Abstract

A new amino-terminated hyperbranched polymer (at-HBP) was synthesized, and its salt-free dyeing property on ramie fabric was studied. The structure and molecular weight of at-HBP were established by Fourier transform infrared spectrometer, H nuclear magnetic resonance and gel permeation chromatography. The untreated ramie fabric and modified ramie fabrics were characterized by an X-ray diffraction (XRD) and field emission scanning electron micrograph (FE-SEM). XRD results showed a transformation of the crystalline structure from ramie cellulose I to cellulose II allomorph during mercerization and epichlorohydrin modification, and the crystalline structure of cellulose II was maintained with an obvious crystallinity index increase after at-HBP modification. FE-SEM results confirmed that at-HBP was successfully grafted onto the fabric surface. Dyed with reactive dye C.I. reactive Blue 4, the color strength of the at-HBP-modified fabric was enhanced, even when dyeing was carried out without the electrolyte. The washing and rubbing fastness of the salt-free dyeing of fabrics was also good compared with those obtained by conventional dyeing. The adsorption isotherm of C.I. reactive Blue 4 on modified fabric was examined and found to follow a Langmuir-type adsorption model. The at-HBP modification mechanism of ramie fabric and dyeing mechanism with reactive dye were suggested.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In current practice, reactive dyes are predominantly used for dyeing of cellulose fabric because of their high wet fastness, brilliancy and wide range of hue. Traditionally, when dyeing cellulose fabric with reactive dyes, it has been necessary to use a large amount of salt (NaCl or Na2SO4) to facilitate the migration of dyes from the bath to the fabric surface and consequently improve dye uptake and fixation. The usage of the salt is usually 30–150 g/l, and it often causes heavy environmental pollution (Tam et al. 1997; Liu et al. 2006).

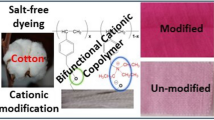

With increasing awareness of environmental pollution and ever more stringent regulations, the textile industry is continuously looking for environmentally benign processes to replace the existing dyeing methods (Zheng et al. 2012). Over the past few years, salt-free/low-salt dyeing technology has become a popular subject for environmentally benign dyeing processes (Hauser and Tabba 2001; Montazer et al. 2007; Ma et al. 2005; Zhang et al. 2007a, b; Zhang et al. 2005). Chemical modification of cellulose is a general method to allow a salt-free/low-salt dyeing process for cotton and ramie fabric (Xie et al. 2008; Zhang et al. 2008a, b; Wang et al. 2009a, b).

Ramie fabric, mainly composed of cellulose, is widely used in the textile industry because of its excellent properties of hygroscopicity, air permeability, having no static electricity, etc. However, its poor dyeability and spinnability limit its industrial application (Pandey 2007).

Chemical modification of ramie fabric to improve its dyeing properties has been studied comprehensively (Kalia et al. 2009; Chen and Jin 2006; Mormann and Michel 2002; Liu et al. 2007; Renfrew and Phillips 2003; Lim and Hudson 2004; Orden and Urreaga 2006; Liu et al. 2008). To our knowledge, the salt-free/low-salt dyeing process of ramie fabric has rarely been studied.

In recent years, a hyperbranched polymer, with a novel three-dimensional dendritic structure, high density of functional terminal groups, and low viscosity, has been considered an important developmental direction in the field of polymer science (Gao and Yan 2004). Because of its unique chemical and physical properties, the hyperbranched polymer exhibits broad perspective applications in additives, macromolecular building blocks and heavy metal ions adsorption (Ma et al. 2009; Li et al. 2011). The amino-terminated hyperbranched polymer (at-HBP), as one of the most important hyperbranched polymers, has several excellent characteristics, such as low viscosity, good solubility, and containing many reactive imino groups and terminal primary amino groups.

Zhang et al. (Zhang et al. 2008a, b, 2007a, b) synthesized a new water-soluble amino-terminated hyperbranched polymer (HBP-NH2) from methyl acrylate and diethylene triamine by melt polycondensation, and the performance of cotton fabrics modified with this amino-terminated hyperbranched polymer (HBP-NH2) was thoroughly studied. The results showed that the amino-terminated hyperbranched polymer can be used as a salt-free auxiliary in reactive dyeing on raw cotton fabric or sodium periodate oxidized cotton fiber. In addition, the treated cotton fabric showed good antimicrobial activities against Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli). The study of the antiultraviolet properties of the treated cotton fabric indicated that the HBP-NH2 contributed to a reduction of ultraviolet (UV) transmission and an increase of the ultraviolet protection factor (UPF).

