Abstract

Thin nanocomposite films of thermoplastic starch, chitosan and cellulose nanofibers (bacterial cellulose or nanofibrillated cellulose) were prepared for the first time by solvent casting of water based suspensions of the three polysaccharides. The role of the different bioploymers on the final properties (thermal stability, transparency, mechanical performance and antimicrobial activity) of the films was related with their intrinsic features, contents and synergic effects resulting from the establishment of interactions between them. Thermoplastic starch displays an important role on the thermal stability of the films because it is the most stable polysaccharide; however it has a negative impact on the mechanical performance and transparency of the films. The addition of chitosan improves considerably the transparency (up to 50 % transmittance for 50 % of chitosan, in respect to the amount of starch), mechanical performance and antimicrobial properties (at least 25 % of chitosan and no more than 10 % of cellulose nanofibers are required to observe bacteriostatic or bactericidal activity) but decrease their thermal stability. The incorporation of cellulose nanofibers had the strongest positive impact on the mechanical properties of the materials (increments of up to 15 and 30 MPa on the Young′s modulus and Tensile strength, respectively, for films with 20 % of BC or NFC). Nonetheless, the impact in thermal stability and mechanical performance of the films, promoted by the addition of chitosan and cellulose nanofibres, respectively, was higher than the expected considering their percentage contents certainly because of the establishment of strong and complex interactions between the three polysaccharides.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

During the last decade, huge efforts have been devoted to the development of novel biodegradable plastic materials based on renewable resources in response to the environmental problems associated with the massive use of non-biodegradable and oil based counterpart materials (Mohanty et al. 2002; La Mantia and Morreale 2011). In this context, polysaccharides such as cellulose, starch and chitosan represent singular sources of such materials because of their abundance, renewable character, biodegradability and specific properties (Belgacem and Gandini 2008).

For example, starch granules can be easily converted into a thermoplastic material, known as thermoplastic starch (TPS) or plasticized starch, through the disruption of the molecular chain interactions under specific conditions and in the presence of plasticizers (Hulleman et al. 1998; Curvelo et al. 2001; Córdoba et al. 2008). Because of its availability, low price and ease of processing, TPS constitutes nowadays an interesting answer for several biodegradable based material markets. However, thermoplastic starch presents some limitations that are mainly associated with its poor mechanical performance and lack of biological activity. One interesting approach to overcome these drawbacks is the combination with other polysaccharides aiming at obtaining biobased materials with distinct functionalities and enhanced properties.

In this vein, the combination with cellulose fibers is a simple way to improve the mechanical performance of starch-based films. In particular, nanocellulose substrates like nanofibrillated cellulose (NFC) and bacterial cellulose (BC), have gained growing and considerable attention in the last decade because of their unique mechanical properties. NFC is obtained, as a viscous shear-thinning transparent gel, by disintegration of plant cellulose fibers, using high-pressure homogenizers combined with chemical or enzymatic treatments (Belgacem and Gandini 2008); while BC is produced by microorganisms of the Gluconacetobacter genus in the form of a tridimensional nanostructured wet membrane (Belgacem and Gandini 2008).

Various types of cellulose fillers have been used in the preparation of thermoplastic starch biocomposites, namely vegetable fibers (Curvelo et al. 2001; Alvarez et al. 2005; Ma et al. 2005), microfibrillated cellulose (Dufresne et al. 2000; Lu et al. 2005), cellulose nanocrystallites (Lu et al. 2006), microcrystalline cellulose (Ma et al. 2008), hemp nanocrystals (Cao et al. 2008), bacterial cellulose (Grande et al. 2009; Martins et al. 2009), cotton fibers (Prachayawarakorn et al. 2010) and bamboo cellulose crystals (Liu et al. 2010). Additionally, blending with chitosan or its derivatives has been employed to prepare starch based materials with antimicrobial properties (Zhai et al. 2004; Liu et al. 2009; Pelissari et al. 2009; Shen et al. 2010; Tome et al. 2012). Nonetheless, physical and chemical properties can be also improved (Lazaridou and Biliaderis 2002; Xu et al. 2005; Ban et al. 2006a, b; Bourtoom and Chinnan 2008). On the other hand, chitosan and cellulose fibers have also been combined to prepare transparent films or coated papers with improved mechanical and thermal properties and antimicrobial activity (Fernandes et al. 2009a, b, 2010a, b, 2011). However, to the best of our knowledge, multi polysaccharide based films that conjugate all the singular properties of each component or novel features resulting from synergic effects between them have never been reported.

