Abstract

Fire resisting property was imparted to cellulosic paper by the application of a bio-enriched version of a banana pseudostem sap (BPS) as well as the only BPS, obtained as a byproduct during fibre extraction from the pseudostem. The papers were evaluated for their flame retardant property by measurement of limiting oxygen index and vertical flammability. They were also characterized by thermogravimetry, scanning electron microscopy and energy dispersive X-ray analysis. The bio-enriched BPS treated paper was found to exhibit a better flame retardancy with distinguished char length, compared to the control and the only BPS treated paper. The impartment of flame resisting property to a paper by the BPS, along with its charring behaviour has been discussed and the mechanism thereon has been postulated. The BPS application was found to enhance the oxygen required for the burning of the paper and reduce its burning rate by promoting more dehydration and char formation. The imparted fire retardant finish found durable to weathering, did not cause any significant loss in tear and tensile properties of the paper.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose is the main backbone of paper, wood, cellulosic textiles, etc. All the cellulosic materials including paper are inherently flammable, and produce smoke and toxic gases like carbon dioxide, carbon monoxide, levoglucosan, pyroglucosan etc., during burning (Mostashari and Mostashari 2009). Since the ancient time, Egyptians have been using alum for imparting flame retardancy to wood and paper (Van Esch et al. 1997). Boric acid and sodium borate are the most commonly used fire retardants for the paper substrate, as have been reported in the literature. However, boron used in higher concentration is toxic and also, the treated paper loses its hand feel property (Katovic et al. 2009). Besides, nitrogen and phosphorous based flame retardants are also used to prepare a fire retardant cellulosic paper. It may be noted that di-ammonium phosphate and ammonium sulphate are the two predominating chemicals used for making fire retardant paper for the past 10 years in the European market (Candan et al. 2012). Borax with diammonium phosphate mixture is also a good fire retardant for paper, as it has practically no detrimental effect on the physical properties of the treated paper. Researchers have also used the mixed formulation of aluminium trihydrate, sodium borate and resin as a fire retardant chemical to be applied by an impregnation method during the manufacturing of the paper (Denholm 2007, Odnima et al. 2013). Water soluble inorganic salt along with resin has also been used prior to the saturation of the base fibre material (Denholm 2009). Recently, the researchers have also used N-hydroxymethyl-3-dimethyl phosphopropionamide as a durable fire retardant of the paper by using citric acid as a binder and phosphoric acid as a catalyst (Katovic et al. 2009). However, this application suffers from the requirement of a large amount of chemicals and the treated paper being stiff and losing its strength due to the application (Katovic et al. 2009). Besides, the treatment is hazardous and non-ecofriendly. Apart from the fire retardancy, as far the pyrolysis of the paper is concerned in the case of existing conventional laser or inkjet printing, hazardous carbon dioxide and other pollutants are evolved at 500 °C (Chen et al. 2014a, b). Cellulosic paper printing showed that the fibres on the paper surface exhibit a yellow discolouration, depending on this yellowing a new eco-friendly inkless printing technique can be developed (Chen et al. 2014a, 2014b). The present day eco-conscious society demands that the product manufacturing processes should be ecofriendly, hygienic, economical and abiding by the government regulations and legislations in ethics and effluent. Keeping in view these points into consideration, a very few researches have so far been reported on imparting fire retardant to cellulosic substrate using natural products. As far as the printing is concerned, heat induced inkless eco-printing of paper is less time consuming and also resulted in fewer toxic pyrolysis volatiles(Chen et al. 2014a, b) as here no ink is required and printing was done via yellowing and blackening of the paper by thermal energy (Chen et al. 2012). With addition, there is no significant damage (weight loss) to the printed paper was evident as heat required for this printing process is lower than that of the Thermogravimetry (TG) experiment (Xie et al. 2014). Regarding the fire retardancy, Notably, the researchers have reported that DNA from herring sperm and Solomon fishes can be applied to the cellulosic cotton fabric to make it thermally stable. They have also reported that DNA contains phosphate, carbonaceous deoxyribose units, polysaccharide dehydrate and some essential amino acids, which are helping in carbonaceous char formation and ammonia release, thus making the cotton textile thermally stable (Alongi et al. 2013). Attempts have also been made to impart fire retardant to cotton fabrics with whey proteins, casein and hydrophobins due to their phosphate, disulphide and protein content, as they can influence the pyrolysis by an early char formation (Bosco et al. 2012; Carosio et al. 2014). Similarly, a very few applications of plant extract (e.g., bio-molecules) being used for imparting flame retardant finishing to any cellulosic material has been reported till date. This research group has recently reported the use of wastage spinach leaves as a fire retardant product for the cellulosic cotton textile (Basak et al. 2014) and the banana pseudostem sap (BPS), for the ligno-cellulosic jute textile (Basak et al. 2015). However, till date, no research has been reported on the use of plant bio-molecules for making fire retardant cellulosic paper. In the present paper, we report the use of a wastage plant bio-molecule, namely the banana pseudostem sap (BPS) and its bio-enriched form, which is also a very good organic fertilizer (Kolambe et al. 2013), as fire retarding agents for the cellulosic paper substrate. A detailed study of fire retardant properties of the treated papers and their characterization related to the thermal stability have also been carried out and the possible mechanism of imparting flame retardancy to paper by the application of BPS has been investigated. As the banana pseudostem sap is widely available in India and also, considered as a wastage product, its use as a fire retardant not only will be a major value addition to the cellulosic substrate like paper, but also will provide a fillip to banana cultivators by way of higher economic returns.

