Abstract

A new, robust method for measuring the average pore size of water-swollen, cellulose I rich fibres is presented. This method is based on the results of solid-state NMR, which measures the specific surface area (area/solids mass) of water-swollen samples, and of the fibre saturation point (FSP) method, which measures the pore volume (water mass/solids mass) of water-swollen samples. These results are suitable to combine since they are both recorded on water-swollen fibres in excess water, and neither requires the assumption of any particular pore geometry. The new method was used for three model samples and reasonable average pore size measurements were obtained for all of them. The structural characterization of water-swollen samples was compared with the dry structure of fibres as revealed using BET nitrogen gas adsorption after a liquid exchange procedure and careful drying. It was concluded that the structure of the water-swollen fibres sets an upper limit on what is obtainable in the dry state.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

It has long been known that cellulose I, the native form of cellulose present in most plant cells, consists of structural elements known as fibrils; these are combined during fibre biogenesis with other polymers such as lignin and other polysaccharides.

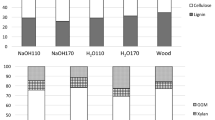

Isolated cellulose rich plant fibres are typically produced via some kind of liberation procedure during which non-cellulose I polymers, extractives, and inorganic substances are removed to varying degrees. Several globally common industrial-scale manufacturing processes, such as the kraft and dissolving pulp processes, are today used to isolate cellulose I rich fibres from wood chips.

The removal on non-cellulose I components creates additional cavities or pores in the native fibre wall, pores that remain in the liquid swollen state as long as the fibre wall does not collapse (Stone and Scallan 1966). Other typical features of such cellulose I enriched plant fibres are their high specific surface area in the liquid swollen state, low specific surface area in the dry state, and hornification, i.e., the irreversible loss of water-binding ability due to first-time-drying (Annergren and Wågberg 1997). Specific surface area and fibre wall porosity are two important features of these water-swollen fibres that affect their suitability for various end-products and the ease of processing. For example, the ease with which a certain fibre material can be dewatered is strongly influenced by its specific surface area and porosity. In the water-swollen state, the measurement of cellulose I specific surface area and the determination of pore size are delicate tasks, partly due to the relative mechanical weakness of the water-swollen fibre wall. Ideally, specific surface area pore size, and pore size distribution should be measured on fibres exposed to similar conditions, for example, both specific surface area and pore size should be measured on water-swollen fibre material in the presence of excess water. To the knowledge of the authors, this has never been done before and is one of the major objectives of the present work.

In the case of fibre wall pores, their small size (1–100 nm) makes accurate determinations of pore sizes difficult (Li et al. 1993). Mercury-intrusion porosimetry (Moura et al. 2005), cryoporometry, NMR (Nuclear Magnetic Resonance) relaxometry (Li et al. 1993; Valckenborg et al. 2002; Östlund et al. 2010), and differential scanning calorimetry (Maloney et al. 1998; Park et al. 2006), can measure pores in the size range typically found in the cellulose I enriched pulp fibre wall. Nitrogen- or krypton-adsorption BET (Brunauer-Emmett-Teller) isotherms (Brunauer et al. 1938) can be used to measure fibre wall pore size distributions and cellulose I specific surface area if the structure typical of a water-swollen fibre wall can be preserved in the dry state by, for example, a liquid exchange procedure or freeze drying.

Furthermore, another common feature to all these methods, for measuring pore size distributions, is that each is based on a particular assumption regarding the average pore shape, i.e., a pore size distribution is computed assuming a certain fundamental surface-to-volume relationship. Cryoporometry is illustrative of this. At a fundamental level, the working principle is a freezing point depression resulting from the pressure difference experienced by water residing in a pore with a curved phase boundary. Assuming cylindrical pores, for example, the surface-to-volume ratio is fixed and the freezing point depression can be related to some form of pore radius, r, applying the well-known Young–Laplace law.

