradation, some cellular infiltration of the sample was evident, this is because the degradation of BC makes it porous which is favorable to cell ingrowth (Fig. 9e–h). It is known that BC consists of glucose units linked with β-1,4 glucosidic bonds and can be degraded into glucose monomers by cellulases. Glucose serves as main source of energy for the mammalian (Mergenthaler et al. 2013), so a minimal systemic toxicity is associated with the use of cellulase/BC composite which is confirmed by the result of good cell proliferation and tissue defect after 4 weeks of incubation (Fig. 9h). It is indicated that the cellulase/BC composites have good biocompatibility and the degradability in vitro.

In vivo evaluation of the biocompatibility of the cellulase/BC composite

Subcutaneous implantation is an international method to evaluate the safety of materials (Catchmark et al. 2010; Czaja et al. 2014). Figure 10 shows the HE staining images of in vivo evaluation for pure BC and cellulase/BC composites for 1–4 weeks. As shown in Fig. 10a–h, no tissue degeneration, necrosis and hyperplasia were observed and a large number of macrophages accumulation phenomenon did not appear. At early time points (1 week), The inflammatory response to the implant materials was found, which was consistent with a foreign body response. From Fig. 10a–d, we can observe a few cells in the BC section, and the boundary was obvious between BC and the tissue. However, no boundary can be observed between materials and tissue in the cellulase/BC composites (Fig. 10e–h). Moreover, a large number of cells ingrowth into implanted material could be seen, especially in Fig. 10h, This finding likely indicates the degradation of BC, which makes cell penetration very easy. And no obvious inflammatory reaction characterized by mononuclear cell infiltrates was observed in the H&E section. The phenomena demonstrated that the cellulases still kept activity to degrade the cellulose in vivo and the degradation products had no effect on the biocompatibility of the cellulose. Therefore the introduction of cellulase into BC may be a good method to modulate and realize the degradation of cellulose, and further applied in tissue engineering applications (Klemm et al. 2001; Helenius et al. 2006; Bodin et al. 2010).

Conclusion

In conclusion, biodegradable BC incorporating different cellulase content was prepared by absorption method. In vitro degradation behaviors of cellulase/BC composites with different cellulase content in SBF up to 24 weeks has been investigated systematically. Results show that BC material could be degraded in SBF and the degradation rate could be controlled by changing the cellulase content in order to match with the growth rate of different tissue. Macroscopic pictures indicate that all samples lost their integrity after 2 weeks, but mechanical data show they also could maintain tensile strength to support cell growth and proliferation. An obvious cell adhesion and growth on cellulase/BC composite was observed, which indicates the good in vitro biocompatibility of material. In vivo evaluations show there were no tissue degeneration, necrosis phenomenon in the tissue section. H&E analysis also indicate the implanted material was degraded along with the cells ingrowth into it. The cellulase/BC composite prepared by absorption method not only shows good degradation behavior, but also has good in vitro and in vivo biocompatibility, which could be an ideal candidate for bioabsorbable tissue scaffold material.

References

Alvarez O, Patel M, Booker J, Markowitz L (2004) Effectiveness of a biocellulose wound dressing for the treatment of chronic venous leg ulcers: results of a single center randomized study involving 24 patients. Wounds 16:224–233

Atala A (1997) Tissue engineering in the genitourinary system. Synthetic biodegradable polymer scaffolds. Birkhäuser, Boston, pp 149–164

Bäckdahl H, Helenius G, Bodin A, Nannmark U, Johansson BR, Risberg B, Gatenholm P (2006) Mechanical properties of bacterial cellulose and interactions with smooth muscle cells. Biomaterials 27:2141–2149

Bäckdahl H, Risberg B, Gatenholm P (2011) Observations on bacterial cellulose tube formation for application as vascular graft. Mater Sci Eng, C 31:14–21

Béguin P, Aubert JP (1994) The biological degradation of cellulose. FEMS Microbiol Rev 13:25–58

Bodin A, Bharadwaj S, Wu S, Gatenholm P, Atala A, Zhang Y (2010) Tissue-engineered conduit using urine-derived stem cells seeded bacterial cellulose polymer in urinary reconstruction and diversion. Biomaterials 31:8889–8901

