Abstract

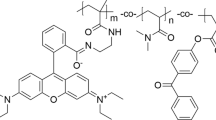

Wet strengthening of paper products is typically performed by thermo-crosslinking reactive polymers or polymer precursors. In this article we introduce a novel concept for generating wet-strength paper grades by using photoreactive polymers and light as the energy source. Statistical, hydrophilic copolymers of dimethylacrylamide and benzophenone-methacrylate monomer, respectively, were synthesised and surface-applied to model paper handsheets. Benzophenone, as a photoreactive group, was selected because of its high crosslinking efficiency when illuminated with UV light (365 or 254 nm). After photo-crosslinking of the polymer-modified handsheets, first results of mechanical testing showed a significant increase of the wet tensile strength. The wet strength is a function of the molar content of the photoreactive group (benzophenone) within the polymer, the mass of the polymer relative to the dry fibre, the wavelength of irradiation and the intensity of UV exposure. Hence, there are a number of options to control and modulate the wet strength of paper sheets between less than 2 % (relative to the dry strength of the paper sheet) up to more than 15 %. In comparison to commercially available wet strength additives, crosslinking can be achieved even in the presence of humidity (up to 10 % water in the handsheet by weight) and at room temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The strength of paper sheets in wet conditions is of utmost importance during paper processing and finishing as well as in many applications. With respect to the latter, wet strengthening of paper materials is relevant for a large number of paper grades, progressing from bank note paper, overlay and laminating paper, to wall and map paper, packaging paper, filter paper and the complete hygienic paper section such as toilet tissue, paper towels, handkerchiefs and napkins (Bates et al.1999; Hamm 1999). Wet strengthening is typically obtained using crosslinking polymer resins, and there are two proposed mechanisms explaining the wet-strengthening effect of a polymer resin in paper products. Homo-crosslinking means crosslinking of the resin itself and formation of a protecting resin shell (i.e. polymer network) around lignocellulosic fibre crossings (often called the “protection mechanism”). In contrast, co-crosslinking means crosslinking of the resin and lignocellulosic material within the paper sheet. By forming covalent bonds between the polymer additive and cellulose microfibres, chemically stable links are created that are resistant to hydrolysis under ambient conditions (i.e. neutral pH) and thus add strength to the paper sheet in wet conditions. This mechanism is often called the “reinforcement mechanism”. Because resins typically align around fibre crossing points because of capillary actions driving the precursor (macro) molecules into such grooves, additives can act as a reinforcement and a protection module at the same time.

The first synthetic additives used for wet strengthening of paper materials were based on chemically crosslinking formulations of formaldehyde and urea or melamine, respectively. In case of urea-formaldehyde resins, wet-strengthening effects are achieved only through homo-crosslinking, whereas wet strength performance of papers treated with melamine–formaldehyde resin is caused by homo- and co-crosslinking, respectively (Espy 1995). Although formaldehyde-based resin formulations have found widespread applications, these additives still also have some limitations. In order to achieve efficient chemical crosslinking, such resins need to be processed at low, acidic pH. The latter thus limits extended use in wet-end applications during paper making processes. Finally, nonreacted resin may cause formaldehyde emissions from the final product (Wallace 1988; Spence 1999).

Another important additive, which is frequently used to improve the wet strength of paper products, is based on poly(amidoamine-epichlorohydrin) (PAAE) resin. PAAE acts on the wet strength of paper via both protection and reinforcement mechanisms, respectively (Wagberg 2003; Lindstrom et al. 2005; Obokata and Isogai 2007). Because PAAE resins require epichlorohydrin reagents, such resins are detrimental to the AOX (adsorbable organic halide) load (Gorzynski and Emanuelsson 1996).

Although the above-mentioned wet-strengthening agents are widely applied in technology, a general limitation that all of these additives have in common concerns the use of thermal heat for crosslinking. Thus, enhancing the structural integrity of paper materials in wet conditions requires large amounts of energy. Because some of the reaction relies on a chemical condensation reaction, high levels of relative wet strength can only be accessed under harsh drying conditions, sometimes only if the paper web is dried to almost 0 % residual water content.