In the present work, we have prepared tri component films by blending thermoplastic starch, chitosan (or a water soluble chitosan derivative) and nanocellulose fibers (bacterial cellulose or nanofibrillated cellulose) aiming to combine, in the same material, different functionalities ranging from transparency, mechanical performance and antimicrobial activity. The role of the distinct polysaccharides on the final properties and the performance of the films was discussed and related with their intrinsic features and contents.

Experimental

Materials

Corn starch (S) (27 % amylose) and glycerol (99.5 %) were supplied by Sigma-Aldrich and used as received.

Bacterial cellulose (BC) (tridimensional network of nano and microfibrils with 10–200 nm width) in the form of wet membranes was produced at our laboratory using the Gluconoacetobacter sacchari bacterial strain (Trovatti et al. 2011) and following established procedures (Hestrin and Schramm 1954). Before use, BC membranes were disintegrated in water using an Ultra-Turrax homogenizer, for 30 min at 500 rpm, and filtered to remove the excess of water.

Nanofibrillated cellulose (NFC) was produced from softwood bisulfite fibers by combining mechanical and enzymatic treatments. The pulp was pre-refined to 25°SR using a 12″ pilot disk refiner at a consistency of 3.5 % followed by an enzymatic treatment using the cellulase 476 (Novozymes, Danmark) at a charge 0.1 ml/kg of the commercial preparation for 1 h at 50 °C. The suspensions were then hyper-refined to 85°SR and diluted to 2.0 wt% consistency before the nanofibrillation. Nanofibrillation was carried out using a microfluidizer processor, model M-110 EH-30 (Microfluidics, USA). The slurry was passed through a piston pump that applies a high pressure. Size reduction of products occurs into Interaction Chambers (IXC) having different internal diameters (400, 200 and 100 μm). In this process, the pulp suspension passed first three times through a chamber of 400 μm with operating pressure of 100 bar, then six times through a chamber of 200 μm, where the operating pressure was 1,200 bar, and finally 6 times through a chamber of 100 μm, where the operating pressure was 2,100 bar. The same concentration (2 wt%) was maintained during the whole process.

Chitosan (CH) was provided by Mahtani Chitosan PVT. Ltd. (India) in the powdered form (molecular weight of 350,000 g/mol, measured by viscosity, and a degree of deacetylation of 97 %). A water-soluble chitosan derivative, N-(2-hydroxypropyl)-3-trimethylammonium chitosan chloride (WCH), was prepared by reacting 5.0 g of CH, dissolved in 250 ml of a 1 % aqueous solution of acetic acid, with glycidyltrimethylammonium chloride (GTMAC, purchased from Fluka, 90 % purity), with a GTMAC/chitosan NH2 groups molar proportion of 4/1, following the procedure described by Seong et al. (2000). This mixture was kept at 65 °C for 24 h under a N2 atmosphere. The ensuing water-soluble chitosan derivative was precipitated and washed with ethanol (purchased from Sigma-Aldrich, 90 % purity). The substitution degree of the amino groups was around 30 %, as determined by 1H NMR, following a previously described method (Desbrières et al. 1996).

