Abstract

The membrane and solute diffusion properties of Cladophora cellulose and polypyrrole (PPy) functionalized Cladophora cellulose were analyzed to investigate the feasibility of using electroactive membranes in hemodialysis. The membranes were characterized with scanning electron microscopy, ζ-potentiometry, He-pycnometry, N2 gas adsorption, and Hg porosimetry. The diffusion properties across the studied membranes for three model uremic toxins, i.e. creatinine, vitamin B12 and bovine serum albumin, were also analyzed. The characterization work revealed that the studied membranes present an open structure of weakly negatively charged nanofibers with an average pore size of 21 and 53 nm for pristine cellulose and PPy-Cladophora cellulose, respectively. The results showed that the diffusion of uremic toxins across the PPy-Cladophora cellulose membrane was faster than through pure cellulose membrane, which was related to the higher porosity and larger average pore size of the former. Since it was found that the average pore size of the membranes was larger than the hydrodynamic radius of the studied model solutes, it was concluded that these types of membranes are favorable to expand the Mw spectrum of uremic toxins to also include conditions associated with accumulation of large pathologic proteins during hemodialysis. The large average pore size of the composite membrane could also be exploited to ensure high-fluxes of solutes through the membrane while simultaneously extracting ions by an externally applied electric current.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hemodialysis (HD), peritoneal dialysis, and kidney transplantation are the only treatment options available for patients suffering from the end-stage renal disease (ESRD). HD treatment was performed for 1,895,000 patients globally in 2009, and the number of patients is expected to increase further (Polaschegg 2010). Despite the advances in HD, the mortality rate among ESRD patients undergoing HD treatment is still very high as only about 50 % of patients remain alive after 3 years from the start of HD, with associated cardiovascular complications being the top cause (Schmid and Schiffl 2012). The patients need to attend the clinic about three times a week to undergo a lengthy 3–5 h treatment. These problems stipulate the continued development of HD technology, including also the improvements of the polymeric membrane materials used. The current status and limitations of HD membrane materials have been extensively covered in literature (Bowry 2002; Ofsthun 2000; Vienken 2002; Zweigart et al. 2010).

When kidneys fail, the uremic toxins can no longer be removed from blood, leading eventually to death. The uremic toxins can generally be divided into four groups: (1) non-protein bound, small water-soluble toxins (Mw < 300 Da, e.g. urea, creatinine, guanidines, potassium, phosphate, oxalate, hypoxanthine, uric acid); (2) protein bound, small toxins (Mw < 300 Da, e.g. cresol, indoxyl sulfate, phenol, indoles, hippuric acid, tryptophane, homocysteine); (3) the middle size toxins (Mw 300–12,000 Da, e.g. parathyroid hormone, β2-microglobulin; peptide-linked advanced glycation end-products); and (4) large size toxins (Mw > 12,000, e.g. leptin, complement factor D) (Bowry 2002). The operating principle of contemporary HD systems includes removal of uremic toxins by combined action of diffusion and convection: the former one decreases with increasing molecular weight, while the latter increases with increased flux, e.g. due to increased transmembrane pressure or higher membrane porosity. Continuous optimization and rigorous control of the pore size distribution has led to improvements in the performance of HD membranes. However, as it has been pointed in the literature, such an approach is nearing its limits and cannot further generate improvements in selectivity (Ofsthun 2000), stipulating the development of innovative approaches to HD. Some examples of conceptually different approaches to traditional HD include combined diffusion-adsorption membranes (Tijink et al. 2012), nanofabricated silicon wafers with controlled pore slit geometry (Fissell et al. 2007; Humes et al. 2006), ferromagnetic nanoparticle-targeted binding substance conjugates (FN-TBS Cs) (Stamopoulos 2008), microfluidic, membraneless devices (Leonard et al. 2004, 2005), and dialysis-free, synthetic renal replacement system termed “human nephron filter” (Nissenson et al. 2005). Another approach to facilitate the removal of uremic toxins during HD includes the use of electrical field across the HD membrane, known as blood electrodialysis (Hedayat et al. 2012; Kokubo et al. 2009; Pirot et al. 2002; Smith et al. 1964).

The research efforts during the past decade were focused mainly on removal of middle size uremic toxins since failure to remove them has been related to cardiovascular and immunological complications. Middle size uremic toxins, e.g. β2-microglobulin, parathyroid hormone and the pro-inflammatory cytokines such as TNF-α, IL-6 and IL-1β, are examples of uremic toxins implicated in numerous aspects of the morbidity of dialysis patients (Vanholder et al. 2001, 2008). It is preferred to retain large (essential) proteins like albumin, immunoglobulins and peptide hormones since low serum levels of such solutes in patients with chronic kidney failure are a well documented predictor of mortality (Owen et al. 1993). Thus, the developments in the design of high-flux HD membranes, mainly focusing on the removal of middle size uremic toxins and the retention of essential proteins. However, the removal of small water-soluble toxins should not be overlooked since such molecules also pose serious health problems. Indeed, one of the major patho-physiological factors responsible for mortality of ESRD patients during HD treatment is hyperphosphatemia leading to vascular calcification (Kuhlmann 2010; Vanholder et al. 2001; Block et al. 1998, 2004). Oxalic acid retained in uremia is also known to be involved in the clinical development of cardiovascular problems (Vanholder et al. 2001). Thus, developing highly selective HD membrane materials featured also with good hemocompatibility is one of the key challenges to improve the current HD apparatus.