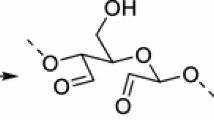

The formation of chemical bonds within polymeric precursor molecules or between a polymer and cellulose fibres may also be triggered by other energy sources, e.g. by light. In this respect, an interesting organic functional group that can be used in photo-chemical reactions is benzophenone. If irradiated by UV light at 365 or 254 nm, respectively, the benzophenone group undergoes an n-pi* (or pi-pi*) transition into a reactive triplet state. The latter chemically corresponds to a biradical, which can further react by an H abstraction/recombination mechanism with any kind of aliphatic C–H groups in close vicinity. If such benzophenone groups are being implemented into functional polymers, interesting new opportunities in designing chemically stable, crosslinked polymer layers at interfaces can arise. For example, such photoreactive polymers have recently been used for the immobilisation of polymer films on various substrates, including paper sheets (Turro 2009; Toomey et al. 2004; Böhm et al. 2013, 2014). Due to the prolonged half-life time of the formed biradical of more than 100 µs, excited benzophenone groups crosslink very efficiently to aliphatic groups that are close enough to the functional site (Prucker et al. 1999). The latter includes aliphatic groups present in the polymer itself as well as those present on the underlying interface to which the polymer is adsorbed. In a recent work, we showed that hydrophobic polymers carrying such benzophenone groups can be used for stable chemical conversion of paper sheets into microstructured papers that can be used as microfluidic devices (Böhm et al. 2013, 2014).

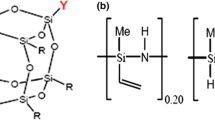

In the present article, we address the mechanical properties, in particular the wet strength of paper sheets, achieved by using photoreactive polymer additives and light as the source to crosslink lignocellulosic fibres within the paper sheet chemically. Figure 1 depicts a schematic illustration of the photo-crosslinking of a polymer within a fibre network and the chemical structure of the model polymer used. In a first set of experiments, we prepared and used statistical copolymers of poly(dimethylacrylamide-co-4-benzoylphenyl-2-methacrylate) (P(DMAA-co-MABP)) containing photoreactive benzophenone functions in a defined amount between 0 and 2 mol %.

The polymer was applied to preformed sheets by surface sizing, and the influence of the amount of applied polymer (relative to the amount of fibre), illumination time (i.e. UV doses) and amount of crosslinker inside the macromolecules on the resulting wet strength of the laboratory sheets was investigated. In addition, the influence of the photoreactive polymer on optical sheet properties and the hydrophobic sizing effects were investigated. Finally, we compare the wet strength of paper sheets in which the fibres were thermally crosslinked by a commercially available poly(amidoamine-epichlorohydrin) resin to photo-crosslinked paper sheets.

Experimental section

Pulp and refining

Pulp made of 80 % bleached eucalyptus kraft pulp (Fibria Aracruz DC) and 20 % bleached softwood kraft pulp (MReal Husum Kraft) was refined in a Voith laboratory refiner (LR 40, Germany). Virgin pulp had a ºSR of 17, measured according to ISO 5267-1. The dewatering resistance increased to ºSR 37 after refining. Refining was performed at a consistency of 4 % with a specific edge load (SEL) of 1 J/m and effective specific energy of 150 kWh/t.

Handsheet preparation

Handsheets were made on a conventional Rapid-Koethen handsheet maker according to DIN 54358 and ISO 5269/2. All sample sheets had a grammage of 80 ± 1 g/m2 and did not contain any additives or fillers. Polymers were applied as aqueous solutions to the sample sheets via sizing in a laboratory size press (Mathis laboratory size press). Polymer content related to dry fibre was calculated by the known consistency of the aqueous polymer solution and determination of the mass difference of the unsized sheet and sheet directly after the sizing step. After the size press all sheets were dried on a drum dryer (steel drum) at 120 °C with contact times of 130–160 s and stored at norm-climate conditions (23 °C, 50 % relative humidity) for at least 24 h or until further use.

