Abstract

Nano-Cu2O particles were synthesized on cotton fabric using CuSO4 as a precursor and glucose as a reducing and capping agent in alkali. The morphology, crystal phase and chemical structure of the fabrics were characterized by scanning electron microscope, X-ray diffraction, Fourier transform infrared spectroscopy and energy-dispersive X-ray spectroscopy. The colorimetric values of the treated fabrics were also measured using reflectance spectra. The treated fabrics showed significant photocatalytic activity toward the degradation of methylene blue under daylight. Excellent antibacterial activity of the treated samples against Staphylococcus aureus and Escherichia coli was also confirmed. Moreover, treated fabrics were proven to have no adverse effects (low toxicity) on human dermal fibroblasts based on the MTT test. Findings suggested the potential of the proposed method in producing a fabric with high antibacterial efficiency, excellent self-cleaning properties, faster wetting time and negligible color change. Bleached cotton fabric treated with 0.02 w/w% copper sulfate and 0.35 w/w% glucose in alkali media (0.35 w/w% sodium hydroxide) at 70 °C for 1 h was found to be the optimum sample, with many applications in various fields including clothing, medical clothing and bedding.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The large surface-to-volume ratio of nanoparticles (NPs) endows them with unique characteristics and a wide range of applications (Sedighi et al. 2014a, b; Harifi and Montazer 2014). Nontoxic nanoparticles with no interaction with DNA have also attracted researchers because of the biological and medical applications (De Jong and Borm 2008; Sedighi et al. 2014a, b). Some studies have reported the toxicity of CuO nanoparticles and carbon nanotubes, causing DNA damage (Karlsson et al. 2008). In this regard, CuO particles of nanosize were found to be more toxic than those of micrometer size. On the other hand, some reports have indicated higher toxicity of micrometer particles of TiO2 (Karlsson et al. 2009).

Recently there has been an increased demand for antibacterial fabrics with applications in medical fields including medical clothing, protective clothing and bed sheets (De Jong and Borm 2008). Several studies have been carried out on the synthesis of different nanoparticles on cellulosic substrates (Harifi and Montazer 2012). For instance, a novel method was introduced for environmentally friendly synthesis of silver nanoparticles on cotton fabric, producing excellent antibacterial activity against Staphylococcus aureus and Escherichia coli even after repeated washing (Montazer et al. 2012a, b; Dastjerdi et al. 2010). Keliab (ashes of burned leaves and stems of the Seidlitzia rosmarinus plant) was used as a natural source for in situ synthesis of silver nanoparticles on cotton fabric acting as both a reducing and stabilizing agent (Aladpoosh et al. 2014). Furthermore, good antibacterial activity and crease resistance were achieved on cotton fabric using colloidal nanosilver (Montazer et al. 2012a, b).

Copper nanoparticles have been synthesized on different textile substrates creating antibacterial, antiviral and insect-repellent properties (Li et al. 2008; Longano et al. 2012). Copper oxide-impregnated pillowcases, bed sheets, patient clothing and nurse uniforms caused no side effects on healthy or damaged skin (Lazary et al. 2014). Copper nanoparticles with antimicrobial properties similar to copper-based biocides were successfully synthesized on composite polymers (Anyaogu et al. 2008). Moreover, the antimicrobial effect of Cu2O nanoparticles on Paramecium caudatum and Euplotesaffinis was studied under dark conditions in secondary wastewater treatment. Polyamide fabrics with good antibacterial properties and higher tensile strength were prepared through synthesis of copper nanoparticles using ascorbic acid and cetyltrimethylammonium bromide (Komeili-Nia et al. 2013). Copper nanoparticles were synthesized on cotton fabrics using sodium hypophosphite as a reducing agent in acidic media, indicating durable antibacterial properties against E. coli and S. aureus. The treated samples also showed higher hydrophobic properties along with lower tensile strength because of acid degradation (Sedighi et al. 2014a, b). Recently, cotton fabrics with durable antibacterial activities against E. coli and S. aureus were prepared through Cu2O nanoparticle synthesis in alkali media using copper sulfate and ammonia (Sedighi et al. 2014a, b). Although ammonia was effective as a reducing agent, it involved difficulties during usage due to volatility.

In comparison to the previous study carried out by Sedighi et al. (2014a, b), here we aimed at introducing a novel method to synthesize copper nanoparticles on cotton fabric using glucose as an environmentally friendly reducing and stabilizing agent. The alkaline condition of the preparation bath was adjusted using sodium hydroxide inducing the reaction between cellulosate anions and copper cations. Another advantage of the proposed study was optimization of antibacterial activity based on a minimum amount of precursor, alkali and reducing agent, with negligible color change. The possibility of imparting antibacterial and self-cleaning properties into cotton fabric along with low toxicity and negligible color change was investigated through different tests. The present research was successful in introducing a novel environmentally friendly procedure, producing safe photo-, bioactive cotton fabric.

