Abstract

A novel hydrogel has synthesized by grafting polyacrylamide chains onto hydroxypropyl methylcellulose in presence of potassium persulphate as initiator using solution polymerization technique. The reaction was carried out in homogeneous aqueous medium. The effect of reaction parameters on percentage of grafting (% G) and grafting efficiency (% GE) were discussed. The parameters were varied systematically to achieve the best hydrogel. Developed hydrogels were characterized by various materials characterization techniques. The dynamic and equilibrium swelling properties of hydrogels were investigated as a function of pH and time in various buffer solutions similar to that of gastric and intestinal fluid. Results showed that with increase in % G and % GE, the rate of swelling decreases, which can opens the door for further study of their utilization as matrices for controlled/sustained/targeted drug delivery.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hydrogels are three-dimensional network polymers that are known to swell in an aqueous environment by absorbing large amounts of water while maintaining their structure. Since their water content and mechanical properties can be controlled by incorporating different contents of hydrophilic and hydrophobic segments, hydrogels have been used in a wide range of biological, medicinal and pharmaceutical applications (Dong et al. 2008; Finne and Albertsson 2003; Huang et al. 2004; Kurian and Kennedy 2002a, b; Lu et al. 2008; Meyer et al. 2002; Peppas et al. 2006; Slaughter et al. 2009; Vishalakshi and Ghosh 2003; Zhang and Chu 2002). Biodegradable hydrogels play an important role in controlled drug delivery (Gils et al. 2009; Soppirnath and Aminabhavi 2002). They are soft and rubbery, resembling the living tissue, exhibiting excellent biocompatibility (Hoffman 2002). Among the numerous polymers that have been proposed for the preparation of hydrogels, polysaccharides are often preferred in comparison to synthetic polymers. This is because of their non-toxicity, low cost, free availability and biodegradability. However, natural polymers can be modified to overcome certain drawbacks like uncontrolled rate of hydration, microbial contamination, drop in viscosity in storing, etc.

Cellulose is one of the most abundant natural polysaccharide. It has been the subject of great deal of research in recent times, mainly with respect to modify its physical and chemical structure by improving its properties and broadening its industrial applications. The chemically modified cellulose is gaining increasing importance in application, because of their natural abundance, special structure and biodegradable property (Choi et al. 1998; Sugohar and Oht 2001). Modification of natural polymers by graft copolymerization is anticipated to be quite promising technique as it functionalizes these natural polymers to their potential, imparting desirable properties onto them. Thus, in recent years, an efficient approach to modify the natural polymers in order to synthesize superabsorbent hydrogels, is graft copolymerization of vinylic monomers onto polysaccharide backbones in presence of free radical initiator/crosslinkers (Behari et al. 2001; Ghosh et al. 2010; Mishra et al. 2011; Nayak and Singh 2001; Pandey et al. 2006; Sen et al. 2009; Singh et al. 2006; Tiwari and Singh 2008; Tripathy and Singh 2001). The chemical combination of natural and synthetic polymer yields new materials, which would have desirable properties including biodegradability. This is the era of materials with tailor made properties (Sen and Pal 2009).

Natural polysaccharides, as well as their derivatives, represent a group of polymers that have been widely used in pharmaceutical formulations and controlled drug release studies (Coviello et al. 2005). Hydroxypropyl methylcellulose (HPMC) is non-carcinogenic, biocompatible having range of applications in drugs, textiles, foods and paper (Barba et al. 2009; Pygall et al. 2010; Viriden et al. 2011). HPMC (Fig. 1) is modified cellulose, developed by reacting cellulose with chloromethane and epoxy propane. HPMC is having number of hydroxypropyl groups, which promote its water solubility. Formation of superabsorbent hydrogel involving HPMC is a suitable option from biomaterial point of view because of its water solubility. However, there are couple of studies on the graft copolymerization of ethyl acrylate onto HPMC (Wang et al. 2007; Wang and Xu 2006) but this article reports the first example of a hydrogel composed of polyacrylamide and hydroxypropyl methyl cellulose.