Polymer synthesis

Homopolymer poly(dimethyl-acrylamide), P(DMAA) and copolymer poly(dimethylacrylamide-co-4-benzoylphenyl-2-methacrylate), P(DMAA-co-MABP(x)) were synthesised by free radical copolymerisation in solution according to procedures described in the literature (Berchtold 2005). Homopolymer P(DMAA) and copolymers having molar contents of MABP of x = 0.5, 1 and 2 %, respectively, were prepared. The molar content of MABP within the copolymer was confirmed by 1H-NMR. A representative example of the evaluation of the molar content of MABP within the copolymer by using NMR spectroscopy is shown in the supplementary information (Figure S1). The molar mass was confirmed by size exclusion chromatography (SEC) using a GRAM/1000/10µ/8*300 mm column and a poly(methyl-methacrylate) standard. Polymers having a typical molar mass (Mn) of 160.000 up to 300.000 g/mol were synthesised.

Characterisation of model paper by IR and SEM

Infrared spectra of polymer-modified paper substrates were recorded on a PerkinElmer Spectrum One FT-IR spectrometer equipped with a PerkinElmer single Universal Attenuated Total Reflectance (UATR; 10 scan resolution of 1 cm−1). SEM photomicrographs were captured using a Phillips XL30 FEG scanning microscope operated at an acceleration voltage of 10 kV.

UV light exposure

Polymer-treated paper samples were exposed to UV light of 254 or 365 nm wavelength in a UV chamber (Vilber, Germany) in order to induce the excitation of the photoreactive benzophenone group and therefore to induce the crosslinking of the polymer. One half-time energy dose (E½) means that 50 % of the benzophenone groups have been transferred to an excited state. Note that due to the scattering of the light within the paper sheet, the latter can only be taken as an estimate. The corresponding light energy to one half-time energy dose (E½) depends on the wavelength of the UV light; 1 E½ of 365 nm wavelength is equal to 4 J/cm2; 1 E½ of 254 nm wavelength is equal to 0.1 J/cm2. The corresponding values are summarised in Table 1.

Tensile measurements

Dry tensile strength was determined as an average of ten measurements on a Zwick tensile strength machine based on DIN ISO 1924-2 in a surrounding standard atmosphere at 23 °C and 50 % humidity. Wet tensile strength measurements were performed after 5 min soaking time in deionised water on the same Zwick tensile strength machine. Examples of the original data of the tensile measurements are shown in the supplementary information (Figure S2). The parameter “wet tensile strength” corresponds to a 1.5 cm width of sample strips and “wet tensile index” values are derived from wet tensile strength figures, in addition taking into account the grammage of 80 g/m2. Relative wet strength was calculated by dividing the absolute wet strength by the dry strength of an equal sample, according to the following equation:

Measurements of the sizing degree

Ultrasonic penetration measurements were performed on a penetration dynamics analyser (PDA.C Emtec, Germany). The diameter of the measuring surface circle was 35 mm and the frequency of ultrasonic waves was set to 2 MHz. All values are an average of two measurements.

Measurements of optical properties

Optical properties of model papers were determined by measuring the a and b values. The measurement was performed on an Elrepho 2000 datacolor type 457.04, no. 143.

Results and discussion

Characterisation of handsheets

Laboratory sheets having a typical grammage of 80 g/m2 were prepared from dry softwood and eucalyptus pulp, and the P(DMAA-co-MABP) copolymer as well as P(DMAA) homopolymer was applied, respectively, to the laboratory sheets using a size press. After drying the sheets and crosslinking of the polymers by UV-light irradiation at room temperature, the polymer-containing paper sheets were first investigated with respect to their chemical identity using FTIR spectroscopy. Figure 2 shows the FTIR spectra taken from the surface of laboratory sheets with different amounts of polymer applied to the paper relative to the amount of fibres. From the spectra it can be inferred that an increase in the concentration of the polymer relative to the dry fibre corresponds to the intensity of the absorption band at 1,630 cm−1, which is related to the carbonyl stretching vibration of the dimethylacrylamide function of the polymer. Hence, FT-IR measurements of untreated and treated model papers prove the presence of the polymer on the paper surface.

In a next step, we investigated whether the polymer application has an influence on the morphology of the laboratory sheets. For this, scanning electron microscopy (SEM) pictures were taken from modified and unmodified paper substrates, respectively.