Multicomponent films preparation

Chitosan (CH or WCH) solutions (1.5 % w/v) were prepared, by dissolving the corresponding powdered CH or WCH samples in aqueous acetic acid (1 % v/v) or in water, respectively. Starch was gelatinized by suspending starch granules in distilled water (3 % w/v) and cooking for 30 min at 95 ± 5 °C with continuous mechanical stirring. Subsequently, glycerol (15 % with respect to the dry weight of starch) was added and dispersed in the starch suspension, which was kept at 65 °C. Then, chitosan solutions were added to starch suspensions (25 and 50 % w/w relative to dry starch mass). After 30 min with stirring, two different contents of BC or NFC (10 and 20 % w/w, in relation to dry CH mass) were dispersed in some of the previous formulations (with 25 and 50 % of CH or WCH) and homogenized, at room temperature, using an Ultra-Turrax equipment during 30 min at 18,000 rpm. Formulations were then filtered to remove impurities and degassed to remove entrapped air. Finally, the multicomponent films were prepared by casting (30 ml of each suspension) at 30 °C in a ventilated oven for 24 h, using acrylic plates (10 × 10 cm2) as molds. The identification of all studied samples is summarized in Table 1.

Before characterization, all films were kept in a conditioning cabinet, at 50 % relative humidity (RH) and 25 °C, to ensure the stabilization of their water content.

Multicomponent films characterization

All the films prepared (Table 1) were characterized using scanning electron microscopy (SEM), X-ray diffraction (XRD), Vis spectroscopy (transparency/opacity), thermogravimetry (TGA), tensile tests and antimicrobial activity.

Scanning electron microscopy micrographs of the films surfaces were obtained on a HR-FESEM SU-70 Hitachi equipment operating at 1.5 kV. Samples were coated with evaporated carbon.

The XRD measurements were carried out with a Phillips X’pert MPD diffractometer using Cu Kα radiation.

The transmittance spectra of the films were measured with an UV–Vis Spectrophotometer (Perkin-Elmer UV 850) equipped with a 15 cm diameter integrating sphere bearing the holder in the horizontal position. Spectra were recorded at room temperature in steps of 1 nm, in the range 400–700 nm.

Thermogravimetry essays were carried out with a Shimadzu TGA 50 analyzer equipped with a platinum cell. Samples were heated at a constant rate of 10 °C/min, from room temperature to 800 °C, under a nitrogen flow of 20 mL/min. The thermal decomposition temperature was taken as the onset of significant (~0.5 %) weight loss, after the initial moisture loss.

Tensile tests were performed in room conditions on a TA-Hdi Stable Micro Systems Texture Analyser using a load cell of 5 kg and operating at a deformation rate of 0.5 mm/s. Tensile strength, tensile modulus and elongation to break were calculated using the Instron Series IX software.

Antibacterial activity essays

Staphylococcus aureus ATCC 6538 (DSM 799) was provided by DSMZ, Deutsche Sammlung von Mikroorganismen und Zellkulturen GmbH (German Collection of Microorganisms and Cell Cultures). S. aureus was maintained frozen (−80 °C) and transferred monthly onto a TSA (Tryptone Soya Agar) made of 15 g/L tryptone; 5 g/L soy peptone; 5 g/L NaCl and 15 g/L neutralised bacteriological agar. The bacterial pre-inoculum culture was grown overnight at 37 °C in 20 ml NB (Nutrient Broth: made of 1 g/L beef extract; 5 g/L neutralised peptone; 2 g/L yeast extract; 5 g/L NaCl) subjected to horizontal shaking at 100 rpm.

A dynamic method was applied to test antibacterial activity based on a standard methodology, the Dynamic Shake Flask Method (ASTM E 2149:2001), usually adopted in the textile field. In order to ensure the best contact between the sample and bacteria, the film samples were placed in contact with the microbial liquid suspension subjected to vigorous shaking for all test duration. At 0 and 24 h contact times, the bacterial concentrations (CFU/mL) of the microbial suspension were determined by plating serial dilutions on Plate Count Agar to obtain the overall number of bacteria (CFU).

