Abstract

The morphology and crystalline structure changes of cellulose during dissolution in 1-butyl-3-methylimidazolium chloride [(BMIM)Cl] were investigated by optical microscopy and synchrotron radiation wide-angle X-ray diffraction (WAXD). Neither swelling nor dissolution of cellulose was observed under the melting point of [BMIM]Cl. While the temperature was elevated to 70 °C, the swelling phenomenon of cellulose happened with the interplanar spacing of (\( 1\bar{1}0 \)) and (020) planes increased slightly. With the temperature further going up to 80 °C, cellulose was dissolved gradually with the crystallinity (W c,x) and crystalline index (CrI) of cellulose decreased rapidly, which indicated the crystalline structure of cellulose was destroyed completely and transformed into amorphous structure.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Ionic liquids (ILs) have been started receiving closer attention in the last two decades due to the advantages of their negligible vapor pressure, recyclability, conductivity, and thermal and air stability. These have motivated research and led to various applications in many fields, for example as solvents in electrochemistry, organic synthesis, catalysis, photochemistry and so on (Plechkova and Seddon 2008). Since Swatloski et al. (2002) in 2002 disclosed that ILs are the nonderivitizing solvents for cellulose, the research interesting was aroused both in scientific and industrial fields of dissolution, solution properties and fiber spinning of cellulose (Kosan et al. 2008; Cao et al. 2009; Cai et al. 2010). Several ionic liquids were found to be good solvents for dissolving cellulose, hemicellulose and lignin (Fort et al. 2007; Pu et al. 2007). It is found that cellulose in ILs exhibit good spinnability and fibers with tenacity as high as 5.34 cN/dtex were prepared (Kosan et al. 2008).

As a novel solvent of ionic liquid, the dissolution mechanism of cellulose has been discussed. Swatloski et al. deduced from the dissolution mechanism of cellulose in dimethylacetamide (DMAc)/LiCl solution that the dissolution of cellulose in ILs is due to the strong hydrogen bond between anion of ILs and the cellulose hydroxyl groups, which disrupts and breaks the hydrogen-bonding network of cellulose (Swatloski et al. 2002). The deducing was verified by the conformation of cellulose in ILs and the stoichiometric interaction between cellulose hydroxyl groups and anions of ILs with the high-resolution 13C NMR and 35/37Cl NMR (Moulthrop et al. 2005; Remsing et al. 2006). The solubility of cellulose in ILs varied with the structure of ILs (Pinkert et al. 2009). It is found that there is weak interaction between the ILs cation and molecule of cellulose (Remsing et al. 2006) although Zhang et al. suggested that the cation also had the ability to form hydrogen bond with hydroxyl groups of cellulose (Zhang et al. 2005; Zhang et al. 2010). Meanwhile, Heinze et al. (2008) suggested that 1-ethyl-3-methylimidazolium acetate [(EMIM)Ac] forms covalent bond between the C-1 carbon of the glucose unit and the C-2 of the imidazolium based on the result of 13C-NMR although this is not the case when cellulose dissolved in [EMIM]Cl, indicating a good solubilization of the chains in [EMIM]Ac.

It seems that there is still some argument about the dissolution mechanism of cellulose in various ILs from molecular level. However, the crystalline structure of cellulose is no doubt transformed after cellulose dissolved in ILs (Dogan and Hilmioglu 2009). Zhang et al. found that the crystalline structure of cellulose II formed in the regenerated cellulose (Zhang et al. 2005; Cao et al. 2010). There is no report on the changes of crystalline structure of natural cellulose during dissolution. In order to avoid the effect of regenerator such as water on the crystalline structure of cellulose during dissolution, in this work, the samples used to do WAXD experiment were taken as the state of swelling or dissolution without regeneration. Combined with the results of optical microscopy, the dissolution mechanism of cellulose in [BMIM]Cl was analyzed based on the changes of hydrogen bond in the crystalline phase.

Experiments

Materials

The cotton linters pulp (degree of polymerization (DP) = 514, 94.2 % α-cellulose and 7.5 % moisture content) was supplied by Shandong Helon Co., Ltd, China. [BMIM]Cl was synthesized according to the procedures described by Csihony et al. (2002) in our laboratory. Both the cotton linters pulp and ILs were dried under vacuum for 24 h at the temperatures of 70 and 100 °C, respectively. To eliminate the effect of water on the dissolution of cellulose in [BMIM]Cl, the water content of all ILs was determined by Karl Fischer titration (ZSD-2 KF with a precision of 0.05 %, Cany Precision Instruments Co., Ltd.).