Materials and methods

A 200 GSM (areal density) handmade paper prepared in CIRCOT paper making laboratory was used for the flame retardant finishing study. The BPS and bio-enriched BPS was supplied by the Navsari Agricultural University, Gujarat, India for the treatment. Both the supplied saps were with 7.5 (neutral) pH. The paper used for the study was first mordanted by dip-dry method by using 5 % tannic acid and 10 % alum. Thereafter, the mordanted papers were impregnated in the as it is the BPS solution for 15–20 min at room temperature, maintaining the material to liquor ratio of 1:10. The treated papers were dried at normal atmosphere.

Testing

Before testing, the paper samples were conditioned for 48 h at 65 % RH and 27 °C temperature.

Determination of percent add-on

The percent add-on was determined by the gravimetric principle, from the difference of the bone dry weights of the sample before and after the treatments, and expressing the results in percentage over the initial bone dry weights as follows:

where, M1 and M2 are the oven dry weights of the control and the treated paper samples, respectively. The reported results are the average of five tests in each case.

Flammability assessment

The burning behaviour of the control and the treated samples were evaluated by the standard methods. For assessing the Limiting Oxygen Index (LOI), IS: 13501 test method was used. In the vertical flammability test, the different parameters were measured as per IS: 1871 method A.

Weathering fastness of finish

Both the treated and the untreated paper samples were exposed to direct sunlight for measuring the weathering fastness as per ISO 105-B03-1978 (E) method. However, the samples were protected from rain and exposed 6 h daily from July to September. After every 50 h, the fire retardant property of the treated and the untreated paper samples were measured in terms of oxygen index.

Characterization of treated paper

Thermogravimetry analysis

Thermogravimetry (TG) measures the gradual weight loss of a sample with respect to time or temperature. It also indicates the effect of flame retardant on the pyrolysis of the polymer substrate (Mostashari and Mostashari 2009). In the present study, the TG curves of the control and the treated papers were obtained by using a Thermo Gravimetric Analyser, METTLER TOLEDO TG-50/MT5 in N2 atmosphere.

SEM and EDX analysis

The Surfaces of both the control and the BPS treated samples, including their char masses were analysed using a scanning electron microscope, Philips XL-30. The samples were coated with a thin layer of conducting material (Gold/palladium) by using a sputter coater, and the same were examined under the SEM with an accelerating voltage of 12 kV. The EDX analysis of the samples was carried out in a Field Emission Gun Scanning Electron Microscope (FEG-SEM) to determine the quantity of the elements present on the surface, and was expressed both in atomic and weight percent.