Experimental

Materials

Copper sulfate (CuSO4), sodium hydroxide (NaOH) and glucose (C6H12O6) were supplied by Merck Co., Germany. Bleached cotton fabric with 100 g/m2 and warp/weft density of 32/27 yarn/cm was purchased from Yazdbaf Co., Yazd, Iran.

Methods

In situ synthesis of Cu2O nanoparticles on cotton fabric

Prior to the treatment, the fabric was washed with 0.5 g/l nonionic detergent at 60 °C for 20 min and rinsed with distilled water to remove any impurities. Copper sulfate was dissolved in distilled water, followed by the addition of sodium hydroxide and glucose to the solution (Tables 1 and 2). The fabric samples were immersed in the solution, and the process was carried out at 70 °C for 1 h. The samples were then rinsed with distilled water and dried at room temperature. Different concentrations of copper sulfate, glucose and sodium hydroxide were used in order to minimize the color change of the treated fabrics.

Test methods

X-ray diffraction analysis (XRD) was performed with the X’Pert Pro MPD (PANalytical) using a Cu Kα radiation source (λ = 1.5418 Å) operating at 40 kV to investigate the crystalline size [Scherrer Eq. (1)] and phases of the synthesized cuprous oxide on cotton fabric.

where B 1/2 is the width at half maximum, λ is the X-ray wavelength and K = 0.89 (Sedighi et al. 2014a, b).

Energy-dispersive spectroscopy (EDX) was used to characterize the elemental composition of the treated fabrics. The surface morphology of the treated samples and particle size of the synthesized nanoparticles were analyzed by scanning electron microscope (SEM) (VEGA IITESCAN-XMU, Czech Republic). Fourier transform infrared spectroscopy (FTIR) was also carried out using a Nicolet spectrometer (USA) between 400 and 4000 cm−1. The percentage of weight gain due to the treatment was determined according to Eq. (2):

where W 1 and W 2 are weights of samples before and after treatment, respectively.

The coloring effect of the treatment on the fabrics was evaluated using a ColorEye XTH spectrophotometer. The L * (lightness), a * (redness-greenness) and b * (yellowness-blueness) color values of treated samples were obtained, and the color difference between the untreated and treated fabrics under illuminant D65 for the 1964 standard observer was quantified according to Eq. (3) (Montazer et al. 2010; Montazer and Pakdel 2011; Montazer et al. 2012a, b):

Moreover, visible reflectance spectra of the treated fabrics were measured in wavelengths ranging from 360 to 750 nm, using a ColorEye 7000A spectrophotometer.

The alteration in wettability of the treated samples was evaluated by measuring the time required for a water droplet to spread on the fabric surface according to AATCC Test Method 79-2000. The fabrics were placed horizontally without creases, and a drop of 0.1 ml distilled water was placed on the fabric from 1 cm height. The time required for the droplet to spread completely on the fabric surface was measured using a stopwatch. The measurement was repeated five times, and the average value was recorded (Dastjerdi et al. 2009).

In addition, to evaluate the effect of treatment on the mechanical properties of the samples, the tensile strength was tested based on ASTMD 5035 using an Instron instrument (USA).

The self-cleaning property of the samples was determined by staining the fabrics with methylene blue (0.005 %) solution. Stained samples were exposed to daylight. The color differences in the CIE L * a * b * color space were evaluated according to Eq. (3) (Montazer et al. 2010, 2012a, b).

Antibacterial activities of the samples were evaluated using the AATCC 100 method. Briefly, a 4.8-cm-diameter fabric sample was prepared and stacked in a 250-ml glass jar with a screw cap. Then 1 ml inoculum was added to the fabric and left in the jar. The swatches were placed separately in a sterile petri dish and transferred to the jar. After inoculation, 100 ml neutralizing solution was added to each jar. The jars were shaken vigorously, and serial dilutions were made with water and plated on nutrient agar. All plates were incubated for 48 h at 37 °C. The percentage of bacteria reduction of the samples was calculated using Eq. (4).

where R is the percentage of bacteria reduction, A is the number of bacteria recovered from the inoculated treated sample in the jar incubated over the various contact periods, and C is the number of bacteria recovered from the inoculated-untreated sample in the jar immediately after inoculation at zero contact time.

