Abstract

Rod-like cellulose nanowhiskers and spherical cellulose nanoparticles were prepared from wood-pulp-derived cellulose powder by mechanical refining processes such as high-pressure homogenization (HPH) and ball-milling (BM). The nanowhiskers obtained by the HPH method were found to be 200–500 nm long and 11–16 nm wide. The diameters of the nanoparticles were in the range 40–200 nm, depending on the BM time, and were reduced to 25–50 nm after extra HPH. By adjusting the BM time, cellulose nanoparticles having different polymorphs with similar morphologies were prepared. The X-ray diffraction patterns revealed the recrystallization of cellulose I (1 h of BM time) or cellulose II (4–8 h of BM time) in ball-milled nanoparticles after water washing and solvent exchange treatments. The nanowhisker widths derived from the specific surface areas (SSA) by adsorption methods such as Congo red dye, nitrogen, and water vapor, sorptions were in agreement with those obtained from transmission electron microscopy and atomic force microscopy images. Similar SSA values were obtained for micro- and nano-scale cellulose materials using water vapor adsorption methods, and the SSAs of nanoparticles obtained by different adsorption methods are also discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cellulose is one of the most abundant naturally occurring and renewable biopolymers on Earth. It exists as nanoscale fibrils in wood/plants and functions as the load-bearing constituent. Fengel (1971) proposed a model for the ultrastructural organization of the cell wall components in wood. According to his model, 16 elementary fibrils with a width of 3 nm are arranged in 12 × 12 nm fibrils that, in turn, form 25–30 nm microfibrillar aggregates. There are several layers of hemicellulose present between the 12 nm fibrils and a monomolecular layer between the elementary fibrils. Lignin surrounds the total microfibrillar system. The cellulose microfibril in wood is found to be approximately 3,500–5,000 nm in length, as determined by a variety of methods (Fengel and Wegner 1989), whereas the average size of each crystallite has been determined to be 2–20 nm wide and 2–17 nm thick by X-ray analysis, depending on the nature of the cellulose source (O’Sullivan 1997).

The strategy of using nanoscale cellulose fibers as the load-bearing constituent to develop new bio-based polymer nanocomposites for a wide range of applications has been recently re-emphasized in accordance with an increasing awareness of sustainability and environmental concerns. In this context, exploring the preparation of nanoscale celluloses such as microfibrillated cellulose (MFC) and cellulose whiskers from wood cell walls by various mechanical and chemical treatments and their combinations is becoming an important topic of research (Eichhorn et al. 2001; Samir et al. 2005; Siró and Plackett 2010).

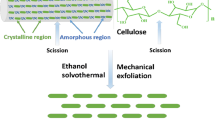

Microfibrillated cellulose (MFC) is generally manufactured by mechanical treatments such as grinding and high-pressure homogenization (HPH). In HPH, a dilute slurry of cellulose flows fast through a spring-loaded valve assembly with high pressure, resulting in a high degree of fibrillation, even to nanoscale. The geometric dimensions of MFC are generally reported to be diameter 10–40 nm and length more than 1 μm, with an aspect ratio of 100–150 (Siró and Plackett 2010). In addition, Pääkkö et al. (2007) have reported that MFC can be prepared by enzymatic hydrolysis combined with mechanical shearing and HPH. MFCs obtained by these methods were separated into two fractions with different lateral dimensions of 5–6 nm and 10–20 nm (Pääkkö et al. 2007). Cellulose whiskers are generally prepared by acid hydrolysis using hydrochloric acid (HCl) or sulfuric acid (H2SO4). When subjected to acid hydrolysis, cellulose microfibrils undergo transverse cleavage along the amorphous regions and rod-like cellulose crystals with a relatively low aspect ratio are obtained. The geometrical characteristics of cellulose whiskers depend on the origin of the cellulose and the acid hydrolysis reaction conditions. Furthermore, the typical width of cellulose whiskers is reported to be around 2–20 nm, but there is a wide length distribution of 100–600 nm and in excess of 1 μm in some cases (Samir et al. 2005; Siró and Plackett 2010). Generally, the cellulose whiskers from tunicate and bacterial cellulose are larger than those obtained from wood (Beck-Candanedo et al. 2005; Bondeson et al. 2006).

