Abstract

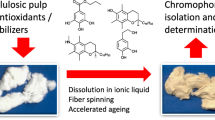

In the present work, bacterial cellulose (BC) was analyzed for its chromophore content with the chromophore release and identification (CRI) method. In aged BC, seven chromophores were unambiguously identified, despite their very low (ppb) presence. The compounds contain 2-hydroxy-[1,4]benzoquinone, 2-hydroxyacetophenone and 5,8-dihydroxy-naphthoquinone moieties. These three classes of key chromophores had also been found in other celluloses such as bleached pulp, fiber and derivatives. The detection of chromophores in lignin-free BC confirms that the chromophores are formed from oxidized and degraded carbohydrate material rather than lignin fragments. Samples that were insufficiently purified before the aging step also yielded three N-heterocyclic compounds. They originated from tryptophan moieties in residual adhering protein and protein degradation products. N-Heteropentacycles 9 and 10 showed strong adsorption onto cellulosic surfaces, and that adsorption aided oxidation of cyclohexadiene derivative 9 into the corresponding aromatic and intensely yellow system 10, consistent with the strain-induced bond localization theory. In purified fresh BC, no chromophores were detectable by the CRI method. The present contribution is the first report on defined chromophoric structures isolated from BC.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Conventionally, the general term “aging” of cellulosics includes all processes that cause physicochemical changes in the material. Aging can result from incident energy, such as irradiation, light or heat, or from chemicals, either in “concentrated” form or in small doses over prolonged times. The most prominent aspect of cellulose aging is yellowing, i.e., the formation of chromophores in the cellulosic matrix. The two terms aging and yellowing are often—but strictly speaking, not correctly—used synonymously. Yellowing actually refers to color formation only, but does not imply changes in other properties nor certain durations of the process. “Yellowing” can last long periods of time (historic documents), several days (transportation of pulps) or just a few minutes (chemical stress). “Aging” in cellulosics is mostly a process occurring over longer times, between days, years, and centuries. It might be reflected in color formation, but also in changes of mechanical or chemical properties. Many studies, which need data faster than produced by natural aging, rely on artificial aging and yellowing processes that try to simulate the outcome of long-term natural processes by more drastic conditions acting on the substrate over a short time.

Yellowing of cellulosic materials is closely linked to other properties, consumer acceptance, and to manufactured quality, so research on yellowing is not only of academic interest, but has major economic implications. Analysis of the underlying chemistry is challenging because of the extremely low concentrations of individual colored compounds called chromophores (from the Ancient Greek: χρωμα—color, ϕερειν—to carry, i.e., “color carrier”) that generally have high extinction coefficients. Present only in ppb-to-ppm concentrations, they add up to give an overall yellowish appearance to the cellulosic material. Chromogens, by contrast, are VIS-inactive compounds that, however, can generate chromophores (VIS-active compounds) in subsequent reactions: they are chromophore precursors. The usage of the term “leucochromophore”, as occasionally occurring in pulping-related literature, is discouraged for two reasons. First, the term is a contradiction in itself: a leucochromophore (from Ancient Greek leukos—colorless, white) would be “a colorless carrier of color” or a “white, colored compound”; second, the term is closely related to dye chemisty (in particular triarylmethane dyes) where it is used for the colorless hydroquinonoid precursor that is later converted to the quinoid dye. The meaning of “chromogen” in current general chromophore chemistry is much wider and not limited to certain compound classes.

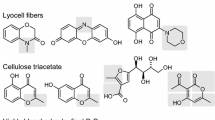

Until the introduction of the chromophore release and identification (CRI) method, an analytical technique to isolate and identify trace chromophores especially in cellulosic matrices (Rosenau et al. 2004a; b; Rosenau et al. 2005a, 2007), only general proposals existed as to possible classes of chromophoric compounds in cellulosics, such as quinones, metal complexes or conjugated structures (Suess and Filho 2003), and no specific structures or defined chromophoric compounds had been isolated and specifically identified. The CRI protocol has been comprehensively tested, analytically validated and sustained by model compound work. The method is selective for electron-rich quinones and aromatic systems; chromophores not belonging to these two groups are not reported. CRI has been applied to regenerated cellulose II substrates, such as fibers, e.g., Lyocell, viscose, and Modal viscose (Adorjan et al. 2004; Rosenau et al. 2004a, b, 2005a); to cellulose derivatives, such as acetates (Rosenau et al. 2004b, 2005a); and to native cellulose I substrates, such as pulps (Rosenau et al. 2007; Krainz et al. 2009) and cotton linters (Rosenau et al. 2011). From three to twelve individual chromophores were identified in the various cellulosic sources. The overall chromophore concentrations ranged from 0.1 ppm (for bleached pulps) to 35 ppm (viscose fibers).

Recently, we applied the CRI method to artificially aged cotton linters and isolated a set of chromophores (Rosenau et al. 2011) that belonged to three key chromophore classes (2,5-dihydroxy-[1,4]benzoquinones, 5,8-dihydroxy-[1,4]naphthoquinones and 2,5-dihydroxy-acetophenones). Those chromophore classes had also been isolated from other cellulosic matrices. In preceding work on cellulose originating from wood, there was substantial mechanistic evidence that the observed chromophores are a consequence of oxidative damage to the cellulose and hemicelluloses rather than some involvement of lignin but a possible lignin contribution could not be ruled out (Rosenau et al. 2007; Krainz et al. 2009). Only with the isolation of similar chromophores from cotton linters, a substrate in which lignin has not been found, was there solid proof of the carbohydrate origin of the chromophores (Rosenau et al. 2011).

In this study, we communicate the structure of the chromophores isolated from aged bacterial cellulose, another substrate without a possible lignin contribution to chromophore formation. Here, the focus is on the chemical structure of the compounds, some analytical peculiarities, possible formation pathways, and dependence of their formation on the purity of the starting material.

Materials and methods

General

All commercially supplied chemicals and solvents were of the highest purity available. Distilled water was used throughout.