Results and discussion

LOI and vertical flammability

LOI is defined as the minimum amount of oxygen required in the mixture of the oxygen and nitrogen for just flaming of the substrate. Any material to be a fire retardant requires to have an oxygen index of 26 (Schindler and Hauser 2004). From Table 1, we can observe that both the control and the mordanted paper showed an oxygen index of 18. However, after treatment with only BPS, the oxygen index increased to 28 and for the Bio-enriched BPS treated paper, it was 33. As far as the vertical flammability is concerned, the control sample paper was found to burn with a flame within a minute with flashing, high-temperature and heat generation, but the BPS treated paper showed no flame and a slower burning rate of 3 cm/min. Here, the afterglow time was observed for 500 s, as the burning rate was 8 times lower than the control paper. On the other hand, the bio-enriched BPS treated paper, though also showed no flame in the vertical flammability test, but got self-extinguished after a short 45 s glow. As a result, the sample showed a char length of 5.3 cm. From Fig. 1 it is clear, that with varying flame contact time the char length of the bio-enriched BPS treated papers were also changing. Like this it was observed that with only 1 s flame contact time (A) char length observed was 0.5 cm. Thus with 2, 3, 4 s flame contact time, (B, C, D) char length observed was 0.5, 0.5 and 1.4 cm respectively. Also, the afterglow duration was found to increase gradually with the increase in the flame contact time. Thus, at 10 s flame contact period (F), a 5.3 cm char length was observed with an afterglow for 45 s. This implies that the bio-enriched BPS provided a better flame retardant property to the paper compared to the only BPS treated sample.

SEM and EDX analysis

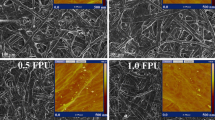

The SEM images of the control and the BPS treated paper samples are shown in Fig. 2. The control sample showed a clean non-woven web of cellulosic fibre and there was no evidence of any coating and deposition on the fibre surface (Fig. 2a) . However, after the BPS treatment, the coating of BPS could easily be visible (Fig. 2b, c), as the BPS coating is uniformly distributed over the entire cellulosic web on the treated paper surface. It can also be observed from Figs. B and C that the interfibre spaces are filled up with BPS coating. The energy dispersive X-ray analysis of both the control and the BPS treated paper is presented and the data reported in Table 2. It can be observed from the Table that the BPS contains elements like magnesium, chlorine, phosphorous, potassium and calcium. However, the control paper contains only carbon and oxygen. As far as the EDX of the bio-enriched BPS is concerned, the same also contains elements predominated by magnesium, chlorine, potassium, silicon, etc. However, the difference is that, here the elements present are in higher amount than those present only in the BPS. Concerning the elemental composition of the BPS, it was found from the literature that the only BPS contain 1.3 gpl nitrogen, 2.29 gpl phosphorous, 1.4 gpl potassium and trace amount of magnesium, calcium and sulphur, whereas the bio-enriched BPS contains 8.5 gpl nitrogen, 0.17 gpl phosphorous, 1.3 gpl magnesium and 1.1 gpl of potassium (Kolambe et al. 2013). It means that the bio-enriched BPS contain around eight times more nitrogen compared to the only BPS. The additional more elemental constituents present in the bio-enriched BPS may be responsible for its better fire retardant attributing property compared to the only BPS.