In addition to fiber or rod-like nanoscale cellulose, spherical cellulose nanoparticles have been reported (Liu et al. 2007; Zhang et al. 2007). The cellulose nanospheres were prepared by using mixed acids (e.g., H2SO4 and HCl), in the size range 60–570 nm, with predominantly the cellulose II polymorph. In another study, cellulose acetate particles with diameters of 5–15 μm were obtained by a solution–gel process (Ougiya et al. 1998).

Previously, all these cellulose nanoparticles, nanowhiskers, and nanospheres described above were prepared by the acid hydrolysis route. In this study, we attempted to prepare nanoscale cellulose materials by mechanical treatments only, such as HPH and ball-milling (BM), without the use of any chemical reagents. The effects of mechanical treatments on crystalline structure, morphology, geometrical dimensions, and the surface area are discussed.

Experimental section

Preparation of nanoscale cellulose

Wood-pulp-derived cellulose (WPC) powder (W100, KC flock, Nippon Paper Chemicals Co., Ltd.) was used as the starting material. Its average particle size was approximately 37 μm (data obtained from supplier) and it was kept under vacuum at 40 °C for 3 days before use. For the nanowhisker preparation, a 1 % (w/v) aqueous slurry was stirred for a few days at room temperature, followed by HPH (Masscomizer X, Masuko Sangyo Co., Ltd., Japan) with a total of ten passes. The samples were collected from one, three, five, seven, and ten passes. For the nanoparticle preparation, vacuum-dried cellulose powder was first ball-milled using a planetary ball-mill (Pulverisette 5, Fritsch, Germany). The grinding of cellulose powder was performed in 10 min intervals, with 10 min pauses in between (up to 8 h) at 400 rpm. Next, the ball-milled samples were subjected to HPH. Finally, the ball-milled and homogenized samples were washed with distilled water once, followed by solvent exchange using t-butyl alcohol (t-BuOH), and then freeze-dried for further analyses. Hereafter, the freeze-dried WPC-BM samples are named as WPC-BM-DWT.

Morphology observation by AFM, FE-SEM and TEM

The morphologies of the nanoscale cellulose samples were observed by atomic force microscopy (AFM, SPM-5200S, JEOL Ltd., Tokyo, Japan), field-emission scanning electron microscopy (FE-SEM, S-4800N, Hitachi High-Tech. Co., Tokyo, Japan), and transmission electron microscopy (TEM, JEM 2000-EXII, JEOL Ltd., Tokyo, Japan). For AFM observations, a drop of diluted aqueous suspension (0.001 wt%) of the sample was loaded on a freshly cleaved mica surface (Digital Instruments, USA) and allowed to dry at room temperature. The samples were imaged in tapping mode using a point probe (4 μm thick, 125 μm long and 30 μm wide), a resonance frequency of 320 kHz, and a cantilever spring constant of 42 N/m. Images were recorded with a resolution of 512 × 512 pixels for 2 μm or 500 nm scan sizes. Histograms of the nanoparticle diameter numerical distribution (hereinafter, size distribution) were obtained from over 100 measurements of more than 10 AFM images. For the SEM observations, dispersed freeze-dried samples on conducting carbon tape fixed on a metal support were coated with platinum (E-1045 Ion Sputter, Hitachi) and the SEM accelerating voltage was set at 1.5 kV. For the TEM observations, a drop (10 μL) of diluted aqueous suspension (0.0001 wt%) of the nanoscale cellulose sample was loaded on a carbon-coated copper grid and carefully dried. Negative staining was performed with 2 % uranyl acetate. The TEM instrument was equipped with a GATAN camera and image intensifier, and was operated at 100 kV.

NMR spectroscopy

The freeze-dried samples were packed in 7 mm SiN4 rotors, and solid-state CP-MAS 13C NMR spectra were obtained at a frequency of 100 MHz using a 400 MHz Varian INOVA 400WB spectrometer. The spinning rate was set at 5.0 kHz, with a 1 ms contact time and a 90° pulse width of 4.0 μs. The sample was acquired using a VACP (variable amplitude CP) pulse sequence. A total of 1,024 scans were accumulated for all the spectra.

X-ray diffraction

Wide-angle X-ray diffraction (WAXD) patterns were obtained using a Rigaku RINT-TTR III X-ray diffractometer (Tokyo, Japan) equipped with nickel-filtered Cu Kα radiation (λ = 0.1542 nm) at 50 kV and 300 mA. The disk pellets were prepared by compacting freeze-dried samples at 2 ton using a KBr-disk apparatus. The diffractograms were detected in the range 2θ = 2–60° at a scan rate of 2°/min.