TLC was performed using Merck silica gel 60 F254 pre-coated plates. Flash chromatography was performed on Baker silica gel (40 µm particle size). All products were purified to homogeneity (TLC/GC analysis). 1H NMR spectra were recorded at 400 MHz for 1H and at 100 MHz for 13C NMR in CDCl3 or DMSO-d6. chemical shifts, relative to a TMS internal standard are given in δ ppm values, and coupling constants are in Hz. 13C peaks were assigned by means of APT, HSQC and HMBC spectra. GCMS analysis was carried out on an Agilent 6890N/5975B instrument in the ESI (70 eV) ionization mode.

Starting material

The BC samples were obtained from different suppliers in Germany and Austria (Prof. Dieter Klemm, Jena University, Germany; FZMB Bad Langensalza, Germany; Lohmann & Rauscher GmbH & Co. KG, Neuwied, Germany and Vienna, Austria). The BC sheets from cultivation were treated with aqueous NaOH (3–5 %) for 1 h at 80–95 °C, washed to neutrality with distilled water, treated with 0.5–3 % hydrogen peroxide at pH 10 (NaOH) for another hour at 50 °C, and washed once more with distilled water until the washing solution was neutral and free of H2O2. The hydrogel samples underwent solvent exchange to ethanol and acetone before being freeze-dried.

Initial brightness of the dry samples was between 89 and 94 % ISO. Accelerated aging was performed under daylight in 4 h intervals at 105 °C according to TAPPI UM 200 and 1 h intervals at 100 °C and 100 % humidity according to Paptac E.4P. Final brightness values were between 68 and 85 % ISO for the different samples, depending on their purification history. Brightness was measured as UV/VIS reflection at 457 nm according to ISO 3688/2470.

CRI procedure

The CRI method was used as previously published (Rosenau et al. 2004a, b, 2005a, b, 2007). Briefly, the cellulosic materials is suspended in a bidistilled solvent in the presence of BF3 acetate complex/sodium sulfite as catalyst. The obtained chromophore mixture of electron-rich aromatics and quinones is separated in the presence of tocopherol antioxidants in the eluant, and the individual components present in concentration sufficient for analysis are identified, in all cases also by comparison with an authentic—independently synthesized—sample. CRI was applied to 0.5–0.8 kg of the different BC samples to obtain sufficiently “large” amounts of chromophores.

GPC and CCOA method

The gel permeation chromatography was based on multiple detection by refractive index (RI), multi-angle laser light scattering (MALLS) and fluorescence detectors. Setup and protocol of the carbonyl-selective fluorescence labeling (“CCOA method”) were as previously reported (Röhrling et al. 2002a, b; Potthast et al. 2003).

Isolated chromophores

2,5-Dihydroxy-[1,4]benzoquinone (1). 1H NMR (DMSO-d6): δ 5.81 (s, 2H, CH), 11.55 (s, 2H, OH). 13C NMR: δ 105.03 (CH, d.i.), 170.80 (b). MS (ESI, −), m/z (%): 110.9 (42), 138.9 (100, [M − H+]). Calcd. C6H4O4, M = 140.10.

2-Hydroxy-[1,4]benzoquinone (2). 1H NMR (DMSO-d6): δ 5.73 (s, 1H, CH-3), 6.30 (d, 1H, CH-5), 6.35 (d, 1H, CH-6), 11.23 (s, 1H, OH). 13C NMR: δ 105.03, 131.9, 134.9 (CH), 169.5 (C–OH), 181.23, 185.13 (C=O). MS (ESI, −), m/z (%): 123.0 (100, [M − H+]). Calcd. C6H4O3, M = 124.10.

2,5-Dihydroxy-6-methyl-[1,4]benzoquinone (3). 1H NMR (DMSO-d6): δ 1.98 (s, 3H, Me), 5.92 (s, 1H, CH), 10.88 (s, 1H, OH), 12.13 (s, 1H, OH). 13C NMR: δ 110.62 (CH), 118.41 (C-Me), 168.90 (b). MS (ESI, −), m/z (%): 125.1 (30), 153.2 (100, [M − H+]). Calcd. C7H6O4, M = 154.12.

5,8-Dihydroxy-[1,4]naphthoquinone (4). 1H NMR (CDCl3): δ 6.55 (s, 2H, CH =), 7.32 (2, 2H, ArCH), 10.30 (s, 2H, OH). 13C NMR: δ 108.97 (CH, d.i.), 115.93 (C, d.i.), 128.22 (CH, d.i.), 146.31 (C–OH, d.i.), 190.20 (CO, d.i.). MS (ESI, −), m/z (%): 189.0 (25, [M − H+]), 204.9 (100, [M + H2O − H+]. Calcd. C10H6O4, M = 190.16.

5,8-Dihydroxy-2-methyl-[1,4]naphthoquinone (5). 1H NMR (CDCl3): δ 2.16 (d, 3H, CH3), 6.90 (m, 1H, CH =), 7.08 (m, 2H, ArCH), 12.30 (s, 2H, OH). 13C NMR: δ 16.42 (CH3), 109.92 (ArCH), 111.13 (ArCH), 118.30 (ArC), 118.38 (ArC), 132.12 (CH=), 148.66 (=C–CH3), 161.15 (ArC–OH), 162.03 (ArC–OH), 184.13 (CO), 191.20 (CO). MS (ESI, −), m/z (%): 203 (100, [M − H+]), 221.5 (80, [M + H2O − H+]), 239.1 (10, [M + 2H2O − H+]. Calcd. C11H8O4, M = 204.18.