In this article, a new amino-terminated hyperbranched polymer, synthesized from diethyl malonate, methyl acrylate, and diethylenetriamine by a two-step procedure, was used for the salt-free dyeing process on ramie fabric. The structure and molecular weight of the amino-terminated hyperbranched polymer were determined using FT-IR, 1HNMR and GPC. The untreated ramie fabric and modified ramie fabrics were characterized by X-ray diffraction (XRD) and field emission scanning electron micrographs (FE-SEM). Color measurement (K/S values), washing fastness, rubbing fastness of at-HBP-modified ramie fabrics and the adsorption isotherm of C.I. reactive Blue 4 on modified ramie fabrics were studied.

Experimental

Materials

Diethyl malonate, methyl acrylate, diethylenetriamine, epichlorohydrin, sodium hydroxide, sodium bicarbonate and sodium chloride were provided by Shanghai Chemical Co., Ltd.

Plain woven 100 % ramie fabric (260 g/m2) was supplied by Huayu Co., Ltd. (Zhejiang, China). All the fabrics were bleached and scoured. Reactive dyes 1 and 2 were supplied by Ciba Dyestuffs Co., Ltd.; reactive dyes 3, 4, 5 and 6 were obtained from Jiangsu Shenxin Dyestuffs & Chemicals Co., Ltd. (Jiangsu, China). All reactive dyes were used as received. They are listed in Table 1, and their structures are given in Fig. 1. All the reactive dyes were dichlorotriazines (dye 1,2 and 3) or monochlorotriazines (dye 4,5 and 6). The majority of experiments were carried out using Reactive Brilliant Blue X-BR (C.I. reactive Blue 4).

The amino-terminated hyperbranched polymer, shown in Fig. 2, was synthesized in the laboratory with diethyl malonate, methyl acrylate and diethylenetriamine as raw materials.

Preparation of the amino-terminated hyperbranched polymer (at-HBP)

Synthesis of tetracarboxylic ester

First, 70 ml petroleum ether, 2 g PEG1000, 3 g anhydrous potassium carbonate and diethyl malonate (30 ml, 0.2 mol) were added to a 500-ml, four-neck, round-bottomed glass flask equipped with a stirrer, thermometer and condensing pipe. Then methyl acrylate (40 ml, 0.44 mol) was slowly dropped into the mixture. The mixture was refluxed for 6 h. Then the mixture was cooled, and the solid crude tetracarboxylic ester was filtered. The crude tetracarboxylic ester was recrystallized with ethyl acetate to obtain tetracarboxylic ester (m.p 45–47 °C; Wang et al. 2009a, b).

Preparation of the amino-terminated hyperbranched polymer (at-HBP)

Diethylene triamine (45 ml, 0.42 mol) was added to a 500-ml, four-neck, round-bottomed glass flask equipped with a constant-voltage dropping funnel, thermometer and nitrogen inlet tube. Then tetracarboxylic ester (33 g, 0.1 mol) in methanol (100 ml) was added dropwise into the flask. The mixture was stirred for 3 h at 45 °C and transferred to an eggplant-shaped flask with an automatic rotary vacuum evaporator (Shanghai Yarong Co.). The mixture was maintained for 4 h at 70 °C under low pressure to remove the methanol and ethanol until the yellow, viscous liquid, amino-terminated hyperbranched polymer (at-HBP), was obtained. The synthesis procedure is outlined in Fig. 2.

Mercerization and crosslinking of ramie fabrics

Ramie fabric (5 g), dried for 24 h at 60 °C before use, was put into a four-mouth flask equipped with a magnetic stirring bar. A mixture of 15 % sodium hydroxide (60 ml) and epichlorohydrin (6 ml) was added. The mercerization and crosslinking were conducted at 50 °C for 5 h. Then the treated ramie fabric was washed with deionized water to pH = 7.0 and dried at 60 °C.

Treating condition of ramie fabric with the amino-terminated hyperbranched polymer (at-HBP)

Mercerized and crosslinked ramie fabrics were padded with the aqueous solution of the amino-terminated hyperbranched polymer (at-HBP; 15 g/l) and sodium bicarbonate (8 g/l) using a laboratory P-AO padder (Ningbo textile instrument factory, China) at 100 % wet pick-up. The padded fabrics were dried at 80 °C for 5 min and then cured in a Mini Rapid XC-32 dryer (Xiamen Rapid Co., Ltd.) at 160 °C for 3 min. The treated ramie fabrics were rinsed thoroughly in hot water for 5 min to remove unfixed materials and air-dried at room temperature.