The adopted testing conditions were:

-

Tested microorganisms: S. aureus ATCC 6538;

-

Microbial liquid suspension: 5 mL of 5 % Nutrient Broth in phosphate buffer (0.3 mM, pH 7.2) inoculated with 10–4 to 10–5 CFU/ml bacteria;

-

Total flask volume: 25 mL;

-

Sample incubation: 24 h at 23 ± 1 °C under vigorous shaking;

-

Quantity of tested material: 30 mg of film, the samples were cut in small pieces and tested in duplicate;

-

The samples were subjected to sterilization by autoclave;

-

Internal reference of the method was the bacteria grow tested on flasks only containing inoculated broth media;

Results and discussion

Multipolysaccharide films (~55 µm thickness) were obtained by blending thermoplastic starch, chitosan (CH or WCH) and cellulose nanofibers (BC or NFC), followed by casting the water based solutions. The ensuing films were then characterized in terms of transparency, morphology, thermal stability, mechanical performance and antibacterial activity.

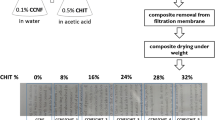

Optical properties

All the obtained films were very homogeneous, even those with 20 % of BC or NFC fibers loading. The transmittance of the films with starch, chitosan (CH or WCH) and BC or NFC as well as images of the some films placed on the top of a colour image are shown in Fig. 1.

The plasticized starch films are quite opaque, with a transmittance value of only 20 %. The addition of increasing amounts of chitosan increases considerably their transparency, attaining about 50 % of transparency for films with 50 % of chitosan (CH and WCH). This is obviously due to the fact that, as previously reported (Fernandes et al. 2009b), individually, chitosan yields very transparent films (up to 90 %). The addition of cellulose nanofibers (NFC or BC) to the SCH and SWCH films promotes in general a decrease on their transmittance (Fig. 1), reaching values similar to those of plasticised starch films for 20 % of BC or NFC. However, the addition of BC had a lower impact on this property when compared to NFC, probably due to the fact that BC presents a considerably higher purity and lower dimension of nanofibrils. For nanocomposite films with 50 % of chitosan and 10 % of BC, the transmittance was ~60 % which is a value reasonable for several applications. Therefore, the transparency of the multipolysaccharide based films was quite dependent on the percentage of the different polysaccharides with chitosan playing the most important role.

Morphology

A selection of SEM micrographs of the film surfaces is shown in Fig. 2. These images provided indication of the good dispersion of BC and NFC nanofibers on the SCH matrices since no significant agglomerates of nanofibers are observed. This is obviously due to the excellent compatibility between the three polysaccharide components of the nanocomposite films that prevent the agglomeration of cellulose nanofibrils. It is also visible that the increase on the chitosan percentage improves the nanofibers dispersion within the matrices since in this case the cellulose fibers are almost completely embebed within the SCH matrix. This is probably due to the higher viscosity of the chitosan solutions that improves the dispersion of the cellulose nanofibrils, previously observed in chitosan (CH or WSCH) nanocomposites with BC or NFC (Fernandes et al. 2009b, 2010b).

In addition, the typical tridimensional network of BC is clearly noticeable on the surface of the films and, in both cases (BC and NFC), the nanofibrils are randomly oriented and assembled.

X-ray diffraction

The XRD patterns of thermoplastic starch (S), chitosan (CH) and SCH25, SCH25BC10 and SCH25BC20 films are shown in Fig. 3, as an example. Starch (S) films give both B and V-type diffraction patterns that are associated with the retrogradation process of gelatinized starch (Buléon et al. 1998), with the main peaks at 2θ 12.9º, 16.8º and 19.8º, respectively. The characteristic X-ray diffractogram of chitosan films displayed two main peaks at around 2θ 12º and 19º, assigned to the crystal forms I and II, respectively (Samuels 1981). The chemical modification (quaternization) of chitosan, leading to WCH, led to an extensive decline in the crystallinity, since this derivative shows a typical X-ray diffractogram of an amorphous material with a broad band centered at around 2θ 20º (not shown). BC and NFC (also not shown) displayed a typical diffraction pattern of native cellule (cellulose I) with the main diffraction peaks at 2θ 14.9º, 16.3º, 22.5º, and 34.6º, normally assigned to the diffraction planes 101, 10–1, 002, and 040, respectively (Hon 1996).