Characterization

The dissolution of cellulose in [BMIM]Cl at different temperatures were observed by polarized light microscopy with a hot stage and a multicolor digital camera (XSZ–360AP, Shanghai Weitu Instruments Technology Development Co., Ltd, China). A small quantity of cotton pulp and [BMIM]Cl solvent were sandwiched between two pieces of cover glasses and put on the hot stage at the temperatures of 60, 70 and 80 °C, respectively. The dissolution process of cellulose was recorded by a digital camera.

The cotton pulp was mixed with [BMIM]Cl at the temperatures of 60, 70 and 80 °C, respectively. Subsequently, the samples without coagulation were put into a completely sealed sample cell which was made from the Kaputon film. WAXD experiments were carried out at the Beamline (BL14B1) in Shanghai Synchrotron Radiation Facility (SSRF) with a wavelength of 0.12398 nm. The sample cell was placed in a sample holder perpendicular to the X-ray beam. The distance between the image plate (Mar 345) and the sample was 209.8 mm. Lanthanum Hexaboride was used for calibration. A typical image acquisition time was 60 s. The distribution of diffraction intensity was obtained from the 2D detector WAXD images as shown in Fig. 1 using FIT2D software (Hammersley 1987–1997).

The crystallinity of regenerated cellulose was quantified from the WAXD pattern using the following procedures. The 2D WAXD pattern was processed with the software package FIT2D (Hammersley, 1987–1997) to subtract the air scattering and the ILs scattering. The diffraction intensity profile was integrated from 0o to 360o. And the data were analyzed with Peak fit software (version 4.12, Seasolve Co., San Jose, CA, USA). During the calculation process of the crystallinity, the Gauss function was applied to separate the contribution of amorphous and crystalline parts in the angular interval 2θ = 5°–30°. The diffraction peak of amorphous region was determined according to the previous report (Chen et al. 2006) that amorphous peak was determined by the diffraction peak of ball-milled cellulose, containing only the amorphous phase at 2θ = 17.3° (λ = 0.12398 nm).

Then, the crystallinity was calculated according to the Eq. (1):

where W c,x is the crystallinity, I c and I a are the total peak area of the crystalline and the amorphous phases, respectively.

The crystalline index of cellulose was determined based on the Segal equation (Segal et al. 1959):

where CrI is the crystalline index for cellulose, I hkl is the intensity of diffraction maximum of crystalline regions, I am is the diffraction intensity of amorphous regions (2θ = 17.3° λ = 0.12398 nm).

Results and discussion

Morphology of cellulose at different temperatures

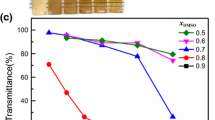

The morphology of cellulose with [BMIM]Cl was observed at different temperatures. As shown in Fig. 2a, the outline of cellulose filament could be clearly observed at 60 °C and neither swelling nor dissolution of cellulose was observed. While the temperature was elevated to 70 °C (Fig. 2b), the cellulose filaments transformed into transparency (30, 75, 120 min) from grayness (0 min) and the diameter of cellulose filaments increased gradually, which implied the swelling phenomenon of cellulose happened without dissolution. With the temperature further going up to 80 °C (Fig. 2c), the cellulose began to dissociate and dissolved gradually. However, the diameter of cellulose filaments unchanged, indicating there is no clear swelling phenomenon. It can be understood that the swelling and dissolution only could be happened above the melting point of [BMIM]Cl (68 °C) (Pinkert et al. 2009).