SSA measurements with Congo red dye, nitrogen, and water vapor adsorption

The specific surface areas (SSAs) of the cellulose nanowhiskers were determined using different molecular sensors such as Congo red dye, nitrogen (N2), and water vapor adsorption. The SSAs of aqueous slurries and freeze-dried samples were determined using a Congo red dye (Direct Red 28, Wako Pure Chemical Industries Ltd., Osaka, Japan) adsorption method (Ougiya et al. 1998). A 10 mg/mL cellulose sample in a 100 mM phosphate buffer (pH 6.5) was incubated with various Congo red dye concentrations in a shaking incubator (1,500 rpm) at 30 °C for 2 h. The samples were centrifuged at 10,000 rpm for 15 min, and the amount of residual Congo red dye in the supernatant was determined from the absorbance at 497 nm (using a JASCO UV-550 spectrophotometer). All runs were duplicated, with the reported values being the average. The maximum amount of Congo red dye adsorbed was calculated using the following equation, derived from Langmuir’s adsorption theory (Ougiya et al. 1998; Ratner 1983).

where [C] (mg/mL) is the free dye concentration at equilibrium, [A] (mg dye/mg substrate) is the amount of dye adsorbed on the substrate, [A]max is the maximum amount of dye adsorbed on the substrate, and K ads is the adsorption equilibrium constant.

The value of [A]max was calculated from the reciprocal of the slope from the linear equation [C] versus [C]/[A]. By assuming that the dye molecule adsorbs parallel to the surface of the cellulose chain, the SSA of the cellulose sample is expressed as follows:

where N A is Avogadro’s constant, SACR is the surface area of one molecule of Congo red dye (1.73 nm2), and MWCR is the molecular weight of Congo red dye (696.7 g/mol).

Nitrogen (at 77 K) and water vapor adsorption isotherms (at 298 K) were measured for the SSAs of nanoscale cellulose samples using a BELSORP-Max (BEL Japan Inc.) apparatus. The freeze-dried samples after exchanging water with t-butyl alcohol were degassed for 6 h at 105 °C before the analysis was carried out. The SSA values were obtained from multipoint analyses of the respective isotherms using the Brunauer–Emmett–Teller (BET) equation (Brunauer et al. 1938) as follows:

where P is the equilibrium pressure of adsorbate, P 0 is the saturation pressure of adsorbate, V is the total volume of adsorbate, V m is the monolayer adsorbed gas quantity, and C is the BET constant. V m and C were calculated from the relationship between P/V(P 0 − P) and P/P 0 using the data points in the range 0.05 < P/P 0 < 0.45 for the fitting procedure. The SSA was obtained using the following equation:

where N A is Avogadro’s number, S N2 is the adsorption cross-section area of nitrogen gas (16.2 Å2), and W is the weight of the adsorbent (sample).

Results and discussion

Particle size and distribution

Figure 1 shows the TEM and AFM images of the nanowhiskers obtained by HPH, and their geometric dimensions as a function of HPH pass number are summarized in Table 1. Nanoscale dimensions for the samples were obtained even after the first HPH pass, even though the fibril bundles did not individually split into nanowhiskers. No significant differences in the length and diameter between the fifth and tenth HPH passes were observed. The nanowhiskers obtained after the tenth HPH pass, as shown in the TEM image (Fig. 1a), displayed an individual rod-like structure. The average length and diameter of the rod-like structures were found to be 202 and 11 nm in the TEM images, respectively, and shown to be 16 nm diameter in the AFM images. These dimensions are comparable to the previously reported values for nanowhiskers obtained by acid hydrolysis of cotton fibers (Teixeira et al. 2010) and wood pulp (Bondeson et al. 2006; Revol et al. 1992).

The morphologies of the cellulose nanoparticles obtained by BM (at different BM times) and HPH are shown in Fig. 2. The particles are mostly spherical in shape, even though some agglomerates with irregular and fibrous shapes are also seen in the samples ball-milled for 15 min. Figure 3 shows the size distribution histogram of these nanoparticles. As the BM time increased, the overall particle size was clearly reduced and also its distribution became narrower.