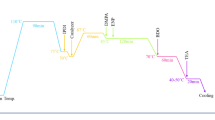

Dyeing procedures

As the supplied ramie fabrics (untreated or control ramie fabrics) and at-HBP-modified ramie fabrics were dyed with C.I. reactive Blue 4 and five other reactive dyes using a liquor ratio of 30:1. The dye dosage was 2 % (owf) for dyes 1, 2 and 3 and 3 % (owf) for dyes 4, 5 and 6 respectively. Salt-free dyeing of the at-HBP-modified ramie fabrics was commenced at 30 °C for dye 1, 2 and 3 and 45 °C for dye 4, 5 and 6, respectively, and kept at this temperature for 40 min. Then fixation was conducted for 30 min using sodium carbonate (20 g/l) at 60 °C for dye 1, 2 and 3 and 80 °C for dye 4, 5 and 6, respectively. Conventional dyeing on the untreated ramie fabric was followed the procedures recommended by the dye manufacturer in the presence of sodium chloride (60 g/l) and sodium carbonate (20 g/l) for dye fixation. After dyeing, the dyed fabrics were rinsed thoroughly in hot water and soaped in a soap solution (5 g/l soap powder) at 90 °C for 5 min, then rinsed thoroughly and air-dried.

Characterization of the tetracarboxylic ester and amino-terminated hyperbranched polymer (at-HBP)

FT-IR spectra of the tetracarboxylic ester and amino-terminated hyperbranched polymer (at-HBP) in KBr pellets were obtained with a Nicolet AUV360 spectrometer (Thermo Fisher Scientific Inc., USA). An approximately 2-mg sample was mixed with 200 mg KBr (spectroscopic grade), and FT-IR spectra were recorded in the range of 4,000–400 cm−1 at a resolution of 4 cm−1 with 32 scans per sample.

1HNMR spectra were recorded on the AVANCE AV-300 or AVANCE AV-500 (Bruker Co., Ltd., Germany) operating at 400 or 500 MHz, and chemical shifts were given in ppm units relative to tetramethylsilane (TMS). The splitting patterns were designated as follows: s, singlet; d, doublet; t, triplet; q, quartet; m, multiplet.

The viscosity of the amino-terminated hyperbranched polymer (at-HBP) was tested using an NDJ-7 rotational viscometer at 25 °C (Shanghai Tianping Instrument Co., Ltd., China). Gel permeation chromatography (GPC) of the amino-terminated hyperbranched polymer (at-HBP) was carried out on an Agilent 1200 series, with a column (TSKgel G3000PWXL column, 7.8 × 300 mm, Tosoh, Japan) using 0.3 M Na2SO4 (pH was adjusted to 4.0 with acetic acid) as the eluent at a flow rate of 0.5 ml/min. The effluent was monitored by a UV detector at 215 nm. The molecular weights were calculated based on polyethylene glycol standards.

XRD diffraction for ramie fabrics

XRD patterns of control ramie fabric and modified ramie fabrics were recorded from 2θ = 10°–60° with a Bruker D8 Advance XRD diffractometer (Bruker Co., Ltd., Germany) equipped with a graphite monochromator and Cu Kα radiation at λ = 0.154 nm (50 kV, 40 mA). The ramie fabrics were cut with scissors to lengths as short as possible, then ground in a Wiley mill to pass through a 20-mesh screen. For each sample, approximately 0.1 g ramie cellulose powder was compressed into a specimen holder (26 × 26 mm).

Diffraction profiles of the samples were fitted with MDI Jade 5.0 software using separate diffraction peaks, and subsequent integration was performed on each peak. The crystallinity index (CI) of samples was determined by the peak separation program of MDI Jade 5.0 software following the equation (Wong et al. 2009; Wang et al. 2007):

where A crystal is the sum of the areas under the crystalline diffraction peaks and A total represents the total area under the diffraction curve between 2θ of 10°–60°.

The crystallite size of each sample, ω (nm), was calculated by the Scherrer equation (Liu et al. 2010; Han et al. 2013):

where θ is the diffraction angle, K = 0.94 (correction factor), λ = 0.154 nm, and β is the peak width in radians at half maximum height (peak FWHM).