An alternative strategy for computing pore size, explored here, is to determine the specific surface area and the total pore volume separately by making different kinds of measurements of the same system while maintaining identical conditions, for example, in the water-swollen state. The task is to design two measurement methods for separately determining the specific surface area and total pore volume while exposing the fibre material to excess liquid. Two such methods exist, i.e., carbon-13 solid-state NMR (Larsson et al. 1997; Wickholm et al. 1998; Chunilall et al. 2010) and fibre saturation point (FSP) measurements (Stone and Scallan 1967), both of which can determine the desired properties in the presence of excess water.

Solid-state cross polarization magic angle spinning carbon-13 nuclear magnetic resonance (CP/MAS 13C-NMR) spectroscopy has been used since the1980s to study cellulose I (Earl and Vanderhart 1980; Vanderhart and Atalla 1984; Teeäär et al. 1987; Newman 1992; Yamamoto and Horii 1993; Jarvis 1994; Larsson et al. 1997; Wickholm et al. 1998; Hult et al. 2001; Larsson and Westlund 2005). Recently, an NMR-based method for determining lateral fibril and lateral fibril aggregate dimensions (Larsson et al. 1997; Wickholm et al. 1998) was extended to the measurement of cellulose I-specific surface area applicable to cellulose-rich fibres in the water-swollen state (Chunilall et al. 2010). Combining this method with the classic FSP method developed by Stone and Scallan (1967), results in a robust method for measuring the average fibre wall pore size. The pore size distribution cannot be determined in this way, only the average pore size, but the method does not require the assumption of any particular pore shape.

This work presents the method protocol and associated theoretical expressions as well as the results for different model systems. Specific surface area and pore size, both measured in the water-swollen state, will be compared with the same properties measured in the dry state, as determined by BET after liquid exchange and careful drying. It will be demonstrated that, for cellulose I rich fibres, the properties in the water-swollen state set an upper limiton what can be obtained in the dry state.

Methods

Samples

The sample materials used were never-dried softwood dissolving pulp, 60 % Norwegian spruce and 40 % Scots pine (from Domsjö, Örnsköldsvik, Sweden), never-dried Eucalyptus dissolving pulp 96a (from Sappi Saiccor, Saiccor, South Africa), and dried cotton linters sheets (from Tumba Bruk, Tumba, Sweden). The glucose content, according to sugar analysis, was above 96 % for the Domsjö dissolving pulp, above 98 % for the 96a pulp (Nocanda et al. 2007), and above 99 % for the cotton linters. All samples were submerged in excess water while being stirred for at least 16 h before recording NMR spectra or measuring the FSP.

The three samples containing isolated cellulose I were labelled according to Table 1 for this work.

NMR spectroscopy

All samples were wetted with deionized water to 40–60 % water content and packed uniformly in a zirconium oxide rotor. Recording spectra on wet rather than dry samples gives a higher apparent resolution (Newman 1992). The CP/MAS 13C-NMR spectra were recorded in a Bruker Avance III AQS 400 SB instrument operating at 9.4 T. All measurements were made at 295 (± 1) K with a MAS rate of 10 kHz. A 4 mm double air-bearing probe was used. Acquisition was performed using a CP pulse sequence, i.e., a 2.95 microseconds proton 90o pulse and a 800 microseconds ramped (100–50 %) falling contact pulse, with a 2.5 s delay between repetitions. A SPINAL64 pulse sequence was used for 1H decoupling. The Hartmann-Hahn matching procedure is based on glycine. The chemical shift scale was calibrated to the TMS ((CH3)4Si) scale by assigning the data point of maximum intensity in the α-glycine carbonyl signal to a shift of 176.03 ppm. A total of 4,096 transients were recorded on each sample, giving an acquisition time of approximately 3 h. The software for spectral fitting was developed at Innventia AB and is based on a Levenberg–Marquardt algorithm (Larsson et al. 1997). All computations are based on integrated signal intensities as obtained from the spectral fitting (Wickholm et al. 1998). Cellulose I specific surface area was calculated from the lateral fibril aggregate dimensions by assigning a density of 1,500 kg/m3 to cellulose I (Chunilall et al. 2010).