The cytotoxicity test was carried out using normal primary human skin fibroblasts. They were cultured in DMEM (1X) + GlutMAXTM (GibcoTM) along with 10 % fetal calf serum (FCS) incubated at 37 °C and 5 % CO2. The passage number of three cells was seeded in a 96-well plate incubated for 48 h. The raw and treated cotton fabrics in 1 × 1 IN2 were soaked in 2 ml culture medium for 24 h and reincubated for 24 h in fresh medium tested with 3-(4,5-dimethylthinazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) assay (Kangwansupamonkon et al. 2009). Experiments were carried out three times, and the percentage of relative cell viability after incubation was calculated using Eq. (5).

where abssample and abscontrol are the absorbance of solutions containing treated and untreated samples, respectively (Behzadnia et al. 2014).

The durability of the proposed finishing method was also confirmed by evaluating the washing fastness using the AATCC 61(2A)-1996 standard method. The treated fabric samples were washed with 2 g/l ECE-1 standard detergent for 45 min at 50 °C and 42 rpm. This procedure was equivalent to five home launderings at 38 °C. The antibacterial efficiency of the samples was evaluated after washing.

Results and discussion

Interaction mechanism of sodium hydroxide, copper sulfate, glucose and cellulose

The alkaline condition of the process along with reducing and stabilizing effects of glucose played key roles in the synthesis and deposition of Cu2O nanoparticles on the cellulosic fabric. First, copper sulfate ionized to Cu2+ and SO4 − in water (Hrenovic et al. 2012). Copper (II) ions were gradually reduced to copper (I) ions because of the alkaline condition of the process and the reducing effect of glucose (reaction 1) (Yan et al. 2010). Oxidation of cellulosic fabric in alkali medium at high temperature forming carboxyl groups (–COOH) was also effective in reducing Cu2+ ions to Cu+ (Aladpoosh et al. 2014).

According to the applied preparation procedure, synthesis proceeded at alkaline pH, during which hydroxylation of Cu+ species occurred, forming CuOH (reaction 2), which was further changed into Cu2O nanoparticles (reaction 3) by heating at 70 °C for 1 h (Fig. 1) (Yan et al. 2010).

Second, in alkali medium cellulose is changed to cellulosate anions, and the alkali treatment of cotton resulted in the transformation of nonactive cellulose to alkali-activated cellulose, creating more adsorption sites (reaction 4) (Sedighi et al. 2014a, b).

In addition to the formation of nanoparticles in the solution, nucleation sites can be produced on the fabric. Moreover, nucleus formation inside the fiber structure is possible because of the possible ionization of cellulosic chains within the amorphous structure of cotton fabric (Sedighi et al. 2014a, b).

Besides, glucose can act as a stabilizing agent and control the particle size and distribution, resulting in smaller Cu2O particle formation. This prevents the agglomeration of particles through competition with cellulose in reaction with Cu+ ions.

Cu(OH)2 interacts with hydroxyl groups of cellulose and controls the size of the synthesized nanoparticles within the cellulosic chains of cotton and rolls as a stabilizer (Sedighi et al. 2014a, b). Reactions 5 and 6 indicate the formation of CuO and Cu2O between the cellulosic chains, respectively. Nobumasa et al. 2007 indicated the complex formation of poly (vinyl alcohol) (PVA) with copper and other metals, which can be used as evidence confirming our proposed mechanism (reaction 6).

The above mechanism shows the synthesis of Cu2O nanoparticles onto cotton fabric. This is a novel method of in situ synthesis of Cu2O nanoparticles on cotton fabric with the aid of glucose as an environmentally friendly reducing agent. The results in Table 2 indicate the weight gain of the treated fabrics confirming more weight gain on the fabric treated with lower glucose levels. Higher glucose levels lead to lower fabrication of nanoparticles on the cotton surface as the weight gain is lower.

XRD analysis

Figure 2 shows the XRD spectra of Cu2O cotton fabrics treated with different concentration of glucose. The successful synthesis of Cu2O nanoparticles with face-centered cubic (fcc) shapes was confirmed by characterization peaks at 2θ angles 29.5°, 36.4°, 42.2°, 61.3° and 73.6°, which are related to the (1 1 0), (1 1 1), (2 0 0), (2 2 0) and (3 1 1) planes, respectively (JCPDS file no. 05-0667). Due to the oxidation of copper metal to Cu2O, no distinctive peak can be attributed to Cu. Moreover, the copper color (reddish brown color) of the treated fabrics ensured the presence of copper (see the colorimetric study section). The crystal size of the synthesized nanoparticles on the fabric surface is 13.6 and 9.37 nm on samples a 1 and a 2 (Table 1).