FE-SEM detection for ramie fabrics

FE-SEM photomicrographs of control ramie fabric and modified ramie fabrics were recorded with an Ultra 55 field emission scanning electron microscope (Carl Zeiss SMT Pte, Ltd., Germany) at an accelerating voltage of 20 kV. The free surfaces were coated with thin layers of gold before observation.

Measurement of the K/S value

The color strength (K/S value) was measured by a computer-assisted predicting instrument, Datacolor 600 (Datacolor Co., Ltd., USA).

Fastness testing

Washing fastness tests were performed according to GB/T 3921-2008(Textiles—Tests for color fastness–color fastness to washing with soap or soap and soda) using the SW-12D washing fastness tester (Ningbo Textile Instrument Factory, China). Rubbing fastness tests were performed according to GB/T 3920-2008(Textiles—Tests for color fastness–color fastness to rubbing) using the Y571A rubbing fastness tester (Ningbo Textile Instrument Factory, China). The samples were balanced at 20 °C and a relative humidity of 60 % for 24 h before the test. The results were given as the arithmetic mean of five different samples.

Adsorption isotherm of reactive dyes onto the treated ramie fabrics

The modified ramie fabrics were dyed with C.I. reactive Blue 4 at a concentration range of 30–360 mg/l for 3 h at 30 °C to determine the adsorption isotherm. The absorbances of the initial dyebath (A 0) and exhaust dyebath (A 1) were measured using an ultraviolet-visible (UV–Vis) 752 s spectrophotometer (Lengguang Tech Co., Ltd., Shanghai) at λ max = 410 nm to calculate the concentration of the reactive dye adsorbed on the treated ramie fabrics ([D f]) and the dye remaining in the dyebath ([D s]).

Results and discussion

Characterization of amino-terminated hyperbranched polymer (at-HBP)

FT-IR spectra of the tetracarboxylic ester and the amino-terminated hyperbranched polymer (at-HBP) are shown in Fig. 3.

Figure 3b shows that bands at 1,730 cm−1 were assigned to C=O stretching vibration of ester bonds (–CO2R); 2,871.5–2,990 cm−1 was assigned to the stretching vibration and bending vibration of methyl and methylene. Bands at 1,170–1,236.7 cm−1 were assigned to the C–O–C asymmetric stretching vibration of methyl ester or ethyl ester. The broad peak at 3,360 cm−1 was assigned to the N–H stretching vibration of the primary amine and secondary amide, 1,650 cm−1 was assigned to the carbonyl stretching vibration of secondary amide bonds (–CONH–), and 1,550.7 cm−1 was assigned to the N–H bending vibration of the primary amine. It was found that the absorption at 1,730 cm−1 (typical C=O stretching vibration of the ester bond in the tetracarboxylic ester) disappeared. The typical C–O–C asymmetric stretching vibration of methyl ester or ethyl ester also disappeared.

Based on the above analysis, it was concluded that the tetracarboxylic ester had successfully polycondensed to the amino-terminated hyperbranched polymer (at-HBP).

The structure of the tetracarboxylic ester and amino-terminated hyperbranched polymer (at-HBP) was also confirmed by 1HNMR spectroscopy (shown in Figs. 2, 4, 5). 1HNMR of tetracarboxylic ester (500 MHz, CDCl3-d3, δ): 1.24 (t, 3H, a), 2.19 (t, 2H; b), 2.34 (t, 2H; c), 3.52 (s, 3H, d), 4.21 (q, 2H, e). For 1HNMR of the amino-terminated hyperbranched polymer (at-HBP; 500 MHz, DMSO-d6, δ), the typical chemical shifts of primary amine (f), secondary amine (g) and amide (h) were found; 1.99–2.06 (d, 27H) was assigned to the chemical shifts of the primary amine (f), 2.47–2.56 (m, 13H) was assigned to the chemical shifts of the secondary amine (g), and 7.91–8.34 (m, 4H) was assigned to the chemical shifts of amide (h).

The viscosity of at-HBP was about 1,800 mPa.s at 25 °C. From the GPC result, the average number (M n) molecular weight of at-HBP was estimated at approximately 1,468 g/mol.

Color strength (K/S) of untreated and modified ramie fabrics

To determine whether the at-HBP-modified ramie fabrics would have enhanced dyeability with reactive dyes, the untreated ramie fabric and at-HBP-modified ramie fabrics were dyed with 2 % owf C.I. reactive Blue 4 in the absence or presence of electrolytes and alkali. The results are shown in Table 2.

