Abstract

Films prepared from aqueous suspensions of cellulose nanocrystals (CNC) often display iridescent colors due to the reflection of light from the helicoidal orientation of the rod-like CNC in the film. Droplets of CNC suspension deposited on a plane surface evaporate to give films that display iridescent rings. Profilometry measurements across the rings show that the outer edge of the films is much thicker than the region in the center. This is ascribed to a “coffee-stain” effect; the CNC are transported to the outer edge for droplets where the contact line is pinned during evaporation. The gradient in concentration across the ring results in a color gradient, with the longer wavelengths decreasing towards the center of the sample, in accord with the hypothesis of a two-stage process for CNC chiral nematic color formation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Evaporation of droplets containing suspensions of colloids on solid substrates leads to the accumulation of particles at the three-phase contact line, the so-called “coffee-stain effect” (Deegan et al. 1997).

The surface self-assembly generated by this process has been extensively investigated for spherical particles, but less attention has been paid to suspensions of shape-anisotropic particles (Dugyala et al. 2013). Examples of rod-like species forming ordered structures by evaporation of suspensions include the self-assembly of semiconductor nanorods (Querner et al. 2008; Nobile et al. 2009).

The evaporation of stable suspensions of rod-like particles is of intrinsic interest, because the concentration must pass through a concentration region where spontaneous formation of an anisotropic (nematic) fluid phase is entropically favored (Onsager 1949). For chiral rod-like species, the anisotropic fluid may demonstrate chiral nematic properties, with a twisted helicoidal structure that may persist in the dry state. This has been observed for suspensions of cellulose nanocrystals (CNC), where the pitch, orientation and refractive index of the helicoidal structure are such that the films display iridescent colors (Revol et al. 1998). The film-forming process may be viewed as involving two stages, an equilibrium change in pitch as the concentration of the chiral rod-like species increases, and a kinetically controlled stage where gel and glass formation occurs as the film dries (Mu and Gray 2014).

As shown by Deegan et al. (1997) in describing the “coffee-stain effect”, solids dispersed in a drying drop migrate to the edge of the drop to form a solid ring (Fig. 1), where the migration is caused by the evaporation-driven outward flow of liquid in the droplet. In the case of the rod-like cellulose nanocrystals, the droplet suspension at 5.2 w/w is already in an ordered (probably biphasic) state, and the increase in CNC concentration at the edge of the evaporating droplet is sufficient for gel formation, resulting in a buildup of nanocrystals at the outer edge of the droplet. In this note, we examine the 3-dimensional concentric iridescent rings that are produced by the evaporation of water from sessile droplets of suspensions containing cellulose nanocrystals.

Stages in droplet evaporation producing “Coffee-stain effect”; a Water evaporates from droplet of CNC suspension on surface b Evaporation-driven mass transfer of CNC to edge of droplet with pinned contact line c Different thicknesses and concentrations of drying gel give a range of iridescent colors

Experimental

Dry Whatman cotton powder (40 g) was treated with a preheated sulfuric acid solution (64 % w/w, 700 mL) at 45 °C for 45 min, after which the reaction was quenched by 5L of deionized water. The suspension was washed by repeated centrifugation and re-dilution before extensive dialysis against deionized water until the effluent remained at neutral pH. The suspensions were dispersed by sonication, mixed-bed ion-exchange resin was added and stirred for 24 h to complex any stray ions and the suspension was filtered through glass microfibre filters (0.45 µm pore size) to remove particulate impurities introduced by the sonicator tip. (Recently, (Beck et al. 2014) recommended the use of a strong acid cation exchange resin to ensure complete conversion of the sulfate half-esters on the CNC surface to acid (H+) form. While critical to analysis of sulfate half-esters, this should have little effect on the work reported here.) The concentration of the acid (H+) form suspensions was determined gravimetrically as 5.2 % w/w. CNC-glucose suspensions were prepared by adding solid d-glucose (anhydrous, Sigma-Aldrich) to known volumes of the 5.2 % w/w CNC suspension to give samples with glucose concentrations of 1, 3, 5, 7 and 10 % w/v. The colloidal CNC-glucose samples were briefly sonicated for 1 min or until all glucose had dissolved, and stirred for 24 h. Droplets (10 µL) of the suspensions were deposited on glass or black acrylic substrates and allowed to evaporate under ambient conditions. Reflected light images of the iridescent films on the black acrylic were taken with a Canon T3i camera, or with a Nikon SMZ-U binocular microscope. The appearance of the iridescent films depends critically on their texture (distribution of orientation, pitch value and disclination pattern of the frozen-in liquid-crystalline structure), and is difficult to capture photographically, due to the variation in reflection colors with angle of illumination and camera position. Transmitted light images were taken with a Nikon Eclipse LV100POL polarized light microscope equipped with a 530 nm wave plate.