Fibre saturation point measurements (FSP)

FSP measurements were made according to Stone and Scallan (Stone and Scallan 1967). Water-swollen sample material of known solids content was mixed with a dextran solution of known concentration (approximately 1 %, dextran mass/solution mass) (CAS No. 9004-54-0, Dextran 2000, Dextran, from Leuconostoc spp., molecular mass approx. 2,000 kDa; Sigma-Aldrich, Stockholm, Sweden) in deionized water, approximately 1 mass unit of wet sample mass being mixed with 3 mass units of dextran solution. The mixture was left for 3 days to equilibrate after mixing in a sealed vessel at room temperature. Subsequently, a liquid sample was taken and filtered through a Puradisc syringe filter (Whatman, Maidstone, UK) equipped with a 0.45 micron PTFE membrane in a polypropylene housing (VWR International AB, Stockholm, Sweden).The dextran concentration of the sample was determined using a calibration curve established for the optical rotation of polarized light measured using a Polartronic NH8 polarimeter (Schmidt + Haensch, Berlin, Germany) operating at 589 nm with a resolution of 0.005 degrees. The calibration curve was computed from three dextran concentrations, i.e., approximately 0.5, 1.0, and 1.5 % (dextran mass/solution mass), covering the range of all measurements. Dynamic light scattering was used to determine the hydrodynamic diameter of the dextran molecule at high dilution in deionized water (Zetasizer ZEN3600; Malvern Instruments Ltd., Malvern, UK), using an He–Ne 4.0mW, 633 nm laser and a detector angle of 178 degrees. The hydrodynamic diameter was found to be 101 ± 2 nm with a polydispersity index of 0.2 measured at a dextran concentration of 0.15 g dextran per liter solution. Based on the determined size of the dextran used, the FSP results obtained were interpreted as representing liquid contained in pores under approximately 100 nm in diameter. The FSP value was expressed as the dimensionless ratio of the mass of pore water divided by the dry solids mass (g/g).

Water retention value measurements (mini-WRV)

A simplified version of the water retention value (WRV) (SCAN 68:00) was determined using 5 mL disposable centrifuge filters (Millipore Ultrafree-CL Centrifugal Device; Millipore, Billerica, MA, USA)equipped with 5micron PVDF membranes. Approximately 1–2 g of wet material was placed in the filter, which was centrifuged at 3,000 g for 15 min at room temperature. The solids content of the filtrand was determined gravimetrically after drying in a heating cabinet at 105 °C for at least 1 h. The ratio of the water mass divided by the dry solids mass (g/g) is the reported dimensionless WRV.

Liquid exchange and BET isotherms

In an attempt to manufacture porous dry fibres, a previously reported liquid exchange procedure was employed (Svensson et al. 2013).

The samples used in the present work were subjected to the same liquid exchange procedure. Pulps were disintegrated (30,000 revolutions) and sheets with a grammage of approximately 110 g/m2 were prepared using a Rapid Köthen sheet forming device (PTI, Vorchdorf, Austria). The sheets were slightly dried (i.e., 2.5 min under reduced pressure of 95 kPa) to remove excess water, simplifying the handling of the samples.

The sheets, still wet with water from the sheet making process, were cut into smaller samples and the water in the samples was gradually replaced with successively less polar liquids in the following order: water, methanol, acetone, and pentane. The fibre concentration in liquid was approximately 1 %, and each liquid was replaced ten times over 2 days before the samples were subjected to a new liquid. Finally, the pentane was removed from the samples with a stream of Argon gas; the samples were thereafter kept in a well-sealed vessel to prevent contact with humid air before BET measurement. The liquid exchange and drying procedures were inspired by earlier work(Herrington and Midmore 1984; Wang et al. 2003; Kohnke et al. 2010).