Table 2 clearly shows that the color strength (K/S) of at-HBP-modified ramie fabrics was much higher than those of untreated ramie fabrics. For the untreated ramie fabrics, the highest color strength was achieved when both electrolyte and alkali were present (K/S = 10.2), and the lowest color strength (K/S = 3.9) was achieved when both electrolyte and alkali were absent. The color strength increased when an electrolyte was used (K/S = 9.1) or alkali was used (K/S = 8.7). It clearly demonstrated the importance of using electrolytes and alkali for the normal dyeing of reactive dyes. For the at-HBP-modified ramie fabrics, the highest color strength was achieved when both electrolyte and alkali were present (K/S = 16.3), and the lowest color strength was achieved when both electrolyte and alkali were absent (K/S = 9.3). The color strength of at-HBP-modified ramie fabrics with either electrolyte or alkali absent was higher than those obtained in the absence of both electrolyte and alkali. The color strength (K/S) was higher than the results obtained in Zhang et al. (2008a, b, 2007a, b), while lower than those obtained in Liu et al. (2008).

Subsequently, five other reactive dyes were applied to the untreated and at-HBP-modified ramie fabrics using competitive dyeing in the absence of electrolyte, but in the presence of alkali. The color strength results are shown in Table 3. It was shown that the color strength of at-HBP-modified ramie fabrics increased for all the dyes in comparison with the control ramie fabrics. Therefore, salt-free dyeing with reactive dyes was possible for ramie fabrics modified with at-HBP.

XRD analysis of ramie fabrics

XRD patterns of untreated ramie fabric, mercerized and epichlorohydrin-modified ramie fabric, and at-HBP-modified ramie fabric at 2θ of 10°–60° are shown in Fig. 5. The diffraction peaks at 14.84°, 16.38°, 22.68° and 34.20° (as shown in Fig. 5a), assigned to the crystallographic planes of (1 −1 0), (1 1 0), (2 0 0) and (0 0 4), were characteristic of the “cellulose I crystal” (Mormann and Michel 2002; Gao et al. 2010; French and Michael 2013; French 2014). The high intensity of the diffraction peak at 22.68° (2 0 0) means that the untreated ramie fabric has a highly crystalline structure. As shown in Fig. 5b, after mercerization and epichlorohydrin modification, the diffraction peaks at 20.22 (1 1 0), 22.28 (0 2 0) and 34.34° (0 0 4) were associated with the typical peaks of the cellulose II allomorph (Mormann and Michel 2002; Liu et al. 2007; French and Michael 2013; French 2014; Yue et al. 2012; Han et al. 2013). This suggests a transformation of the crystalline structure from cellulose I to cellulose II allomorph during mercerization and epichlorohydrin modification. Comparing with Fig. 5a, the (1 −1 0) peak at 2θ = 14.84 and (1 1 0) peak at 2θ = 16.38 completely disappeared. The at-HBP-modified ramie fabric also showed the characteristic XRD pattern of cellulose II (2θ = 20.38°, 22.42° and 34.20°, as shown in Fig. 5c), suggesting that the at-HBP modification has no effect on the crystallite structure of the mercerized fabric.

Using MDI Jade 5.0 software and equation (1), the CIs of untreated ramie fabric, mercerized and epichlorohydrin-modified ramie fabric, and at-HBP-modified ramie fabric were calculated as 85.2, 50.2 and 64.7 %, respectively. The CIs of mercerized and epichlorohydrin-modified ramie fabric decreased sharply, while the CI of at-HBP-modified ramie fabric was higher than that of mercerized and epichlorohydrin-modified ramie fabric. This can probably be attributed to the three-dimensional dendritic structure of at-HBP with low viscosity, good solubility, and rich imino groups and terminal primary amino groups. When at-HBP is applied to ramie fabric, it can easily penetrate into the treated ramie fabrics and combines with cellulose in abundant hydrogen bond and Van der Waals force (Wong et al. 2009; Zhang et al. 2008a, b; Wang et al. 2007).

The crystallite sizes of untreated ramie fabric, mercerized and epichlorohydrin-modified ramie fabric, and at-HBP-modified ramie fabric were calculated using MDI Jade 5.0 software and Scherrer equation (2); the values of crystallite size were 5.8, 3.1 and 3.6 nm, respectively.

XRD suggested a transformation of the crystalline structure from ramie cellulose I to cellulose II allomorph during mercerization and epichlorohydrin modification, and the crystalline structure of cellulose II was retained with an obvious CI increase when the ramie fabric was modified with at-HBP.