Char analysis

Char residual analysis of the control and the BPS treated paper samples was carried out and the results are presented in Fig. 3. It showed that while the control paper has the light-weight, ash-like white char mass, the BPS treated paper samples showed a hard, solid and a blackish char mass. However, the bio-enriched BPS treated paper showed more hard, blackish carbonaceous char residuals. To understand this phenomena more vividly, SEM analysis of the char mass samples was carried out. Here, the control paper char showed a net like open capillary structure through which, the volatile flammable gases can easily pass through and help to burn the paper continuously. However, both the treated paper chars showed intact honeycombed like char structures formed of closed cells containing pockets of gases. This closed cell char structure helped to restrict the flow of flammable gases and prevent them from coming out in contact with the flame source. Accordingly, two char models have been proposed and represented in the Fig. 3. In case of the control paper, the cellulose decomposes/pyrolyses by the heat of flame at 350–400 °C. The gaseous products, thus formed at this temperature migrate/wick through the net like char structure of the cellulose by capillary action in the presence of oxygen, and contact the flame source. It may be noted the pyrolysis or cellulose decomposition also produce hydrocarbon fragments. These fragments, in addition to the flammable gases also migrate towards the flame source and here, cyclisation and aromatisation leads to the formation of carbonaceous soot. These are then transported further and produce the glow. However, in the case of the BPS treated paper, pyrolysis/decomposition starts in an early stage (as seen from the TG curve B1 and C1: Fig. 5) compared to the control paper, (as seen from the TG curve A1: Fig. 5) resulting in an extensive dehydration and the formation of more hydrocarbon mass that may have been partially migrated through the closed cell char-structure, and may be one of the reasons of the observed afterglow during curing. But in case of the bio-enriched BPS treated paper, the formation of more closed-cell char may have restricted the wicking of the flammable gases and hydrocarbons, preventing them to come in contact with the heat source or the flame. Hence, here the burning does not happen and only a very little glow could be observed, which too, also self-extinguished after a few seconds showing the char length.

TG analysis

Thermogravimetry analysis of the only dried BPS powder, control cellulosic paper, BPS treated paper and bio-enriched BPS treated paper have been carried out and presented in Figs. 4 and 5. The TG curve of the dried BPS powder (D1) showed an initial weight-loss at below 50 °C for evaporation of moisture present in it, followed by gradual weight-loss from 170 to 500 °C. The BPS showed only 45 % weight loss at 350 °C, which is the pyrolysis temperature of cellulose. At higher temperature around 500 °C also, it maintained more than its 40 % weight. This slow weight-loss rate of the BPS proved its potential for use as a fire retardant applicant. The TG curve of the cellulosic paper (A1) showed a rapid fall at 350 °C, which is the pyrolysis temperature of the cellulose polymer. At a high temperature of 500 °C, it maintained below 20 % weight. Thus, the phenomenon proved the poor thermal stability of the cellulosic paper polymer. As far as the BPS treated paper is concerned, it showed an initial weight-loss below 100 °C, might be due to evaporation of moisture from the BPS coating. Thereafter, it again started losing weight from around 200 °C due to early degradation of cellulose. However, the weight-loss rate was found lower than the control cellulosic paper, and at 350 °C, it retained more than 40 % weight of the polymer. This early degradation helps to restrict the formation of the flammable gases and also, promotes the carbonaceous char-mass formation. On the other hand, the TG curve of bio-enriched BPS treated paper sample C1 also showed an early pyrolysis, like in the case of the only BPS treated paper. However, here the char formation is much higher compared to the only BPS treated paper, as it retains around 50 and 40 % mass at 350 and 450 °C, respectively.

Weathering durability

The durability of the imparted flame retardant finish in the treated paper was tested to study the weathering durability of the finish. The fastness of both the control and the treated papers were measured under sunlight, and the LOI values after every 50 h were recorded (Table 3). It was observed that after 150 h of exposure, the LOI of the treated paper remained almost the same. However, after the long-exposure to the weather, the index values got slightly reduced. It means that the harmful UV rays of the sun and the humidity conditions of the weather were no deterrent, and did not affect adversely on the fire retardant property of the treated paper. However, the result suggests that in the long run the weather may have some deterrent effects on the flame retardant property of the paper, which needs to be investigated further.

Strength and color parameters

It was found that the application of the BPS flame retardant finish has no adverse effect on the tensile and the tear strength of the treated paper sample. The only BPS treatment reduced 5 % tear strength and 7 % tensile strength of the treated paper, and the bio-enriched BPS treatment reduced 5–6 % in both the tear and the tensile strength. As far as the colour parameter is concerned, the only BPS treated paper showed a slight yellowish colour, whereas the bio-enriched BPS treated paper showed a deep yellowish (Khaki colour) type colour. However, this colour was found stable in sunlight and humid condition.