The specific surface area (m2/g), according to the Brunauer-Emmett-Teller (BET) theory (Brunauer et al. 1938), was determined by means of N2 physisorption using an Micromeritics ASAP 2020 for samples treated according to the liquid exchange procedure described above. The average pore size was measured as the adsorption average pore width by assuming cylindrical pores, i.e., pore width corresponding to 4 V/A, where V is the single-point adsorption total pore volume of pores under approximately 168 nm in size and A is the BET-specific surface area.

Results and discussion

A well-established property of cellulose I is its fibrillar structure. Depending on the specie, the lateral fibril dimension (thickness) may range from a few nanometres up to several tens of nanometres (Jakob et al. 1995; Fink et al. 1995). Furthermore, cellulose I fibrils can form structural elements by means of the coaxial alignment of fibrils into structures known as fibril aggregates. Such fibril aggregation is typically present in the fibre wall of plants and in isolated cellulose (Wickholm et al. 1998; Hult et al. 2001).

NMR spectra recorded on the three sample materials used here are shown in Fig. 1. In general appearance, the spectra are typical of spectra recorded on water-swollen materials characterized by high purity with respect to cellulose I.

The comparatively high purity with respect to cellulose I, high resolution, and high signal-to-noise ratio of the spectra shown in Fig. 1 indicate that these spectra are particularly amenable for further analysis of the supramolecular structure of cellulose. If spectral fitting is applied to feature-rich NMR spectra recorded on cellulose I, a detailed account of the cellulose I supramolecular structure can be obtained (Larsson et al. 1997; Wickholm et al. 1998; Chunilall et al. 2010).

This paragraph summarizes the calculation of cellulose I specific surface area in the water swollen state, a necessary prerequisite for the calculation of average pore sizes, details can be found in references10−12. The information about the supra-molecular structure of cellulose I was extracted from the C4-region of CP/MAS 13C-NMR spectra recorded on water swollen cellulose I samples. The spectral fitting of the C4-region separately quantifies signal intensities from C4-atoms in anhydroglucose units residing on surfaces and those residing in the fibril aggregate interior. Based on these signal intensities a surface-to-volume ratio (q) of the cellulose I fibril aggregate was calculated. Assuming that the fibril aggregate is compact and have a square cross-section, the average number of anhydroglucose units along one side of the fibril aggregate (n) can be estimated from the equation below, describing the surface-to-volume ratio of a solid body with a square cross-section:

The sought average value of n can be found by solving Eq. 1 for an experimentally determined value of q. Further, assuming that an anhydro glucose unit have a width of 0.57 nm (Krässig 1996), the average lateral fibril aggregate dimension can be computed in meters, here denoted by a. Introducing a density for the cellulose I fibril aggregate (ρ S) the specific surface area in the water swollen state can be computed by Eq. 2 below:12

Where σ sat is the specific surface area in the water-swollen state (m2/kg), a is the average lateral dimension of the cellulose I fibril aggregate, and ρ S is the density of cellulose I (1,500 kg/m3).

The spectral fitting procedure benefits from the NMR method’s characteristics, i.e., recording signals averaged over a large sample volume. This averaging leads to highly reproducible spectra; this is reflected in the spectral fitting results as stable computable average values of the lateral fibril aggregate dimensions (LFAD).

When dealing with cellulose I, isolated in the form of cellulose-rich wood fibres, the remaining fibre wall morphology results in a porous system in which part of the specific surface area exists within the fibre wall, accessible only indirectly via the (water-filled) cavities that make up the porous system. In such a system, the accessible surface area may be restricted by the small dimensions of the typical pore size, a situation undesirable when, for example, attempting to chemically modify the phase boundaries of a swollen fibre wall by means of heterogeneous reactions or when trying to tailor the sorption properties of a wood fibre-based material. The typical pore dimensions of the fibre wall pore system constitute a supramolecular property of the fibre wall that is important when substances are to be transported into or out of a liquid swollen fibre wall.