As can be inferred from Fig. 3, the porous structure and morphology of the paper sheets are not affected by addition of the polymer. Even at a polymer concentration of 2.1 wt% relative to dry fibre, no significant alterations can be observed regarding the surface structure and cross-section properties.

Variation of intensity of UV exposure

In order to obtain a significant wet strength, it is a crucial requirement to crosslink the polymers inside the laboratory sheets sufficiently. As explained above, the amount of excited photoreactive benzophenone groups that can form crosslinks between the polymer and the fibres inside the sheet is directly linked to the UV exposure. Therefore, we investigated the influence of UV exposure on the resulting wet strength development of the sample paper. Laboratory sheets were prepared as described above, and the copolymer containing about 1 mol % of crosslinker was applied to the surface. The amount of polymer transferred to the paper sheets was 0.95 % relative to the fibre. After drying, the sheets were placed in a UV chamber and irradiated from one side with variable UV exposures of 0–16 J/cm2 at two different wavelengths (254 and 365 nm). In order to investigate also the effect of double-sided illumination, another series of sheets were prepared accordingly and illuminated from both sides consecutively.

Figure 4 shows the wet tensile strength and wet tensile index, respectively, as a function of the UV exposure. Note that double-sided illumination was implemented within the same graph for comparison. Without UV light exposure, the wet tensile strength and the wet tensile index were measured to 0.2 kN/m and about 2 Nm/g, respectively. A significant increase of the wet tensile strength to about 0.5/0.6 kN/m was observed after UV irradiation of polymer-modified paper at UV exposures exceeding 8 J/cm2 (365 nm) and 0.2 J/cm2 (254 nm). Two-sided UV exposure results in slightly but not significantly higher wet strength values. The observed wet tensile strength corresponds to a “relative wet strength” in the range of 14 to 16 %. Furthermore, no significant influence of the used wavelength (254 or 365 nm) on the resulting wet tensile strength was observed. Hence, lower energy UV light is also suitable for photochemical crosslinking of the copolymer within the paper sheet. Note that the time necessary to achieve (i.e. apply) 1 E½ is much lower in case of an exposure at 254 nm (4 min) compared to an exposure at 365 nm (20 min). Considering this time difference for excitement of about 50 % of the benzophenone units within the paper sheet, we decided to stay with UV exposure at 254 nm in subsequent experiments.

Wet tensile strength (left y-axis) and wet tensile index (right y-axis) as a function of the exposure at 365 nm (black squares) and 254 nm (grey circles), respectively, after sizing with aqueous solution of P(DMAA-co-MABP(1 %)) at a concentration of 2 % by weight (0.95 wt% polymer relative to dry fibre)

Next, we reduced the UV exposure to the possible minimum working with our UV chamber in order to investigate the wet strength of paper sheets crosslinked at very low UV exposures. Figure 5 shows the wet tensile strength of a paper sheet as a function of the UV exposure. Already at an exposure of 0.005 J/cm2, a significant increase of wet tensile strength to about 0.4 kN/m was observed, corresponding to about 11 % relative wet strength. Here 0.005 J/cm2 at 254 nm is equivalent to about 13-s UV exposure in the UV chamber, i.e. already after this very short time of UV irradiation significant wet strengthening of paper sheets can be achieved.

Variation of molar content of MABP within the copolymer

As a next step, copolymers containing different molar amounts of the photoreactive unit MABP were prepared and the influence of the amount of MABP in the polymer (i.e. in the paper sheet) on the resulting wet tensile strength was investigated. Copolymers P(DMAA-co-MABP(x)) having 0.0 [i.e. reference P(DMAA) homopolymer], 0.5, 1 and 2 mol % MABP, respectively, were applied to model paper sheets. In order to determine the maximum effect on strength development of copolymers, UV exposures of 0.4 J/cm2 (254 nm) and 16 J/cm2 (365 nm), which equals 4 E1/2, were chosen during the illumination step. Figure 6 shows the wet tensile strength and wet tensile index as a function of the amount of crosslinker (MABP) in the applied copolymers after UV exposure at 254 and 365 nm given in the graph.