Structure changes of cellulose with [BMIM]Cl at 70 °C

Figure 3 shows the 2D WAXD patterns and 1D WAXD profiles of cellulose with [BMIM]Cl at 70 °C. The typical crystalline structure of cellulose I was observed in the cotton pulp with the characteristic diffraction peaks of (\( 1\bar{1}0 \)), (110), (012) and (020) (corresponding to 2θ of 11.8°, 13.3°, 16.4°, and 18.1°, respectively) based on the unit cell parameters, a = 8.17 Å (1 Å = 0.1 nm), b = 7.86 Å, c = 10.40 Å (parallel to the fiber axis), and γ = 97°. Although the diffraction intensity decreased gradually along with the dissolution time increasing, the sample still shows a character of cellulose I crystalline structure. It suggested that [BMIM]Cl mainly diffused into the amorphous part of the cellulose pulp initially and the fibril was swollen by the solvent with the interplanar spacing of (\( 1\bar{1}0 \)) planes increased, and that one of (020) plane also increased slightly (shown in Table 1). It should be pointed that in this work, as mentioned above, in this work, in order to avoid the effect of regenerator such as water on the crystalline structure of cellulose during dissolution, the samples used to do WAXD experiment were taken as the state of swelling or dissolution different without regeneration.

With the progress of diffusion, some incomplete crystalline structure was destroyed, resulting in the crystallinity (W c,x ) and crystalline index (CrI) of cellulose decreased gradually as shown in Table 1. The (\( 1\bar{1}0 \)) planes run parallel to the chain sheet which are formed by the binding of glucosyl group along the direction of c axis and intermolecular hydrogen bonding (6-OH···O-3′ bonds) formed from adjacent molecular chains (Oh et al. 2005). During the diffusion process of [BMIM]Cl into cellulose, the hydrogen bonding was destroyed by [BMIM]Cl and the movement of cellulose chain segments increased and consequently the interplanar spacing increased (Scheme 1).

Unfortunately, the ultrastructure of cellulose possesses unexpected complexity in the form of two crystal phases, namely Iα and Iβ (Atalla and Vanderhart 1984). Iα and Iβ can be found not only within the same cellulose sample (Sugiyama et al. 1990), but also along a given microfibril (Sugiyama et al. 1991). Moreover, it has been reported that the hydrogen bonds in Iβ are distributed over a region of better geometry than those in Iα. The more favorable intra-sheet hydrogen bonding in Iβ must be due to the difference in cellulose chain conformation between Iα and Iβ. And the hydrogen-bonded sheets along the (110) plane and (\( 1\bar{1}0 \)) plane for cellulose Iβ and cellulose Iα, respectively (Nishiyama et al. 2003).

Structure changes of cellulose with [BMIM]Cl at 80 °C

Figure 4 shows the 2D WAXD patterns and 1D WAXD profiles of cellulose with [BMIM]Cl at 80 °C. Compared with Fig. 3a, due to the molecular to move fast at 80 °C lead to the ILs exhibited a stronger dissolving ability, it can be clearly seen from Fig. 4 that the intensity of diffraction peaks decreased soon with the progress of dissolution time and disappeared at last. No swelling was observed because there is no increase of the interplanar spacing (shown in Table 2). Moreover, the W c,x and CrI of cellulose decreased rapidly with the dissolution time at 80 °C, which indicated the crystalline structure of cellulose was destroyed completely and transformed into amorphous structure after 120 min (Fig. 4b).

Conclusions

The results of the morphology and crystalline structure changes of cellulose during dissolution in [BMIM]Cl indicated that cellulose was neither dissolved nor swollen in [BMIM]Cl when the experiment temperature was below the melting point of [BMIM]Cl. The swelling phenomenon was observed at 70 °C by polarized light microscopy and also verified by the increase of interplanar spacing of (\( 1\bar{1}0 \)) and (020) planes in the cellulose crystalline structure. When the experiment temperature exceed 80 °C, the crystalline structure was destroyed and transformed into amorphous structure, which means that cellulose dissolved in [BMIM]Cl completely.

References

Atalla RH, Vanderhart DL (1984) Native cellulose: a composite of two distinct crystalline forms. Science 223:283–285

Cai T, Zhang HH, Guo QH, Shao HL, Hu XC (2010) Structure and properties of cellulose fibers from ionic liquids. J Appl Polym Sci 115:1047–1053

Cao Y, Wu J, Zhang J, Li HQ, Zhang Y, He JS (2009) Room temperature ionic liquids (RTILs): a new and versatile platform for cellulose processing and derivatization. Chem Eng J 147:13–21

Cao Y, Li HQ, Zhang Y, Zhang J, He JS (2010) Structure and properties of novel regenerated cellulose films prepared from cornhusk cellulose in room temperature ionic liquids. J Appl Polym Sci 116:547–554