This investigation reports the development of a novel hydrogel based on HPMC grafted with polyacrylamide. The effect of % G and % GE onto the swelling behaviour of hydrogels in various pH solutions was also studied.

Experimental

Materials

Hydroxypropyl methylcellulose was purchased from Lancaster, UK. Acrylamide, sodium hydroxide was procured from E. Marck, Germany. Potassium persulphate of analytical grade was supplied by Qualigens Fine chemicals, Mumbai, India. Potassium chloride was supplied by SRL Pvt. Ltd., Mumbai, India. Potassium dihydrogen phosphate and hydrochloric acid was purchased from Rankem Pvt. Ltd., New Delhi, India. Analar grade acetone and hydroquinone were purchased from S. D. Fine chemicals, Mumbai, India. All the chemicals were used as received, without further purification.

Preparation of polyacrylamide grafted hydroxypropyl methyl cellulose (HPMC-g-PAM)

The graft copolymerization of polyacrylamide onto HPMC was carried out in a 250 mL three necked round bottom flask. The flask was fitted with an electrically operated magnetic stirrer (Tarsons, Model: Spinot Digital) and kept in a water bath maintained at the desired temperature (50–75 °C). At first, required amount of HPMC (1 g) was dissolved in 100 mL of distilled water with constant stirring and bubbling of a slow stream of nitrogen for about 15 min. Desired quantity of acrylamide reported in Table 1 was dissolved in 20 mL distilled water and mixed with HPMC solution. Afterwards, oxygen free nitrogen gas was purged through the solution mixture for about 30 min. At this stage, 5 mL of potassium persulphate solution of required concentrations (Table 1) was added and nitrogen gas purging was continued for another 1 h. The reaction mixture was stirred at a constant speed (400 rpm) to avoid the adverse effect of stirring on graft copolymerization. The grafting reaction was allowed to continue for 6 h, after which the reaction was terminated using saturated solution of hydroquinone. The product (graft copolymer) was precipitated by adding 400 mL of acetone. It was dried in a hot air oven at 60 °C until constant weight, pulverized and sieved through a 125 μm sieve.

Extraction of homopolymers

The small amount of homopolymer (PAM) may be present along with graft copolymers. If any occluded polyacrylamide (PAM) formed by competing homopolymer formation reaction, was extracted from the graft copolymers by solvent extraction using a mixture of formamide and acetic acid (1:1 by volume) (Fanta 1973). The detailed procedure is as follows: 3 g of graft copolymer was taken in a 250 mL beaker. 100 mL of the prepared solvent (1:1 formamide: acetic acid) was added to it. The reactants were kept at 40 °C for 12 h. After that, the mixture was filtered using Buchner funnel. The residue was washed with same solvent mixture for ten times and in every time the filtrate was checked with acetone whether there was a precipitation of polyacrylamide or not. After which, the polymer was again washed with methanol and kept it for 24 h to remove the solvent. It was then dried in a hot air oven.

Definition of grafting parameters

Percentage of grafting (% G) and grafting efficiency (% GE) was measured gravimetrically and calculated using the following equations:

where Wg, Wi, and Wm are weights of graft copolymer, ungrafted cellulose beads (HPMC), and monomer (AM) respectively.

Characterization

Intrinsic viscosity measurements of the aqueous polymer solutions were carried out with an Ubbelohde viscometer with a capillary diameter of 0.58 mm at 25 °C. The time of flow was measured at six (0.1, 0.05, 0.025, 0.0125, 0.00625 and 0.003125 wt %) concentrations. The intrinsic viscosity (Table 1, Fig. 3) for the polymer system at a given temperature (25 °C) was measured by the intercept of the plot of ηsp/c versus c and ln ηrel/c versus c, when the linear experimental plot is extrapolated to zero concentration, or more precisely, to infinite dilution condition (Collins et al. 1973; Biswal and Singh 2004).

CHN analysis (Table 2) of HPMC, polyacrylamide (PAM) and various graft copolymers were undertaken with an Elemental-Analyzer (Make—M/s Elementar, Germany; Model—Vario EL III).