The X-ray diffractograms of the multipolysaccharide films showed essentially the typical diffraction peaks of the retrograded thermoplastic starch matrix and cellulose nanofibers. In fact, for films with 20 % of BC (or NFC) the diffraction peaks of cellulose are very intense and well defined. The incorporation of chitosan or cellulose did not prevent the retrogradation of starch because the corresponding peaks are still visible even for high amounts of cellulose or chitosan. However, the broad peaks of chitosan are not visible in the diffractograms of any of the multicomponent films, probably because the chitosan chains are well distributed within the starch matrix and cellulose nanofibers avoiding their crystallization.

Thermal properties

Thermogravimetric analysis of nanocomposite films was carried out to assess their thermal stability and degradation profile. S, CH and WCH films and BC and NFC, were also analysed for comparative purposes. Table 2 summarizes the most important thermal parameters for each sample.

The TGA tracing of the nanocomposite films are a combination of those of starch and CH (or WCH) matrices and of cellulose nanofibres (BC and NFC), with a maximum degradation step in the range 290–320 °C. However, the Td1 and Tdi of the nanocomposite films clearly reflect the contents of the different components. In general, the addition of CH, and in particular of WCH, promotes a slight decrease (up to 50 and 30 °C, in Tdi and Td1, respectively) on the thermal stability of starch films since chitosan is less stable than starch. On the other hand, the addition of nanocellulose fibers (NFC or BC) had in several cases a slight positive impact on the thermal stability of the films observed by increments particularly on the Tdi (up to 15 °C, in respect to the SCH or SWCH films) (Table 2). In fact, for the films with higher contents of BC or NFC a second degradation step (Td2) appears, probably associated with the degradation of cellulose enriched fractions. Similar behaviors have already been observed for chitosan/cellulose (Fernandes et al. 2009b, 2010b) and starch/cellulose based films (Ma et al. 2005; Prachayawarakorn et al. 2010).

Starch and cellulose play the most important role on the thermal stability of the multicomponent films, however the negative impact of chitosan is less pronounced in this case (rather than in simple SCH films) probably because of the strong interactions established between all components, as will be also observed in the mechanical properties. For example, SCH25BC20 and SCH50BC10 showed higher stability than similar nanocomposite films composed only of CH and BC (Fernandes et al. 2009b) and similar to those composed of S and BC (Martins et al. 2009).

Finally, the mass losses observed before the onset temperature, before 100 °C, at around 100 °C and at 250 °C are related to the volatilization of acetic acid, water and glycerol, respectively.

Mechanical properties

The Young modulus, tensile strength and elongation at break, determined from the typical stress–strain curves, of S, SCH, SWCH and corresponding nanocomposite films with BC and NFC are displayed in Fig. 4. The Young modulus of the S films increased considerably with the addition of CH and WCH, specifically from less than 1 MPa for S films to 14 MPa for SCH50 films, and to 3 MPa for SWCH50 films with 50 % of chitosan. The observed positive impact on the mechanical properties of S films by the incorporation of chitosan has already been demonstrated in other studies (Lazaridou and Biliaderis 2002; Ban et al. 2006a; Xu et al. 2005; Zhai et al. 2004). Furthermore, the incorporation of WCH promoted a more modest improvement of the mechanical properties because of the well-known lower crystallinity of this derivative (Fernandes et al. 2009b, 2010b).

Young modulus (a), Tensile strength (b) and Elongation to break (c) of thermoplastic starch (S) film and corresponding films with different contents of chitosan and water-soluble chitosan (SCH and SWCH), and of the ternary films based on starch, chitosan its water soluble derivative and cellulose nanofibers (SCHNFC/SCHBC and SWCHNFC and SWCHBC)

The SCHBC and SCHNFC films showed the highest Young modulus values (more than 20Mpa for all SCHBC and SCHNFC films) because of the additional incorporation of BC and NFC nanofibers. This is obviously associated with the high resistance and stiffness of highly crystalline BC and NFC nanofibers. The addition of increasing amounts of chitosan (CH and WCH) and nanocellulose fibers promoted also a considerable increment of the tensile strength of the films (up to 65 %, in respect to the S film), which was obviously more evident with the addition of nanofibers. Similar improvements on Young modulus and tensile strength have already been observed for S nanocomposites with BC (Martins et al. 2009) or CH nanocomposites with BC or NFC (Fernandes et al. 2009b, 2010b). However, for multicomponent films the observed increments (up to 65 %, in respect to S films, for both Young modulus and tensile strength) reflect not only their compositions but also the strong synergic effects between all the components, since they are, in particular for tensile strength, higher than those expected considering their compositions.