2,5-Dihydroxyacetophenone (6). 1H NMR (DMSO-d6): δ 2.58 (s, 3H, CH3), 6.79 (d, 1H, 3 J = 8.85 Hz), 7.00 (dd, 1H, 3 J = 8.85 Hz, 4 J = 3.00 Hz), 7.19 (d, 1H, 4 J = 3.00 Hz), 9.18 (s, 1H, 5-OH), 11.88 (s, 1H, 2-OH). 13C NMR: δ 27.60 (CH3), 115.36 (ArCH), 118.23 (ArCH), 120.11, 124.42 (ArCH), 149.32, 153.76, 203.92 (CO). MS (ESI, −), m/z (%): 108.0 (25), 150.9 (100, [M − H]−). Calcd. C8H8O3, M = 152.15.

2,5-Dihydroxy-3-methylacetophenone (7). 1H NMR (DMSO-d6): δ 2.18 (s, 3H, Me), 2.52 (s, 3H, CH3CO), 6.86 (d, 1H, 4 J = 3.2 Hz), 7.02 (d, 2H, 4 J = 3.2 Hz), 8.23, (s, b, 5-OH), 12.16 (s, 1H, 2-OH). 13C NMR: δ 15.88 (Me), 27.36 (CH3CO), 116.72 (ArCH), 122.34 (ArCH), 120.52 (ArC), 123.31 (ArC), 150.12 (ArC–OH), 152.95 (ArC–OH), 202.54 (CO). MS (ESI, −), m/z (%): 122.1 (35), 165.3 (100, [M − H+]). Calcd. C9H10O3, M = 166.18.

1H-Indol-3-yl-acetic acid (8). 1H NMR (DMSO-d6): δ 3.63 (s, 2H, CH2), 6.97 (dd, J = 7.4/7.4 Hz, 1H, 5-H), 7.07 (dd, J = 7.4/7.8 Hz, 1H, 6-H), 7.22 (s, 1H, 2-H), 7.34 (d, J = 8.2 Hz, 1H, 7-H), 7.49 (d, J = 7.8 Hz, 1H, 4-H), 10.88 (s, 1H, 1-H), 12.13 (s, br, 1H, 12-H). 13C NMR: δ 31.2 (CH2), 107.8 (Cq, 3-C), 111.5 (CH, 7-C), 118.6 (CH, 5-C), 118.7 (CH, 4-C), 121.1 (CH, 6-C), 124.1 (CH, 2-C), 127.4 (Cq, 4a-C), 136.3 (Cq, 7a-C), 173.3 (C=O). MS (ESI, −), m/z (%): 174 (100, [M − H]−). M = 175.19. Calcd. for C10H9NO2: C 68.56, H 5.18, N 8.00; found C 68.42, H 5.27, N 7.72 (isolated sample).

5,6,11,12-Tetrahydroindolo[3,2-b]carbazole (9). 1H NMR (DMSO-d6): δ 4.05 (s, 4H, 6-CH2 + 12-CH2), 7.02 (dd, J = 7.0/7.4 Hz, 2H, 2-H + 8-H), 7.09 (dd, J = 7.0/7.8 Hz, 2H, 3-H + 9-H), 7.37 (d, J = 7.8 Hz, 2H, 4-H + 10-H), 7.52 (d, J = 7.4 Hz, 2H, 1-H + 7-H), 11.01 (s, 2H, 5-NH + 11-NH). 13C NMR: δ 21.0 (6-CH2 + 12-CH2), 105.6 (13-Cq + 18-Cq), 110.9 (4-CH + 10-CH), 117.6 (1-CH + 7-CH), 118.4 (2-CH + 8-CH), 120.7 (3-CH + 9-CH), 127.0 (16-Cq + 19-Cq), 133.0 (14-Cq + 17-Cq), 136.7 (15-Cq + 20-Cq). M = 258.32. Calcd. for C18H14N2: C 83.69, H 5.46, N 10.84; found: C 83.92, H 5.42, N 11.02 (isolated sample).

5,11-Dihydroindolo[3,2-b]carbazole (10). 1H NMR (DMSO-d6): δ 7.13 (dd, J = 7.0/7.4 Hz, 2H, 2-H + 8-H), 7.39 (dd, J = 7.0/7.8 Hz, 2H, 3-H + 9-H), 7.47 (d, J = 7.8 Hz, 2H, 4H + 10-H), 8.12 (s, 2H, 6H + 12-H), 8.20 (d, J = 7.4 Hz, 2H, 1-H + 7-H), 11.00 (s, 2H, 5-NH + 11-NH). 13C NMR: δ 100.6 (6-CH + 12-CH), 110.6 (4-CH + 10-CH), 117.8 (2-CH + 8-CH), 120.3 (1-CH + 7-CH), 122.8 (13-Cq + 18-Cq + 16-Cq + 19-Cq), 125.6 (3-CH + 9-CH), 135.2 (14-Cq + 17-Cq), 141.3 (15-Cq + 20-Cq). M = 256.31. Calcd. for C18H12N2: C 84.35, H 4.72, N 10.93; found: C 84.22, H 4.88, N 11.08 (isolated sample).

Synthesis of authentic samples for comparison

Authentic samples of chromophores 1–7 were available from previous work (cf. preceding parts of the present series on chromophores in cellulosics). Indole-3-acetic acid (8) was available from Sigma-Aldrich. Heterocycles 9 and 10 were prepared according to the following protocol, modified from the literature (Kim et al. 2011; van Snick and Dehaen 2012): 1,4-Cyclohexanedione (1.00 g, 9 mmol) and phenylhydrazine hydrochloride (2.61 g, 18 mmol) were suspended in a mixture of EtOH (17 mL) and AcOH (50 µL). The suspension was heated to 50 °C for 1 h and then cooled to room temperature. The resulting solid was filtered and washed with EtOH (3 × 6 mL). The solid, slightly pink intermediate was directly used for the next step without further purification. AcOH (10 mL) and concentrated sulfuric acid (1.2 mL) were cooled in an ice bath and the intermediate compound was added. The mixture was vigorously stirred at 0 °C for 10 min, then the ice bath was removed and stirring was continued at room temperature for a further 10 min. The suspension was then heated to 45 °C while stirring for 10 min and slowly cooled to room temperature. The resulting solid was filtered and washed consecutively with acetic acid, water and ethyl ether (6 mL each). The product was dried under high vacuum at room temperature overnight to provide 200 mg (9 %) of a mixture of 9 and 10 as a slightly yellowish solid.