FTIR spectra of HPMC and polyacrylamide grafted HPMC were recorded on KBr pellets using JASCO FTIR spectrophotometer.

13C nuclear magnetic resonance (NMR) spectroscopic analysis was carried out in solid state using a 500 MHz Bruker Advance II-500 spectrometer.

A scanning electron microscope (SEM) (HITACHI, Japan; Model: S-3400 N) equipped with INCA was used to determine the morphology of samples. The powder samples were coated with gold by plasma prior to measurement.

Thermal analysis of HPMC and polyacrylamide grafted HPMC have been carried out by recording thermogravimetric (TG) and differential thermogravimetric (DTG) curves using Shimadzu DTG-60 system at a heating rate of 10 °C/min under nitrogen atmosphere.

Biodegradation studies of HPMC and HPMC-g-PAM based hydrogels

HPMC and synthesized hydrogels were subjected to biodegradation studies using viscometric method (Sen et al. 2011). The progress of biodegradation was monitored by measuring intrinsic viscosity after certain interval of time (after 2 days).

Swelling measurements

The swelling characteristics of HPMC and graft copolymer based hydrogels were studied at 37 °C temperature in aqueous solution as well as in buffer solutions similar to that of gastric and intestinal fluids. The buffer solutions were prepared from a mixture of potassium chloride, hydrochloric acid, potassium dihydrogen phosphate and sodium hydroxide. The pH values were measured using pH meter (ELICO digital pH meter, model LI 614, equipped with calomel glass electrode having accuracy ±0.01). The dried and pre-weighed sample (0.05 g) was immersed in water or in various buffers (100 mL) for 24 h at 37 °C during which the polymer attained equilibrium swelling. The surface water on the swollen polymers has removed by softly pressing it between the folds of filter paper. An increase in weight of swollen polymers has recorded after a certain interval of time (every 3 h). The equilibrium percentage of swelling (Ps) was calculated using following equation (Sen and Pal 2010; Srivastava et al. 2010):

Results and discussions

Synthesis of HPMC-g-PAM

HPMC-g-PAM was synthesized using potassium persulphate as free radical initiator, in inert atmosphere of nitrogen. Various grades of graft copolymers have been prepared (Table 1) by varying the reaction temperature, monomer (acrylamide) concentration, and initiator concentration. The optimized grade of graft copolymer (HPMC-g-PAM 10) was determined through its higher % G, % GE, and intrinsic viscosity. A plausible explanation for mechanism of graft copolymerization is based on the assumption that potassium persulphate (KPS) generates free radical sites on HPMC backbone. These free radical sites reacting with monomer generate the graft copolymer as shown in Scheme 1.

Effect of reaction temperature

Figure 2a shows the influence of reaction temperature on % G and % GE. It is obvious that both the parameters increased with increase in temperature from 50 to 70 °C, beyond which decreased. The significant increase in both the parameters, mainly in the region of 50–70 °C is a consequence of increase in the reaction rate. Initially, with increase in temperature, the decomposition rate of initiator accelerates, generating more reactive sites on HPMC backbone. As a result, the initiation rate and propagation rate of grafting reaction has been accelerated. Also, at the same time, the mobility of monomers from the aqueous phase to HPMC backbone is enhanced. However, beyond 70 °C temperature, the % G and % GE decreased, which may be because of more homopolymer formation took place at higher temperature (Singh et al. 2004; Wang and Xu 2006). In addition, various hydrogen abstraction and chain transfer reactions may also be accelerated at higher temperature, leading to depletion in % G and % GE (Wang and Xu 2006).