Changes in crystallinity after mechanical treatment

Figure 4 shows the X-ray diffraction patterns of nanowhiskers as a function of different HPH passes. Successive HPH passes resulted in broadening of the peaks, compared to that of the starting cellulose powder sample. The crystallinity index (CI) was calculated according to the method described by Isogai and Usuda (1990), which is expressed by the following equation:

where \(I_{{ 1 {\bar{\text{l}}\text{o}}}}\) and \(I_{{ 1 {\bar{\text{l}}\text{oB}}}}\) are the intensities at peak of \(1 {\bar{\text{l}}\text{o}}\) and that of the line slope at the same peak, respectively. As shown in Fig. 4, the slope was drawn in the basis of the amorphous peak at 2θ = around 18.5°. The peak of \(1 {\bar{\text{l}}\text{o}}\) was observed at 2θ = 16° because the two peaks at 2θ = 15° and around 17° for cellulose I are overlapped, due to its low crystalline structure of the sample (Isogai and Usuda 1990). The crystallinity decreases with increasing HPH pass (Table 2).

Figure 5 shows the X-ray diffraction pattern of the nanoparticles. In Fig. 5a (WPC-BM), the cellulose I patterns of the initial cellulose powder gradually broaden with increasing BM time, showing a broad peak at approximately 2θ = 21° at more than 1 h BM time, and this indicates that the material is in an amorphous state. In contrast, the nanoparticles (WPC-BM-DWT) after t-BuOH exchange and subsequent freeze-drying (Fig. 5b) show a diffraction pattern similar to the cellulose II structure at 4 and 8 h of BM time. Therefore, the amorphous portion of nanoparticles in these samples was partially recrystallized into cellulose II with the characteristic peaks of cellulose II at approximately 2θ = 12°, 20°, and 22.0° (Ago et al. 2004; Kocherbitov et al. 2008). However, WPC-BM and WPC-BM-DWT nanoparticle samples obtained after a BM time of 2 and 3 h both showed the same amorphous state. This indicates that the recrystallization of cellulose I to cellulose II apparently depends on the extent of the amorphous portion. It has been reported that the recrystallization of cellulose I into cellulose II does not start unless the amorphous content is as high as 75 % or more (Iyer et al. 1984). It can be said that in this study, at least 4 h of BM time is required to change the crystalline structure of WPC powder from cellulose I to cellulose II, even though the cellulose II crystalline peaks were very weak because of the short contact time with water and t-BuOH. Ago et al. (2004) and Ouajai and Shanks (2006) have reported that dry-ball-milled cellulose powder (obtained by mechanical agitation in water for 2 h followed by fast drying) can be mostly recrystallized into cellulose II containing 30 wt% of water. Figure 6 shows the solid-state 13CNMR spectra of the nanoparticles (WPC-BM and WPC-BM-DWT) that were ball-milled for 8 h, initial WPC, mercerized WPC, and CF11 (the same samples were used for the X-ray diffraction analyses). The C1 signals of the WPC-BM samples did not split with sufficient resolution, indicating the presence of cellulose II, whereas a shoulder was observed at about 107 ppm in WPC-BM-DWT and mercerized WPC samples. Moreover, a strong C4 signal in WPC-BM sample was not observed, whereas a shoulder at about 88 ppm for a C4 signal was found in the WPC-BM-DWT sample (VanderHart and Atalla 1984).

SSAs of nanowhiskers

The SSAs of nanowhiskers prepared by different HPH passes were obtained by adsorption methods (Congo red dye, nitrogen, and water vapor adsorption). Figure 7a shows the Langmuir isotherms of Congo red dye adsorption on the nanowhiskers and the relationship between [C/A] and [C] in Langmuir’s adsorption equation. The correlation coefficients for a linear fit of the Langmuir isotherm are greater than 0.99 for all the plots, as shown in Fig. 7b, clearly corresponding to Langmuir-type monolayer adsorption. The adsorption behavior of dyes on cellulose substrates at low dye concentrations follows the Langmuir isotherm, where the dye is adsorbed as a monolayer (Yoshida et al. 1989).