The surface topology of the samples on a black acrylic surface was measured by a surface profilometer (Ambios XP200) with a minimum resolution step of 1 nm. The sample was positioned on a 6 inch stage. A stylus (tip radius, 2.5 µm) scanned the sample surface at a speed of 0.2 mm/s to give the height profile across the dried droplet.

Results and discussion

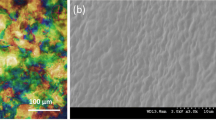

When placed on acrylic and glass surfaces, the suspensions formed sessile droplets with a finite contact angle. When the contact line remains pinned at the droplet edge, the apparent contact angle decreases during evaporation. The evaporation-driven mass transfer of CNC to the edge of the drop produces a high concentration of CNC relative to the center, leading to gel formation, starting at the perimeter of the drying drop, and trapping the chiral nematic pitch at the red end of the spectrum. The residual more dilute suspension at the center has more time to attain its equilibrium (shorter pitch) helicoidal arrangement before being trapped in a gel or glassy state. Thus, the films produced by surface evaporation show a concentric distribution of colors across the visible spectrum, with shorter wavelength reflection towards the center (Fig. 2). Furthermore, the final disc-shaped film was not flat, but appeared to be thicker at the outer edge. Profilometry scans across the disc confirmed this observation. The edge is raised to about four times the height at the centre, as shown by the cross-section shown in Fig. 3.

The interpretation is supported by profilometry measurements on samples where glucose is added to the evaporating CNC droplets. As shown previously (Mu and Gray 2014), glucose enhances the onset of glass formation, trapping the chiral nematic pitch values at longer pitch values. Figure 4 shows the trend to longer reflection wavelengths towards the centre of the samples with the addition of glucose. (Increasing ultrasonic treatment of CNC suspensions also results in a trend to longer reflection wavelengths from films (Beck et al. 2011), but the samples shown here were subjected to similar ultrasonication times of under a minute.)

The general profile of the cross-section is maintained (Fig. 5) but the thickness of the film increased on addition of glucose. The 5 and 10 % glucose samples contains as much or more glucose as CNC, which adds to the bulk of the film and shifts the reflection band to longer wavelengths, since glucose itself forms a glass, and presumably can enhance gel formation. It also acts as a diluent, which also will prevent the CNC attaining their short-pitch state. The greater the difference in height across the sample, the greater is the range of colours displayed by the sample. Thus the sample with 10 % glucose appears a uniform dark red, implying that there is little mass transfer before freezing in of the pitch, presumably because of the high viscosity of the glucose-rich suspension. In contrast, the samples with 0 % (Fig. 2) and 1 % (Fig. 4a) glucose show a broad range of reflection colors, from red at the edge to blue (and possibly ultra-violet) in the centre, in line with the strong coffee-stain effect observed for these samples.

It is possible that the shape of the upper surface of the dried droplets might influence the observed reflected color. However, we think that this is unlikely for our samples. From the profilometer measurements, the maximum angle between the surface of the film and the flat substrate surface is less than 6° at the edge of the sample. Even allowing for the smoothing effect of the spherical profilometer tip, any tilt in the chiral nematic director at the surface of the film seems too small to have a major effect on the observed color.

In general, the iridescent colors displayed by films made by evaporation of aqueous CNC droplets decrease in wavelength from the outside edge to the centre of the films (Mu and Gray 2014; Lagerwall et al. 2014). In a recent paper, Dumanli et al. (2014) characterized neighbouring domains of different iridescent colors in thin CNC films by optical and electron microscopy, showing that the wavelength of the reflection colors matched the pitch values measured by scanning electron microscopy of the film cross-section. They also ascribed the formation of different-colored rings at the edge of their films to the coffee-stain effect. Their observations were made on films prepared in polystyrene Petri dishes, and the thickest region at the wall of the Petri dish edge showed a blue-shifted iridescence. Their geometry is rather more complex than that of the sessile droplets reported above, because capillary forces tend to trap the liquid at the edge of the samples close to the wall of the dish, slowing up evaporation and allowing a decrease in pitch before final freezing in of the colors, resulting in a blue ring at the dish wall. The film in the bottom of the Petri dish shows the usual progression from red at the outside to blue in the center.

