Abstract

In this work we report on the procedure for fast and controlled preparation of nanocrystalline cellulose (NCC) from commercially available microcrystalline cellulose using microwave-assisted hydrolysis. By varying the sulfuric acid concentration and hydrolysis temperature, an average hydrodynamic diameter of NCC between 126 and 1,310 nm with corresponding yields between 16 and 82 %, respectively, was obtained in a very short reaction time of 10 min. An additional advantage of the described procedure is its high reproducibility and ability to fine-tune the average NCC particle size by adjusting the reaction conditions, i.e., the sulfuric acid concentration and/or reaction temperature.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose represents the most abundant renewable polymer resource that is biodegradable and non-toxic. It is a linear carbohydrate polymer consisting of β-d-glucopyranose repeating units. Nanocrystalline cellulose (NCC) obtained by acid hydrolysis of cellulose fibers has been realized as a new class of nanomaterials and has been the subject of a wide array of research efforts as a reinforcing agent in nanocomposites because of its low cost, availability, renewability, light weight, nanoscale dimension, and high aspect (length-to-width) ratio (Habibi et al. 2010; Lima and Borsali 2004). The NCC has great strength because of its dense and ordered crystalline structure. The modulus of elasticity of the perfect crystal of native cellulose has been estimated by various authors and is between 130 and 250 GPa, and the tensile strength is assessed to be between 0.8 and 10 GPa (Zimmermann et al. 2004). Many new nanocomposite materials with attractive properties have been prepared by physical incorporation of NCC into a natural or synthetic polymeric matrix (Pandey et al. 2013; Kumar et al. 2012; Schroers et al. 2004; Mendez et al. 2011). The NCC also holds promise in many different applications such as in nanopaper, coatings, adhesives, optical sensors, biomedical scaffolds, filtration membranes, electronic devices, foams, aero gels, etc., which make NCC of significant interest from a scientific and industrial perspective (Habibi et al. 2010; Peng et al. 2011; Moon et al. 2011; Klemm et al. 2011; Lam et al. 2012; Eichhorn et al. 2010; Brinchi et al. 2013).

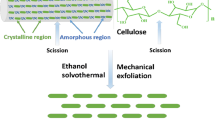

The NCC is usually produced from native cellulose by isolation of its crystalline regions, whereas the amorphous regions are hydrolyzed and degraded into soluble products. In general, acid hydrolysis of native cellulose induces a rapid decrease in its degree of polymerization (DP), which then reaches a plateau level, the so-called level-off DP (LODP) (Battista et al. 1956). A wide distribution of DP is typically observed for different cellulose sources, even at the LODP (Habibi et al. 2010). The method of choice for the isolation of NCC is based on controlled hydrolysis of cellulose by sulfuric acid (Ranby 1951; Beck-Candanedo et al. 2005; Elazzouzi-Hafraoui et al. 2008; Favier et al. 1995), owing to the stability of the resulting suspensions, although other acids such as hydrochloric (Yu et al. 2013), phosphoric (Espinosa et al. 2013), and hydrobromic (Sadeghifar et al. 2011) have also been explored. The typical procedure currently employed for the production of NCC consists of subjecting the cellulosic material to strong acid hydrolysis under strictly controlled conditions of temperature, agitation, and time. The type of acid, cellulose source, and acid-to-cellulose ratio are also important parameters that affect the efficiency of NCC preparation (Habibi et al. 2010). The concentration of sulfuric acid for the hydrolysis reaction does not vary much from a typical value of ca. 65 wt%; however, the temperature can range from room temperature up to 70 °C; thus, the corresponding hydrolysis time varies from 30 min to overnight, depending on the temperature.

Bondeson et al. (2006) optimized the experimental conditions for hydrolysis of microcrystalline cellulose (MCC) as the cellulosic raw material. They studied the median size of the cellulose particles and the yield of the reaction in dependence of the concentrations of MCC and sulfuric acid, the hydrolysis time and temperature, and the ultrasonic treatment time. The authors demonstrated that with a sulfuric acid concentration of 63.5 % (wt/wt) over a time of approximately 2 h at 45 °C, it was possible to obtain NCC with a length between 200 and 400 nm and a width <10 nm in a yield of 30 % (based on initial weight). Lu et al. (2013) prepared the NCC from filter paper by sulfuric acid hydrolysis and simultaneous application of ultrasound and microwaves (SUMAT technique). Under optimized reaction conditions (sulfuric acid concentration 50 %, temperature 70 °C, reaction time 1.5 h), NCC in 78 % yield was obtained. The above results show that the NCC yield depends on several experimental parameters; however, the authors do not report on a relationship between the reaction conditions and NCC average particle size.