Wet tensile strength (left y-axis) and wet tensile index (right y-axis) as a function of the content of MABP within the copolymer used in surface sizing (1.36 wt% P(DMAA-co-MABP(0.5)) relative to dry fibre weight; 1.23 wt% P(DMAA-co-MBP(1.0)) relative to dry fibre; 1.0 wt% P(DMAA-co-MABP(2.0)) relative to dry fibre). Paper sheets were exposed to 254 nm (grey circles) and 365 nm (grey triangles), respectively. Nonexposed paper sheets (black squares) are shown superimposed to the data as reference

First, we measured the wet tensile strength and wet tensile index as a function of the amount of the photoreactive MABP group with paper sheets that were not exposed to UV light (black squares in Fig. 6). It was observed that model paper sized with a copolymer without UV exposure did not show any increase of the wet tensile strength within the experimental error, regardless of the amount of photoreactive crosslinker in the copolymer. Another important reference experiment concerns polymers that do not carry any photoreactive group respectively homopolymer PDMAA of the same range of molar mass as the copolymers. UV irradiation after sizing paper sheets with this reference polymer did not result in any increase of the wet tensile strength or tensile index. The latter is also independent of the applied doses as well as of the chosen wavelength of the UV light (see Figure S3, supplementary information), respectively. In all reference experiments, wet tensile strength was measured to 0.1–0.2 kN/m and the wet tensile index was about 2 Nm/g, respectively.

Next, we measured the tensile strength/tensile index of UV-exposed papers that were sized with copolymers carrying different amounts of the photoreactive group prior to the UV irradiation. From Fig. 6 it can be inferred that with increasing amounts of the MABP function in the copolymer, the wet tensile strength increased to about 0.6–0.8 kN/m, and the wet tensile index increased accordingly to about 8–10 Nm/g. A molar content of 0.5 mol % MABP in the copolymer already resulted in a wet tensile strength/wet tensile index of about 0.6 kN/m and 6 Nm/g, respectively. The latter corresponds to a relative wet strength of more than 13 %. If the amount of photoreactive group in the copolymer is further increased up to 2 mol %, a further increase of the latter parameter is observed; 0.5 mol % cross-linker corresponds to about 200 benzophenone groups, whereas 2 mol % corresponds to about 800 benzophenone groups in the copolymer, respectively. At 4 E1/2 more than 96 % of these groups had been excited by the UV light. Hence, already with copolymers having 0.5 mol % MABP, it is expected that a very large number of crosslinks will be formed, and a further increase of the amount of crosslinks may not affect further strength development inside the sheets. Note that at present we do not know the exact number of crosslinks formed, as an excited MABP group may undergo a number of reactions, including the formation of crosslinks inside the polymer itself, and chemical links to the fibres. More detailed analysis of this crosslinking reaction within paper sheets will be carried out in follow-up experimental investigations. Finally, the results do also not exclude that a small amount of homopolymer is being covalently bonded to the cellulose or is crosslinked within the paper sheet by treatment with high-energy photons. However, if the results of the reference homopolymer are compared to the results using the photoreactive copolymer, it can be stated that the photoreactive benzophenone is exclusively responsible for the highly significant increase of the wet tensile strength up to 0.8 kN/m.

Surface sizing effect

Besides homo- and co-crosslinking, hydrophobic moieties inside paper sheets may also cause an increase of wet strength. Because the used copolymers carry a small number of hydrophobic groups (benzophenone), we were interested in investigating the sizing effects of the copolymer. The higher the molar MABP content within the copolymer is, the more hydrophobic its character, and hence the water solubility decreases. In order to investigate whether the copolymers act as a sizing agent, ultrasonic penetration analysis was carried out. The t60 value was chosen as a qualitative measure for water penetration behaviour into the paper web. This parameter equals the time in seconds to reach 60 % of the primal ultrasonic intensity once the measurement has started. The higher the t60 value is, the higher the sizing degree of the paper sample. Model papers were prepared as outlined above, and copolymers having different amounts of 0 mol % (no polymer), 0.5, 1.0 and 2.0 mol % benzophenone, respectively, were applied to the paper sheets by surface sizing. Figure 7 shows the t60 value as a function of the molar amount of MABP within the applied copolymers for UV-unexposed (grey squares) and UV-exposed model paper (grey circle: exposed to 254 nm; black triangle: exposed to 365 nm). In a first set of experiments, the model papers were measured with respect to the t60 value without UV-linking of the polymer to the paper (grey squares). It can be seen that the t60 value increases with increasing hydrophobicity of the polymer, i.e. with increasing MABP content, from 0.2 to about 1.2 s. Because the polymer is only physically adsorbed to the paper, aqueous solutions penetrating the paper web will partly dissolve the polymer, and hence the viscosity will increase. Increasing viscosity is known to slow down the penetration dynamics of the solutions, which will thus lead to a slight increase of the t60 value. However, 1.2 s is still a very short time as compared to other surface-sized papers. Standard copy papers for example are in the range of 35 to 60 s of t60.