Effect of initiator concentration

The effect of initiator (KPS) concentration on % G and % GE was investigated at fixed temperature (70 °C), monomer, and polysaccharide concentration (Fig. 2b). It is obvious that with increase in initiator concentration, % G and % GE increased till 0.92 × 10−5 mol, beyond which it decreased. It is desirable that a low concentration of catalyst should initiate a few grafting sites, which results in longer polyacrylamide chains, compared to a high concentration of catalyst, which will initiate a larger number of grafting sites, thus making the average polyacrylamide chains shorter for the same acrylamide concentration. So by grafting polyacrylamide chains onto HPMC, two possibilities are there—one can either have a small number of long polyacrylamide chains or a large number of short polyacrylamide chains in the graft copolymer. In the former case, the compact shape of the graft copolymer would change, because of the presence of long polyacrylamide chains. This would result in larger hydrodynamic volume, leading to higher intrinsic viscosity (Table 1). On the other hand, a large number of short polyacrylamide chains will not alter the original compact shape to a great extent and hence lower would be hydrodynamic volume (i.e. intrinsic viscosity) (Table 1). Also with increase in KPS concentration beyond 0.92 × 10−5 mol, it is assumed that the initiator starts to participate in the termination step of the growing chains, which in turn reduce the % G and % GE.

Effect of monomer concentration

Figure 2c explains the influence of monomer concentration on % G and % GE, keeping other reaction parameters (i.e. temperature, initiator concentration and polysaccharide concentration) constant. With increase in monomer concentration (from 0.14–0.25 mol), % G and % GE increased continuously and achieved the maximum when the concentration of acrylamide is 0.17 mol. Afterwards, the % G and % GE decreased. This may be because of the fact that an increase in monomer concentration leads to the accumulation of monomer molecules in close proximity to the polymer backbone. The decrease in the % G and % GE after optimization could be associated with the reduction in the active sites on the HPMC backbone as graft copolymerization proceeds. In addition to this, with excess monomer concentration, the competing homopolymer formation reaction becomes significant, leading to depletion in % G and % GE.

Characterization of graft copolymers

Intrinsic viscosity

The intrinsic viscosity of HPMC and graft copolymers were determined and reported in Table 1.

From the relative viscosity (ηrel = t/t0) of various polymer solutions of known strength, inherent viscosity (ηinh = ln ηrel/c) and reduced viscosity (ηred = ηsp/c) were evaluated and plotted against concentration. The intrinsic viscosity (Table 1, Fig. 3) for the polymer system at a given temperature (25 °C) was determined by the intercept of the plot of ηsp/c versus c or ln ηrel/c versus c, when the linear experimental plot is extrapolated to zero concentration, or more precisely, to infinite dilution condition. The concentration dependence of polymer solution viscosity is conveniently expressed by two empirical equations, known as Huggins’ equation (given by Eq. 4) and Kraemer’s equation (given by Eq. 5).

The slope of each plot (Fig. 3), reduced viscosity (ηsp/c) or inherent viscosity (ln ηrel/c) versus c based on Eqs. (4) and (5) are proportional to square of the intercept, i.e. of the intrinsic viscosity, and the two plots made using common ordinate and abscissa would extrapolate to a common point on the ordinate, thus enabling a precise determination of the intrinsic viscosity value (Fig. 3).

It is well known that intrinsic viscosity of a polymer is a measure of its hydrodynamic volume in solution, which in turn, is a function of the polymer molecular weight, its structure, the nature of the solvent and the temperature of the medium. Keeping other factors constant, for two polymers of approximately similar molecular weight, a branched polymer will have higher hydrodynamic volume i.e. higher intrinsic viscosity as compared to its linear counter part. For a series of branched polymers, the longer the branches, the higher will be the intrinsic viscosity and vice versa. The higher intrinsic viscosity of the graft copolymers relatively to the HPMC backbone, indicates that the grafted PAM chains are of high molecular weight.

Elemental analysis

The elemental analysis result of HPMC and graft copolymers are reported in Table 2. HPMC shows the presence of negligible amount of nitrogen, which may be because of the trace quantities of unisolated proteins present in the polysaccharide. It has been observed that there is considerable percentage of nitrogen in the graft copolymers, which is accounted for the presence of grafted PAM chains. In the series of graft copolymers, the variation of the nitrogen content is although not much, but significant in case of HPMC-g-PAM 10. The higher percentage of nitrogen in HPMC-g-PAM 10 is due to its higher % G and % GE.