The size of fibre wall pores in cellulose-rich wood fibres is typically in the range of several tens of nanometers (Li et al. 1993; Andreasson et al. 2003); these comparatively small dimensions mean that reliable measurement techniques are scarce.

Typically, gas adsorption techniques such as the BET isotherm and mercury porosity methods can be used to determine pore size distributions and average pore size. However, the BET method calls for drying the fibre material before measuring the specific surface area and pore size distribution, while the mercury porosity method entails hazards related to mercury handling and involves high pressures, which might compress the soft fibre wall, when evaluating the smallest pore dimensions.

Although the NMR method is limited to cellulose-rich samples, its stability makes it a promising platform for other measurement techniques. FSP determination (Stone and Scallan 1967) is a technique for measuring the total mass of water present in the fibre wall pores in the presence of excess water. Interestingly, high-quality NMR spectra are typically recorded on water-saturated cellulose-rich fibres, fibres in a state similar to that used for determining the FSP value. Furthermore, FSP measurement can be made reasonably stable by establishing a suitable experimental protocol, by using optical rotation for concentration determinations, optimizing the liquid-to-solid ratios and sample amounts, and measuring a large number of replicates.

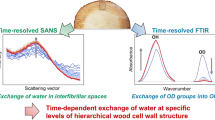

Figure 2 shows how the NMR and FSP methods are combined to calculate the average pore size. The water filling the fibre wall (measured using FSP (water mass/solids mass)) will form a layer of thickness t if spread out on all available pore surfaces in the fibre wall (measured using NMR (area/solids mass)). The average pore size can be estimated as two times the thickness of the water layer covering the fibre wall surfaces.

Figure 2 shows a simplified image of a fibre wall pore. From this simple image it is obvious that when the pore system is completely water filled, the water–solid phase boundary equals the specific surface area as determined using NMR from spectra recorded on water-saturated cellulose-rich fibres. Hence, by measuring the FSP and the specific surface (using NMR) on the same sample material, stable estimates of the fibre wall average pore size can be obtained. Mathematically, this can be expressed by the following, simple derivation:

where FSP is the fibre saturation point value (water mass/solids mass) as determined using the method of Stone and Scallan (Stone and Scallan 1967), σ sat is the specific surface area in the water-swollen state (m2/kg) obtained from NMR measurements by Eq. 2 (Chunilall et al. 2010), ρ L the density of the liquid filling the pores (1,000 kg/m3 in the case of water), and t the thickness (meters) of the water layer assumed to cover the surface area in a homogeneous fashion. Equation 3 illustrates one advantage of the presented method, the pore-volume and the specific surface area (or pore-surface area) are determined separately, not only a numerical value representing their ratio. This way the length scale (denoted by t in Eq. 3) becomes a well-defined system property independent on any particular pore geometry.

A convention introduced here is to report average pore size as 2t, relatable to average pore diameters as measured by other methods. Once the FSP value and the specific surface area are experimentally determined, the average pore size (2t) can be computed by:

The concept of average pore size is essentially defined by Eq. 3 (defining t), and it must be stressed that the introduced measure of average pore size is defined without the need to introduce any assumptions about pore shape geometry.

Table 2 shows the results obtained when calculating average pore sizes according to Eq. 4. The average pore sizes obtained by combining NMR and FSP results are in the range typically expected for cellulosic fibre wall pores. For comparative purposes, average pore sizes recorded on never-dried fully bleached softwood kraft pulp fibres (by means of 2H relaxation time measurements) are typically in the range of 18–19 nm (Li et al. 1993). This is somewhat larger than the values observed for the wood-based, never-dried, fully bleached pulp fibres used here (i.e., samples D and S). This discrepancy was expected in view of the sample preparation method used by Li et al.(Li et al. 1993), in which water not located in fibre wall pores may remain after wet pressing the pulp sample, leading to overestimation of the average pore size. From the BET measurements it is possible to determine the average pore width. However, reliably determining the pore size from BET measurements is not straightforward, since the models used are based on different pore geometry assumptions and are suitable for pores in different size ranges. Furthermore, in a substrate such as a nanoporous cellulose fibre network, the pores cover a large range of sizes (including both pores within the fibre wall and pores between fibres), the pore shape varies, and pores of different sizes can be interconnected, causing hysteresis in the sorption curve. Judging from the lower specific surface area found in the samples prepared using the liquid exchange and drying procedure, the average pore size is also expected to be smaller than indicated by the FSP/NMR estimates, since some pore closure is expected to occur. As can be seen from Table 2, this turns out to be the case.