Figure 8a shows a comparison of SSA values determined by three different methods. The SSAs of the never-dried and re-dispersed freeze-dried nanowhiskers in water were also compared using the Congo red dye adsorption method. In general, the accessibility of cellulose to water and consequently to dyes dissolved in water varies with the size and distribution of crystalline, amorphous, and connecting regions of lesser order. It has been reported that in adsorption Congo red dye is docked onto the cellulose surface with their long axes parallel to and aligned with the polymer chains, with a length of five anhydroglucose units (Inglesby and Zeronian 2002; Wood 1980; Woodcock et al. 1995). Therefore, this particular length of intermediate-molecular-ordered structure on the cellulose surface is necessary for dye adsorption. The higher SSA values in WPC and one-pass homogenization of never-dried nanowhiskers (SSA-Lang-CRs) than those of freeze-dried samples (SSA-Lang-CRt) indicates enhanced accessibility of the water-swollen state. The water-swollen state facilitated the dye diffusion rate in the case of WPC powder having micron-range fibrils with relatively high crystallinity. A sudden drop in the ten-pass sample of never-dried nanowhiskers was due to particle agglomeration, where strong hydrogen bonds between the individual nanowhiskers were likely to form a gel-like slurry. Because the geometric dimensions of ten-pass nanowhiskers were smaller than those of five-pass samples (Table 1), a high value for SSA was expected. The SSA of ten-pass cellulose nanowhiskers (202 m2/g) was smaller than those of chitin, pulp cellulose, and bacterial cellulose nanocrystals prepared by acid hydrolysis, which were reported to be 347, 249, and 272 m2/g, respectively (Goodrich and Winter 2007). Since the sample preparation method and material resources in this study are different from those for chitin, pulp, and bacterial cellulose, the surface properties, including SSAs, of the respective products are expected to vary accordingly.

The monolayer volume capacity (V m), fitting coefficient (R 2), and total pore volume (V p) derived from the BET equation are listed in Table 2, and the SSA values obtained from the respective adsorption isotherms are plotted in Fig. 8, along with the surface areas for dye adsorption. Fig. 8b–d show the adsorption isotherms of WPC powder, one-pass, and ten-pass homogenized samples. The adsorption isotherms are of type IV with a characteristic hysteresis loop, which is generally associated with capillary condensation in mesopores and/or limiting uptake over a range of high P/P 0 values (Sing et al. 1985). In particular, the shape of the hysteresis loop in the N2 adsorption isotherms of nanowhiskers (Fig. 8c–d) did not exhibit any limiting adsorption at high P/P 0 values, whereas hysteresis was extended to the lowest attainable pressures in WPC powder (Fig. 8b). The former is associated with aggregates of plate-like particles, giving rise to slit-shaped pores, whereas the later may be observed with materials containing micropores (Sing et al. 1985). However, a much lower surface area (2.28 m2/g) for the WPC powder was observed due to intrinsic porosity, and the absence of a pronounced capillary condensation regime. Zografi et al. (1984) used krypton to measure the adsorptions of samples with very low surface areas. A value of 1.3 m2/g, with no evidence of extensive microporosity, was observed for both nitrogen and krypton adsorptions on microcrystalline cellulose (Avicel, 101). Kocherbitov et al. (2008) reported surface areas of 1.04 and 0.55 m2/g for microcrystalline cellulose MCC Avicel PH-101 and PH-301, respectively. Shigapov et al. (2001) found values of 0.77 and 1.22 m2/g for air-dried Whatman 50 filter paper and MCC powder, respectively. All MCCs produced from different sources showed scarcely any pores with low SSAs, measured by N2 adsorption isotherm.

In contrast, the hysteresis loop of the desorption branch in vapor adsorption isotherms extended to the lowest attainable pressure. Generally, this phenomenon is associated with the swelling of a non-rigid porous structure or with the irreversible uptake of molecules in pores of approximately the same width as that of the adsorbate molecule or, in some instances, with an irreversible chemical interaction of the adsorbate with the adsorbent (Sing et al. 1985). In this study, the hysteresis observed in the lower pressure range of the water vapor isotherms is associated with swelling due to specific interactions of water adsorbed on the bulk surface (Kachrimanis et al. 2006; Mihranyan et al. 2004), which will be discussed in the following section. It was noticed that the hysteresis width between the adsorption and desorption curves was broader in micron-sized WPC powder than in nanowhiskers, particularly in the high P/P 0 regime.

The adsorbed vapor content calculated from BET monolayer coverage, V m, ranged from 0.034 to 0.037 mg/g cellulose. At a water vapor content of about ~3 wt%, every available C(6)–OH group in the amorphous chain-surface region of the cellulose was occupied by one water molecule, as proposed by Khan and Pilpel (1987). Based on the corresponding sample’s crystallinity, the calculated amount of water adsorbed per anhydroglucose unit corresponds to a one-to-one stoichiometric relationship in WPC and one-pass nanowhiskers, which was in agreement with the results reported by Khan and Pilpel (1987). The BET constant c (energy parameter) of the nanowhiskers was about that of the micron-range WPC powder (Table 2), indicating that the driving force for water vapor adsorption was lower in nanowhiskers than that for WPC powder.