FTIR spectroscopy

FTIR analysis has been utilized to prove the grafting. The FTIR spectra of HPMC and HPMC-g-PAM 10 are shown in Fig. 4a and b, respectively. From the spectrum of HPMC (Fig. 4a), it is evident that it shows a broad absorption band at 3,485 cm−1, due to the stretching frequency of the –OH group. The band at 2,936 cm−1 is result of C–H stretching vibration. The bands around 1,458 and 1,378 cm−1 are assigned to –CH2 scissoring and –OH bending vibration, respectively. The bands at 1,063 and 943 cm−1 are due to C–O–C stretching vibrations.

However, in the spectrum of HPMC-g-PAM 10 (Fig. 4b), it is apparent that all the characteristics absorption peaks of HPMC are present along with two additional peaks at 1,672 and 1,565 cm−1. These two additional peaks are assigned to amide—I and amide—II band of the amide group of grafted polyacrylamide chains. Since the homopolymer (PAM) was removed from the graft copolymer using solvent extraction, the presence of these additional bands gives strong evidence of grafting.

13C NMR spectroscopy

The 13C NMR spectrum of HPMC (Fig. 5a) shows four distinct peaks in the region of 61.0–105.8 ppm. The absorption peak at δ = 105.8 ppm is for anomeric carbon atom and the peak at δ = 82.2 ppm is for carbon atoms connected by –OH groups (i.e. the carbon atoms in the six membered ring except anomeric carbon atom- C-2 to C-5). The peak at δ = 73.5 ppm is attributed for the carbon atom of CH2OR group (Ibbett et al. 1992; Tezuka et al. 1987). Another peak at 61.0 ppm is assigned for –OCH3 group (C-7) (Ibbett et al. 1992; Tezuka et al. 1987).

The 13C-NMR spectrum of acrylamide has three major peaks (Fig. 5b). The peak at δ = 177.3 ppm is from the amide carbonyl carbon. Peaks at δ = 130.5 and δ = 138.2 ppm are for two sp2 hybridized carbon atoms (i.e. CH2=CH–).

The graft copolymers (Fig. 5c, d) are having two additional peaks in comparison to HPMC. The peak at δ = 180.8 ppm (HPMC-g-PAM 10) was for the amide carbonyl carbon. The peak at δ = 42.3 (HPMC-g-PAM 10) ppm was for –CH2–CH2– groups which were formed during the polymerization reaction. As seen in the 13C NMR spectra of the graft copolymer and acrylamide, acrylamide had two peaks at δ = 130.5 and 138.2 ppm of two sp2 hybridized carbon atoms which were absent in the graft copolymer. Moreover, one additional peak was found at δ = 42.3 ppm, which was sp3 hybridized carbon atoms (i.e. –(CH2–CH)n units in the graft copolymer). Neither HPMC nor acrylamide spectrum had this peak. So, the absence of peaks at δ = 130.5 and 138.2 ppm and presence of peak at δ = 42.3 ppm is evidence of covalent attachment of the polyacrylamide chains to the HPMC backbone. Again, the peak intensity at δ = 82.2 ppm, which is for the carbons with secondary hydroxyl groups in the HPMC, is less in case of graft copolymer. This may be due to the less number of carbon atoms connected by the secondary hydroxyl groups, since secondary hydroxyl groups of HPMC form free radicals, which are responsible for the grafting reaction (As explained in the proposed mechanism; Scheme 1 ). Consequently, the number of carbon atoms with secondary hydroxyl groups became less in graft copolymers. Hence, NMR spectroscopic analysis confirmed that polyacrylamide chains have been grafted onto HPMC backbone.

SEM analysis

Figure 6 shows the scanning electron micrographs of HPMC and HPMC-g-PAM 10 (Magnification 800×). Surface morphology of HPMC shows granular morphology. After grafting with polyacrylamide, the granular morphology of HPMC has distorted and transferred to fibrillar. This is because of the presence of grafted PAM chains on HPMC, which got agglomerated and makes the morphology of graft copolymer as fibrillar. This observation suggests that grafting of polyacrylamide affects the morphological arrangement of HPMC.