Chen XM, Burger C, Fang DF, Ruan D, Zhang LN, Hsiao BS, Chu B (2006) X-ray studies of regenerated cellulose fibers wet spun from cotton linter pulp in NaOH/thiourea aqueous solutions. Polymer 47:2839–2848

Csihony S, Fischmeister C, Bruneau C, Horváth IT, Dixneuf PH (2002) First ring-opening metathesis polymerization in an ionic liquid. Efficient recycling of a catalyst generated from a cationic ruthenium allenylidene complex. New J Chem 26(11):1667–1670

Dogan H, Hilmioglu ND (2009) Dissolution of cellulose with NMMO by microwave heating. Carbohydr Polym 75:90–94

Fort DA, Remsing RC, Swatloski RP, Moyna P, Moyna G, Rogers RD (2007) Can ionic liquids dissolve wood? Processing and analysis of lignocellulosic materials with 1-n-butyl-3-methylimidazolium chloride. Green Chem 9:63–69

Hammersley (1987–1997) A FIT2D 2-D detector calibration/correction; file re-formatting; 2-D fitting; European Synchrotron Radiation Facility (ESRF)

Heinze T, Dorn S, Schobitz M, Liebert T, Kohler S, Meister F (2008) Interactions of ionic liquids with polysaccharides-2: cellulose. Macromol Symp 262:8–22

Kosan B, Michels V, Meister F (2008) Dissolution and forming of cellulose with ionic liquids. Cellulose 15:59–66

Moulthrop JS, Swatloski RP, Moyna G, Rogers RD (2005) High-resolution 13C NMR studies of cellulose and cellulose oligomers in ionic liquid solutions. Chem Commun 12:1557–1559

Nishiyama Y, Sugiyama J, Chanzy H, Langan P (2003) Crystal structure and hydrogen bonding system in cellulose Iα from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 125:14300–14306

Oh SY, Yoo DI, Shin Y, Kim HC, Kim HY, Chung YS, Parkd WH, Youk JH (2005) Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr Res 340:2376–2391

Pinkert A, Marsh KN, Pang SS, Staiger MP (2009) Ionic liquids and their interaction with cellulose. Chem Rev 109:6712–6728

Plechkova NV, Seddon KR (2008) Applications of ionic liquids in the chemical industry. Chem Soc Rev 37:123–150

Pu Y, Jiang N, Ragauskas AJ (2007) Ionic liquid as a green solvent for lignin. J Wood Chem Technol 27(1):23–33

Remsing RC, Swatloski RP, Rogers RD, Moyna G (2006) Mechanism of cellulose dissolution in the ionic liquid 1-n-butyl-3-methylimidazolium chloride: a 13C and 35/37Cl NMR relaxation study on model systems. Chem Commun 28(12):1271–1273

Segal L, Greely JJ, Mattin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Sugiyama J, Okano T, Yamamoto H, Horii F (1990) Transformation of valonia cellulose crystals by an alkaline hydrothermal treatment. Macromolecules 23:3196–3198

Sugiyama J, Vuong R, Chanzy H (1991) Electron diffraction study on the two crystalline phases occurring in native cellulose from an algal cell wall. Macromolecules 24:4168–4175

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellulose with ionic liquids. J Am Chem Soc 124:4974–4975

Zhang H, Wu J, Zhang J, He JS (2005) 1-allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Zhang JM, Zhang H, Wu J, Zhang J, He JS, Xiang JF (2010) NMR spectroscopic studies of cellobiose solvation in EmimAc aimed to understand the dissolution mechanism of cellulose in ionic liquids. Phys Chem Chem Phys 12:1941–1947

Acknowledgments

The work was supported by a grant from National Natural Science Foundation of China (50873025), Shanghai Leading Academic Discipline Project (B603) and the Innovation Funds for PhD Students (Jiang Guansen) of Donghua University, and the Fundamental Research Funds for the Central Universities. WAXD experiments were performed at both U7B Beamline station in the National Synchrotron Radiation Laboratory (NSRL) and the Beamline (BL14B1) in Shanghai Synchrotron Radiation Facility (SSRF).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, G., Huang, W., Wang, B. et al. The changes of crystalline structure of cellulose during dissolution in 1-butyl-3-methylimidazolium chloride. Cellulose 19, 679–685 (2012). https://doi.org/10.1007/s10570-012-9689-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9689-1