FE-SEM analysis of ramie fabrics

FE-SEM micrographs (2,000× magnification) of the untreated ramie fabrics and modified-ramie fabrics are shown in Fig. 6. Figure 6a showed that the surface of untreated ramie fabric was relatively smooth and appeared as a layered structure (Ma et al. 2005; Liu et al. 2008). When ramie fabric was modified with at-HBP, a very rough surface partly covered with polymer-like granules was observable (Fig. 6b), suggesting that at-HBP was crosslinked onto the surface of ramie fabric.

Fastness properties

The washing fastness and rubbing fastness of untreated ramie fabrics (dyed in the presence of electrolyte and alkali) and salt-free dyeing of at-HBP-modified ramie fabrics (dyed in the absence of electrolytes, but in the presence of alkali) with C.I. reactive Blue 4 are shown in Table 4. Compared with the untreated ramie fabrics, the at-HBP-modified ramie fabrics had good washing fastness and rubbing fastness. Clearly, the washing and rubbing fastness of reactive dye dyeing was maintained.

Investigation of the adsorption isotherm

To investigate the adsorption isotherm of C.I. reactive Blue 4 on the modified ramie fabric in the absence of the electrolyte, dyeings were carried out at a concentration range of 30–360 mg/l for 3 h at 30 °C. The concentration of the dye adsorbed on the fabric ([D f]) and the dye remaining in the dyebath ([D s]) were calculated to draw the adsorption isotherms for C.I. reactive Blue 4 on the modified ramie fabric (shown in Fig. 7a). Figure 7b was the curves plotted 1/[D f] against 1/[D s], where the Langmuir model fitted the experimental data very well with a high correlation coefficient (R = 0.985). It indicates that the adsorption pattern of C.I. reactive Blue 4 on the modified ramie fabric in the absence of the electrolyte is Langmuir-type adsorption (Zhang et al. 2007a, b). Similar observations were reported for the adsorption of Reactive Brilliant Yellow A-4GLN on HBP-NH2 grafted onto the oxidized cotton fabric (Zhang et al. 2008a, b).

The typical Langmuir-type adsorption of C.I. reactive Blue 4 on the modified ramie fabric demonstrated the mechanism of salt-free dyeing on the at-HBP-modified ramie fabric. In the dyeing of the modified ramie fabrics in the absence of electrolytes, the adsorption of the reactive dyes is assisted by the attraction between the amino of the amino-terminated hyperbranched polymer on the ramie fabrics and the disulfonate anions on the reactive dyes and the elimination of hydrogen chloride between the amino group and chloride atom of reactive dyes (monochlorotriazines or dichlorotriazines).

Modification and dyeing mechanisms

The at-HBP modification of ramie fabric involved two steps: the first was the mercerization and epichlorohydrin crosslinking of ramie fabric; the next was the crosslink between at-HBP and ramie cellulose. After mercerization with a high concentration of sodium hydroxide, the high reactivity of the hydroxyl group of ramie cellulose would form a large amount of oxygen anions (O−). Then the O− anion would react with epichlorohydrin to form an intermediate under alkaline conditions, eliminating hydrogen chloride and H2O (Liu et al. 2007; Liu et al. 2008). A large amount of the amino group of at-HBP would react with epoxy to form at-HBP-modified ramie cellulose. Then, the ramie cellulose had large amounts of active amide, amino and hydroxyl groups covalently bound to the at-HBP chains.

As shown in Fig. 8, the dyeing mechanism between at-HBP-modified ramie cellulose and the reactive molecular dye was proposed. Large amounts of active amide, amino and hydroxyl groups covalently bound to the ramie cellulose would strongly attract anionic groups (disulfonate anions) of reactive dyes, and abundant active groups would react with chloride atoms of reactive dyes (monochlorotriazines or dichlorotriazines) to eliminate hydrogen chloride, which results in the fixation between cellulose and reactive dyes. Due to abundant crosslinking between cellulose and amino active groups of at-HBP, the reactive sites on cellulose fabric with reactive dyes were remarkably increased, thus leading to higher dye uptake. Also, this at-HBP-modified ramie fabric could be dyed with reactive dyes without large amounts of electrolytes, even free of salt, which are normally needed to drive the dyes from the water onto the fabrics.