Brown AJ (1886) XLIII. On an acetic ferment which forms cellulose. J Chem Soc, Faraday Trans 49:432–439

Catchmark JM, Fugmann B, Hu Y (2010) Degradable biomolecule compositions. Google patents, US 2010/0172889 A1

Czaja W, Kyryliouk D, DePaula CA, Buechter DD (2014) Oxidation of γ-irradiated microbial cellulose results in bioresorbable, highly conformable biomaterial. J Appl Polym Sci 131:39995–40006

Endo K, Hakamada Y, Takizawa S, Kubota H, Sumitomo N, Kobayashi T, Ito S (2001) A novel alkaline endoglucanase from an alkaliphilic Bacillus isolate: enzymatic properties, and nucleotide and deduced amino acid sequences. Appl Microbiol Biotechnol 57:109–116

Gusakov AV, Salanovich TN, Antonov AI, Ustinov BB, Okunev ON, Burlingame R, Emalfarb M, Baez M, Sinitsyn AP (2007) Design of highly efficient cellulase mixtures for enzymatic hydrolysis of cellulose. Biotechnol Bioeng 97:1028–1038

Helenius G, Bäckdahl H, Bodin A, Nannmark U, Gatenholm P, Risberg B (2006) In vivo biocompatibility of bacterial cellulose. J Biomed Mater Res A 76:431–438

Hu Y, Catchmark JM (2011a) In vitro biodegradability and mechanical properties of bioabsorbable bacterial cellulose incorporating cellulases. Acta Biomater 7:2835–2845

Hu Y, Catchmark JM (2011b) Integration of cellulases into bacterial cellulose: toward bioabsorbable cellulose composites. J Biomed Mater Res B 97:114–123

Hu W, Liu S, Chen S, Wang H (2011) Preparation and properties of photochromic bacterial cellulose nanofibrous membranes. Cellulose 18:655–661

Huang Y, Zhu C, Yang J, Nie Y, Chen C, Sun D (2014) Recent advances in bacterial cellulose. Cellulose 21:1–30

Jeffries T, Eveleigh D, Macmillan J, Parrish F, Reese E (1977) Enzymatic hydrolysis of the walls of yeasts cells and germinated fungal spores. BBA Gen Subj 499:10–23

Klemm D, Schumann D, Udhardt U, Marsch S (2001) Bacterial synthesized cellulose-artificial blood vessels for microsurgery. Prog Polym Sci 26:1561–1603

Kokubo T, Takadama H (2006) How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27:2907–2915

Kokubo T, Kushitani H, Sakka S, Kitsugi T, Yamamuro T (1990) Solutions able to reproduce in vivo surface-structure changes in bioactive glass-ceramic A-W3. J Biomed Mater Res 24:721–734

Li J, Wan Y, Li L, Liang H, Wang J (2009) Preparation and characterization of 2,3-dialdehyde bacterial cellulose for potential biodegradable tissue engineering scaffolds. Mater Sci Eng, C 29:1635–1642

Li Z, Wang L, Chen S, Feng C, Chen S, Yin N, Yang J, Wang H, Xu Y (2015) Facilely green synthesis of silver nanoparticles into bacterial cellulose. Cellulose 22:373–383

Liu S-L, Chen W-Z, Wang Y, Liu G, Yu S-W, Xing M (2008) Purification and characterization of a novel neutral β-glucanase and an alkaline β-glucanase from an alkaliphilic Bacillus isolate. World J Microbiol Biotechnol 24:149–155

Maurel W, Thalmann D, Wu Y, Thalmann NM (1998) Constitutive modeling. Biomechanical models for soft tissue simulation. Springer, Berlin, pp 79–120

Mergenthaler P, Lindauer U, Dienel GA, Meisel A (2013) Sugar for the brain: the role of glucose in physiological and pathological brain function. Trends Neurosci 36:587–597

Müller D, Rambo C, Recouvreux D, Porto L, Barra G (2011) Chemical in situ polymerization of polypyrrole on bacterial cellulose nanofibers. Synth Met 161:106–111