Results and discussion

Bacterial cellulose is of increasing interest for many bio-applications, particularly in the medical and cosmetic sectors. This is because of its special properties, especially its gel and hydration/dehydration behaviour (Barud et al. 2008; Sheridan et al. 2002). Bacterial cellulose is mostly cultivated discontinuously in batch mode (Bungay and Serafica 1997; Geyer et al. 1994), which is further distinguished into static and dynamic cultivation types according to the nutrient supply, but also (semi-)continuous variants have been reported (Kralisch et al. 2008, 2010).

Acetobacter xylinum is the most frequently used strain in commercial bacterial cellulose production, most commonly grown in the Hestrin–Schramm medium (Hestrin and Schramm 1954). Extracellular secretion of bacterial cellulose as cellulose allomorph I occurs after an induction phase on the liquid-to-air interface of the growth medium. The thickness of the produced cellulose layer is in the range of about 3–4 cm at a temperature of 30 °C. To liberate the produced cellulose pellicles from adhering cultivation medium and protein, they are treated with lye at elevated temperatures (typically 3–5 % NaOH for 0.25–1 h at 80–95 °C) and undergo mild bleaching (typically 0.5–3 % hydrogen peroxide at pH 10 (NaOH) for about 1 h at 50–70 °C) with thorough washing between and after the treatment steps. The resulting hydrogel consists of 1–3 % cellulose besides water. It can be cut into pieces and converted into solvogels by solvent exchange.

Figure 1 presents the molecular weight distribution of a typical fresh BC as measured by gel permeation chromatography in DMAc/LiCl (9 % w/v). The distribution of another representative cellulosic material, a dissolving pulp (beech wood, sulfite pulp), is given for comparison. Most important is the large molecular weight of the bacterial cellulose, some 1 million g mol−1 (6,000 anhydroglucose residues) or more. The comparison with a different cellulose makes this feature obvious. At such high MW values the separation columns in GPC are not efficient anymore, and the shape of the MW distribution is somewhat skewed, with the highest MW regions being insufficiently resolved. The MW distributions of bacterial celluloses are thus not fully reliable on their high-MW side.

In addition, the carbonyl content was determined according to the CCOA method (Röhrling et al. 2002a, b; Potthast et al. 2003), which ranged between 2 and 4 µmol g−1. These values are very low compared to other cellulosics which usually are in the range of 20–40 µmol g−1 for pulps and fibers and can reach up to 100 µmol g−1 for degraded or oxidatively damaged samples. The content in pure BC corresponds to the amount of reducing ends—which are masked carbonyl groups in the form of hemiacetals. No other carbonyls are contained so that the cellulose chain is principally free of oxidative lesions and represents a largely ideal cellulose structure.

Interestingly, some BC samples exhibited a MWD shoulder in the region between approx. 50,000 and 300,000 g mol−1 (Fig. 2, top). At the same time, these samples exhibited nitrogen contents upon microanalysis. Extensive washing (NaOH) possibly followed by a mild bleaching step (H2O2) removed this shoulder and lowered the nitrogen content to zero level according to microanalysis. The same samples exhibited also significant yellowing upon aging and afforded N-heterocyclic chromophores. The shoulder in the MWD corresponded to a region of increased carbonyl content (Fig. 2, bottom). From these data, it was evident that the samples still contained some adhering protein which was insufficiently removed during the purification steps. While the GPC separation does not allow deriving any details about the structure of the impurities, the combination with fluorescence labeling and fluorescence detection is well suited to report the presence of even minor concentrations.

Top molecular weight distribution (MWD) of two BC samples, one of them insufficiently purified and still containing adhering protein parts from BC cultivation (solid line), the other one showing the typical profile of pure BC (dashed line). The corresponding MW region is marked by a box. Bottom differences in the carbonyl content between a non-purified BC sample and a pure BC sample (dots) and between a water-purified sample and a pure BC sample (squares), illustrating the significantly higher carbonyl content of the former sample, being more impure, i.e., having a higher content of residual protein. Data are given as ΔDS-plots displaying the difference in carbonyl contents between the two respective samples

When the CRI method was applied to pure, non-aged BC, no chromophores were isolated. Evidently, their content was too low. This was the first case that a cellulosic substrate did not provide any isolable chromophore traces. Such pure BC thus represents a good model for genuine cellulose without chemical impurities. This also indicates a near absence of carbonyl groups along the cellulose chain, i.e., there are almost none of the oxidized “spots” that frequently occur in processed cellulosics, such as pulp or fibers.

The situation was different for the imperfectly purified BC that had not been cleansed of adhering protein. The CRI procedure released a complex product mixture that contained mainly amino acids and oligopeptides. A quick mass spectrometric (MALDI) scan showed masses up to 8,400 g mol−1; its nitrogen content was 4.45 %. Further analysis was not performed because the CRI method is specific for electron-rich quinones and aromatics, but evidently fails in the case of completely different analyte compound classes, such as protein degradation mixtures.

The aged material also gave different results. From the aged pure BC sample, a mixture of chromophoric compounds was isolated by the CRI method, and seven individual compounds were identified (Scheme 1). The chromophore mixture appeared as a brownish red wax; the sum concentration of all isolated chromophores was 3 ppm. This concentration is in the range of chromophores found in bleached pulps (0.1 to approx. 4 ppm) but considerably lower than the content in cellulose II fibers and cellulose acetates (up to 35 ppm and up to 60 ppm, respectively). The concentration of the individual compounds in the chromophore mixtures is more than one order of magnitude lower. Again, it is emphasized that the CRI method cannot provide a reliable quantification of chromophores, because of the complexity of the mixtures and the extremely low concentrations involved. It is only possible to qualitatively determine the presence of chromophoric compounds and to identify the structure of the main contributors, provided that sufficient amounts were isolated.