SEM and EDX

SEM images of raw cotton fabric and Cu2O treated samples (treated with low and high concentrations of precursor, alkali and reducing agent) are shown in Fig. 3. While the surface of the untreated fabric is smooth (Fig. 3c), the synthesized Cu2O nanoparticles can be seen on the surface of the treated fibers (Fig. 3a, b). According to Fig. 3b, more Cu2O nanoparticles were synthesized and fabricated on the cotton surface because of a higher amount of copper sulfate, NaOH and glucose in the preparation bath. Moreover, the prepared nanoparticles were more agglomerated in a higher concentration of chemicals. This could be due to more interaction of nanoparticles with each other than cellulosic chains producing bigger nanoparticles with lower energy. Although glucose was effective in preventing the agglomeration of particles, formation of a few agglomerated particles is unavoidable.

The images at higher magnification indicate the particles with average size of 73 nm and 56 nm for samples 1 (Fig. 3a) and 3 (Fig. 3b), respectively. The successful synthesis of the nanoparticles on the treated sample was further confirmed by the chemical composition analyzed by EDX. As shown in Fig. 4, Cu and oxygen are the main elements on the treated fabrics apart from the carbon that relates to the cotton substrate. Synthesis of more Cu2O nanoparticles in higher concentrations of CuSO4/glucose/NaOH was further confirmed by more copper weight percentage on sample 3 (Fig. 4b) than sample 1 (Fig. 4a).

FTIR spectra

FTIR spectra of the synthesized Cu2O nanoparticles

FTIR spectra of CuSO4, glucose and synthesized Cu2O nanoparticles are presented in Fig. 5a–c, respectively. According to Fig. 5a, the main peak of CuSO4 appeared at 615.81 cm−1. Figure 5b indicates some peaks within 1000–1800 and 2800–3000 cm−1 attributed to the stretching of –CH2, terminal –CH3 and =CH of glucose. Further, a weak peak at 2937.64 cm−1 was attributed to stretch vibrations of C–H in glucose. Also, the bands in the range of 900–1300 and 1300–1500 cm−1 were associated with C–O and C–H vibrations of glucose. The broad band at 3100–3700 cm−1 was also characteristic of –OH functional groups (free and H-bonded). The peak observed at 623.57 cm−1 confirmed the interaction of CuSO4 with glucose in alkali media forming Cu2O nanoparticles (Fig. 5c) (Rahman et al. 2009). Interaction of glucose with the surface of synthesized Cu2O nanoparticles was further proved through the characteristic peaks of glucose observed in Fig. 3c. Therefore, glucose capped Cu2O nanoparticles to prevent them from agglomeration in solution (Salavati-Niasari and Davar 2009). Compared with the FTIR spectrum of glucose (Fig. 5b), the intensity of the free –OH band at 3434.35 cm−1 was decreased for Cu2O nanoparticles (Fig. 5c). Thus, some of the hydroxyl functional groups were occupied by Cu2O nanoparticles (Ghule et al. 2006).

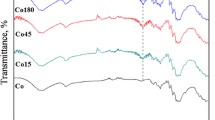

FTIR spectra of raw and treated cotton fabrics

FTIR spectra of untreated and treated cotton fabrics are shown in Fig. 6a, b, respectively. The FTIR spectra of both samples indicated the characteristic peaks attributed to C–H (stretching vibration), C–O vibration of cellulose and hydrogen bonding of OH groups of cellulose at 2901.11, 900–1300, 1300–1500 and 3347.68 cm−1, respectively (Ghule et al. 2006; Gopalakrishnan et al. 2012). The presence of Cu2O nanoparticles was confirmed by the peak at 616.22 cm−1 indicating Cu(I)–O vibration of Cu2O nanoparticles in the treated fabric (Fig. 6b) (Gopalakrishnan et al. 2012). Also, a weak band was observed for the treated sample (Fig. 6b) at 436.61 cm−1, characteristic of metal–oxygen (M–O) vibration (Ghule et al. 2006). The peak at 1592.74 cm−1 indicated the presence of carboxylate ions (–COO−) responsible for stabilization of Cu2O nanoparticles (Fig. 6b) for the treated sample (Gopalakrishnan et al. 2012).

Antibacterial activity

The antibacterial test was carried out on cultured microbe colonies of Staphylococcus aureus as gram-positive and E. coli as gram-negative bacteria. Except sample a 6 with antibacterial activity of 91.6 % against E. coli, all the treated samples indicated excellent antibacterial efficiency of 99.9 % against both S. aureus and E. coli bacteria (Table 2). The lower antibacterial property of sample a 6 against E. coli could be explained by the different cell wall of E. coli, with more resistance to Cu2O nanoparticles than S. aureus. Lipids, proteins and lipopolysaccharides (LPS) in the E. coli cell wall lead to excellent protection against biocides, while there is no LPS in S. aureus (Abboud et al. 2013).