The t60 values as a function of the molar content of MABP in the polymer at different wavelengths and exposures: 0.4 J/cm2, 254 nm (grey circles) and 16 J/cm2, 365 nm (black triangles), respectively, after sizing with aqueous solutions of P(DMAA-co-MABP) at a concentration of 2 % (1.36 wt% P(DMAA-co-MABP(0.5 %)) relative to fibre weight; 1.23 wt% P(DMAA-co-MABP(1 %)) relative to dry fibre; 1.0 wt% P(DMAA-co-MABP(2 %)) relative to dry fibre. Data from nonexposed, polymer-loaded paper sheets are superimposed in the graph as grey squares

If the polymer is covalently linked to the model paper prior to the measurements of the t60 values, we observed that this value did not change, independently of the amount of MABP in the copolymer. It stayed constant at values well below 0.5 s. Hence, an increase of wet strength resulting in an accretive hydrophobicity of the paper can therefore be excluded.

Effect on optical properties

Optical properties of paper products are very important with respect to the colour and brightness of high-quality printing papers, tissue grades and also some speciality paper grades. Since crosslinking of photoreactive polymers within the paper sheets was performed by UV irradiation, the influence of UV exposure on the colour of the paper sheets was investigated. As a reference, an unexposed sheet containing no additive and no polymer was measured.

The relative shifts of the a and b value of different sample sheets are shown in Fig. 8. The initial colour value of the nonexposed and nonpolymer-modified model paper is −0.37 a value and 0.74 b value. Paper samples that contain no polymer and no additives exposed to 365 nm result in a shift to greenish of 0.14 and to yellowish of 1.0. Irradiation with 254 nm gives a stronger shift to greenish of 0.35 and to yellowish of 2.3. The influence of the photoreactive polymer on the colour shift was also investigated. Applying the photoreactive polymer P(DMAA-co-MABP(1 %)) on the sample sheet results in a slight colour shift to green (0.01) and yellow (0.16). This trend of colour shift grows with UV irradiation time and with lower irradiation wavelength. Exposition to UV light of 365 nm results in a shift to greenish of 0.15 (at 254 nm of 0.45) and to yellowish of 1.14 (at 254 nm of 3.05), respectively. As UV irradiation influences the colour of paper products, wet strengthening by photo- crosslinking polymers within the paper sheet will be limited to paper grades that do not have high prerequisites on optical properties.

Influence of polymer concentration on wet strength

One important value that affects the quantity of wet strength of a paper sheet gained by crosslinking the fibres with appropriate polymer additives is the amount of polymer applied to the paper sheet relative to dry fibre (weight). In order to learn about the effect of varying amounts of photo-crosslinked polymers on the resulting wet strength, we prepared model papers that were surface sized using different amounts of copolymer carrying 1 mol % of the MABP crosslinker. The quantity of the wet tensile strength/tensile index was measured as outlined previously. Figure 9 shows these parameters as a function of the applied polymer concentration relative to the dry fibre weight. Wet strength was evaluated after two-sided exposure to 254 nm UV light (black squares).