Finally, the addition of chitosan promotes an increase on the elongation at break while the addition of nanocellulose fibers promotes a huge decrease of this parameter. These behaviors are obviously associated with the intrinsic properties of the distinct polysaccharides but reflect again synergic effects, because even pure chitosan films present slightly higher elongations at break than S films.

As expected, cellulose nanofibers displayed the most important role on this property but the excellent compatibility between the three polysaccharides contributed also for the improved mechanical performances.

Antimicrobial activity

The antibacterial activity of multicomponent films against S. aureus, a widely diffused human pathogenic bacterium, is shown in Fig. 5 for a set of selected samples with distinct amounts of the different polysaccharides. Chitosan and WCH are the only components of the nanocomposite films that individually present antimicrobial properties (Benhabiles et al. 2012) and therefore the biocide activity of the studied nanocomposites is strongly dependent on the percentage content of the distinct polysaccharides. The starch films with 25 and 50 % of chitosan had partial bactericidal effect against S. aureus and the addition of only 10 % of cellulose nanofibers reduces considerably the activity of the films, and particularly for the NFC fibers. For example, the samples SCH50BC10 and SCH50NFC10 are only slightly bactericidal and bacteriostatic, respectively.

Antibacterial activity of the multicomponent films with variable content of thermoplastic starch, chitosan and its water soluble derivative and containing 10 % of BC or NFC. The log CFU values were determined in the testing broth after 24 h contact time and were compared to those of pure starch as well as to the inoculated broth alone. Horizontal dark line refers to the initial inoculum (log CFU at time 0)

The samples with the WCH derivative are more active against this microorganism because of the higher antibacterial activity induced by the presence of quaternary ammonium groups (Seong et al. 2000). The films SWCH25 and SWCH50 had a total bactericidal effect. The addition of 10 % of BC and NFC to the SWCH50 reduces also the activity of the films but they are still partial bactericidal. Therefore, for multipolysaccharide films, contents of more than 25 % of CH (and less amounts for WCH) and less than 10 % of nanocellulose fibres are required to have considerable bactericidal activity.

Conclusions

Thin films composed of thermoplastic starch, chitosan and cellulose nanofibers were successfully prepared and characterized. Thermoplastic starch is the most economic polysaccharide matrix used but its films display poor mechanical properties, low transparency and no biological activity. The addition of chitosan improves the transparency and antimicrobial properties of the films but decrease considerably their thermal stability; while the incorporation of cellulose nanofibers had a positive impact on the mechanical properties and on the thermal stability of the materials. Synergic effects, resulting from potential chemical interactions between the three polysaccharides were observed because the impacts referred were not the same as those expected considering the relative contents of the different polysaccharides. By varying and adequately adjusting the contents of the different polysaccharides a wide variety of films with distinct performances (in terms of mechanical performance, thermal stability and antimicrobial activity) and costs could be obtained. This set of films could find applications in functional packaging, wound healing, among others.

References

Alvarez V, Vázquez A, Bernal C (2005) Fracture behavior of sisal fiber–reinforced starch-based composites. Polym Compos 26(3):316–323

Ban WP, JianguoSong AD, Lucia LA (2006a) Improving the physical and chemical functionality of starch-derived films with biopolymers. J Appl Polym Sci 100(3):2542–2548

Ban WP, Song JG, Argyropoulos DS, Lucia LA (2006b) Influence of natural biomaterials on the elastic properties of starch-derived films: an optimization study. Ind Eng Chem Res 45(2):627–633

Belgacem MN, Gandini A (2008) Monomers, polymers and composites from renewable resources, 1st edn. Elsevier, Amsterdam