The synthesized copper oxide nanoparticles on the cotton fabric indicated significant antibacterial properties on both gram-negative and -positive bacteria. This could be attributed to the abundance of amines and carboxyl groups on the bacteria cell surface and affinity of copper ions toward these groups. Further, the subsequent release of copper ions could be effective in disordering the helical structure of DNA molecules crosslinking within and between the nucleic acid strands (Prabhu and Poulose 2012). Also, copper ions inside bacterial cells disrupt biochemical processes (Abboud et al. 2013). The reactive hydroxyl radicals generated through copper oxide excitation also oxidize lipids and proteins and damage the membrane (Pena et al. 1998). Sedighi et al. (2014a, 2014a, b) also reported a remarkable antibacterial effect on a cotton/nano-Cu2O composite against both gram-negative and -positive bacteria through the disc diffusion test and quantitative method.

Due to the high antibacterial performance of copper compounds, even a small amount of synthesized copper compounds provides excellent protection against bacterial growth (Longano et al. 2012). As indicated in Table 2, samples treated with different CuSO4/glucose/NaOH concentrations showed an efficient antibacterial property. However, the amount of each chemical should be optimized based on the end use of the product.

Mechanical properties

Mechanical properties of different samples were measured and are summarized in Table 3. Compared with raw cotton fabric with a maximum load of 318.63 N, the tensile strength of samples 1 and 2 was reduced by 13 and 5 %, respectively. This arose from the alkaline condition of the process and its detrimental effect on the oxidation of cellulose and damage to the fabric causing weight reduction (Table 2) (Yang et al. 2012). However, sample 3 treated with a higher amount of CuSO4/glucose/NaOH showed a 3 % increased maximum load due to the formation of nano-bonding between cellulosic chains of cotton fabric overcoming the harmful effect of alkali at high temperature (Komeili-Nia et al. 2013).

The higher tensile strain of samples 2 and 3 is possibly related to the slight rupture of cellulosic chains and cotton fiber shrinkage (Ravindra et al. 2010).

Colorimetric study

The applied treatment had different coloring effects on treated fabrics and the corresponding preparation bath. The synthesis of nanoparticles on the surface, morphological changes occurring during the assembly of nanoparticles on the surface and fabric yellowing due to oxidation can be all assumed to be factors creating different coloring effects (Aladpoosh et al. 2014).

According to Table 4, sample 3 showed the lowest lightness (L * = 71.75) because of the surface plasmon resonance. Surface plasmon resonance (SPR) is a collective excitation of the electrons in the conduction band near the nanoparticle surface. Electrons are limited to specific vibration modes by the particle size and shape (Courrol et al. 2007). Therefore, metallic nanoparticles have characteristic optical absorption spectra in the UV-Vis region.

Visible reflectance spectra of different samples are shown in Fig. 7, indicating different spectra due to the SPR effect of synthesized nanoparticles on the treated fabrics. A weak peak was observed for sample 3 treated with a higher amount of CuSO4/glucose/NaOH and possibly larger nanoparticles. At this stage it is rather difficult to determine whether the differences are due to the influence of the particle size or extrinsic phenomena such as the arrangement of the capping layer around the smaller particles (Dang et al. 2011).

Wettability

In comparison to the raw cotton fabric with a water spreading time of 19.33 s, all the Cu2O-treated samples had a faster wetting time (Table 5), indicating more hydrophilic surfaces. This arose from the alkaline condition of the preparation procedure and binding of hydrophilic hydroxyl groups of glucose and copper ions. Glucose as a hydrophilic substance increases the hydrophilicity of the treated fabrics, as reported by others (Sedighi et al. 2014a, b).

Comparing samples with different CuSO4/glucose/NaOH concentrations showed decreased wettability with increased chemical concentration. For instance, the water spreading time of sample 1 with 0.02 w/w% CuSO4, 0.35 w/w% NaOH and 0.35 w/w% C6H12O6 (0.63 s) increased to 2.89 s for sample 3 treated with 2 w/w% CuSO4, 35 w/w% NaOH and 35 w/w% C6H12O6. Therefore, the samples treated with a larger amount of precursors indicated lower water absorption. Further, in situ synthesis of nanoparticles led to the formation of nano-crosslinks between the cellulosic chains of cotton fabric and blocking of hydrophilic hydroxyl groups resulting in decreased hydrophilicity (Sedighi et al. 2014a, b).