Wet tensile strength (left y-axis) and wet tensile index (right y-axis) as a function of the weight content of copolymer within the paper after sizing with (1) aqueous solutions of P(DMAA-co-MABP(1 %)) and exposure at 254 nm (black squares) and (2) surface sizing of aqueous solutions of PAAE and subsequent curing via contact drying on a steel drum dryer at 120 °C for 158 s (grey circles)

Model papers that had no polymer implemented exhibited a wet tensile strength and wet tensile index of about 0.15 kN/m and 1.88 Nm/g, respectively, after UV exposure. If the amount of polymer inside the paper is increased from about 0.2 wt% to more than 1 wt% (relative to dry fibre weight), the wet tensile strength and wet tensile index steadily increased to more than 0.7 kN/m and 8.75 Nm/g, respectively. Already 0.5 wt% polymer within the sheet resulted in a gain in wet tensile strength of about 0.4 kN/m. The gain in wet strength, as observed here, corresponds to a relative wet strength in comparison to dry model paper of about 14 % for surface-sized model papers having 1 wt% polymer relative to the dry fibre weight (for details see supplementary information S4).

In a final set of experiments, we were interested in comparing the wet strength of model papers gained by photo-attachment of the new copolymers to similar model papers treated with commercially available wet strength agents crosslinked by thermal treatment. With respect to the latter, we chose poly(amidoamin-epichlorohydrin) (PAAE) resin as a model because it is used as wet strength additive in a number of technologically important paper grades. This additive is typically crosslinked inside paper by applying temperatures well above 100 °C. In our model experiment, we applied PAAE at concentrations between 0.1 wt% and about 1.5 wt% relative to dry fibre weight. After surface sizing the PAAE-loaded model papers were cured via contact drying on a steel drum at 120 °C and a contact time of 158 s. This procedure represents an artificial curing step of the wet-strengthened paper. The wet tensile strength and wet tensile index of the model papers were measured as outlined above, and they are shown as a function of the applied amount of polymer in Fig. 9, too. Similarly to the photo-crosslinked model papers, the thermally treated paper sheets show a steady increase of the wet tensile strength and wet tensile index, which is very similar to the wet strength obtained through photo-attachment. However, if the P(DMAA-co-MABP) copolymers are used, wet-strengthening effects are achieved at room temperature and in the presence of humid air (norm-climate conditions, 23 °C, 50 % relative humidity).

Since the dry strength is also a very important parameter besides the wet strength properties of the sample papers, some investigations were carried out. At low concentrations, a small decrease in dry tensile strength can be observed possibly due to the size press application step. A further increase of the polymer content within paper sheets results in a small but still not significant increase of the dry strength. In general, it can be stated that with increasing MABP content within the paper sheet, and with increasing intensity of UV exposure, the dry strength increases (a graph is included in the supplementary information S5).

Conclusion

First results of a novel, innovative approach to wet strengthening of paper by light as an energy source have been presented. Wet strengthening was realized and attested to the crosslinking of photoreactive copolymers P(DMAA-co-MABP) within the paper sheet by exposure to UV light of 254 or 365 nm wavelength. Reference experiments performed with analogous homopolymer P(DMAA) showed no significant increase of wet strength. In addition, no increase of the degree of sizing of model paper treated by P(DMAA-co-MABP) was observable. Applying about 1 wt% copolymer related to dry fibre resulted in a significant increase of wet tensile strength by 700 % regardless of the molar content of MABP within the polymer. The latter was kept in the range of 0.5 up to 2 mol %, respectively. The intensity of UV exposure, which determines the rate of excitation of the photoreactive benzophenone groups, and thus influences the rate of crosslinking, proved to be a key parameter as well. An exposure intensity of only 0.005 J/cm2 at 254 nm, which is equivalent to about 13-s exposure time in our UV chamber, was enough to significantly increase the wet tensile strength by 400 %.

UV irradiation has an influence on the resulting colour of the paper sheet. Both higher irradiation energy and smaller wavelength UV light result in larger colour shifts to more yellow-coloured paper sheets. Since crosslinking relies on the close vicinity of an excited benzophenone and an aliphatic C–H group within the lignocellulosic network, we can assume that both homo- and co-crosslinking mechanisms contribute to the wet-strengthening effect. Taking into account that many more lignocellulosic C–H groups compared to C–H groups originating from the polymers P(DMAA-co-MABP(x)) are present within the paper sheet, and that the photo-crosslinking mechanism can be considered “nonspecific”, one can conclude that the main effect of wet strengthening is caused by co-crosslinking (i.e. reinforcement mechanism).