The artificial aging caused brightness of the BC to drop by nine ISO points, from initially 94 % ISO before aging to 85 % ISO after aging. After the chromophore extraction, the residual BC returned to 92 % ISO brightness (and did not change further upon another CRI treatment). As in the previous reports on CRI-isolated chromophores, all structures reported in the following were verified by thorough analytical characterization and by comparison to authentic samples, either available from previous work or independently synthesized.

All the chromophores isolated were either quinones or aromatics, corresponding to the isolation principle that renders the CRI procedure selective for those compounds. As in the case of all of the cellulosic substrates studied so far, three main chromophore classes were found for BC: hydroxy-[1,4]benzoquinones (1–3), 5,8-dihydroxy-[1,4]naphtho-quinones (4–5) and 2-hydroxyacetophenones (6–7). In Scheme 1, hydroxyl groups are drawn in a way to indicate the presence of strong hydrogen bonds that significantly contribute to the stability of the compounds. The compounds 2,5-dihydroxy-[1,4]benzoquinone (1), 5,8-dihydroxy-[1,4]-naphthoquinone (4) and 2,5-dihydroxyacetophenone (6), the three key chromophores in cellulosics, are also present among BC chromophores. These compounds are almost ubiquitous in the chromophore mixtures and can be considered as “lead structures” from which the majority of the other chromophore structures are formally derived. The chemistry of these compounds and the reasons for their frequent occurrence in cellulosics have recently been reviewed (Hosoya et al. 2013a, b) and the data are not repeated here. It suffices to reiterate that hydrogen bonding in solid state and acidic media and resonance effects in neutral and alkaline media give strong stabilization to these compounds. That accounts on one hand for their ready formation in condensation reactions during aging, and on the other hand also for their relative insensitivity towards common bleaching agents, allowing them to survive bleaching treatments much longer than other chromophores that lack that special stabilization, see Scheme 2. One interesting feature of the compounds is the acidity of the hydroxyl groups, which is due to the special stabilization of the anions. The pKa values range between 4 and 7, similar to weak-to-medium organic acids.

Compound 3 is distinguished from parent compound 1 by an additional methyl group at position 6. The resonance of the dianion is also in effect for 3 and the reactivity of both compounds is similar apart from the blocking of position 6 for electrophilic substitutions by the substituent already present. Compound 2 does not possess such extensive stabilization; the resonance effect upon deprotonation of the hydroxyl group is limited to ‘one side” of the compound. Oxidation of 2 affords 1 readily, even in solid state under ambient conditions (Rosenau et al. 2011). It is therefore reasonable to assume that some of the total amount of 1 in the isolated chromophore mixture from aged BC originated from oxidation of 2.

Compound 5 is a C-methyl derivative of key chromophore 4 (as is 3 with regard to 1). Again, chemical behavior of parent compound and derivative are nearly congruent. Condensations of polyphenols or hydroxybenzoquinones can provide hydroxynaphthoquinones (Rao and Venkateswarlu 1965), so that the possibility of 4 and 5 being formed from structures such as 1–3 and like compounds cannot be excluded. Also the follow-up chemistry of naphthoquinone 4 and similar compounds is rich and offers ample starting points for mechanistic studies (Hosoya et al. 2013b). Compounds 6 and 7 are distinguished by an additional methyl group in the latter; they can be regarded as 2,5-dihydroxyacetophenones or, alternatively, 2-acetylhydroquinones. The hydrogen bond from the 2-OH group to the carbonyl oxygen is exceptionally strong in the solid state as well as neutral and acidic media. This is reflected by the behavior in common derivatization reactions, such as acylations or alkylations, which provide the 5-O-monosubstituted compounds, while the 2-O-position remains rather non-reactive in these processes.

Aging of the BC sample that was incompletely purified from adhering protein caused visible yellowing that was significantly more pronounced than for the well-purified starting material. The decrease in ISO brightness from 89 to 68 % for the former was more pronounced than that of the aged, well-purified sample (94 % ISO–85 % ISO). Application of the CRI method provided three major compounds (8–10, Scheme 3) that all contained nitrogen. Thus, they evidently did not originate from cellulose, but from the protein impurities. Moreover, all three compounds contained indole moieties, so that tryptophan residues can be assumed to be the actual precursor structures. The N-heterocycles were accompanied by minor amounts of compounds 1 and 7. At present it cannot be answered whether the formation of the protein-derived degradation products somehow suppressed the chromophore generation from cellulose or whether the excess of compounds 8–10 influenced the analytical procedure in a way such that the cellulose derived chromophores 1–7 were harder to detect. The overall amount of the chromophore compound mixture isolated was 24 ppm and thus considerably higher than in the case of the aged, pure BC (3 ppm) discussed above. The major components 8–10 amounted to 83 % of that total chromophore amount, the minor contributors 1 and 7 to an additional 6 %.

Chemical structures of individual chromophores isolated from aged BC that was imperfectly purified from adhering protein residues. Compounds 8–10 are evidently derived from the amino acid tryptophan (given for comparison), compounds 1 and 7 are minor constituents and typical cellulose-based chromophores (cf. Scheme 1)

All three isolated nitrogen compounds contain the heterocyclic indole ring system, which is also part of the essential proteinogenic amino acid tryptophan. It was thus reasonable to assume that compounds 8, 9, and 10 were aging products of these moieties in the protein impurities still contained in the imperfectly purified BC. It might be hypothesized that other degradation and transformation products of the protein impurity and its amino acids were formed upon aging, but the selectivity of the isolation method for aromatic and quinoid systems only reported the compounds presented above.