Since the NMR/FSP method does not suffer from any of the complications associated with the sample preparation methods necessary for recording BET isotherms or making the 2H relaxation time measurements, it is considered a robust method for estimating average pore sizes. Furthermore, since both the NMR estimate of specific surface area and the FSP values are recorded on sample material in the same state (i.e., water-swollen fibres in excess water in both cases), combining these two results into one common expression (as in Eq. 3) is coherent. The values obtained for fibre wall average pore sizes and their expected relationships with the values obtained using the other method (used for comparative purposes), combined with the theoretical aspects of the method, strongly support the model introduced in Eq. 4 for calculating average pore sizes.

Notably, although the BET sample was prepared by means of a careful liquid exchange procedure, and although the resulting fibre materials were dried as gently as possible, only 50 % of the water-swollen surface area remains. Although this is indeed a very successful result for the liquid exchange procedure, the specific surface area is still significantly smaller than it was in the water-swollen state.

A decrease in specific surface area after liquid exchange and drying is reasonable, since the specific surface area in the water-swollen state as recorded using NMR can be considered to constitute an upper limit on the specific surface area achievable using the liquid exchange method.

In addition, a distinction is evident between the never-dried samples (samples D and S) and the dried and rewetted sample (sample L). The irreversible loss of specific surface area induced by first-time drying (not experienced by the never-dried samples D and S) reduces the specific surface area of the L sample before liquid exchange and drying. Since the major decrease in specific surface area has already been realized, the subsequent liquid exchange and drying induces a relatively smaller decrease in specific surface area, increasing the BET/NMR ratio to approximately 70 %.

Combining the results for LFAD, specific surface area, and pore size (2t) in the water-swollen state gives an illustrative schematic cross-section of the water-swollen interior of the fibre wall. In the case of sample materials D and S, the solid material is laterally thin and quite sparse, surrounded by comparatively large water-filled cavities. In the case of a cross-section through the L material, the lateral dimensions of the cellulose are larger and the separating water-filled cavities are significantly smaller on average. These two cases are depicted in Fig. 3.

FSP measurement according to Stone and Scallan (Stone and Scallan 1967) is a theoretically sound and statistically stable method, with the drawback that the required sample preparation is time consuming. For this reason, a faster but more arbitrary method for determining the amount of water present in fibre wall pores was also tested, i.e., the so called mini-WRV method given in the experiment section. The mini-WRV estimate of the water bound in the fibre wall pores is made after the assumed complete removal of water not bound in the fibre wall pores. The inter-fibre water is normally removed by means of accelerated filtration in a centrifuge. As discussed earlier (Forsstrom et al. 2005), such a selective removal of inter-fibre water is subject to arbitrary choices of acceleration and of centrifugation time during the sample preparation procedure. The WRV-based values would typically be expected to overestimate the amount of water bound in fibre wall pores, due to incomplete removal of the inter-fibre water. This overestimation is illustrated in Table 3, for two of the investigated samples, which presents the average pore size calculated based on both FSP and WRV. In the case of the WRV method, the average pore size was calculated based on Eq. 4 by replacing the FSP value with the corresponding mini-WRV value. As expected, the average pore size calculated from the mini-WRV value overestimates the average pore size computed from the corresponding FSP value; this discrepancy was the greatest in the case of the lower FSP value, since in this case the remaining inter-fibre water constituted a proportionally larger fraction of the fibre wall water.