Benhabiles MS, Salah R, Lounici H, Drouiche N, Goosen MFA, Mameri N (2012) Antibacterial activity of chitin, chitosan and its oligomers prepared from shrimp shell waste. Food Hydrocoll 29(1):48–56

Bourtoom T, Chinnan MS (2008) Preparation and properties of rice starch-chitosan blend biodegradable film. LWT-Food Sci Technol 41(9):1633–1641

Buléon A, Colonna P, Planchot V, Ball S (1998) Starch granules: structure and biosynthesis. Int J Biol Macromol 23(2):85–112

Cao X, Chen Y, Chang PR, Stumborg M, Huneault MA (2008) Green composites reinforced with hemp nanocrystals in plasticized starch. J Appl Polym Sci 109(6):3804–3810

Córdoba A, Cuéllar N, González M, Medina J (2008) The plasticizing effect of alginate on the thermoplastic starch/glycerin blends. Carbohyd Polym 73(3):409–416

Curvelo AAS, de Carvalho AJF, Agnelli JAM (2001) Thermoplastic starch–cellulosic fibers composites: preliminary results. Carbohyd Polym 45(2):183–188

Desbrières J, Martinez C, Rinaudo M (1996) Hydrophobic derivatives of chitosan: characterization and rheological behaviour. Int J Biol Macromol 19(1):21–28

Dufresne A, Dupeyre D, Vignon MR (2000) Cellulose microfibrils from potato tuber cells: processing and characterization of starch–cellulose microfibril composites. J Appl Polym Sci 76(14):2080–2092

Fernandes SCM, Freire CSR, Silvestre AJD, Neto CP, Gandini A, Desbrieres J, Blanc S, Ferreira RAS, Carlos LD (2009a) A study of the distribution of chitosan onto and within a paper sheet using a fluorescent chitosan derivative. Carbohyd Polym 78(4):760–766

Fernandes SCM, Oliveira L, Freire CSR, Silvestre AJD, Neto CP, Gandini A, Desbrieres J (2009b) Novel transparent nanocomposite films based on chitosan and bacterial cellulose. Green Chem 11(12):2023–2029

Fernandes SCM, Freire CSR, Silvestre AJD, Desbrieres J, Gandini A, Neto CP (2010a) Production of coated papers with improved properties by using a water-soluble chitosan derivative. Ind Eng Chem Res 49(14):6432–6438

Fernandes SCM, Freire CSR, Silvestre AJD, Neto CP, Gandini A, Berglund LA, Salmen L (2010b) Transparent chitosan films reinforced with a high content of nanofibrillated cellulose. Carbohyd Polym 81(2):394–401

Fernandes SCM, Freire CSR, Silvestre AJD, Neto CP, Gandini A (2011) Novel materials based on chitosan and cellulose. Polym Int 60(6):875–882

Grande CJ, Torres FG, Gomez CM, Troncoso OP, Canet-Ferrer J, Martínez-Pastor J (2009) Development of self-assembled bacterial cellulose–starch nanocomposites. Mater Sci Eng, C 29(4):1098–1104

Hestrin S, Schramm M (1954) Synthesis of cellulose by acetobacter-Xylinum 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58(2):345–352

Hon DN-S (1996) Chemical modification of lignocellulosic materials. Marcel Dekker, New York

Hulleman SHD, Janssen FHP, Feil H (1998) The role of water during plasticization of native starches. Polymer 39(10):2043–2048

La Mantia FP, Morreale M (2011) Green composites: a brief review. Compos Part A Appl S 42(6):579–588

Lazaridou A, Biliaderis CG (2002) Thermophysical properties of chitosan, chitosan–starch and chitosan–pullulan films near the glass transition. Carbohyd Polym 48(2):179–190

Liu F, Qin B, He L, Song R (2009) Novel starch/chitosan blending membrane: antibacterial, permeable and mechanical properties. Carbohyd Polym 78(1):146–150

Liu D, Zhong T, Chang PR, Li K, Wu Q (2010) Starch composites reinforced by bamboo cellulosic crystals. Bioresour Technol 101(7):2529–2536