Herein, we report on the development of an optimized process for rapid preparation of NCC of controlled size (length) using microwave heating. As a source, we used commercially available MCC. We systematically studied the influence of the sulfuric acid concentration and hydrolysis temperature on the NCC average hydrodynamic diameter and the reaction yield.

Experimental section

Materials

Microcrystalline cellulose (Acros Organics, extra pure, average particle size = 90 μm); H2SO4 (Merck, 95–97 wt%, p.a.); deionized water, sodium dodecylsulfate (SDS, Sigma-Aldrich, >98 %, GC, Reagent Plus).

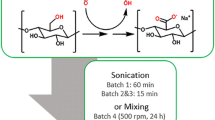

Procedure for nanocrystalline cellulose (NCC) preparation

Typically, 0.5 g MCC was put into a microwave reaction vial (30 ml, G30), and 10 g of sulfuric acid solution with a concentration in the range between 50 and 64 % (wt/wt) was added (Table 1). The suspension was sonicated in an ultrasound bath for 5 min and transferred to a microwave reactor (Anton Paar, Monowave 300) where it was heated according to the following program: (1) heating to the predetermined temperature in 1 min, (2) maintaining the temperature for 10 min, and (3) cooling to 50 °C within ca. 2 min (Fig. S1). During the whole procedure, the suspension was stirred with a magnetic stirring bar (600 rpm). After the reaction completion, the reaction vial was removed from the microwave oven and cooled under tap water to room temperature. The suspension was transferred to a 15-ml plastic centrifuge tube and centrifuged at 4,700 rpm for 10 min in order to remove excess acid and water. Purification of the precipitate was performed by five washing cycles with deionized water (5 × 50 ml) and repeated sonication of the suspension in an ultrasound bath for 5 min followed by centrifugation at 9,000 rpm for 20 min (Hettich universal 320). The last purified suspension was sonicated (ultrasonic processor UP400S, 400 W, 24 kHz, Hielscher) for 30 min at 230 W/cm2 power output in a 50-ml plastic centrifugation tube to obtain homogeneous dispersion. The pH of purified suspensions was between 4 and 5. The NCC yield was determined gravimetrically by drying the precipitate after centrifugation of 10 g aliquot (8,000 rpm, 10 min) at 40 °C under vacuum (Table 1). The reproducibility of the procedure in terms of reaction yield and average hydrodynamic diameter at each set of experimental conditions was determined on nine parallel prepared samples. The samples are marked with NCC-XX, YY where XX represents the sulfuric acid concentration (50, 55, 60, 64 wt%) and YY the reaction temperature (70, 80, 90 °C).

Characterization

Fourier transform infrared spectroscopy (FTIR)

Dried samples were analyzed by FTIR spectroscopy using an FTIR spectrometer “Spectrum One” (PerkinElmer) with the Universal ATR Sampling Accessory in transmission mode, in the range between 4,000 and 650 cm−1 with a spectral resolution of 4 cm−1.

X-ray diffraction (XRD)

NCC was characterized by wide-angle X-ray diffraction (XRD) on a Siemens D-5000 diffractometer with a Cu anode as the X-ray source. X-ray diffractograms were measured at 25 °C in the 2Θ range from 5° to 40° with a step of 0.04° and step time of 300 s. The cellulose crystallinity index (CrI) was calculated from the crystalline (I 200) and amorphous (I am) signal intensities at 2Θ = 22.5° and 2Θ = 18°, respectively, according to Eq. (1) (Segal et al. 1959; Mao et al. 2013; French 2014).

Dynamic light scattering (DLS)

The average hydrodynamic diameter (d H) of NCC in water suspension was determined by DLS at 25 °C using a Malvern Zetasizer Nano-ZS (Malvern Instruments Ltd.) at an angle of 173°. The average hydrodynamic diameter and size distribution of the sample (given by the dispersity factor, σ) were evaluated using the fully automatic mode of the Nano-ZS system. For the DLS measurements, the final purified suspensions of NCC were diluted 100× with deionized water and sonicated for an additional 30 min (ultrasonic processor UP400S: 400 W, 24 kHz, Hielscher) before measurements.