The BET surface area derived from N2 adsorption isotherms increased with increasing homogenization passes, and a similar trend was observed for the Congo red dye adsorption. However, the BET surface area derived from N2 adsorption was found to be lower than that obtained by dye adsorption, whereas a similar surface area was observed for all the homogenization passes in water vapor adsorption (Fig. 8a). A pronounced difference was found between the BET surface areas for N2 adsorption and vapor adsorption in WPC. The difference in surface area on the same adsorbent was due to the difference in the adsorption mechanism of the respective molecular sensors, i.e., Congo red dye, nitrogen, and water vapor. Since both N2 and water (H2O) are small molecules (surface areas of one molecule of nitrogen and water are 0.162 and 0.125 nm2, respectively), the very large difference between the BET surface area of WPC powder for N2 and vapor adsorption indicates that the adsorption of nitrogen occurred mainly on the surface of cellulose particles. Therefore, the SSA increases with increasing homogenization passes as the nanoscale whiskers provided more surface adsorption sites than the microscale WPC powder. The adsorption of water vapor predominantly occurs within the cellulose particles rather than on their external surface (Khan and Pilpel 1987; Kocherbitov et al. 2008; Mihranyan et al. 2004), i.e., water adsorption occurs on the interface between cellulose microfibrils, the structural units of cellulose with a nanometer range (Kocherbitov et al. 2008). The similar BET surface area from water vapor adsorption between the microscale WPC powder (141 m2/g) and nanoscale whiskers (146, 153, and 153 m2/g for one pass, five passes, and ten passes, respectively) in Fig. 8a further strengthened the above assumption, although the effect of pore structure and lower crystallinity was also taken into account for a slight increase in surface area for five-pass and ten-pass nanowhiskers.

Furthermore, similar surface areas in micron-size WPC powder and nano-size cellulose nanowhiskers clearly showed a fine structure of microfibrils assembly. The mean width (W) of the structural elements into which cellulose dissociates in the adsorbate vapor is expressed as follows:

where 4 is the shape factor for microfibrils with a square cross-section; and ρ (1.55 g cm−3) is the density of cellulose. It therefore appears that the cellulose was dissociated into structural elements that are 17–18 nm in diameter, and formed aggregates of 5–6 elementary fibrils according to the model for ultrastructural organization of the cell wall components in wood proposed by Fengel (1971). In Fengel’s model, 16 elementary fibrils that have a width of 3 nm each are arranged in 12 nm fibrils that, in turn, form 25–30 nm fibrils. It is noteworthy that the mean widths of all the samples obtained from the surface areas of water vapor adsorption are comparable with those of ten-pass nanowhiskers determined by SSA of N2 (15 nm) and Congo red dye adsorption (17 nm), as well as the observed lateral widths from the AFM images (16 ± 2 nm). In particular, the lateral width determined from TEM images (11 ± 3 nm) and the mean width obtained from SSA Congo red dye adsorption on freeze-dried nanowhiskers (13 nm) almost exactly corresponded to Fengel’s model.

SSAs of nanoparticles

The SSAs of nanoparticles (WPC-BM-DWT) as a function of BM time, obtained from different adsorption isotherms, are shown in Fig. 9a. The surface area determined from the water vapor adsorption increased with increasing BM time (up to 2 h, 226 m2/g) and leveled off, whereas the trend in the N2 adsorption method was an increase for 1 h (17 m2/g) and then a slight decrease until 3 h (12 m2/g), followed by a small increase at 4–8 h (23 m2/g). In the Congo red dye adsorption method, the SSA value increased with increasing milling time (up to 1 h, 140 m2/g) and decreased gradually up to 8 h BM time (99 m2/g).

Since water vapor adsorption occurred on the amorphous region, the SSA is expected to increase with increasing BM time up to 8 h, as reported by Nakai et al. (1977). However, the ball-milled WPC used for adsorption studies consisted of solvent-exchanged and freeze-dried samples and hence partial recrystallization to cellulose I (BM time 1 h) or cellulose II (BM time 8 h) occurred, depending on the milling time (Fig. 5). Because the recrystallized parts in WPC-BM-DWT-8 h are no longer accessible for water vapor adsorption, the numbers of water vapor adsorption sites decreased to some extent. Therefore, similar surface areas (226–221 m2/g) were obtained from 2 to 8 h, whereas a high surface area of 330 m2/g was determined for the WPC-BM-8 h sample (Table 2). The vapor adsorption isotherms of WPC-BM-8 h and WPC-BM-DWT-8 h samples are shown in Fig. 9b together with that of the initial WPC powder. It was noted that the solvent exchange altered not only the number of adsorption sites but also the hysteresis shape in milled samples. In addition, the lower value of the BET constant c for WPC-BM-8 h than for WPC-BM-DWT-8 h (Table 2) indicates that the driving force for vapor adsorption is low in almost all the amorphous samples.