Recently, the feasibility of using novel, electrochemically-controlled HD membrane materials, particularly suitable for removal of small size, non-protein bound, water-soluble uremic toxins, such as oxalate or phosphate anions, was investigated (Ferraz et al. 2012a, b). The materials are highly porous composite membranes of Cladophora cellulose nanofibers coated with a thin (~50 nm) layer of the conductive polymer, polypyrrole (PPy) (Mihranyan et al. 2008). Cladophora cellulose is featured with exceptional properties for a cellulosic material such as high degree of crystallinity (about 95 %) and large specific surface area (on the order of 100 m2/g), comparable to that of industrial absorbents (Mihranyan 2011; Mihranyan et al. 2007). Furthermore, due to its high degree of crystallinity, Cladophora cellulose nanofibers do not swell, and one of the early suggested applications of Cladophora cellulose included its use as a filtration medium (Mihranyan 2011). By coating the Cladophora cellulose nanofibers with a thin layer of PPy, a composite conductive paper material featuring high porosity and externally potential-controlled anion exchange properties is obtained (Mihranyan et al. 2008). If a sufficiently positive potential is applied, the PPy layer on Cladophora cellulose nanofibers is oxidized which results in positive charges along the PPy chains (Strømme et al. 2009; Gelin et al. 2009). The anions present in the electrolyte then move to the polymer to compensate for the positive charges and to maintain the overall electroneutrality of the system. If a sufficiently negative potential is applied to the oxidized film, the polymer fibers are reduced, and the anions are released back into the electrolyte. Further, PPy can also be rendered cation-exchange properties by incorporating large, immobile anions in its structure during synthesis (Liljegren et al. 2002). The composite PPy-Cladophora cellulose paper, functioning as an electroactive membrane, was shown efficient in extracting inorganic and organic ions: For instance, the extraction capacity of PPy-Cladophora cellulose composite membrane for chloride ions is about 5 mol/kg (Gelin et al. 2009). The membrane was also shown efficient in extracting aminoacids and even DNA oligonucleotides of varying length from aqueous solutions (Razaq et al. 2009, 2011a, b; Rubino et al. 2010). By exploiting the electroactive ion exchange properties of PPy, the so-called affinity electromembranes (Loh et al. 1990) have been developed for electrically facilitated extraction of, e.g. hemoglobin (Shi et al. 2010) or thrombin (Wang et al. 2011, 2013) directly from blood. Further, the electroactive properties of PPy have been studied with respect to controlled drug delivery (Jagur-Grodzinski 2012). Therefore, these and other properties have triggered interest in investigating the feasibility of using porous PPy-Cladophora cellulose electroactive membranes for removal of small water-soluble uremic toxins from blood. Such electrochemically-controlled membranes could either be integrated into hybrid systems with conventional HD apparatus to offer additional modality or be used on their own, provided that the pore size distribution is tailored for size exclusion.

The potential benefits of using PPy-Cladophora cellulose as electrochemically-controlled HD membrane include:

-

Rapid, current-controlled removal of water-soluble ions (both anion- and cation-exchange membranes), which could potentially shorten the HD session;

-

Highly porous structure with potentially tunable pore size distribution, which could enable combined ultrafiltration and electrochemically-controlled solute removal;

-

Possibility of simultaneous electrochemically-controlled drug release.

The in vitro and in vivo studies by Ferraz et al. showed that PPy-Cladophora cellulose composites do not leach toxic substances when appropriately rinsed after the synthesis (Ferraz et al. 2012b), although excessive rinsing with water has some negative impact on the electroactive properties of PPy (Carlsson et al. 2013). Further, upon storage PPy is oxidatively degraded into shorter oligomers having a negative effect on the overall toxicity of the composite (Ferraz et al. 2012b). The hemocompatibility of the PPy-Cladophora cellulose composite was also studied in vitro (Ferraz et al. 2012a). The composite showed low complement activation, and the thrombogenic properties of the material were improved by applying a heparin coating. The hemocompatibility of the obtained heparinized samples was comparable and sometimes even better than that for commercially available HD membranes (Ferraz et al. 2012a). Both heparinized and non-heparinized PPy-Cladophora cellulose membranes exhibited good phosphate and oxalate extraction capacity at physiological pH and isotonicity (Ferraz et al. 2012a). The electroactive properties of PPy-Cladophora cellulose membrane were also confirmed for uric acid (unpublished data). Before the electroactive membranes can be considered in a clinical setting, it is important to weigh the benefits against the limitations of the proposed approach. Since the PPy-Cladophora cellulose membrane may in principle combine active ion exchange with ultrafiltration, the evaluation of the membrane solute diffusion properties is needed. This work is the continuation of the preliminary feasibility studies of using porous composite PPy-Cladophora cellulose electroactive membranes for HD, specifically focusing on the membrane characterization and solute transport properties at recommended ISO-standard concentrations for three model uremic toxins, i.e. creatinine, vitamin B12, and bovine serum albumin (BSA).