Conclusions

A new amino-terminated hyperbranched polymer (at-HBP) was synthesized, and its dyeing property on ramie fabric was studied using a salt-free dyeing process. The structure and molecular weight of at-HBP was established by FT-IR, 1HNMR and GPC. The untreated and modified ramie fabrics were characterized by XRD and field emission scanning electron micrographs (FE-SEM). FE-SEM results confirmed that at-HBP was successfully grafted onto the fabric surface. XRD results showed a transformation of the crystalline structure from ramie cellulose I to cellulose II allomorph during mercerization and epichlorohydrin modification, and the crystalline structure of cellulose II was maintained with an obvious CI increase after at-HBP modification. Dyed with the reactive dye C.I. reactive Blue 4, the at-HBP-modified ramie fabric displayed obviously enhanced color strength, even when dyeing had been carried out in the absence of the electrolyte. The washing fastness and rubbing fastness of the salt-free dyeing of modified ramie fabrics were also favorable compared with those obtained by conventional dyeing. The dyeing behavior of C.I. reactive Blue 4 on the treated ramie fabric was examined and found to follow a Langmuir-type adsorption curve. The at-HBP modification mechanism of ramie fabric and dyeing mechanism with reactive dye were suggested. It is concluded that the amino-terminated hyperbranched polymer (at-HBP) can be used as a salt-free auxiliary in reactive dyeing on ramie fabric.

Therefore, this ramie fabric modification procedure could be used to improve the utilization of dyes, increase the dyeing color strength and reduce pollution, showing prospective applications for ramie fabric treatment.

Abbreviations

- at-HBP:

-

Amino-terminated hyperbranched polymer

- XRD:

-

X-ray diffraction

- FT-IR:

-

Fourier transform infrared spectrometer

- 1HNMR:

-

H nuclear magnetic resonance

- GPC:

-

Gel permeation chromatography

- FE-SEM:

-

Field emission scanning electron micrograph

References

Chen HZ, Jin SY (2006) Effect of ethanol and yeast on cellulase activity and hydrolysis of crystalline cellulose. Enzyme Microb Technol 39:1430–1432

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

French AD, Michael SC (2013) Cellulose polymorphy, crystallite size, and the Segal crystallinity index. Cellulose 20:583–588

Gao C, Yan DY (2004) Hyperbranched polymers: from synthesis to applications. Prog Polym Sci 29:183–275

Gao M, Chen S, Han JS, Luo DH, Zhao L, Zheng QK (2010) Effects of a pretreatment with N-Methylmorpholine-NOxide on the structures and properties of ramie. J Appl Polym Sci 117:2241–2250

Han JQ, Zhou CJ, French AD, Han GP, Wu QL (2013) Characterization of cellulose II nanoparticles regenerated from 1-butyl-3-methylimidazolium chloride. Carbohydr Polym 94:773–781

Hauser PJ, Tabba AH (2001) Improving the environmental and economic aspects of cotton dyeing using a cationised cotton. Color Technol 117:282–288

Kalia S, Kaith BS, Kaur I (2009) Pretreatments of natural fibers and their application as reinforcing material in polymer composites—a review. Polym Eng Sci 49:1253–1272

Li N, Wei XY, Mei Z, Xiong XL, Chen SM, Ye M, Ding SG (2011) Synthesis and characterization of a novel polyamidoamine–cyclodextrin crosslinked copolymer. Carbohydr Res 346:1721–1727

Lim SH, Hudson SM (2004) Application of a fibre-reactive chitosan derivative to cotton fabric as a zero-salt dyeing auxiliary. Color Technol 120:108–113

Liu ZT, Zhang LL, Liu ZW, Gao Z, Dong W, Xiong HP, Peng YD, Tang SW (2006) Supercritical CO2 dyeing of ramie fiber with disperse dye. Ind Eng Chem Res 45:8932–8938

Liu ZT, Yang YN, Zhang LL, Liu ZW, Xiong HP (2007) Study on the cationic modification and dyeing of ramie fiber. Cellulose 14:337–345

Liu ZT, Yang YN, Zhang LL, Sun P, Liu ZW, Lu J, Xiong HP, Peng YD, Tang SW (2008) Study on the performance of ramie fiber modified with ethylenediamine. Carbohydr Polym 71:18–25

Liu HY, Liu DG, Yao F, Wu QL (2010) Fabrication and properties of transparent polymethylmethacrylate/cellulose nanocrystals composites. Bioresour Technol 101:5685–5692