TGA analysis

The TGA and DTG curves of HPMC and HPMC-g-PAM 10 in nitrogen atmosphere are shown in Fig. 7a and b, respectively. In case of HPMC, two distinct zones of weight loss are observed. The initial weight loss is in the region of 0–100 °C. This is because of traces of moisture present. The second zone of weight loss (250–375 °C) may be because of the degradation of polymer backbone. However, in case of HPMC-g-PAM 10 (Fig. 7b), in addition to the above zones, have an extra zone of weight loss (450–650 °C). This extra zone of weight loss is due to the degradation of the grafted polyacrylamide chains. Also from the TGA as well as DTG curves, it is obvious that HPMC-g-PAM 10 is thermally more stable than HPMC. Hence, the presence of an additional zone of weight loss in HPMC-g-PAM 10 clearly indicates that graft copolymerization do takes place. Also, the chemical change in HPMC in terms of grafting has enhanced the thermal stability of the synthesized polymer.

Biodegradation study

It was found from the biodegradation studies (Fig. 8) that HPMC as well as all the hydrogels are prone to biodegradation. It is obvious that polymer solutions after 48 h of its preparation start degrading and during 20 days the solutions showed considerable loss of viscosity. This is in agreement with the fact that incorporating a synthetic polymer onto polysaccharide backbone, it is possible to develop a novel hydrogel, which is biodegradable in nature.

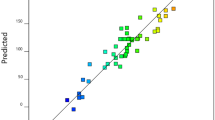

Swelling study

The % equilibrium swelling values of synthesized hydrogels are measured at different time intervals at 37 °C temperature. Figure 9 shows the equilibrium swelling of different hydrogels at pH: 1.2 (Fig. 9a); neutral pH (Fig. 9b) and at pH: 7.4 (Fig. 9c). On comparison of amount of swelling at same pH (Table 3), it was noted that with increase in PAM content, the % swelling decreases, indicating an increase in extent of grafting on the hydrogel structure. HPMC grafted with polyacrylamide have higher % equilibrium swelling than the parent polysaccharide (Fig. 9), due to the incorporation of hydrophilic PAM chains. However, the % swelling of graft copolymer decreases with increase in % G and % GE. This can be explained by the process of swelling. When a sample of the grafted polysaccharide is put in an aqueous dissolution medium, the water molecules starts diffusing into the space between the backbone polymer chains, hydrating the grafted PAM chains in the process. This diffusion of the water molecules slowly pushes the backbone polymer chains away from each other, thus resulting gradual dissolution of the polymer moiety. However, higher the % G and % GE, higher will be the entanglement between grafted chains of neighbouring backbone polymer, making it more difficult for diffusing water molecules to push away the neighbouring backbone chains. As a consequence the % swelling, rate of swelling and rate of dissolution of the polymer moiety remains low. The results indicated that swelling of hydrogels was found to be highest in simulated intestinal fluid (SIF) (pH: 7.4) and lowest in simulated gastric fluid (SGF) (pH: 1.2) (Table 3) resembling that required in colon targeted drug delivery. This can also opens up the perspective for using these graft copolymer based hydrogels as matrices for colon targeted drug delivery.

Conclusion

A novel polymeric hydrogel has been developed by grafting polyacrylamide chains onto HPMC backbone. Various physicochemical characterizations were carried out to confirm that graft copolymerization took place. Further, it has been observed that higher is the % G and % GE, the lower is the rate of swelling, thus arising the possibility of further optimization of grafted HPMC matrix as a potential candidate for controlled/sustained/targeted drug delivery.

References

Barba AA, d,Amore M, Chirico S, Lamberti G, Titomanlio G (2009) Swelling of cellulose derivative (HPMC) matrix systems for drug delivery. Carbohydr Polym 78:469–474

Behari K, Pandey PK, Taunk K, Kumar R (2001) Graft copolymerization of acrylamide onto xanthan gum. Carbohydr Polym 46(2):185–189

Biswal DR, Singh RP (2004) Characterization of carboxymethyl cellulose and polyacrylamide graft copolymer. Carbohydr Polym 57:379–387

Choi WM, Jung ID, Kwon SK, Ha CS, Cho WJ (1998) Syntheses and photobiodegradable properties of graft copolymers of vinyl ketones and starch. Polym Degrad Stabil 61:15–20