Experimental part

Materials

Three model uremic toxin substances corresponding to small, medium, and large size toxins were used: creatinine (Mw = 113 g/mol; Merck, Germany), vitamin B12 (Mw = 1,135 g/mol; Sigma Aldrich, Germany), albumin from bovine serum, BSA (Mw = 66,000 g/mol, lyophilized powder, Sigma Aldrich, Germany). The following compounds were used for synthesis of the PPy-Cladophora cellulose membrane: pyrrole, tween-80, iron (III) chloride and sodium chloride (Sigma Aldrich, Germany). Cladophora cellulose was supplied by FMC Biopolymer, USA (batch G-3095-10). Microfibrillated cellulose (MFC) was supplied by Innventia AB, Sweden. The phosphate buffer (PBS; pH = 6, 8) tablets were ordered from Merck, Germany.

Membrane preparation

Two types of membranes were prepared: Cladophora cellulose and PPy-Cladophora cellulose.

Cladophora cellulose membranes were prepared by dispersing 300 mg of Cladophora cellulose powder in 50 mL of deionized water using a high-energy ultrasonicator (Vibracell, 750 W, Sonics, USA) for 12 min. The mixture was then drained on a nylon 0.1 μm filter in a Buchner funnel to form a filter-cake and dried at ambient conditions under heavy load to obtain a paper sheet with an average thickness of 0.3 mm.

In order to produce, PPy-Cladophora cellulose composite membrane, 300 mg of Cladophora cellulose powder was added to 50 mL deionized water and dispersed using a high-energy ultrasonicator (Vibracell, 750 W, Sonics, USA) for 12 min. To the produced dispersion, 3 drops of Tween-80 and 3 mL of pyrrole in 100 mL deionized water were added and stirred for 10 min. In order to induce polymerization, 100 mL of 8 % (w/v) iron (III) chloride solution was added to the cellulose-pyrrole mixture and stirred for 15 min. The obtained material was then drained on a Nylon 0.1 μm filter in a Buchner funnel and rinsed with 10 L of 0.1 M NaCl. Following the rinsing, the product was dispersed in 100 mL of water together with 10.6 g of 2.26 % (w/v) MFC using a high-energy ultrasonicator (Vibracell, 750 W, Sonics, USA) for 3 min. The product was then drained on a 0.1 μm nylon filter in a Buchner funnel to form a filter-cake and then dried in ambient conditions under heavy load to produce a composite sheet with an average thickness of 0.6 mm.

Scanning electron microscopy (SEM)

Cladophora cellulose and cellulose-based composite samples were sputtered with a thin gold/palladium layer prior to analysis to avoid charging of samples. SEM analyses were done using a Leo 1550 SEM instrument (Zeiss, Germany) equipped with an in-lens detector.

N2 gas adsorption

Nitrogen (N2) gas adsorption isotherms (77 K) were obtained using an ASAP 2020 (Micromeritics, USA) instrument. The specific surface areas of the samples were calculated from the isotherms using the Brunauer–Emmett–Teller (BET) method (Brunauer et al. 1938). The samples were degased at 95 °C under vacuum for at least 24 h prior to analysis. The pores size distribution was calculated using the Barrett–Joyner–Halenda (BJH) method (Barrett et al. 1951) supplied in the software to ASAP 2020 instrument.

Hg intrusion porosimetry

Hg intrusion porosimetry was performed using an Autopore IV 9500 instrument (Micromeritics, USA) at Particle Analytical ApS (Hørsholm, Denmark).

Total porosity

A value for porosity was calculated from the bulk density and true density:

where ε is the total porosity, %; ρ bulk is membrane bulk density from its dimensions; ρ true is membrane true density, i.e. 1.64 g/cm3 (Mihranyan 2011). The membrane thickness was measured using a digital caliper (Mitutoyo ID-C15OXB, Japan) directly before diffusion experiment. The measurement was carried out at 5 different positions of the membrane. At least 11 samples per membrane type were used to determine the total porosity.

ζ-potential

A membrane sample of 10 mg was added to 50 mL 10 mM NaCl (pH 6.5) and ultrasonicated (Vibracell, 750W, Sonics, USA) for 12 min. Then, these samples were diluted 20 times. ζ-potential (n = 3) was measured with a Zetasizer Nano ZS (Malvern, UK) instrument.