The possibility of applying the photoreactive copolymer to paper products regardless of the system or production parameters of paper machine processes is of great advantage. Fibre crosslinking can be achieved with photoreactive polymers at room temperature, even in the presence of significant amounts of water, thus providing a measure to further reduce energy consumption during wet-strength development. Our research will next focus on a fundamental understanding of wet-strength properties of photo-crosslinked paper sheets on a molecular scale, and we will report on these findings in future communications. Another benefit of our approach concerns a further reduction of the AOX load of the effluent if such photoreactive polymers are used instead of the presently relevant epichlorohydrin-based polymer systems. Finally, by using photoreactive copolymers, functional elements can be easily implemented onto/into paper materials to result in chemically and thermally stable sheets, useful for the future design of sustainable high-tech (at low cost) materials for various applications.

References

Bates R, Beijer P, Podd B (1999) Wet strengthening of paper. Papermaking Science and Technology 4. Papermaking chemistry, chapter 13, pp 288–301

Berchtold B (2005) Oberflächengebundene Polymernetzwerke zur Re-Endothelialisierung von porcinen Herzklappenbioprothesen. PhD Thesis, Albert-Ludwigs Universität

Böhm A, Gattermayer M, Trieb C, Schabel S, Fiedler D, Miletzky F, Biesalski M (2013) Photo-attaching functional polymers to cellulose fibers for the design of chemically modified paper. Cellulose 20(1):467–483

Böhm A, Carstens F, Trieb C, Schabel S, Biesalski M (2014) Engineering microfluidic papers: effect of fiber source and paper sheet properties on capillary-driven fluid flow. Microfluid Nanofluid 16(5):789–799

Espy HH (1995) The mechanism of wet-strength development in paper: a review. Tappi J 78(4):90–99

Gorzynski M, Emanuelsson J (1996) Development of environmentally friendly neutral wet-strength agents. Trans Papermak Conf Phila 459–473

Hamm U (1999) Wet strength resins in hygienic paper production. Proceedings of TAPPI `99 Preparing for the next millennium, vol 2. Atlanta, USA, pp 829–839

Lindstrom T, Wagberg L, Larsson T (2005) On the nature of joint strength in paper: a review of dry and wet strength resins used in paper manufacturing. Transactions of 13th fundamental research symposium 457–562

Obokata T, Isogai A (2007) The mechanism of wet-strength development of cellulose sheets prepared with polyamideamine-epichlorohydrin (PAE) resin. Colloids Surf 302(1–3):525–531

Prucker O, Naumann CA, Rühe J, Knoll W, Frank CW (1999) Photochemical attachment of polymer layers to solid surfaces via monolayers of benzophenone derivatives. J Am Chem Soc 121(38):8766–8770

Spence GG (1999) Wet and dry strength additives—application, retention and performance. Tappi Press, Atlanta, USA

Toomey R, Freidank D, Rühe J (2004) Swelling behavior of thin, surface-attached polymer networks. Macromolecules 37(3):882–887

Turro NJ (2009) Principles of molecular photochemistry: An introduction. University science books, Herndon, USA

Wagberg L (2003) On the mechanisms behind the action of dry and wet strength agents. Transactions of 5th international paper and coating chemistry symposium 281–284

Wallace PD (1988) Urea-formaldehyde resins. Transactions of Nonwoven Binders and Additives Seminar, Boston, p p 6

Acknowledgments

The authors wish to thank Martina Ewald and Heike Herbert for valuable technical support. Financial support from the Verband der Deutschen Papierindustrie (VDP) within the INFOR programme (MAP154, MAP164) is gratefully acknowledged. The work was funded in part by the Bundesministerium für Wirtschaft und Energie (BMWi) under AiF-IGF Grant No. 17919 N “PhoreNast”.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Jocher, M., Gattermayer, M., Kleebe, HJ. et al. Enhancing the wet strength of lignocellulosic fibrous networks using photo-crosslinkable polymers. Cellulose 22, 581–591 (2015). https://doi.org/10.1007/s10570-014-0477-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0477-y