Conversely, the lowest SSA values, observed in WPC-BM-DWT-2 h and WPC-BM-DWT-3 h samples in N2 adsorption, indicated that almost the entire amorphous surface had a lower number of adsorption sites than the partially recrystallized cellulose surface. With the exceptions of these two samples, the SSAs in cellulose nanoparticles increased with increasing BM time (up to 1 h), and contained a mixture of amorphous and cellulose I structures, followed by a gradual increase to 4 h and leveling off at 8 h, and both contained a mixture of amorphous and cellulose II structures, as shown in Fig. 9a.

The decrease in SSA in 2 h BM time in the Congo red dye adsorption method also reflects the accessible surface structure of ball-milled cellulose. It was reported in a study with a series of oligosaccharides ranging from cellobiose to celloheptaose that a minimum DP of five is necessary for interaction with Congo red dye for binding (Wood 1980). In addition, molecular modeling results also showed that the dyes docked onto the cellulose surface with their long axes parallel to and aligned with the polymer chains, and preferentially adsorbed to the 110 plane of the monoclinic cell rather than its 100 plane (Woodcock et al. 1995). Because the WPC-BM-DWT samples obtained after 1 h BM time are in an almost amorphous state, the available intermediate-ordered regions decrease for Congo red dye adsorption. After partial recrystallization to cellulose II in the 4–8 h samples, new intermediate-ordered regions may have formed to some extent, but the chain orientation may not provide the best fit for Congo red dye to dock onto its surface. Therefore, the SSA did not increase in the WPC-BM-DWT-8 h sample, similar to the trend for SSA in N2 adsorption.

Conclusions

Rod-like nanowhiskers of length 200–500 nm and width 11–16 nm were obtained. Spherical nanoparticles with diameters in the range 40–200 nm, depending on the BM time, and diameters of 25–50 nm after ten-pass HPH were obtained. The conversion of cellulose I to cellulose II was observed after 4 h of BM time. Therefore, by selecting an appropriate BM time, cellulose nanoparticles of different polymorphs with similar particle morphologies can be prepared starting from WPC. The nanoscale cellulose diameters derived from SSAs by adsorption using Congo red dye, N2, and water vapor adsorption are in agreement with those obtained from TEM and AFM images. Based on the SSAs of micro-range WPC to nanowhiskers, the adsorption behaviors of sensing molecules can be summarized as follows. (a) The adsorption of N2 molecule occurs mainly on the surface, and also penetrates into the sub-surface layers of cellulose to some extent. (b) The adsorption of Congo red dye occurs on the surface and the dye also diffuses into the structural elements of cellulose possessing intermediate-ordered regions. (c) Water vapor adsorption occurs on the amorphous surface of structural elements of nanoscale cellulose.

References

Ago M, Endo T, Hirotsu T (2004) Crystalline transformation of native cellulose from cellulose I to cellulose ID polymorph by a ball-milling method with a specific amount of water. Cellulose 11:163–167

Beck-Candanedo S, Roman M, Gray DG (2005) Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromolecules 6(2):1048–1054

Bondeson D, Mathew A, Oksman K (2006) Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 13:171–180

Brunauer S, Emmet PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319

Eichhorn SJ, Baillie CA, Zafeiropoulos N, Mwaikambo LY, Ansell MP, Dufresne A, Entwistle KM, Herrera-Franco PJ, Escamilla GC, Groom L, Hugues M, Hill C, Rials TG, Wild PM (2001) Review current international research into cellulosic fibres and composites. J Mater Sci 36:2107–2131

Fengel D (1971) Ideas on the ultrastructural organization of the cell wall components. J Polym Sci Part C Polym Sci 36:383–392

Fengel D, Wegner G (1989) Wood: chemistry, ultrastructure, reactions. deGruyter, Berlin, p 66

Goodrich JD, Winter WT (2007) α-chitin nanocrystals prepared from shrimp shells and their specific surface area measurement. Biomacromolecules 8:252–257