Solute diffusivity through membranes

The horizontal diffusion cell technique was used to measure the diffusivity of selected uremic toxins. A horizontal diffusion cell (PermeGear, USA) consisting of two identical compartments (donor and acceptor) with water-jacketed walls was used. Each compartment was shaped as a 34-mL cylinder. The cylinders were separated by rubber gaskets, between which the membrane was fixed. The effective membrane area A for perfusion was 0.785 cm2 with an average (dry) membrane weight of 46 mg for the Cladophora cellulose membranes and 74 mg for the PPy-Cladophora cellulose membranes. The diffusion cell was thermostated at 37 ± 1 °C using a water bath. The solution inside each compartment was magnetically stirred at about 400 rpm. Aliquots of 1 mL were taken at regular intervals from both donor and acceptor compartments. The concentration profiles of the solutes were recorded using an UV spectrophotometer (Shimadzu UV-1800, Japan). The absorbance for creatinine, vitamin B12 and BSA was recorded at 234, 361 and 280 nm, respectively. For the diffusion cell experiments, the solutions were prepared according to ISO 8637 (ISO-8637:2010 2010). Thus, the donor compartment was filled with 500 μM creatinine, 40 μM vitamin B12 or 900 μM BSA in PBS (5 mM, pH = 7.4), whereas the acceptor cell was filled with pure PBS (5 mM, pH = 7.4). Thus, the driving force for mass transfer was the concentration gradient across the membrane. Prior to the measurement the membranes were pre-swollen in PBS for 5 min. The diffusion experiments were carried out three times for each solute and each membrane type. Table 1 summarizes the physico-chemical properties of the studied solutes.

The diffusion coefficients, D, were calculated according to the time-lag method (Zhang and Furusaki 2001), in which the total amount, Q, of solute, transferred through the membrane after time t is expressed as:

Here V ac (0) and C ac is the initial volume and the solute concentration at time t in the acceptor compartment, respectively, whereas l and C d (0) is the membrane thickness and initial concentration of solute in the donor compartment, respectively.

To extract the diffusion coefficient from Eq. (2) the total amount of solute transferred through the membrane Q(t) was plotted versus t and the diffusion coefficient was obtained from the slope of this plot in the time interval where quasi-steady-state conditions prevailed (Zhang and Furusaki 2001).

Solute retention

Solute retention was estimated as the solute mass, M m , accumulated after t = 24 h in the membrane according to

Here V d (0) is the initial volume in the donor compartment. The volumes used for calculating the solute retention were compensated for each 1 mL aliquots withdrawn from the diffusion cell.

Statistical analysis

Data for diffusion coefficients were statistically evaluated by one-way ANOVA with Fisher’s LSD post hoc test using KaleidaGraph software. Samples were considered statistically different at p < 0.05.

Results and discussion

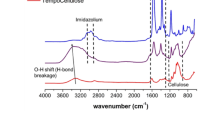

The studied samples were flat, non-woven membranes composed of cellulose nanofibers or cellulose nanofibers coated with PPy. Figure 1 shows the SEM images of the studied membranes. The images reveal an open structure of intertwined nanofibers. The surface of the composite membranes (Fig. 1b) is more uneven than that of the pure cellulose membranes (Fig. 1a), featuring clearly visible nodes and blobs due to the PPy-coating on the nanocellulose fibers.

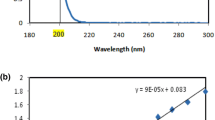

Figure 2 shows the pore size distribution of the two membrane types under study as obtained from BJH analysis of N2 gas adsorption isotherms (Fig. 2a) and Hg intrusion porosimetry (Fig. 2b). Both of the samples feature a broad pore size distribution over the entire mesoporous range, i.e. between 2 and 50 nm, and the lower macroporous range. Neither of the analysis techniques revealed presence of pores larger than 200 nm. It is seen from the BJH pore size distribution curves (Fig. 2a) that PPy-Cladophora cellulose membranes feature a pore size distribution shifted towards larger pore sizes as compared to the Cladophora cellulose membrane. The average pore size of the Cladophora cellulose membrane was around 18 nm, whereas that of the PPy-Cladophora cellulose membrane was around 41 nm. The pore size distribution curves obtained from Hg intrusion porosimetry suggest a similar shift to larger pore sizes for PPy-Cladophora cellulose membranes as compared to Cladophora cellulose membranes, although the average pore size values are slightly larger than those obtained using BJH analysis of N2 gas adsorption isotherms, viz. 21 and 53 nm, respectively. The average pore size of the studied membranes is an order of magnitude larger than that for commercially available HD membranes: For comparison, the pore size of a typical high-flux polysulfone membrane is 3.1 and 1.6 nm for low-flux polysulfone (Bowry 2002). This, however, should not necessarily be seen as an impediment since electroactive membranes rely on electrochemically driven removal of solutes rather than pore size dependent exclusion, especially if development of hybrid systems is envisaged.

Table 2 summarizes some of the physical characteristics of the membranes such as their specific surface area, pore size distribution, and ζ-potential. It is seen from this table that the specific surface area of Cladophora cellulose membranes is somewhat larger than that for the PPy-Cladophora membrane. Both of the membranes were weakly (negatively) charged with ζ-potential values in the range between −18 and −23 mV at pH = 7.4 for Cladophora cellulose and PPy-Cladophora cellulose membranes, respectively.