Nakanishi Y, Chen G, Komuro H, Ushida T, Kaneko S, Tateishi T, Kaneko M (2003) Tissue-engineered urinary bladder wall sing PLGA mesh-collagen hybrid scaffolds: a comparison study of collagen sponge and gel as a caffold. J Pediatr Surg 38:1781–1784

Ni J, Wang M (2002) In vitro evaluation of hydroxyapatite reinforced polyhydroxybutyrate composite. Mater Sci Eng, C 20:101–109

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:1

Peng S, Zheng Y, Wu J, Wu Y, Ma Y, Song W, Xi T (2012) Preparation and characterization of degradable oxidized bacterial cellulose reacted with nitrogen dioxide. Polym Bull 68:415–423

Pértile RA, Moreira S, Gil da Costa RM, Correia A, Guãrdao L, Gartner F, Vilanova M, Gama M (2012) Bacterial cellulose: long-term biocompatibility studies. J Biomater Sci Polym Ed 23:1339–1354

Petersen N, Gatenholm P (2011) Bacterial cellulose-based materials and medical devices: current state and perspectives. Appl Microbiol Biotechnol 91:1277–1286

Schumann DA, Wippermann J, Klemm DO, Kramer F, Koth D, Kosmehl H, Wahlers T, Salehi-Gelani S (2009) Artificial vascular implants from bacterial cellulose: preliminary results of small arterial substitutes. Cellulose 16:877–885

Scrivener A, Zhao L, Slaytor M (1997) Biochemical and immunological relationships between endo-β-1, 4-glucanases from cockroaches. Comp Biochem Physiol B: Biochem Mol Biol 118:837–843

Svensson A, Nicklasson E, Harrah T, Panilaitis B, Kaplan D, Brittberg M, Gatenholm P (2005) Bacterial cellulose as a potential scaffold for tissue engineering of cartilage. Biomaterials 26:419–431

Tanaka T, Takahashi M, Nitta N, Furukawa A, Andoh A, Saito Y, Fujiyama Y, Murata K (2006) Newly developed biodegradable stents for benign gastrointestinal tract stenoses: a preliminary clinical trial. Digestion 74:199–205

Vitta S, Drillon M, Derory A (2010) Magnetically responsive bacterial cellulose: synthesis and magnetic studies. J Appl Phys 108:053905

Walker L, Wilson D (1991) Enzymatic hydrolysis of cellulose: an overview. Bioresour Technol 36:3–14

Wang J, Zhu Y, Du J (2011) Bacterial cellulose: a natural nanomaterial for biomedical applications. J Mech Med Biol 11:285–306

Watanabe K, Tabuchi M, Morinaga Y, Yoshinaga F (1998) Structural features and properties of bacterial cellulose produced in agitated culture. Cellulose 5:187–200

Yang J, Lv X, Chen S, Li Z, Feng C, Wang H, Xu Y (2014) In situ fabrication of a microporous bacterial cellulose/potato starch composite scaffold with enhanced cell compatibility. Cellulose 21:1823–1835

Yin N, Stilwell MD, Santos TM, Wang H, Weibel DB (2015) Agarose particle-templated porous bacterial cellulose and its application in cartilage growth in vitro. Acta Biomater 12:129–138

Yu L, Lin J, Tian F, Li X, Bian F, Wang J (2014) Cellulose nanofibrils generated from jute fibers with tunable polymorphs and crystallinity. J Mater Chem A 2:6402–6411

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (51273043, 51573024 and 81370795), the Fundamental Research Funds for the Central Universities and DHU Distinguished Young Professor Program.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

All applicable international, national, and/or institutional guidelines for the care and use of animals were followed.

Additional information

Baoxiu Wang and Xiangguo Lv have contributed equally to this work and also co-first authors.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, B., Lv, X., Chen, S. et al. In vitro biodegradability of bacterial cellulose by cellulase in simulated body fluid and compatibility in vivo. Cellulose 23, 3187–3198 (2016). https://doi.org/10.1007/s10570-016-0993-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0993-z