Conclusion

Droplets of aqueous CNC suspensions on a plane surface evaporate to give approximately circular iridescent films with concentric colored rings. For the suspensions and surfaces observed in this work, the radius of the droplets remains constant during evaporation. The ring structure is associated with a strong “coffee-stain” effect, involving mass transport of the rod-like CNC particles towards the edge of the evaporating droplet. This results in films whose outer region is many times thicker than the central region. The increased concentration of CNC in the outer region enhances the tendency of the suspension to “freeze-in” the chiral nematic pitch, thus generating longer wavelength reflection colors in the outer region (Fig. 6). It is also possible that some fractionation of the rod-like CNC particles occurs during evaporation, with the longer rods being more likely to form a gel at the edge of the droplet.

Rationale for ring color for CNC films formed by evaporation of pinned sessile drops. At edge of droplet a, evaporation-driven mass transfer causes an increase of CNC concentration, leading to thickening of the film, and to the onset of gelation, freezing in the chiral nematic pitch at red wavelengths. The initially depleted CNC concentration in the centre b allows the chiral nematic pitch to decrease to shorter wavelengths before the freezing-in of the pitch

In general, mass transfer and concentration gradients during film preparation will result in changes in chiral nematic pitch and helicoid orientation. Optimization of the wavelength, wavelength distribution and intensity of the reflected light from these potentially useful photonic materials is challenging.

References

Beck S, Bouchard J, Berry R (2011) Controlling the reflection wavelength of iridescent solid films of nanocrystalline cellulose. Biomacromolecules 12(1):167–172

Beck S, Méthot M, Bouchard J (2014) General procedure for determining cellulose nanocrystals sulfate half-ester content by conductometric titration. Cellulose. doi:10.1007/s10570-014-0513-y

Deegan RD, Bakajin O, Dupont TF, Huber G, Nagel SR, Witten TA (1997) Capillary flow as the cause of ring stains from dried liquid drops. Nature 389:827–829

Dugyala VR, Daware SV, Basavaraj MG (2013) Shape anisotropic colloids: synthesis, packing behavior, evaporation driven assembly, and their application in emulsion stabilization. Soft Matter 9(29):6711–6725

Dumanli AG, van der Kooij HM, Kamita G, Reisner E, Baumberg JJ, Steiner U, Vignolini S (2014) Digital color in cellulose nanocrystal films. ACS Appl Mater Interfaces 6(15):12302–12306

Lagerwall JPF, Schütz C, Salajkova M, Noh JH, Park JH, Scalia G, Bergström L (2014) Cellulose nanocrystalbased materials: from liquid crystal self-assembly and glass formation to multifunctional thin films. NPG Asia Mater 6(1):e80

Mu X, Gray DG (2014) Formation of chiral nematic films from cellulose nanocrystal suspensions is a two-stage process. Langmuir 30(31):9256–9260

Nobile C, Carbone L, Fiore A, Cingolani R, Manna L, Krahne R (2009) Self-assembly of highly fluorescent semiconductor nanorods into large scale smectic liquid crystal structures by coffee stain evaporation dynamics. J Phys Condens Matter 21(26):264013–264017

Onsager L (1949) The effects of shape on the interaction of colloidal particles. Ann NY Acad Sci 51(2):627–659

Querner C, Fischbein MD, Heiney PA, Drndić M (2008) Millimeter-scale assembly of CdSe nanorods into smectic superstructures by solvent drying kinetics. Adv Mater 20(12):2308–2314

Revol J-F, Godbout L, Gray DG (1998) Solid films of cellulose with chiral nematic order and optically variable properties. J Pulp Pap Sci 24(5):146–149

Acknowledgments

We thank Dr. Tiffany Abitbol for preparation of the CNC suspension, and Dr. H.P.T. Nguyen and the McGill Nanotools Microfab facility for the profilometry measurements. Funding from the Natural Sciences and Engineering Research Council Canada, and support from Fonds Québecois de la Recherche sur la Nature et les Technologies through the Center for Self-Assembled Chemical Structures is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mu, X., Gray, D.G. Droplets of cellulose nanocrystal suspensions on drying give iridescent 3-D “coffee-stain” rings. Cellulose 22, 1103–1107 (2015). https://doi.org/10.1007/s10570-015-0569-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0569-3