Concern about the use of negatively charged HD membranes has been related to high thrombogenicity and bradykinin formation leading to anaphylactoid-like reactions in sensitive patients (Schaefer et al. 1993; Vienken 2002; Coppo et al. 2000). This is due to the fact that the coagulation factor XII is activated by negatively charged surfaces, which in turn, triggers the formation of the vasodilating agent bradykinin. We have previously described the use of a stable heparin coating on PPy-Cladophora cellulose composite to render the membrane non-thrombogenic (Ferraz et al. 2012a). This heparin coating, acting as a passivating layer, could significantly contribute to maintaining low levels of active factor XII (Nilsson et al. 2010) and thus preventing the formation of bradykinin, thereby reducing the risks of anaphylactoid-like reactions.

Figure 3 summarizes the total porosity values of the studied membranes. The PPy-Cladophora cellulose membranes have a higher porosity than the Cladophora cellulose membranes. The average porosity of Cladophora cellulose membranes was 45 % whereas that of PPy-Cladophora cellulose membranes was 61 %. The higher variability in the total porosity of Cladophora cellulose membranes was ascribed to a larger extent of shrinking during drying. Less shrinking in the PPy-Cladophora cellulose membranes could also explain the shift of the pore size distribution to larger values as compared to the Cladophora cellulose membrane as discussed previously (Mihranyan et al. 2012). Future efforts will be directed at controlling the total porosity and pore size distribution by rigorous control of the drying conditions, e.g. temperature, applied tension during drying, etc.

Considering the hydrodynamic radii of the solutes at pH = 7.4 in Table 1 and the pore size distribution data summarized in Table 2, it can be concluded that the average pore size of the membranes is considerably larger than the hydrodynamic radii of solutes. The average pore size of the studied membranes is comparable to those of high cutoff dialysis membranes, which range from 10 nm up to 200 nm (Zweigart et al. 2010). This property opens the possibility of using the composite membranes to maximize the removal of proteins in the Mw range of 15–50 kDa that are involved in pathophysiological conditions. This group of proteins includes free light-chain proteins, which are excessively produced and accumulated in diseases such as kidney myeloma, and inflammatory cytokines, which are overexpressed in acute inflammatory diseases and lead to sepsis-induced acute renal failure (Zweigart et al. 2010). Special attention needs to be paid to high permeability membrane-associated albumin loss since hypoalbuminemia has been described as a predictor of morbidity and mortality in HD patients (Foley et al. 1996; Owen et al. 1993). On the other hand, the loss of albumin could also be related to the removal of albumin-bound uremic toxins and harmful oxidized proteins, and, thus, the use of a highly permeable membrane may be beneficial to treat a certain group of patients (Krieter and Canaud 2003; Ward 2005).

Figure 4 shows the concentration profiles of the studied solutes diffusing through Cladophora cellulose and PPy-Cladophora cellulose membranes. The results in Fig. 4 were normalized with respect to the solute fraction permeating through the membrane since different concentrations of model toxins were used. As expected, the fraction of the solute gradually decreased in the donor compartment and increased, accordingly, on the acceptor side, see Fig. 4. However, both membranes featured significant solute retention capacity as estimated from the mass of the solute accumulated in the membrane during diffusion, see Table 3. After 24 h, the solute retention capacity of the membranes accounted to values between 20 and 35 % of the initial amount of the solute added in the donor compartment due to the large surface area of the studied membranes. High solute retention capacity is not uncommon for conventional HD membranes since it has been shown that as much as 17–60 % of β2-microglobulin can be removed due to adsorption (Klinke et al. 1989; Ofsthun 2000).

In order to estimate the diffusion coefficients of the solutes through the membranes, the time-lag model was used. According to this model, the diffusion coefficients are obtained from the linear region of the plots described in the experimental section corresponding to the quasi-steady state diffusion region, which is first preceded by a time-lag. Under the experimental conditions of the present study, the quasi-steady state diffusion region was found to be located between 3 and 7 h. The obtained values for the diffusion coefficients are summarized in Fig. 5.

It is seen from this plot, that the diffusion coefficient values in the Cladophora cellulose membranes were in general lower than those in the PPy-Cladophora cellulose membranes for all three solutes. Statistical analysis confirmed that such difference was significant. Lower diffusion coefficient values in the Cladophora cellulose membrane for solutes having hydrodynamic diameters ranging between ~0.5 and 7.2 nm (i.e. twice the radii values in Table 1) can most likely be explained by the fact that these membranes have a significant number of pores in the sub 10 nm region (Fig. 2), as detected with BJH pore size distribution analysis (see Fig. 2a), while such narrow pores are absent in the PPy-Cladophora cellulose.