Conclusions

A new method for measuring average pore sizes in cellulose-rich plant fibres has been developed. The method combines specific surface areas recorded using solid-state NMR on fibres in the water-swollen state with fibre saturation point (FSP) measurements recorded on fibres in the presence of excess water. One advantage of the method is that the separate NMR and FSP measurements are made on sample material in the same state. Furthermore, both the FSP and NMR methods yield statistically stable averages, allowing for the computation of an equally stable estimate of average pore size. The method was tested on three model samples and in all cases reasonable estimates were obtained for the average fibre wall pore sizes. Reasonable agreements and good correlations were also found when results of the NMR method were compared with those of BET measurements, and it could be concluded that the NMR estimates of fibre wall specific surface area constitute an upper limit for the specific surface areas recorded using BET measurements. This is in accordance with expectations, since the BET measurements require drying of the sample material, a procedure not easily performed without inflicting a loss in specific surface area.

References

Andreasson B, Forsstrom J, Wågberg L (2003) The porous structure of pulp fibres with different yields and its influence on paper strength. Cellulose 10(2):111–123

Annergren G, Wågberg L (1997) Physiochemical characterization of papermaking fibres. The fundamentals of papermaking materials: Transaction of the 11th Fundamental Research Symposium held at Cambridge

Brunauer S, Emmett PH, Teller E (1938) Adsorption of gases in multimolecular layers. J Am Chem Soc 60:309–319

Chunilall V, Bush T, Larsson PT, Iversen T, Kindness A (2010) A CP/MAS C-13-NMR study of cellulose fibril aggregation in eucalyptus dissolving pulps during drying and the correlation between aggregate dimensions and chemical reactivity. Holzforschung 64(6):693–698

Earl WL, Vanderhart DL (1980) High-resolution, magic angle sample spinning C-13 Nmr of solid cellulose-I. J Am Chem Soc 102(9):3251–3252

Fink HP, Hofmann D, Philipp B (1995) Some aspects of lateral chain order in cellulosics from X-ray-scattering. Cellulose 2(1):51–70

Forsstrom J, Andreasson B, Wågberg L (2005) Influence of pore structure and water retaining ability of fibres on the strength of papers from unbleached kraft fibres. Nord Pulp Paper Res J 20(2):176–184

Herrington TM, Midmore BR (1984) Adsorption of Ions at the Cellulose Aqueous-Electrolyte Interface. Part 2. Determination of the Surface-Area of Cellulose Fibers. J Chem Soc Faraday Trans I 80:1539–1552

Hult EL, Larsson PT, Iversen T (2001) Cellulose fibril aggregation—an inherent property of kraft pulps. Polymer 42(8):3309–3314

Jakob HF, Fengel D, Tschegg SE, Fratzl P (1995) The elementary cellulose fibril in Picea abies: comparison of transmission electron microscopy, small-angle X-ray scattering, and wide-angle X-ray scattering results. Macromolecules 28(26):8782–8787

Jarvis MC (1994) Relationship of chemical-shift to glycosidic conformation in the solid-state C-13 Nmr-Spectra of (1–4)-linked glucose polymers and oligomers—anomeric and related effects. Carbohydr Res 259(2):311–318

Kohnke T, Lund K, Brelid H, Westman G (2010) Kraft pulp hornification: a closer look at the preventive effect gained by glucuronoxylan adsorption. Carbohydr Polym 81(2):226–233

Krässig HA (1996) Cellulose structure, accessibility and reactivity, polymer monographs, vol 11. Gordon and Breach Science Publishers

Larsson PT, Westlund PO (2005) Line shapes in CP/MAS C-13 NMR spectra of cellulose I. Spectroc Acta Pt A-Molec Biomolec Spectr 62(1–3):539–546