Photocatalytic activity

One of the novelties of the current research is evaluating the self-cleaning property of Cu2O-treated cotton fabrics for the first time. The self-cleaning property of different samples toward methylene blue dye degradation was evaluated based on ∆E in CIE L * a * b * color space, and the result is summarized in Table 5. Under daylight irradiation of stained treated samples, electrons and holes were generated through Cu2O excitation (reaction 7) (Zheng et al. 2009; Montazer and Pakdel 2011). The negative electrons (e−[cb]) were scavenged by oxygen (O2) to generate superoxide ions \({\text{O}}_{2}^{ - }\) (reaction 8) and H2O2 (reaction 9). Then, \({\text{O}}_{2}^{ - }\) reacted with H2O2 to produce hydroxyl radicals (OH·) (reaction 10) (Deng et al. 2015). The holes (h+[vb]) reacted with water molecules and generated hydroxyl groups (OH·) (reaction 11) (Montazer and Pakdel 2011). The holes have the great tendency to decompose harmful compounds (Montazer and Pakdel 2011). Finally, the stain (MB) was oxidized into nontoxic products by hydroxyl radicals (OH·) (reaction 12) (Deng et al. 2015). Production of more hydroxyl groups on the fabric increased the tendency of the fabric surface toward methylene blue (Allahyarzadeh et al. 2013) and degradation of the stain during the photocatalytic action (Zhang et al. 2010).

According to Table 5, an increasing CuSO4/glucose/NaOH concentration in the preparation bath resulted in greater ΔE values (increased self-cleaning property of sample 2 compared with sample 1). This arose from more Cu2O nanoparticles being synthesized on the fabric and the existence of more hydroxyl groups on the surface. However, an excessive amount of chemicals decreased the photocatalytic activity because of the possible agglomeration of nanoparticles. Therefore, the optimum amount of CuSO4/glucose/NaOH should be used as indicated in Fig. 8.

Cytotoxicity test

Another novelty of this study is evaluating the cell viability of Cu2O-treated cotton fabrics for the first time. Although it is known that toxic agents affect the shape, metabolism and health of cells, the specific effects of cotton fabric treated with Cu2O nanoparticles have not been studied so far. Based on ISO10993-5, textiles with good biocompatibility possess an average cell viability of over 70 % (Kim et al. 2009).

The cytotoxicity test was carried out on different samples to investigate any harmful effects of Cu2O-treated fabrics on human dermal fibroblasts. As indicated in Table 6 and Fig. 9, for all the treated samples the viability values were over 70 %, indicating good biocompatibility properties. The only cytotoxic fabric was sample 3 treated with the highest amount of CuSO4, indicating cell viability of 0.8 %. This sample should not be used in general medical applications.

High dosage of Cu2O nanoparticles is toxic to blood cells and causes serious membrane damage to red blood cells (RBCs). Generation of reactive oxygen species and the direct interaction between Cu2O nanoparticles and the cell membrane are suggested as possible mechanisms of cytotoxicity. The adsorption of plasma proteins on the surfaces of Cu2O NPs leads to aggregation in the whole blood, significantly alleviates the hemolytic effect and subsequently mediates the phagocytosis of Cu2O NPs with leukocytes (Chen et al. 2013). Also Cu2O generates OH· radicals, which damage membranes by oxidation of their lipids (Pena et al. 1998).

Washing fastness

Washing stability of the synthesized Cu2O nanoparticles on the treated samples was evaluated, and the change in antibacterial efficiency of the washed sample (for instance, sample 1) was recorded. The appropriate durability of the synthesized Cu2O on the treated fabric was confirmed by the small change occurring in the reported antibacterial activity (99.79 % against S. aureus and 89.83 % against E. coli) after ten washing cycles. The excellent antibacterial property of the samples after washing could be related to the presence of glucose as a stabilizer in the synthesis bath. The effective role of glucose as a capping agent chemically bound to cuprous oxide and its subsequent interaction with cellulose enhanced the stability of cuprous oxide nanoparticles on the fabric surface (Pawar and Chaure 2009). Therefore, chemical binding among copper, glucose and cellulose leads to the durable antibacterial property of the fabrics even after ten washing cycles.

Conclusions

In situ synthesis of Cu2O nanoparticles on cellulosic fabric was carried out by an environmentally friendly chemical reduction method using copper sulfate as precursor, sodium hydroxide as alkali and glucose as reducing agent. Glucose was also responsible for controlling the size of the synthesized nanoparticles, stabilizing them on the cotton fabric surface. The XRD pattern confirmed cuprous oxide nanoparticles on the fabric surface. Also, SEM images proved the presence and distribution of the nanoparticles on the fabric surface. Further, different reflectance spectra of the treated samples indicated an SPR effect. The treated samples indicated durable antibacterial efficiency against S. aureus and E. coli even after ten washing cycles due to the capping role of glucose surrounding the synthesized nanoparticles on the fabric surface. Although decreased tensile strength was obtained for samples treated with lower amounts of precursors, fabric shrinkage and nano-crosslinking between cellulosic chains of cotton and Cu2O nanoparticles enhanced the tensile strength of samples treated with higher CuSO4/glucose/NaOH. Compared with raw cotton fabric, the Cu2O-treated samples had a faster wetting time due to the hydrophilic effect of the alkali condition. The prepared bioactive samples were capable of methylene blue dye degradation, indicating an appropriate self-cleaning property. In addition to the remarkable effects of the applied method, treated cotton fabrics were proven to be less toxic to human skin cells.