Collins EA, Bares J, Billmeyer FW (1973) Experiments in polymer science. Wiley, New York, pp 394–399

Coviello T, Palleschi A, Grassi M, Matricardi P, Bocchinfuso G, Alhaique F (2005) Scleroglucan: a versatile polysaccharide for modified drug delivery. Molecules 10:6–33

Dong H, Xu Q, Li Y, Mo S, Cai S, Liu L (2008) The synthesis of biodegradable graft copolymer cellulose-graft-poly(L-lactide) and the study of its controlled drug release. Colloids Surf B Biointerf 66:26–33

Fanta GF (1973) Synthesis of graft and block copolymers of starch. Wiley, New York, pp 11–30

Finne A, Albertsson AC (2003) Polyester hydrogels with swelling properties controlled by the polymer architecture, molecular weight, and cross linking agent. J Polym Sci Part A Polym Chem 41:1296–1305

Ghosh S, Sen G, Jha U, Pal S (2010) Novel biodegradable polymeric flocculant based on polyacrylamide-grafted tamarind kernel polysaccharide. Bioresour Technol 101:9638–9644

Gils PS, Ray D, Sahoo PK (2009) Characteristics of xanthan gum-based biodegradable super porous hydrogel. Int J Biol Macromol 45:364–371

Hoffman AS (2002) Hydrogels for biomedical applications. Adv Drug Deliv Rev 43:3–12

Huang X, Nayak BR, Lowe TL (2004) Synthesis and characterization of novel thermo responsive co-biodegradable hydrogels composed of N-isopropylacrylamide, poly(L-lactic acid) and dextran. J Polym Sci Part A Polym Chem 42:5054–5066

Ibbett RN, Philp K, Price DM (1992) 13C n.m.r. studies of the thermal behaviour of aqueous solutions of cellulose ethers. Polymer 33:4087–4094

Kurian P, Kennedy JP (2002a) Novel tricontinuous hydrophilic-lipophilic-oxyphilic membranes: synthesis and characterization. J Polym Sci A Polym Chem 40:1209–1217

Kurian P, Kennedy JP (2002b) Novel tricomponent membranes containing poly (ethylene glycol)/poly(pentamethylcyclopentasiloxane)/poly(dimethylsiloxane) domains. J Polym Sci A Polym Chem 40:3093–3102

Lu D, Yang L, Zhou T, Lei Z (2008) Synthesis, characterization and properties of biodegradable polylactic acid-β-cyclodextrin cross-linked copolymer micro gels. Eur Polym J 44:2140–2145

Meyer T, Hellweg T, Spange S, Hesse S, Jager C, Bellmann C (2002) Synthesis and properties of crosslinked polyvinyl formamide and polyvinyl amine hydrogels in conjunction with silica particles. J Polym Sci A Polym Chem 40:3144–3152

Mishra MM, Yadav M, Mishra DK, Behari K (2011) Synthesis of graft copolymer (CmgOH-g-NVP) and study of physicochemical properties: characterization and application. Carbohydr Polym 83:1749–1756

Nayak BR, Singh RP (2001) Synthesis and characterization of grafted hydroxypropyl guar gum by ceric ion induced initiation. Eur Polym J 37:1655–1666

Pandey PK, Srivastava A, Tripathy J, Behari K (2006) Graft copolymerization of acrylic acid onto guar gum initiated by vanadium(V)-mercapto succinic acid redox pair. Carbohydr Polym 65:414–420

Peppas NA, Hilt JZ, Khademhosseini A (2006) Hydrogels in biology and medicine: from molecular principles to bionanotechnology. Adv Mater 18:1345–1360

Pygall SR, Kujawinski S, Timmins P, Melia CD (2010) The suitability of tris (hydroxyimethyl) aminomethane (THAM) as a buffering system for hydroxypropyl methylcellulose (HPMC) hydrophilic matrices containing a weak acid drug. Int J Pharmaceut 387:93–102