Scanning transmission electron microscopy (STEM)

The microtopographies of NCC samples were observed by STEM. The STEM micrographs were taken on a Zeiss Supra 35 VP at an acceleration voltage of 20.0 kV and working distance of 4.5–5.0 mm using a STEM electron detector. Samples for the STEM measurements were prepared by drop-casting of 100× diluted NCC water dispersion on the copper grid. In order to reduce the aggregation of NCC particles during drying on the copper grid, 6 wt% (relative to the NCC content) of sodium dodecylsulfate (SDS) was added as a dispersing agent to suspensions prior to microscopic measurements.

Results and discussion

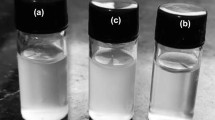

Our aim was to develop a rapid and optimized procedure for the preparation of NCC of defined size (length) in high yields. The hypothesis was that NCC can be prepared in high yields and in short reaction time with a modified standard NCC preparation procedure in a microwave reactor. We applied microwave-assisted acid hydrolysis of cellulose with sulfuric acid (Fig. 1). As a cellulose source, we used commercially available MCC. The microwave reactor allows precise control and repeatable reaction conditions, with a homogeneous temperature profile and preparation of NCC in much shorter reaction times as compared to the standard NCC preparation procedure. We varied the sulfuric acid concentration in the range between 50 and 64 % (wt/wt) and the reaction temperature between 70 and 90 °C at a fixed reaction time of 10 min and MCC-to-sulfuric acid solution ratio of 0.05 (Table 1). The obtained NCC was purified by five repeated washings with deionized water and, subsequently, homogenized by sonication. Thus, prepared suspensions of NCC in water, stored at room temperature, were stable for at least 1 month (Fig. 1). Reproducibilities of the reaction yield and average NCC size were determined on nine parallel prepared samples at each set of experimental conditions.

Schematic presentation of the NCC preparation procedure (left) and suspensions of NCC with concentration of 0.1 wt% prepared in a microwave reactor (right). For experimental conditions of NCC preparation, see Table 1

The sample NCC-64,70 was prepared with the 64 wt% of sulfuric acid, which is a concentration typically used in the standard NCC preparation procedure. However, contrary to standard procedure, we performed the hydrolysis reaction at a temperature of 70 °C and reaction time of only 10 min (Table 1). The obtained NCC particles of nine parallel prepared samples had an average hydrodynamic diameter of 148 ± 19 nm as determined by DLS, whereas the NCC yield was 19.9 ± 2.8 % (Table 1). After 10 min reaction time, the experiments performed at lower 60 wt% sulfuric acid concentration gave the NCC with narrow particle size distribution and the average hydrodynamic diameter between 126 and 282 nm as determined by DLS (Fig. S1), whereas the NCC yields were between 16 and 38 %, depending on the reaction temperature at which the hydrolysis was performed (Table 1). With further lowering of the sulfuric acid concentration to 55 and 50 wt%, even higher yields between 44–64 and 68–82 %, respectively, were obtained; however, the particles were of significantly larger size with the average hydrodynamic diameter ranging from 300 to 1,310 nm (Table 1, Fig. S1). It should be stressed that the reduction of MCC size from the original 90 μm to around 1 μm (sample NCC1) occurred at 70 °C and 50 wt% sulfuric acid concentration within 10 min, while approximately 82 % of mass was isolated.

The reaction yield decreased when NCC of smaller size was prepared by increasing the reaction temperature at fixed sulfuric acid concentration or by increasing the sulfuric acid concentration at fixed reaction temperature (Table 1). Precise control over NCC particle size is a consequence of the controlled temperature regime in the microwave reactor. At harsher hydrolysis conditions, especially at sulfuric acid concentration of 60 and 64 %, the obtained NCC particles were smaller, but a large decrease in NCC yield was observed since hydrolysis took place to an extent that allows complete cellulose dissolution. In conclusion, by relating the NCC particle size and the yield, it is possible to define optimal experimental conditions for isolation of NCC with desired particle length in optimal yield.