Generally, the diffusion coefficient is inversely correlated with the square root of molecular weight (Frigon et al. 1983; Ofsthun 2000). However, the value of the diffusion coefficient increases with increasing concentration in good solvents (Han and Ziya Akcasu 1981), which could explain the observed relatively high values of the diffusion coefficient for BSA.

The results of this study suggest that the large pore size distribution of the PPy-Cladophora cellulose membrane will be favorable to expand the Mw spectrum of uremic toxins to be removed during HD and, especially, to treat diseases were the accumulation of proteins with Mw up to 50 kDa is related to the pathological mechanism of the disease. Certainly, this will only be relevant if the composite membranes are not to be integrated into hybrid systems with conventional HD apparatus. The large average pore size of the composite membrane could also be exploited to ensure high-fluxes of solutes through the membrane while simultaneously enabling ion-extraction through a current-controlled process. Earlier studies suggested that the ion-extraction capacity of PPy-Cladophora cellulose membranes decreases with decreasing porosity (Carlsson et al. 2012; Mihranyan et al. 2012). Therefore, maintaining high porosity is expected to be favorable for ensuring effective removal of uremic toxins by utilizing electroactive properties of the composite. In this respect, further studies will focus on the feasibility of active ion exchange extraction of small water-soluble uremic toxins from blood and the effect of such process on the activation of blood, i.e. the membrane blood compatibility under applied potential.

Conclusion

The solute diffusion across the PPy-Cladophora cellulose membranes was faster than that across the Cladophora cellulose membranes for all solutes under study, which was explained by differences in the pore size distribution between the membranes with the latter having a lower total porosity and a higher presence of narrower pores than the former. The large average pore size of the composite membrane is beneficial to ensure high-fluxes of solutes through the membrane while simultaneously extracting ions by an externally applied electric current. Whereas it was previously suggested that electroactive PPy-Cladophora cellulose membranes are particularly interesting for removal of small water-soluble uremic toxins, the results presented here imply that such membranes may also be favorable for expanding the Mw spectrum of uremic toxins needing removal to also include the large pathogenic proteins otherwise accumulated during HD.

References

Barrett EP, Joyner LG, Halenda PP (1951) The determination of pore volume and area distributions in porous substances. I. Computations form nitrogen isotherms. J Am Chem Soc 73(1):373–380

Block GA, Hulbert-Shearon TE, Levin NW, Port FK (1998) Association of serum phosphorus and calcium x phosphate product with mortality risk in chronic hemodialysis patients: a national study. Am J Kidney Dis 31(4):607–617

Block GA, Klassen PS, Lazarus JM, Ofsthun N, Lowrie EG, Chertow GM (2004) Mineral metabolism, mortality, and morbidity in maintenance hemodialysis. J Am Soc Nephrol 15(8):2208–2218

Bowry SK (2002) Dialysis membranes today. Int J Artif Organs 25(5):447–460

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60(2):309–319

Carlsson DO, Nyström G, Zhou Q, Berglund LA, Nyholm L, Stromme M (2012) Electroactive nanofibrillated cellulose aerogel composites with tunable structural and electrochemical properties. J Mater Chem 22(36):19014–19024

Carlsson DO, Sjödin M, Nyholm L, Strømme M (2013) A comparative study of the effects of rinsing and aging of polypyrrole/nanocellulose composites on their electrochemical properties. J Phys Chem B 117(14):3900–3910

Conder JR, Hayek BO (2000) Adsorption kinetics and equilibria of bovine serum albumin on rigid ion-exchange and hydrophobic interaction chromatography matrices in a stirred cell. Biochem Eng J 6(3):215–223

Coppo R, Amore A, Cirina P, Scelfo B, Giacchno F, Comune L, Atti M, Renaux JL (2000) Bradykinin and nitric oxide generation by dialysis membranes can be blunted by alkaline rinsing solutions. Kidney Int 58(2):881–888

Ferraz N, Carlsson DO, Hong J, Larsson R, Fellström B, Nyholm L, Strømme M, Mihranyan A (2012a) Haemocompatibility and ion exchange capability of nanocellulose polypyrrole membranes intended for blood purification. J R Soc Interface 9(73):1943–1955

Ferraz N, Strømme M, Fellström B, Pradhan S, Nyholm L, Mihranyan A (2012b) In vitro and in vivo toxicity of rinsed and aged nanocellulose-polypyrrole composites. J Biomed Mater Res Part A 100(8):2128–2138

Fissell WH, Humes HD, Fleischman AJ, Roy S (2007) Dialysis and nanotechnology: now, 10 years, or never? Blood Purif 25:12–17

Foley RN, Parfrey PS, Harnett JD, Kent GM, Murray DC, Barre PE (1996) Hypoalbuminemia, cardiac morbidity, and mortality in end-stage renal disease. J Am Soc Nephrol 7(5):728–736

Frigon RP, Leypoldt JK, Uyeji S, Henderson LW (1983) Disparity between stokes radii of dextrans and proteins as determined by retention volume in gel permeation chromatography. Anal Chem 55(8):1349–1354