Mechanism of imparting fire retardancy

Paper being pure cellulosic in nature, has a low LOI value of 18 and does not show any protection from flame. The mordanting of the paper with 5 % tannic acid and 10 % alum also, did not improve the flame retardancy. The paper was then treated with the BPS or the bio-enriched BPS under neutral PH and the LOI was found to improve to 28 and 33, respectively. This implies that the paper was exhibiting flame retardancy, mainly because of the chemicals present in the BPS/bio-enriched BPS. More explicitly, the effect of flame retardancy imparted by the BPS and its bio-enriched version may be attributed due to the presence of various mineral salts in them, in the form of chloride, phosphate, phosphite and silicate. The presence of these salt molecules was observed from the FTIR and mass spectroscopy analysis of the BPS (Basak et al. 2015). Phosphorous esters present in the phosphate and phosphite, catalyse the dehydration of cellulose by blocking –OH group in the C6 position of the cellulose units. Other inorganic salts like chloride present in the BPS readily form the corresponding strong acids upon heating and also help to dehydrate cellulose more extensively (Schindler and Hauser 2004). As reported in the literature, the BPS contain 1.3 gpl nitrogen, 0.2 gpl phosphorous, 1.4 gpl potassium and trace amounts of calcium, magnesium, sulfur, copper, zinc, etc., whereas the bio-enriched BPS is actually a fermented (1:1) mixture of BPS and cow dung, cow-urine, nitrogen-rich neem, alfalfa leaves, and fermented by jaggery and nitrogen fixing bacteria (Kolambe et al. 2013). As a result, it contains 8.5 gpl nitrogen, 0.2 gpl phosphorous, 1.15 gpl potassium, 1.3 gpl magnesium and trace amounts of calcium, sulfur, manganese and copper (Kolambe et al. 2013). The higher amount of metallic salts present in the bio-enriched BPS compared to the only BPS, may be acting as fillers in the application and helping to absorb more heat per unit weight by the endothermic process. The additional nitrogenous matter present in the bio-enriched BPS may be helping to produce more nonflammable gases like ammonia, carbon dioxide and water during decomposition of the paper cellulose and diluting the flammable gas formation. Therefore, both of these factors, in combination, are helping the formation of more carbonaceous insulating char-mass. As far as the afterglow and smoke formation are concerned, the only BPS treated paper showed more afterglow and smoke compared to the bio-enriched BPS treated paper. It may be due to the fact that the inorganic salt molecules present in the BPS are helping to restrict the flame. However, some aromatic compounds are also present in the BPS (as shown from MS) (Sayed et al. 2001) helping in the formation of more afterglow and smoke. In the literature, it has been mentioned that aromatic polymers have a greater tendency to smoke formation (Price et al. 2001). However, in case of the bio-enriched BPS, the more amounts of inorganic salts and nitrogenous matter present in it are helping to arrest the glow as well as smoke formation, by more carbonaceous char formation.

Conclusion

The present research reports on the application of an agricultural waste, namely the banana pseudostem sap (BPS), obtained during fibre extraction and its bio-enriched version for the paper substrate a fire retardant. The BPS application was found to enhance the oxygen required for the burning of the paper and reduce its burning rate by promoting more dehydration and char formation. The same was substantiated from the observations on the TG curves. Further, the bio-enriched BPS was found comparatively more effective in imparting fire retardancy to the paper. It has been postulated that the more amounts of nitrogen and other inorganic salts present in the enriched sap may be responsible for the same, while the additional nitrogen may be helping to produce more nonflammable gases and diluting the flammable gas formation, the higher amount of metallic salts may be acting as fillers and helping to absorb more heat per unit weight. A detailed mechanism of imparting fire retardancy to paper by the BPS, supported by analysis of the paper samples and their char has been proposed. In both the cases, the physical property of the treated paper remains more or less unchanged. The application process is very simple, cost effective and the BPS is an agricultural waste product and available abundantly all over the India. This kind of fire retardant paper has the potential to be used for making safe and fire-proof paper document, cover and bag, etc.