Larsson PT, Wickholm K, Iversen T (1997) A CP/MAS C-13 NMR investigation of molecular ordering in celluloses. Carbohydr Res 302(1–2):19–25

Li T-Q, Henriksson U, Ödberg L (1993) Determination of pore sizes in wood cellulose fibres by 2H and 1H NMR. Nord Pulp Paper Res J 3:326–330

Maloney TC, Paulapuro H, Stenius P (1998) Hydration and swelling of pulp fibers measured with differential scanning calorimetry. Nord Pulp Paper Res J 13(1):31–36

Moura MJ, Ferreira PJ, Figueiredo MM (2005) Mercury intrusion porosimetry in pulp and paper technology. Powder Technol 160(2):61–66

Newman RH (1992) Solid-State C-13 Nmr-Spectroscopy of Multiphase Biomaterials. ACS Symp Ser 489:311–319

Nocanda X, Larsson PT, Spark A, Bush T, Olsson A, Madikane M, Bissessur A, Iversen T (2007) Cross polarisation/magic angle spinning C-13-NMR spectroscopic studies of cellulose structural changes in hardwood dissolving pulp process. Holzforschung 61(6):675–679

Östlund Å, Köhnke T, Nordstierna L, Nyden M (2010) NMR cryoporometry to study the fiber wall structure and the effect of drying. Cellulose 17(2):321–328

Park S, Venditti RA, Jameel H, Pawlak JJ (2006) Changes in pore size distribution during the drying of cellulose fibers as measured by differential scanning calorimetry. Carbohydr Polym 66(1):97–103

Stone JE, Scallan AM (1966) Influence of drying on the pore structures of the cell wall. In: Consolidation of the paper web: transactions of the symposium, Cambridge, vol 1, pp 145–174

Stone JE, Scallan AM (1967) The effect of component removal upon the porous structure of the cell wall of wood II. Swelling in water and the fibre saturation point. Tappi 50(10):496–501

Svensson A, Larsson PT, Salazar-Alvarez G, Wågberg L (2013) Preparation of dry ultra-porous cellulosic fibres: characterization and possible initial uses. Carbohydr Polym 92(1):775–783

Teeäär R, Serimaa R, Paakkari T (1987) Crystallinity of Cellulose, as Determined by Cp/Mas Nmr and Xrd Methods. Polym Bull 17(3):231–237

Valckenborg RME, Pel L, Kopinga K (2002) Combined NMR cryoporometry and relaxometry. J Phys D-Appl Phys 35(3):249–256

Vanderhart DL, Atalla RH (1984) Studies of microstructure in native celluloses using solid-state C-13 Nmr. Macromolecules 17(8):1465–1472

Wang XS, Maloney TC, Paulapuro H (2003) Internal fibrillation in never-dried and once-dried chemical pulps. Appita J 56(6):455–459

Wickholm K, Larsson PT, Iversen T (1998) Assignment of non-crystalline forms in cellulose I by CP/MAS C-13 NMR spectroscopy. Carbohydr Res 312(3):123–129

Yamamoto H, Horii F (1993) Cp Mas C-13 Nmr analysis of the crystal transformation induced for Valonia cellulose by annealing at high-temperatures. Macromolecules 26(6):1313–1317

Acknowledgments

Dr. Derek Weightman at Sappi Saiccor in South Africa is kindly acknowledged for supplying samples of the eucalyptus dissolving pulp. Domsjö Fabriker AB is acknowledged for supplying the softwood dissolving pulp. Thanks are expressed to German Salazar-Alvarez at the Department of Material and Environmental Chemistry, Stockholm University, Stockholm, for help with the BET nitrogen gas adsorption measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Larsson, P.T., Svensson, A. & Wågberg, L. A new, robust method for measuring average fibre wall pore sizes in cellulose I rich plant fibre walls. Cellulose 20, 623–631 (2013). https://doi.org/10.1007/s10570-012-9850-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9850-x