References

Abboud Y, Saffaj T, Chagraoui A, El Bouari A, Brouzi K, Tanane O, Ihssane B (2013) Biosynthesis, characterization and antimicrobial activity of copper oxide nanoparticles (CONPs) produced using brown alga extract (Bifurcaria bifurcata). Appl Nanosci 4:571–576

Aladpoosh R, Montazer M, Samadi N (2014) In situ green synthesis of silver nanoparticles on cotton fabric using Seidlitzia rosmarinus ashes. Cellulose 21:3755–3766

Allahyarzadeh V, Montazer M, Hemmati Nejad N, Samadi N (2013) In situ synthesis of nano silver on polyester using NaOH/nano TiO2. J Appl Polym Sci 129:892–900

Anyaogu K, Fedorov A, Neckers D (2008) Synthesis, characterization, and antifouling potential of functionalized copper nanoparticles. Langmuir 24:4340–4346

Behzadnia A, Montazer M, Rashidi A, Mahmoudi Rad M (2014) Sonosynthesis of nano TiO2 on wool using titanium isopropoxide or butoxide in acidic media producing multifunctional fabric. Ultrason Sonochem 21:1815–1826

Chen LQ, Kang B, Ling J (2013) Cytotoxicity of cuprous oxide nanoparticles to fish blood cells: hemolysis and internalization. J Nanopart Res 15(3). doi:10.1007/s11051-013-1507-7

Courrol LC, Oliveira Silva FR, de Gomes L (2007) A simple method to synthesize silver nanoparticles by photo-reduction. Colloids Surf A 305:54–57

Dang TMD, Le TTT, Fribourg-Blanc E, Dang MC (2011) Synthesis and optical properties of copper nanoparticles prepared by a chemical reduction method. Adv Nat Sci 2:015009

Dastjerdi R, Montazer M, Shahsavan Sh (2009) A new method to stabilize nanoparticles on textile surfaces. Colloids Surf A 345:202–210

Dastjerdi R, Montazer M, Shahsavan Sh (2010) A novel technique for producing durable multifunctional textiles using nanocomposite coating. Colloids Surf B 81:32–41

De Jong WH, Borm PJ (2008) Drug delivery and nanoparticles: applications and hazards. Int J Nanomed 3:133–149

Deng X, Zhang Q, Zhao Q, Ma L, Ding M, Xu X (2015) Effects of architectures and H2O2 addition on the photocatalytic performance of hierarchical Cu2O nanostructures. Nanoscale Res Lett 10:8–17

Ghule K, Ghule AV, Chen BJ, Ling YC (2006) Preparation and characterization of ZnO nanoparticles coated paper and its antibacterial activity study. Green Chem 8:1034–1041

Gopalakrishnan K, Ramesh C, Ragunathan V, Thamilselvan M (2012) Antibacterial activity of Cu2O nanoparticles on E. coli synthesized from tridaxprocumbens leaf extract and surface coating with polyaniline. Dig J Nanomater Bios 7:833–839

Harifi T, Montazer M (2012) Past, present and future prospects of cotton cross-linking: new insight into nanoparticles. Carbohydr Polym 88:1125–1140

Harifi T, Montazer M (2014) Fe3+:Ag/TiO2 nanocomposite: synthesis, characterization and photocatalytic activity under UV and visible light irradiation. Appl Catal A 473:104–115

Hrenovic J, Milenkovic J, Daneu N, Kepcija R, Rajic N (2012) Antimicrobial activity of metal oxide nanoparticles supported onto natural clinoptilolite. Chemosphere 88:1103–1107

Kangwansupamonkon W, Lauruengtana V, Surassmo S, Ruktanonchai U (2009) Antibacterial effect of apatite-coated titanium dioxide for textiles applications. Nanomed Nanotech Biol Med 5:240–249

Karlsson HL, Cronholm P, Gustafsson J, Möller L (2008) Copper oxide nanoparticles are highly toxic: a comparison between metal oxide nanoparticles and carbon nanotubes. Chem Res Toxicol 21(9):1726–1732

Karlsson HL, Gustafsson J, Cronholm P, Möller L (2009) Size-dependent toxicity of metal oxide particles—a comparison between nano- and micrometer size. Toxicol Lett 188(2):112–118

Kim J, Kwon S, Ostler E (2009) Antimicrobial effect of silver-impregnated cellulose: potential for antimicrobial therapy. J Biol Eng 3:1–9