In order to confirm the conservation of the original crystalline structure (cellulose I) of MCC during NCC preparation, the powder X-ray diffraction measurements were performed. With XRD (Fig. 2), it was demonstrated that NCC exhibited a similar diffraction pattern as MCC at 2θ equals 15.1, 16.4, 20.6, 22.5, and 34.6°, which correspond to the crystallographic planes (1–10), (110), (012), (200), and (004) of cellulose I, respectively (Nishiyama et al. 2002, 2003; French 2014). The crystallinity index (CrI) of the prepared NCC samples (Table 1) slightly increased (83 % for NCC-50, 80 and 85 % for NCC-55,80 and NCC-60,80) as compared to that of parent MCC (81 %) as expected. A rather small increase in CrI is attributed to high crystallinity of the MCC itself. Also, the FTIR spectra of dried NCC samples were similar to the spectrum of the original MCC (Fig. S2), showing the bands for OH stretching at 3,330 cm−1, CH stretching at 2,896 cm−1, the characteristic band for the CH2 bending vibration of cellulose I at 1,428 cm−1, the bands for CO stretching at 1,029 and 1,053 cm−1, and the band for antisymmetric out-of-phase stretching vibration of the C–O bond at 897 cm−1 (Hon and Shiraishi 2000).

In order to correlate the average hydrodynamic diameter of NCC determined by DLS, the STEM micrographs of sample NCC-60, 70 were recorded (Fig. 3). The sample for STEM was prepared by drop-casting of diluted NCC suspension immediately after sonication. Evaluation of the average particle length and width from the STEM micrograph of the sample NCC-60, 70 gave the values of 360 ± 90 nm (Fig. 3a, Fig. S3) and 29 ± 10 nm (Fig. 3b, Fig. S4), which results in the aspect ratio of 12. Thus, the average hydrodynamic diameter of NCC determined by DLS (280 nm, Table 1, Fig. S1b) is smaller as compared to the average particle length determined by STEM (360 nm, Fig. S3). Nevertheless, DLS is the suitable technique for a fast evaluation of NCC average particle size in comparison to the more established electron microscopic method (Kvien et al. 2005). Fan and Li (2012) measured the NCC nanoparticles by DLS (size between 174 and 551 nm) without making the correlation with the NCC average particle length from SEM images. Morais et al. (2013) correlated the NCC length determined from the TEM micrograph (177 nm) with the DLS data (multimodal distribution), stating that the light-scattering technique can replace TEM for returning a good estimation of nanocrystals’ dimensions. The DLS method offers the advantage since it is simple and fast and allows the determination of NCC average particle length in suspension. The disadvantage of this method is that the average particle width and therefore the aspect ratio cannot be determined.

Conclusions

We developed an optimized process of NCC preparation from commercially available MCC. The procedure allows rapid (10 min reaction time) and reproducible preparation of NCC of defined size. We varied the reaction temperature between 70 and 90 °C and the sulfuric acid concentration in the range between 50 and 64 % (wt/wt) at the fixed reaction time (10 min) and the weight ratio of MCC-to-sulfuric acid solution (0.05). The resulting products retain the cellulose I crystalline structure as shown in the XRD measurements. All the products formed stable suspensions in water with an average hydrodynamic diameter between 125 nm and 1,310 nm as measured by DLS. An additional advantage of the process is the ability to fine-tune the NCC average particle size by suitable reaction conditions (sulfuric acid concentration and/or reaction temperature at the fixed reaction time), which are assured by good process control of the microwave reactor. At optimal reaction conditions (70 °C temperature, 60 % sulfuric acid concentration and 10 min of microwave heating), the NCC with average particle length of 360 nm and average particle width of 29 nm was prepared in 38 % yield.

References

Battista OA, Coppick S, Howsmon JA, Morehead FF, Sisson WA (1956) Level-off degree of polymerization. Ind Eng Chem 48:333–335

Beck-Candanedo S, Roman M, Gray DG (2005) Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromolecules 6:1048–1054

Bondeson D, Mathew A, Oksman K (2006) Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 13:171–180

Brinchi L, Cotana F, Fortunati E, Kenny JM (2013) Production of nanocrystalline cellulose from lignocellulosic biomass: technology and applications. Carbohydr Polym 94:154–169

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux JL, Heux L, Dubreuil F, Rochas C (2008) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules 9:57–65

Espinosa SC, Kuhnt T, Foster EJ, Weder C (2013) Isolation of thermally stable cellulose nanocrystals by phosphoric acid hydrolysis. Biomacromolecules 14:1223–1230