Lu Y, Weng L, Cao X (2005) Biocomposites of plasticized starch reinforced with cellulose crystallites from cottonseed linter. Macromol Biosci 5(11):1101–1107

Lu Y, Weng L, Cao X (2006) Morphological, thermal and mechanical properties of ramie crystallites—reinforced plasticized starch biocomposites. Carbohyd Polym 63(2):198–204

Ma X, Yu J, Kennedy JF (2005) Studies on the properties of natural fibers-reinforced thermoplastic starch composites. Carbohyd Polym 62(1):19–24

Ma X, Chang PR, Yu J (2008) Properties of biodegradable thermoplastic pea starch/carboxymethyl cellulose and pea starch/microcrystalline cellulose composites. Carbohyd Polym 72(3):369–375

Martins IMG, Magina SP, Oliveira L, Freire CSR, Silvestre AJD, Neto CP, Gandini A (2009) New biocomposites based on thermoplastic starch and bacterial cellulose. Compos Sci Technol 69(13):2163–2168

Mohanty AK, Misra M, Drzal LT (2002) Sustainable bio-composites from renewable resources: opportunities and challenges in the green materials world. J Polym Environ 10(1–2):19–26

Pelissari FM, Grossmann MVE, Yamashita F, Pineda EAG (2009) Antimicrobial, mechanical, and barrier properties of cassava starch − chitosan films incorporated with oregano essential oil. J Agric Food Chem 57(16):7499–7504

Prachayawarakorn J, Sangnitidej P, Boonpasith P (2010) Properties of thermoplastic rice starch composites reinforced by cotton fiber or low-density polyethylene. Carbohyd Polym 81(2):425–433

Samuels RJ (1981) Solid state characterization of the structure of chitosan films. J Polym Sci B Polym Phys 19(7):1081–1105

Seong H-S, Whang HS, Ko S-W (2000) Synthesis of a quaternary ammonium derivative of chito-oligosaccharide as antimicrobial agent for cellulosic fibers. J Appl Polym Sci 76(14):2009–2015

Shen XL, Wu JM, Chen Y, Zhao G (2010) Antimicrobial and physical properties of sweet potato starch films incorporated with potassium sorbate or chitosan. Food Hydrocoll 24(4):285–290

Tome LC, Fernandes SCM, Sadocco P, Causio J, Silvestre AJD, Neto CP, Freire CSR (2012) Antibacterial thermoplastic starch-chitosan based materials prepared by melt-mixing. BioResources 7(3):3398–3409

Trovatti E, Serafim LS, Freire CSR, Silvestre AJD, Neto CP (2011) Gluconacetobacter sacchari: an efficient bacterial cellulose cell-factory. Carbohyd Polym 86(3):1417–1420

Xu YX, Kim KM, Hanna MA, Nag D (2005) Chitosan–starch composite film: preparation and characterization. Ind Crop Prod 21(2):185–192

Zhai M, Zhao L, Yoshii F, Kume T (2004) Study on antibacterial starch/chitosan blend film formed under the action of irradiation. Carbohyd Polym 57(1):83–88

Acknowledgments

FCT (Fundação para a Ciência e Tecnologia) is acknowledge for Liliana C. Tomé PhD Grant (SFRH/BD/72830/2010) and for Susana C. M. Fernandes Postdoctoral Grant (SFRH/BPD/70119/2010), and for financial support through the Projects PTDC/QUI/68472/2006, PEst-OE/EQB/LA0004/2011 (ITQB) and Pest-C/CTM/LA0011/2011 (CICECO). Isabel M. Marrucho would like to acknowledge FCT/MCTES (Portugal) for a contract under Programa Ciência 2007. The authors are also grateful to Ricardo J. B. Pinto (CICECO, University of Aveiro) for performing the SEM experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tomé, L.C., Fernandes, S.C.M., Perez, D.S. et al. The role of nanocellulose fibers, starch and chitosan on multipolysaccharide based films. Cellulose 20, 1807–1818 (2013). https://doi.org/10.1007/s10570-013-9959-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-9959-6