Indole-3-acetic acid (IAA, 8) is readily formed from tryptophan by oxidative decarboxylation/deamination. The same pathway is used in plant biosynthesis (Mashiguchi et al. 2011; Won et al. 2011). IAA is one of the most common plant hormones (an auxin) that occurs naturally in all higher plants (Zhao, 2010). Since its original synthesis from indol-3-ylacetonitrile (Majima and Hoshino 1925) many alternative synthetic approaches have been developed and it is a very well-investigated compound. Its identification in the isolated product mixture was not challenging, but the presence of a plant growth hormone in the aged BC sample came as a surprise.

Identification of compounds 9 and 10 was more demanding. Due to the high symmetry of the compounds, NMR spectra were less predictive, and final confirmation of the structures was provided by comparison with independently synthesized samples (see Materials and methods section for details). Compound 10 is a pentacyclic aromatic system and thus has a high degree of bond conjugation. It can be perceived as a benzene moiety bis-[2,3-b]-anellated with indole, or a carbazol [2,3-b]-anellated with indole. Compound 9 is the dihydro derivative of 10. Its central ring system is not aromatic but instead has a cyclohexadiene structure. With regard to the generation of compounds 9 and 10, it is reasonable to assume a formation from tryptophan. One of the final products of tryptophan metabolism in mammals is 3-methylindole (skatole, 11) (Yao et al. 2011), a compound that gives feces the characteristic odor (Brieger 1877). Assuming that similar degradation processes of tryptophan could occur upon aging in the BC system, compound 9 is the product of dehydrogenative dimerization of skatole, and compound 10 the product of further oxidation (Scheme 4). An alternative pathway starts from indole-3-carbinol (12), another breakdown product of tryptophan that is contained in significant amounts in cruciferous vegetables (Higdon et al. 2007). Upon protonation, the compound readily forms a resonance-stabilized cation (13) by elimination of water, which dimerizes in a double Friedel–Crafts-type process. This pathway would also account for the fact that only the compounds with a central p-phenylenediamine structure (9 and 10) are found, but not the corresponding o-phenylenediamine derivatives (14) (Scheme 4).

Compound 9, and especially the pentacyclic aromatic 10, are largely insoluble in common organic solvents, but show some solubility in DMSO and DMF. They are barely soluble in warm mineral acids and mixtures of such acids with organic solvents. Both compounds are readily adsorbed by cellulose. Adding 1 g of cellulosic pulp to 10 mL of a 1 mM solution of 10 in warm acetic acid will cause immediate adsorption to such completeness that 10 is no longer detectable in the solvent by UV spectrometry. Even more interesting is the fact that dihydro derivative 9, once absorbed by cellulose, becomes much more prone to oxidation than in solution. This oxidation process can also be visually followed by the transition from colorless (9) to intense yellow (10).

Oxidation of 9 (as a 0.1 mM solution in 50 % aqueous acetic acid at 40 °C) by an excess of dichloro-dicyano-[1,4]benzoquinone (DDQ, 50 eq.) follows first-order kinetics (data not shown) with a half-time of 415 s (approx. 7 min), meaning that half of the compound´s amount is converted into product 10 after that time. When absorbed on cellulose, under otherwise identical conditions, the half-time for the oxidation of 9 dropped to 18 s, and the color change that was gradual in solution became almost immediate. The kinetic rate constants k—following from the equation k = ln2/t that applies for first-order reactions—are k sol = 1.67*10−3 s−1 for the reaction in solution and k ads = 3.85*10−2 s−1 for the adsorption case with cellulose present. The apparent catalytic effect of added cellulose can be nicely demonstrated. If cellulose is added to a thoroughly degassed solution of 9, there will be no visible change. When added into an aerated solution instead, the solid cellulose will immediately turn yellow due to heterocycle 9 being almost immediately absorbed and simultaneously oxidized to 10 in its absorbed form.

The term “catalytic” must be used with care in this case as catalysts form a chemical intermediate between starting material and catalyst that subsequently splits into product and regenerated catalyst. That precise role cannot be taken for granted for cellulose in the conversion of 9–10. However, independent of whether the effect is truly catalytic or not, the results from adding cellulose are not just from adding a generic solid. Polystyrene beads, polyethylene powder, or glass pearls, to which neither 9 nor 10 is absorbed, had no comparable effect. By contrast, wool fibers strongly adsorbed the two compounds and also accelerated the oxidation reaction. It was evident from these observations that adsorption is crucial for the promoting effect to occur, and a reasonable explanation attempt might be the following: the pentacyclic aromatic system 10 is a completely planar compound (180° between the two indole parts), while compound 9 has a V-shaped geometry, for which geometry optimization (B3LYP/6-31 + G*) predicts a dihedral angle of 107.4° between the two indole planes. While 10 can be flatly adsorbed on cellulose crystal planes which optimizes the contact area and thus the binding forces, compound 9 in its equilibrium geometry can only adsorb in a less efficient way, for example just with one “half” of the molecule. The adsorption forces would attempt to force the adsorbed 9 into a more planar, “10-like” geometry. The change of the dihedral angle would have a direct effect on the ease of oxidation of the compound, and since the geometry of adsorbed 9 is closer to that of 10 as compared to non-adsorbed 9, the effect would be an accelerating one. This is fully consistent with the SIBL theory (strain-induced bond localization, Stanger and Tkachenko 2001) that was, for instance, invoked to explain effects of bond angle changes on the oxidation behavior of vitamin E-type antioxidants (Rosenau et al. 2005b). Strain exerted on the twisted dihydro derivative 9, in a way that it is forced towards planar geometry would facilitate oxidation to the aromatic system.

Interesting findings were that the oxidation rate of 9–10 increased with increasing crystallinity of the cellulosic substrate, and that cellulose II substrates had a larger promoting effect (approx. three times) on the oxidation rate than cellulose I substrates at comparable crystallinity. A more detailed study of the reaction system and this interesting phenomenon is pending, and we hope to achieve a better understanding of adsorption geometries and rate-promoting effect by means of quantum chemistry and molecular simulations. Besides the benefit of an improved general understanding of adsorption on cellulose surfaces, there might be an unexpected application. Cellulose crystallinity could be rapidly estimated by a simple UV-method based on the redox couple 9/10 as a molecular probe, provided there is a reasonably sensitive dependence of the changes in reaction rate on the crystallinity index.