Gelin K, Mihranyan A, Razaq A, Nyholm L, Strømme M (2009) Potential controlled anion absorption in a novel high surface area composite of Cladophora cellulose and polypyrrole. Electrochim Acta 54(12):3394–3401

Han CC, Ziya Akcasu A (1981) Concentration dependence of diffusion coefficient at various molecular weights and temperatures. Polymer 22(9):1165–1168

Harland RS, Peppas NA (1989) Solute diffusion in swollen membranes VII. Diffusion in semicrystalline networks. Colloid Polym Sci 267(3):218–225

Hedayat A, Elmoselhi H, Shoker A (2012) Theoretical application of irreversible (Nonequilibrium) thermodynamic principles to enhance solute fluxes across nanofabricated hemodialysis membranes. Int J Nephrol 2012. doi:10.1155/2012/718085

Humes HD, Fissell WH, Tiranathanagul K (2006) The future of hemodialysis membranes. Kidney Int 69:1115–1119

ISO-8637:2010 (2010) Cardiovascular implants and extracorporeal systems: haemodialysers, haemodiafilters, haemofilters and haemoconcentrators. TC150/SC2. International Organization for Standardization, Geneva, Switzerland

Jagur-Grodzinski J (2012) Biomedical applications of electrically conductive polymeric systems. E-Polymers 12(1):722–740

Klinke B, Rockel A, Abdelhamid S, Fiegel P, Walb D (1989) Transmembranous transport and adsorption of beta-2-microglobulin during hemodialysis using polysulfone, polyacrylonitrile, polymethylmethacrylate and cuprammonium rayon membranes. Int J Artif Organs 12(11):697–702

Kokubo K, Otani Y, Tsukao H, Shibo T, Hirose M, Kobayashi H (2009) Urea concentrating ability of artificial renal tubule based on countercurrent multiplier system using electrodialysis, dialysis and filtration. IFMBE Proc 25(7):499–501

Krieter DH, Canaud B (2003) High permeability of dialysis membranes: what is the limit of albumin loss? Nephrol Dial Transpl 18(4):651–654. doi:10.1093/ndt/gfg054

Kuhlmann MK (2010) Phosphate elimination in modalities of hemodialysis and peritoneal dialysis. Blood Purif 29(2):137–144

Leonard EF, West AC, Shapley NC, Larsen MU (2004) Dialysis without membranes: how and why? Blood Purif 22:92–100

Leonard EF, Cortell S, Vitale NG (2005) Membraneless dialysis—is it possible? Contrib Nephrol 149:343–353

Liljegren G, Pettersson J, Markides KE, Nyholm L (2002) Electrochemical solid-phase microextraction of anions and cations using polypyrrole coatings and an integrated three-electrode device. Analyst 127(5):591–597

Loh IH, Moody RA, Huang JC (1990) Electrically conductive membranes: synthesis and applications. J Membr Sci 50(1):31–49

Mihranyan A (2011) Cellulose from Cladophorales green algae: from environmental problem to high-tech composite materials. J Appl Polym Sci 119(4):2449–2460

Mihranyan A, Edsman K, Strømme M (2007) Rheological properties of cellulose hydrogels prepared from Cladophora cellulose powder. Food Hydrocoll 21(2):267–272

Mihranyan A, Nyholm L, Garcia Bennett AE, Strømme M (2008) A novel high specific surface area conducting paper material composed of polypyrrole and Cladophora cellulose. J Phys Chem B 112(39):12249–12255

Mihranyan A, Esmaeili M, Razaq A, Alexeichik D, Lindström T (2012) Influence of the nanocellulose raw material characteristics on the electrochemical and mechanical properties of conductive paper electrodes. J Mater Sci 47(10):4463–4472

Nilsson B, Korsgren O, Lambris JD, Ekdahl KN (2010) Can cells and biomaterials in therapeutic medicine be shielded from innate immune recognition? Trends Immunol 31(1):32–38

Nissenson AR, Ronco C, Pergamit G et al (2005) Continuously functioning artificial nephron system: the promise of nanotechnology. Hemodial Int 9:210–217

Ofsthun NJ (2000) Limitations of membrane structure and dialyzer design on large solute removal in dialysis. Blood Purif 18(4):264–266

Owen WF Jr, Lew NL, Liu Y, Lowrie EG, Lazarus JM (1993) The urea reduction ratio and serum albumin concentration as predictors of mortality in patients undergoing hemodialysis. N Engl J Med 329(14):1001–1006

Pirot F, Faivre V, Bourhis Y, Aulagner G, Falson F (2002) Faster phenytoin removal from serum by electrodialysis: a potential use in hemodialysis? J Membr Sci 207:265–272

Polaschegg HD (2010) Hemodialysis machine technology: a global overview. Expert Rev Med Devices 7(6):793–810

Razaq A, Mihranyan A, Welch K, Nyholm L, Strømme M (2009) Influence of the type of oxidant on anion exchange properties of fibrous Cladophora cellulose/polypyrrole composites. J Phys Chem B 113(2):426–433