Sen G, Pal S (2009) Microwave initiated synthesis of polyacrylamide grafted carboxymethylstarch (CMS-g-PAM): application as a novel matrix for sustained drug release. Int J Biol Macromol 45:48–55

Sen G, Pal S (2010) A novel polymeric biomaterial based on carboxymethylstarch and its application in controlled drug release. J Appl Polym Sci 114:2798–2805

Sen G, Kumar R, Ghosh S, Pal S (2009) A novel polymeric flocculant based on polyacrylamide grafted carboxymethylstarch. Carbohydr Polym 77:822–831

Sen G, Ghosh S, Jha U, Pal S (2011) Hydrolyzed polyacrylamide grafted carboxymethylstarch (Hyd. CMS-g-PAM): an efficient flocculant for the treatment of textile industry wastewater. Chem Eng J 171:495–501

Singh V, Tiwari A, Tripathi DN, Sanghi R (2004) Microwave assisted synthesis of guar-g-polyacrylamide. Carbohydr Polym 58:1–6

Singh V, Tiwari A, Tripathi DN, Sanghi R (2006) Microwave enhanced synthesis of chitosan-graft-polyacrylamide. Polymer 47:254–260

Slaughter BV, Khurshid SS, Fisher OZ (2009) Hydrogels regenerative medicine. Adv Mater 21:3307–3329

Soppirnath KS, Aminabhavi TM (2002) Water transport and drug release study from cross linked polyacrylamide grafted guar gum hydrogel microspheres for the controlled release application. Eur J Pharmaceut Biopharmaceut 53:87–98

Srivastava A, Mishra DK, Behari K (2010) Graft copolymerization of N-vinyl-2-pyrrolidone onto chitosan: synthesis, characterization and study of physicochemical properties. Carbohydr Polym 80:790–798

Sugohar Y, Oht T (2001) Synthesis of starch-grafted-polyacrylonitrile hydrolyzed and its characterization. J Appl Polym Sci 82:1437–1443

Tezuka Y, Imai K, Oshima M, Chiba T (1987) Determination of substituent distribution in cellulose ethers by means of a carbon—13 NMR study on their acetylated derivatives. 1. Methylcellulose. Macromolecules 20:2413–2418

Tiwari A, Singh V (2008) Microwave-induced synthesis of electrical conducting gum acacia grafted-polyaniline. Carbohydr Polym 74:427–434

Tripathy T, Singh RP (2001) Characterization of polyacrylamide grafted sodium alginate: a novel polymeric flocculant. J Appl Polym Sci 81:3296–3308

Viriden A, Wittgren B, Larsson A (2011) The consequence of the chemical composition of HPMC in matrix tablets on the release behaviour of model drug substances having different solubility. Eur J Pharmaceut Biopharmaceut 77:99–110

Vishalakshi B, Ghosh S (2003) Nonstoichiometric polyelectrolyte complex of carboxymethylcellulose and N-methylated poly (2-vinylpyridine): formation of a gel-like structure. J Polym Sci, Part A: Polym Chem 41:2288–2295

Wang L, Xu Y (2006) Preparation and characterization of graft copolymerization of ethyl acrylate onto hydroxypropyl methylcellulose in aqueous medium. Cellulose 13:191–200

Wang L, Dong W, Xu Y (2007) Synthesis and characterization of hydroxypropyl methylcellulose and ethyl acrylate graft copolymers. Carbohydr Polym 68:626–636

Zhang YL, Chu CC (2002) Thermal and mechanical properties of biodegradable hydrophilic-hydrophobic hydrogels based on dextran and poly (lactic acid). J Mat Sci Mater Med 13:773–781

Acknowledgments

The corresponding author (SP) earnestly acknowledges the financial support from Department of Science and Technology, New Delhi, India in form of a research grant (NO: SR/FT/CS-094/2009) to carry out the reported investigation.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Das, R., Panda, A.B. & Pal, S. Synthesis and characterization of a novel polymeric hydrogel based on hydroxypropyl methyl cellulose grafted with polyacrylamide. Cellulose 19, 933–945 (2012). https://doi.org/10.1007/s10570-012-9692-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9692-6