Conclusions

In cellulosic materials such as pure BC that lack lignin and other impurities, the formation of chromophoric compounds must proceed via degradation of carbohydrates. Quinoid and aromatic compounds are well known to form from monosaccharides and oligosaccharides upon either thermal, acidic, or basic treatment in the presence of air. Such compounds are often called “Theander products” (Popoff and Theander 1972, 1976a, b; Popoff et al. 1978; Olsson et al. 1978; Theander and Nelson 1978; Theander and Westerlund 1980). It is reasonable to assume that chromophore formation from cellulose requires “reactive spots” for degradation and condensation, which can only be carbonyl groups, either in their free or in their masked hemiketal/hemiacetal form. In pure BC without any other carbonyls than the reducing ends, no chromophore formation was detectable. After aging, however, cellulose was oxidatively damaged, carbonyl groups were introduced, and chromophore formation ensued.

The fact that the chromophoric compounds isolated from BC are similar in structure to those detected in other cellulosics such as pulps, fibers, and cotton linters confirms the previous hypothesis of a “carbohydrate origin” of these compounds rather than a “lignin origin”. These chromophores belong to three key chromophore classes, with 2,5-dihydroxy-[1,4]benzoquinone (1), 5,8-dihydroxy-[1,4]naphthoquinone (4), and 2,5-dihydroxyacetophenone (6) being the main representatives and “lead structures”. These three compounds were also the major contributors to color in aged BC. Such chromophores, as discussed previously (Rosenau et al. 2011), are typical primary chromophores. They are formed from polysaccharides by oxidative, hydrolytic, thermal, or chemical stress. Their detailed formation pathways, which are currently a matter under intensive study, involve oxidative degradation to monosaccharides and smaller C2–C4 fragments followed by recondensation to the actual chromophores. Secondary chromophores, by contrast, involve process chemicals, such as solvents or derivatizing chemicals, and the formation of degradation products from them is thus strongly process-dependent.

The studies on chromophore formation in BC have shown that, on one hand, carefully purified BC consists largely of “ideal” cellulose, i.e., does not contain oxidized spots or other irregularities. It is a very good model for chemically pure cellulose. On the other hand, protein impurities from cultivation that have not been completely removed, have a large influence on the aging behavior. These byproducts are detectable by GPC measurements combined with carbonyl-selective fluorescence labeling. Chromophore generation from these amino acid-based impurities is pronounced and overwhelms chromophore development from the carbohydrate. It is important to note that the protein impurities are not readily apparent in the starting material, which has very high brightness. They only become evident after aging. However, protein impurities might also interfere with chemical modifications of cellulose that could, most importantly, influence physiological properties of BC in medical or cosmetic applications. Careful purification of the BC by alkaline treatment with washing and mild bleaching to reliably remove adhering protein from cultivation is thus an indispensable prerequisite to BC applications in the bio-sector. Both GPC with fluorescence labeling and accelerated aging provide good means for a purity check. While aging of pure material does not cause a significant drop in brightness, the decrease in the case of impure samples is drastic.

All protein-derived chromophores contained indole units and were thus derived from tryptophan. One compound, indole-3-acetic acid (8) is a direct oxidative decarboxylation/deamination product, whereas the other two (9, 10) are dimers of 3-methyl(ol)-indole. Both compounds have limited solubility in common organic solvents and readily adsorb onto cellulosic surfaces. Compound 9 is a dihydro derivative and is oxidized to the corresponding pentacyclic aromatic system 10. In solution, this oxidation is slow and is not effected by molecular oxygen. After adsorption to cellulose, it proceeds about 20 times faster and also with dioxygen as the oxidant. An apparent influence of cellulose crystallinity and allomorph is currently under study.

References

Adorjan I, Potthast A, Rosenau T, Sixta H, Kosma P (2004) Discoloration of cellulose solutions in N-methylmorpholine-N-oxide (Lyocell). Part 1: studies on model compounds and pulps. Cellulose 12(1):51–57

Barud HS, Barrios C, Regiani T, Marques RFC, Verelst M, Dexpert-Ghys J, Messaddeq Y, Ribeiro SJL (2008) Self-supported silver nanoparticles containing bacterial cellulose membranes. Mater Sci Eng C 28:515–518

Brieger L (1877) Über die flüchtigen Bestandtheile der menschlichen Excremente. Ber Dtsch Chem Ges 10:1027–1032

Bungay HR, Serafica GC (1997) Production of microbial cellulose. United States Patent 6071727

Geyer U, Heinze T, Stein A, Klemm D, Marsch S, Schumann D, Schmauder HP (1994) Formation, derivatization and applications of bacterial cellulose. Int J Biol Macromol 16(6):343–347

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352

Higdon J, Delage B, Williams D, Dashwood R (2007) Cruciferous vegetables and human cancer risk: epidemiologic evidence and mechanistic basis. Pharmacol Res 55(3):224–236

Hosoya T, French AD, Rosenau T (2013a) Chemistry of 2,5-dihydroxy-[1,4]-benzoquinone, a key chromophore in aged cellulosics. Mini Rev Org Chem 10(3):302–308

Hosoya T, French AD, Rosenau T (2013b) Chemistry of 5,8-dihydroxy-[1,4]-naphtho-quinone, a key chromophore in aged cellulosics. Mini Rev Org Chem 10(3):309–315

Kim HY, Yang SG, Yi JI, Lee JY, Kwak YH (2011) Condensed-cyclic compound and organic light-emitting device including the same. Patent EP 2 371 828 A1, p 61

Krainz K, Potthast A, Suess U, Dietz T, Nimmerfroh N, Rosenau T (2009) Effects of selected key chromophores on cellulose integrity upon bleaching. Holzforschung 63(6):647–656