Razaq A, Nyström G, Strømme M, Mihranyan A, Nyholm L (2011a) High-capacity conductive nanocellulose paper sheets for electrochemically controlled extraction of DNA oligomers. PLoS One 6(12):e29243. doi:10.1371/journal.pone.0029243

Razaq A, Strømme M, Nyholm L, Mihranyan A (2011b) Electrochemically controlled separation of DNA oligomers with high surface area conducting paper electrode. In, pp 135–142

Rubino S, Razaq A, Nyholm L, Strømme M, Leifer K, Mihranyan A (2010) Spatial mapping of elemental distributions in polypyrrole-cellulose nanofibers using energy-filtered transmission electron microscopy. J Phys Chem B 114(43):13644–13649

Schaefer RM, Fink E, Schaefer L, Barkhausen R, Kulzer P, Heidland A (1993) Role of bradykinin in anaphylactoid reactions during hemodialysis with AN69 dialyzers. Am J Nephrol 13(6):473–477

Schmid H, Schiffl H (2012) Hemodiafiltration and survival of end-stage renal disease patients: the long journey goes on. Int Urol Nephrol 44(5):1435–1440

Sharma AC, Jana T, Kesavamoorthy R, Shi L, Virji MA, Finegold DN, Asher SA (2004) A general photonic crystal sensing motif: creatinine in bodily fluids. J Am Chem Soc 126(9):2971–2977

Shi W, Ma Y, Song C, Jiang H, Ru X, Tu J, Jiang S, Wang J, Ge D (2010) Affinity electromembrane: electrically facilitated adsorption. J Membr Sci 354(1–2):86–92

Smith AL, Berkowitz HD, Bluemle LWJ (1964) Electrodialysis of blood: evaluation of a high capacity unit. Trans Am Soc Artif Intern Organs 10(1):273–279

Stamopoulos D (2008) Magnetic nanoparticles utilized in hemodialysis for the treatment if hyperhomocysteinemia: the new challenge for nanobiotechnology. Curr Nanosci 4:302–307

Strømme M, Frenning G, Razaq A, Gelin K, Nyholm L, Mihranyan A (2009) Ionic motion in polypyrrole-cellulose composites: trap release mechanism during potentiostatic reduction. J Phys Chem B 113(14):4582–4589

Tijink MSL, Wester M, Sun J, Saris A, Bolhuis-Versteeg AM, Saiful S, Joles JA, Borneman Z, Wessling M, Stamatialis DF (2012) A novel approach for blood purification: mixed-matrix combining diffusion and adsorption in one step. Acta Biomater 8:2279–2287

Vanholder R, Argilés A, Baurmeister U, Brunet P, Clark W, Cohen G, De Deyn PP, Deppisch R, Descamps-Latscha B, Henle T, Jörres A, Massy ZA, Rodriguez M, Stegmayr B, Stenvinkel P, Wratten ML (2001) Uremic toxicity: present state of the art. Int J Artif Organs 24(10):695–725

Vanholder R, Baurmeister U, Brunet P, Cohen G, Glorieux G, Jankowski J (2008) A bench to bedside view of uremic toxins. J Am Soc Nephrol 19(5):863–870

Vienken J (2002) Polymers in nephrology: characteristics and needs. Int J Artif Organs 25(5):470–479

Wang J, Shi W, Jiang H, Wu G, Ruan C, Ge D (2011) Heparin-doped affinity electromembranes for thrombin purification. J Membr Sci 373(1–2):89–97

Wang J, Wu G, Shi W, Liu X, Ruan C, Xue M, Ge D (2013) Affinity electromembrane with covalently coupled heparin for thrombin adsorption. J Membr Sci 428:70–77

Ward RA (2005) Protein-leaking membranes for hemodialysis: a new class of membranes in search of an application? J Am Soc Nephrol 16(8):2421–2430. doi:10.1681/asn.2005010070

Zhang W, Furusaki S (2001) On the evaluation of diffusivities in gels using the diffusion cell technique. Biochem Eng J 9(1):73–82

Zweigart C, Neubauer M, Storr M, Böhler T, Krause B (2010) Progress in the development of membranes for kidney-replacement therapy. In: Drioli E, Giorno L (eds) Comprehensive membrane science and engineering, vol 2. Elsevier B.V, Oxford, UK, pp 351–390

Acknowledgments

The Swedish Research Council (Vetenskapsrådet), the Bo Rydin Foundation, the Carl Trygger Foundation, the Swedish Foundation for Strategic Research, and the Lars Hiertas Minne Foundation are gratefully acknowledged for their support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Natalia Ferraz and Anastasiya Leschinskaya have contributed equally to this work.

Rights and permissions

About this article

Cite this article

Ferraz, N., Leschinskaya, A., Toomadj, F. et al. Membrane characterization and solute diffusion in porous composite nanocellulose membranes for hemodialysis. Cellulose 20, 2959–2970 (2013). https://doi.org/10.1007/s10570-013-0045-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-0045-x