Komeili-Nia Z, Montazer M, Latifi M (2013) Synthesis of nano copper/nylon composite using ascorbic acid and CTAB. Colloids Surf A 439:167–175

Lazary A, Weinberg I, Vatine JJ, Jefidoff A, Bardenstein R, Borkow G, Ohana N (2014) Reduction of healthcare-associated infections in a long-term care brain injury ward by replacing regular linens with biocidal copper oxide impregnated linens. Int J Infect Dis 24:23–29

Li Y, Liang J, Tao Z, Chen J (2008) CuO particles and plates: synthesis and gas-sensor application. Mater Res Bull 43:2380–2385

Longano D, Ditaranto N, Sabbatini L, Torsi L, Cioffi N (2012) Synthesis and antimicrobial activity of copper nanomaterials. In: Cioffi N, Rai M (eds) Nano-antimicrobials: progress and prospects, Chapter 3. Springer, New York, pp 85–117

Montazer M, Pakdel E (2011) Functionality of nano titanium dioxide on textiles with future aspects: focus on wool. J Photochem Photobiol C: Photochem Rev 12:293–303

Montazer M, Nazari A, Moghadam MB, Anary-Abbasinejad M (2010) Self-cleaning properties of bleached and cationized cotton using nano TiO2: a statistical approach. Carbohydr Polym 83:1119–1127

Montazer M, Alimohammadi F, Shamei A, Rahimi M (2012a) Durable antibacterial and cross-linking cotton with colloidal silver nanoparticles and butane tetracarboxylic acid without yellowing. Colloids Surf B 89:196–202

Montazer M, Alimohammadi F, Shamei A, Rahimi M (2012b) In situ synthesis of nano silver on cotton using Tollens’ reagent. Carbohydr Polym 87:1706–1712

Nobumasa H, Hirofusa Sh, Sadao H (2007) Complex formation between poly(vinyl alcohol) and metallic ions in aqueous solution. J Polym Sci 47:299–307

Pawar MJ, Chaure SS (2009) Synthesis of CdS nanoparticles using glucose as a capping agent. Chalcogenide Lett 6:689–693

Pena MMO, Koch KA, Thiele DJ (1998) Dynamic regulation of copper uptake and detoxification genes in Saccharomyces cerevisiae. Mol Cell Biol 18:2514–2523

Prabhu S, Poulose EK (2012) Silver nanoparticles: mechanism of antimicrobial action, synthesis, medical applications, and toxicity effects. Int Nano Lett 2:32–41

Rahman A, Ismail A, Jumbianti D, Magdalena S, Sudrajat H (2009) Synthesis of copper oxide nano particles by using Phormidium cyanobacterium. Indo J Chem 9(3):355–360

Ravindra S, Mohan YM, Reddy NN, Raju KM (2010) Fabrication of antibacterial cotton fibers loaded with silver nanoparticles via ‘‘Green Approach’’. Colloids Surf A 367:31–40

Salavati-Niasari M, Davar F (2009) Synthesis of copper and copper (I) oxide nanoparticles by thermal decomposition of a new precursor. Mater Lett 63:441–443

Sedighi A, Montazer M, Hemmatinejad N (2014a) Copper nanoparticles on bleached cotton fabric: in situ synthesis and characterization. Cellulose 21:2119–2132

Sedighi A, Montazer M, Samadi N (2014b) Synthesis of nano Cu2O on cotton: morphological, physical, biological and optical sensing characterizations. Carbohydr Polym 110:489–498

Yan C, Yue-jun W, Kang-gen ZH, Zhen B (2010) Morphology control of ultrafine cuprous oxide powder and its growth mechanism. Trans Nanferrous Met Soc China 20:216–220

Yang Z, Chen S, Hu W, Yin N, Zhang W, Xiang C et al (2012) Flexible luminescent CdSe/bacterial cellulose nanocomposite membranes. Carbohydr Polym 88:173–178

Zhang Y, Deng B, Zhang T, Gao D, Xu A-W (2010) Shape effects of Cu2O polyhedral microcrystals on photocatalytic activity. J Phys Chem C 114:5073–5079

Zheng Zh, Huang B, Wang Z, Guo M, Qin X, Zhang X, Wang P, Dai Y (2009) Crystal faces of Cu2O and their stabilities in photocatalytic reactions. J Phys Chem C 113:14448–14453

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Montazer, M., Dastjerdi, M., Azdaloo, M. et al. Simultaneous synthesis and fabrication of nano Cu2O on cellulosic fabric using copper sulfate and glucose in alkali media producing safe bio- and photoactive textiles without color change. Cellulose 22, 4049–4064 (2015). https://doi.org/10.1007/s10570-015-0764-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0764-2