Inglesby MK, Zeronian SH (2002) Direct dyes as molecular sensors to characterize cellulose substrates. Cellulose 9:19–29

Isogai A, Usuda M (1990) Crystallinity indexes of cellulosic materials. Sen-i Gakkaishi 46(8):324–329

Iyer PB, Sreenivasan S, Chidambareswaran PK, Patil NB (1984) Crystallization of amorphous cellulose. Text Res J 54:732–735

Kachrimanis K, Noisternig MF, Griesser UJ, Malamataris S (2006) Dynamic moisture sorption and desorption of standard and silicified microcrystalline cellulose. Eur J Pharm Biopharm 64:307–315

Khan F, Pilpel N (1987) The effect of moisture on the density, compaction and tensile strength of microcrystalline cellulose. Powder Technol 50:237–241

Kocherbitov V, Ulvenlund S, Kober M, Jarring K, Arnebrant T (2008) Hydration of microcrystalline cellulose and milled cellulose studied by sorption calorimetry. J Phys Chem B. 112:3728–3734

Liu ZT, Fan X, Wu J, Zhang L, Song L, Gao Z, Dong W, Xiong H, Peng Y, Tang S (2007) A green route to prepare cellulose acetate particle from ramie fiber. React Funct Polym 67:104–112

Mihranyan A, Llagostera AP, Karmhag R, Strømme M, Ek R (2004) Moisture sorption by cellulose powders of varying crystallinity. Int J Pharm 269:433–442

Nakai Y, Fukuoka E, Nakajima S, Yamamoto K (1977) Crystallinity and physical characteristics of microcrystalline cellulose. II. Fine structure of ground microcrystalline cellulose. Chem Pharm Bull 25:2490–2496

O’Sullivan AC (1997) Cellulose: the structure slowly unravels. Cellulose 4:173–207

Ouajai S, Shanks RA (2006) Solvent and enzyme induced recrystallization of mechanically degraded hemp cellulose. Cellulose 13:31–44

Ougiya H, Hioki N, Watanabe K, Morinaga Y, Yoshinaga F, Samejima M (1998) Relationship between the physical properties and surface area of cellulose derived from adsorbates of various molecular sizes. Biosci Biotechnol Biochem 62:1880–1884

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Ratner BD (1983) Surface characterization of biomaterials by electron spectroscopy for chemical analysis. Ann Biomed Eng 11:313–336

Revol JF, Bradford H, Giasson J, Marchessault RH, Gray DG (1992) Helicoidal self-ordering of cellulose microfibrils in aqueous suspension. Int J Biol Macromol 14(3):170–172

Samir AMAS, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules 6:612–626

Shigapov AN, Graham GW, McCabe RW, Plummer JHK (2001) The preparation of high-surface area, thermally-stable, metal-oxide catalysts and supports by a cellulose templating approach. Appl Catal A: Gen 210:287–300

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquérol J, Siemieniewska T (1985) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl Chem 75:603–619

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494

Teixeira EM, Corrêa AC, Manzoli A, Leite FL, Oliveira CR, Mattoso LHC (2010) Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 17(3):595–606

VanderHart DL, Atalla RH (1984) Studies of microstructure in native cellulose using solid-state 13C NMR. Macromolecules 17:1465–1472

Wood PJ (1980) Specify in the interaction of direct dyes with polysaccharides. Carbohydr Res 85:271–287

Woodcock S, Henrissat B, Sugiyama J (1995) Docking of congo red to the surface of crystalline cellulose using molecular mechanics. Biopolymers 36:201–210

Yoshida H, Kataoka T, Maekawa M, Nango M (1989) Surface diffusion of direct dyes in porous cellulose membrane. Chem Eng J 41:1–9

Zhang J, Elder TJ, Pu Y, Ragauskas AJ (2007) Facile synthesis of spherical cellulose nanoparticles. Carbohydr Polym 69:607–611

Zografi G, Kontny MJ, Yang AYS, Brenner GS (1984) Surface area and water vapor sorption of macrocrystalline cellulose. Int J Pharm 18:99–116

Acknowledgments

The authors thank Prof. Junji Sugiyama, Kyoto University, for his kindness in allowing us to use the TEM instrument facility for cellulose nanowhisker imaging analysis.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Nge, T.T., Lee, SH. & Endo, T. Preparation of nanoscale cellulose materials with different morphologies by mechanical treatments and their characterization. Cellulose 20, 1841–1852 (2013). https://doi.org/10.1007/s10570-013-9962-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-9962-y