Ma W, Zhang SF, Tang BT, Yang JZ (2005) Pretreatment of cotton with poly (vinylamine chloride) for salt-free dyeing with reactive dyes. Color Technol 121:193–197

Ma F, Qu RJ, Sun CM, Wang CH, Ji CN, Zhang Y, Yin P (2009) Adsorption behaviors of Hg (II) on chitosan functionalized by amino-terminated hyperbranched polyamidoamine polymers. J Hazard Mater 172:792–801

Montazer M, Malek R, Rahimi A (2007) Salt free reactive dyeing of cationized cotton. Fibers Polym 8:608–612

Mormann W, Michel U (2002) Hydrocellulose with low degree of polymerization from liquid ammonia treated cellulose. Carbohydr Polym 50:349–353

Orden MU, Urreaga JM (2006) Photooxidation of cellulose treated with amino compounds. Polym Degrad Stab 91:2053–2060

Pandey SN (2007) Ramie fibre: part I. Chemical composition and chemical properties. A critical review of recent developments. Text Prog 39:1–66

Renfrew AHM, Phillips DAS (2003) Protection of lyocell fibres against fibrillation: mode of action of the crosslinking agent 2, 4-dichloro-6-(sulphatoethylsulphonyl)anilino-s-triazine. Coloration Technol 119:116–120

Tam KY, Smith ER, Booth J, Compton RG, Brennan CM, Atherton JH (1997) Kinetics and mechanism of dyeing pocesses: the dyeing of cotton fabrics with a procion blue dichlorotriazinyl reactive dye. J Colloid Interface Sci 186:387–398

Wang N, Ding EY, Cheng RS (2007) Thermal degradation behaviors of spherical cellulose nanocrystals with sulfate groups. Polymer 48:3486–3493

Wang GW, Zhuang LH, Wang JT (2009a) A route to a tetrabenzothiazole from Michael bis-addition compounds. J Chem Res 33:212–213

Wang LL, Ma W, Zhang SF, Teng XX, Yang JZ (2009b) Preparation of cationic cotton with two-bath pad-bake process and its application in salt-free dyeing. Carbohydr Polym 78:602–608

Wong SS, Kasapis S, Tan YF (2009) Bacterial and plant cellulose modification using ultrasound irradiation. Carbohydr Polym 77:280–287

Xie KL, Hou AQ, Wang XJ (2008) Dyeing and diffusion properties of modified novel cellulose with triazine derivatives containing cationic and anionic groups. Carbohydr Polym 72:646–651

Yue YY, Zhou CJ, French AD, Xia G, Han GP, Wang QW, Wu QL (2012) Comparative properties of cellulose nano-crystals from native and mercerized cotton fibers. Cellulose 19:1173–1187

Zhang SF, Ma W, Ju BZ, Dang NY, Zhang M, Wu SL (2005) Continuous dyeing of cationised cotton with reactive dyes. Color Technol 121:183–186

Zhang F, Chen YY, Lin H, Lu YH (2007a) Synthesis of an amino-terminated hyperbranched polymer and its application in reactive dyeing on cotton as a salt free dyeing auxiliary. Color Technol 123:351–357

Zhang M, Ju BZ, Zhang SF, Ma W, Yang JZ (2007b) Synthesis of cationic hydrolyzed starch with high DS by dry process and use in salt-free dyeing. Carbohydr Polym 69:123–129

Zhang F, Chen YY, Lin H, Zhang DS (2008a) Performance of cotton fabric treated with an amino-terminated hyperbranched polymer. Fibers Polym 9:515–520

Zhang F, Chen YY, Lin H, Wang H, Zhao B (2008b) HBP-NH2 grafted cotton fiber: preparation and salt-free dyeing properties. Carbohydr Polym 74:250–256

Zheng CL, Yuan AL, Wang HB, Sun J (2012) Dyeing properties of novel electrolyte free reactive dyes on cotton fibre. Color Technol 128:204–207

Acknowledgments

This work was supported by the Natural Science Founndation of Jiangsu Province (no. BK2011799 and no. BK20140939) and the specialized research fund for the Doctoral Program of Higher Education of China (no. 20113221120006). The authors also gratefully appreciate the support from the National Natural Foundation of Science, China (no. 51003047).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, GW., Zhuang, LH., Sun, J. et al. Salt-free dyeing of ramie fabric with an amino-terminated hyperbranched polymer. Cellulose 21, 3725–3736 (2014). https://doi.org/10.1007/s10570-014-0345-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0345-9