Kralisch D, Hessler N, Klemm D (2008) Kontinuierliches Verfahren zur Darstellung von bakteriell synthetisierter Cellulose in flächiger Form. Patent EP2331699A2

Kralisch D, Hessler N, Klemm D, Erdmann R, Schmidt W (2010) White biotechnology for cellulose manufacturing—the HoLiR concept. Biotechnol Bioeng 105(4):740–747

Majima R, Hoshino T (1925) Synthetische Versuche in der Indol-Gruppe, VI.: Eine neue Synthese von β-Indolyl-alkylaminen. Ber Dtsch Chem Ges (A and B) 58(9):2042–2046

Mashiguchi K, Tanaka K, Sakai T, Sugawara S, Kawaide H, Natsume M, Hanada A, Yaeno T (2011) The main auxin biosynthesis pathway in Arabidopsis. Proc Natl Acad Sci 108(45):18512–18517

Olsson K, Pernemalm PA, Theander O (1978) Formation of aromatic compounds from carbohydrates. Part 7. Acta Chem Scand B 32:249–256

Popoff T, Theander O (1972) Formation of aromatic compounds from carbohydrates. Part 1. Carbohydr Res 22:135–149

Popoff T, Theander O (1976a) Formation of aromatic compounds from carbohydrates. Part 3. Acta Chem Scand B 30:397–402

Popoff T, Theander O (1976b) Formation of aromatic compounds from carbohydrates. Part 4. Acta Chem Scand B 30:705–710

Popoff T, Theander O, Westerlund E (1978) Formation of aromatic compounds from carbohydrates. Part 6. Acta Chem Scand B 32:1–7

Potthast A, Röhrling J, Rosenau T, Borgards A, Sixta H, Kosma P (2003) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labeling. 3. Monitoring oxidative processes. Biomacromolecules 4(3):743–749

Rao TVP, Venkateswarlu V (1965) Chemical examination of Embelia ribes-VII. Synthesis of some new N-bis(anhydrobenzoquinones). Tetrahedron 21:389–390

Röhrling J, Potthast A, Rosenau T, Lange T, Ebner G, Sixta H, Kosma P (2002a) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labeling. 1. Method development. Biomacromolecules 3:959–968

Röhrling J, Potthast A, Rosenau T, Lange T, Borgards A, Sixta H, Kosma P (2002b) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labeling. 2. Validation and applications. Biomacromolecules 3:969–975

Rosenau T, Potthast A, Milacher W, Adorjan I, Hofinger A, Kosma P (2004a) Discoloration of cellulose solutions in N-methylmorpholine-N-oxide (Lyocell). Part 2: isolation and identification of chromophores. Cellulose 12(2):197–208

Rosenau T, Potthast A, Milacher W, Hofinger A, Kosma P (2004b) Isolation and identification of residual chromophores in cellulosic materials. Polymer 45(19):6437–6443

Rosenau T, Adorjan I, Potthast A, Kosma P (2005a) Isolation and identification of residual chromomophores in cellulosic materials. Macromol Symp 223(1):239–252

Rosenau T, Ebner G, Stanger A, Perl S, Nuri L (2005b) From a theoretical concept to biochemical reactions: strain induced bond localization (SIBL) in oxidation of vitamin E. Chem Eur J 11(1):280–287

Rosenau T, Potthast A, Kosma P, Suess H-U, Nimmerfroh N (2007) First isolation and identification of residual chromophores from aged bleached pulp samples. Holzforschung 61(6):656–661

Rosenau T, Potthast A, Krainz K, Yoneda Y, Dietz T, Shields ZPI, French AD (2011) Chromophores in cellulosics, VI. First isolation and identification of residual chromophores from cotton linters. Cellulose 18(6):1623–1633

Sheridan RL, Morgan JR, Mohamed R (2002) Biomaterials in burn, wound dressings. In: Severian D (ed) Handbook of polymeric biomaterials. Marcel Dekker, New York

Stanger A, Tkachenko E (2001) Strain induced bond localization in strained aromatic compounds with extended π systems. J Comp Chem 22(13):1377–1386

Suess HU, Filho CL (2003) How to improve brightness stability of Eucalyptus Kraft pulp. Proceedings ABTCP 2003, 36° Congresso Internacional de Celulose e Papel, São Paulo, Brazil

Theander O, Nelson DA (1978) Aqueous, high-temperature transformation of carbohydrates relative to utilization of biomass. Adv Carbohydr Chem Biochem 46:273–326

Theander O, Westerlund E (1980) Formation of aromatic compounds from carbohydrates. Part 8. Acta Chem Scand B 34:701–705

van Snick S, Dehaen W (2012) Synthesis of novel 2,8-disubstituted indolo[3,2-b]carbazoles. Org Biomol Chem 10:79–82

Won C, Shen X, Mashiguchi K, Zheng Z, Dai X, Cheng Y, Kasahara H, Kamiya Y (2011) Conversion of tryptophan to indole-3-acetic acid by tryptophan aminotransferases of Arabidopsis and yuccas in Arabidopsis. Proc Natl Acad Sci 108(45):18518–18523

Yao K, Fang J, Yin YL, Feng ZM, Tang ZR, Wu G (2011) Tryptophan metabolism in animals: important roles in nutrition and health. Front Biosci 3:286–297

Zhao Y (2010) Auxin biosynthesis and its role in plant development. Annu Rev Plant Biol 61:49–64

Acknowledgments

We would like to thank the Austrian Christian-Doppler-Society for financial support through the “Christian Doppler Laboratory for Advanced Cellulose Chemistry and Analytics”. Prof. Dieter Klemm, Jena University, Germany, as well as the FZMB Bad Langensalza are acknowledged for the gift of differently prepared BC samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rosenau, T., Potthast, A., Krainz, K. et al. Chromophores in cellulosics, XI: isolation and identification of residual chromophores from bacterial cellulose. Cellulose 21, 2271–2283 (2014). https://doi.org/10.1007/s10570-014-0289-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0289-0