References

Alongi J, Carletto RA, Balsio AD, Cuttica F, Carosio F, Bosco F, Malucelli G (2013) Intrinsic intumescent like flame retardant properties of DNA treated cotton fabrics. Carbohydr Polym 96:296–305

Basak S, Samanta KK, Chattopadhyay SK (2014) Fire retardant property of the cotton fabric treated with herbal extract. J Text Inst. doi:10.1080/00405000.2014.995456

Basak S, Samanta KK, Chattopadhyay SK (2015) Self extinguishing lingo-cellulosic fabric treated with banana pseudostem sap. Curr Sci 108:372–383

Bosco F, Carletto RA, Alongi J, Blasio AD, Malucelli G (2012) Thermal stability of flame resistantance of cotton fabrics treated with whey proteins. Carbohydr Polym 94:372–375

Candan Z, Ayrilmis N, Dundar T, Atar M (2012) Fire performance of LVL panels treated with fire retardant chemicals. Wood Res 57:651–658

Carosio F, Blasio AD, Cuttica F, Alongi J, Malucelli G (2014) Polyester and polyester cotton blend fabrics have been treated with caseins. Int Eng Chem Res 53:3917–3925

Chen JX, Wang Y, Xie J, Meng C, Wu G, Zu Q (2012) Concept of a heat induced inkless eco-printing. Carbohydr Polym 89:849–853

Chen JX, Pan L, Xie J, Wu G, Ren H, Wang Y (2014a) Pyrolysis volatiles and environmental impacts of printing paper in air. Cellulose 21:2871–2878

Chen JX, Xie J, Pan L, Wang X, Xu L, Lu Y (2014b) The microstructure of paper after heat-induced inkless eco-printing and its features. J Wood Chem Technol 34:202–210

Denholm A (2007) Borax and diammonium phosphate introduced into the paper, US 20070082194A1

Denholm A (2009) Fire retardant paper. US7510628B2

Katovic D, Vukusic SV, Grage SF, Lozo B, Banic D (2009) Flame retardancy of paper obtained with environmentally friendly agents. Fibres Text East Eur 17:90–94

Kolambe BN, Patel KK, Pawar SL, Patel JM, Prajapati DR (2013) A novel organic fertilizer of banana pseudostem. WIPO patent application No. WO/2013/001478

Mostashari SM, Mostashari SZ (2009) Thermogravimetry of deposited ammonium aluminium sulphate dodecahydrate used as flame retardant for cotton fabrics. Cellul Chem Technol 43:455–459

Odnima SC, Okoye NH, Okoro VE (2013) Comparative study on the effect of three flame retardant compounds on flame behaviour of a roofing Thatch. Int J Eng Sci Invent 2:56–60

Price D, Anthony G, Carty P (2001) Polymer combustion, condensed phase pyrolysis and smoke formation. In: Price D (ed) Fire retardant materials. Cambridge, UK, pp 1–30

Sayed ME, Monsour OY, Selim IZ, Ibrahim MM (2001) Identification and utilization of banana plant juice and its pulping liquor as anticorrosive materials. J Sci Ind Res 60:738–747

Schindler WD, Hauser PJ (2004) Chemical finishing of textiles. Cambridge, UK

Van Esch GJ (1997) Flame retardants: a general introduction, environment health criteria (EHC) ISBN9241571926: 192

Xie J, Chen J, Wang Y, Liu Y, Noori NM, Pan L (2014) Weight loss phenomenon of paper and the mechanism for negligible damage of heat induced inkless eco-printing. Cellul Chem Technol 48:577–584

Conflict of interest

None.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Basak, S., Samanta, K.K., Chattopadhyay, S.K. et al. Thermally stable cellulosic paper made using banana pseudostem sap, a wasted by-product. Cellulose 22, 2767–2776 (2015). https://doi.org/10.1007/s10570-015-0662-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0662-7