Fan JS, Li YH (2012) Maximizing the yield of nanocrystalline cellulose from cotton pulp fiber. Carbohydr Polym 88:1184–1188

Favier V, Canova GR, Cavaille JY, Chanzy H, Dufresne A, Gauthier C (1995) Nanocomposite materials from latex and cellulose whiskers. Polym Adv Technol 6:351–355

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500

Hon N-SD, Shiraishi N (2000) Wood and cellulosic chemistry. Marcel Dekker Inc, New York, p 297

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466

Kumar S, Hofmann M, Steinmann B, Foster EJ, Weder C (2012) Reinforcement of stereolithographic resins for rapid prototyping with cellulose nanocrystals. ACS Appl Mater Interfaces 4:5399–5407

Kvien I, Tanem BS, Oksman K (2005) Characterization of cellulose whiskers and their nanocomposites by atomic force and electron microscopy. Biomacromolecules 6:3160–3165

Lam E, Male KB, Chong JH, Leung ACW, Luong JHT (2012) Applications of functionalized and nanoparticle-modified nanocrystalline cellulose. Trends Biotechnol 30:283–290

Lima MMD, Borsali R (2004) Rodlike cellulose microcrystals: structure, properties, and applications. Macromol Rapid Commun 25:771–787

Lu ZX, Fan LW, Zheng HY, Lu QL, Liao YQ, Huang B (2013) Preparation, characterization and optimization of nanocellulose whiskers by simultaneously ultrasonic wave and microwave assisted. Bioresour Technol 146:82–88

Mao J, Osorio-Madrazo A, Laborie MP (2013) Preparation of cellulose I nanowhiskers with a mildly acidic aqueous ionic liquid: reaction efficiency and whiskers attributes. Cellulose 20:1829–1840

Mendez J, Annamalai PK, Eichhorn SJ, Rusli R, Rowan SJ, Foster EJ, Weder C (2011) Bioinspired mechanically adaptive polymer nanocomposites with water-activated shape-memory effect. Macromolecules 44:6827–6835

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994

Morais JPS, Rosa MD, de Souza MDM, Nascimento LD, do Nascimento DM, Cassales AR (2013) Extraction and characterization of nanocellulose structures from raw cotton linter. Carbohydr Polym 91:229–235

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose 1 beta from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124:9074–9082

Nishiyama Y, Sugiyama J, Chanzy H, Langan P (2003) Crystal structure and hydrogen bonding system in cellulose 1(alpha), from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 125:14300–14306

Pandey JK, Nakagaito AN, Takagi H (2013) Fabrication and applications of cellulose nanoparticle-based polymer composites. Polym Eng Sci 53:1–8

Peng BL, Dhar N, Liu HL, Tam KC (2011) Chemistry and applications of nanocrystalline cellulose and its derivatives: a nanotechnology perspective. Can J Chem Eng 89:1191–1206

Ranby BG (1951) Fibrous macromolecular systems. Cellulose and muscle. The colloidal properties of cellulose micelles. Discuss Faraday Soc 11:158–164

Sadeghifar H, Filpponen I, Clarke SP, Brougham DF, Argyropoulos DS (2011) Production of cellulose nanocrystals using hydrobromic acid and click reactions on their surface. J Mater Sci 46:7344–7355

Schroers M, Kokil A, Weder C (2004) Solid polymer electrolytes based on nanocomposites of ethylene oxide–epichlorohydrin copolymers and cellulose whiskers. J Appl Polym Sci 93:2883–2888

Segal L, Creely JJ, Martin AE Jr, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Yu HY, Qin ZY, Liang BL, Liu N, Zhou Z, Chen L (2013) Facile extraction of thermally stable cellulose nanocrystals with a high yield of 93% through hydrochloric acid hydrolysis under hydrothermal conditions. J Mater Chem A 1:3938–3944

Zimmermann T, Pöhler E, Geiger T (2004) Cellulose fibrils for polymer reinforcement. Adv Eng Mater 6:754–761

Acknowledgments

The authors gratefully acknowledge the Slovenian Research Agency for financial support (program P2-0145).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kos, T., Anžlovar, A., Kunaver, M. et al. Fast preparation of nanocrystalline cellulose by microwave-assisted hydrolysis. Cellulose 21, 2579–2585 (2014). https://doi.org/10.1007/s10570-014-0315-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0315-2