Abstract

The transesterification-active enzyme subtilisin Carlsberg was successfully solubilized into organic solvents such as isooctane by enzyme–bis(2-ethylhexyl) sulfosuccinate (AOT) ion-pairing while retaining its natural secondary structure and catalytic activity. The optimal CaCl2 concentration and pH for enzyme extraction were 2 mM and 5.0, respectively, while the optimal pH for transesterification capability of enzyme was around 7.5. Within the critical micellar concentration (CMC) of AOT in isooctane, increasing the initial AOT concentration enhanced the extraction efficiency. As the hydrophobicity of the solvent decreased, so did the catalytic efficiency of the enzyme, while transesterification of cotton fabrics (medical gauze and knitted cotton cloth) occurred only in less hydrophobic solvents such as toluene. Transesterification was verified by infrared spectral analysis. The final degree of substitution (DS, the number of propionate groups per cellulose monosaccharide unit) of the medical gauze and knitted cotton cloth was 0.00282 and 0.00228, respectively. The surface properties of the modified cotton fabrics were characterized using X-ray diffraction, scanning electron microscopy, thermogravimetry, water contact angle, etc.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Enzyme-catalyzed surface modification of natural fibers such as wool has been widely investigated and applied in the textile industry (Karmakar 1998). Most of these industrial applications in the textile processing field were aimed at improving surface properties by removing absorbed components such as fats, waxes, and proteins. However, enzymes could do much more than surface modification of fibers and fabrics; for example, new functional components or polymers could be introduced onto the surface of natural as well as synthetic fibers by enzymatic reaction.

Cotton fiber, one of the most important textile materials, is mainly composed of cellulose, which contains abundant hydroxyl residues, which could undergo acylation, etherification, esterification or transesterification under suitable conditions.

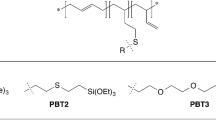

Transesterification with proteinase or lipase in organic solvents has great potential applications in production of biofuels and modification of hydroxyl-rich materials (Roy and Gupta 2005; Roy et al. 2004). However, enzymes are generally insoluble in organic solvents and usually lose their activity quickly upon contact with such solvents. In suspended form, enzymes interact poorly with solid substrates such as cotton fabrics and thus can barely catalyze their transesterification. Chemical modification of enzymes and reverse micelles have often been used to enhance enzyme solubilization in organic solvents. However, chemical modification of enzymes is tedious and often results in lower enzyme activities (Castillo et al. 2007). Reverse micelles increase local water content and promote hydrolysis of ester donation by proteinase (Tonova and Lazarova 2008).

Ion-pair extraction using anionic surfactants such as sodium bis(2-ethylhexyl) sulfosuccinate (AOT) for protein solubilization is the preferred approach (Zhang et al. 2010). The ion-pair enzyme–surfactant complex improves interaction of enzyme with substrate, and most importantly, it may retain a more native structure than heterogeneous enzyme suspension in solvents (Paradkar and Dordick 1994).

By ion-pair extraction of enzymes, Bruno et al. (1996) tried to modify insoluble amylose membrane and hydroxyl ethyl cellulose through transesterification in solvents with subtilisin, and Xie and Hsieh (2001) used subtilisin Carlsberg to catalyze transesterification between vinyl esters and solid cellulosic materials, including test cotton fabrics. Transesterification of practical cotton cloth with enzymes in solvents, however, has not been reported to date.

Cotton fabrics, compared with cellulose powder, are much more difficult to transesterify, due to limited accessibility of the hydroxyl group and steric hindrance of the enzyme. In this study, medical gauze and knitted cotton cloth with affluent hydroxyl groups were chosen as solid substrates for transesterification with subtilisin Carlsberg in solvents. Medical gauze is a sparse, net-like material, and its surface has less compact cellulosic fiber terminals than knitted cotton cloth due to the strong defatting treatment applied. The aim of this study is to investigate surface modification by enzymatic transesterification of practical cotton fabrics and changes of their surface characteristics after such modification. X-ray diffraction, one of the most powerful techniques for qualitative and quantitative analysis of crystalline compounds, was used to investigate whether transesterification of cotton cloth affected the cotton cloth’s crystalline phases (Lin et al. 2006). Surface changes of the modified cotton cloth were observed by scanning electron microscopy (SEM). Thermogravimetric analysis was used to measure the thermal stability of the modified cotton cloth. Surface hydrophobic capabilities of the modified cotton fabrics were compared with the original fabrics by measuring their water contact angle. This is the first time that modification of practical cotton cloth by transesterification in solvents has been attempted.

Materials and methods

Materials

Subtilisin Carlsberg (EC 3.4.24.69) was obtained from Sigma (St. Louis, USA). AOT was purchased from Sigma (St. Louis, USA) and used directly without further purification. 4-Hydrazino-7-nitro-2,1,3-benzoxadiazole hydrazine (NBD-H·NH2NH2), vinyl propionate was purchased from TCI (Shanghai). The salts and reagents used in this work were of the highest purity commercially available.

Medical gauze was purchased from a hospital (Wuxi). The knitted cotton cloth was obtained from a local textile company (Pacific Textile Co. Ltd., Wuxi, China). It was finished but not dyed. Both the medical gauze and knitted cotton cloth were cleaned by bathing in boiling 1.0 M NaOH solution for 1 h and washing thoroughly with deionized water, then dried at 60 °C in vacuum overnight.

The medical gauze and knitted cotton cloth were cut into pieces of about 8 mm × 8 mm (10 mg) and 4 mm × 4 mm (10 mg), respectively, for transesterification.

Ion-pair extraction of enzyme into the organic phase

Enzyme solution was prepared from salt-free enzyme powder dissolved in sodium acetate buffer (pH 5.0, 10 mM, including 2 mM CaCl2) at concentration of 1.0 mg/mL.

Enzyme solution (4 mL) was transferred to a 20-ml vial, and 4 mL isooctane containing 3 mM AOT was added gradually. The two phases were mixed using magnetic stirring (250 rpm, thereby ensuring complete mixing) for 1 h. The mixture was then centrifuged at 10,000 rpm for 5 min to obtain clear phase separation. The organic phase was then recovered and assayed for enzyme and AOT. Subtilisin Carlsberg was assayed using an ultraviolet (UV) spectrophotometer (UV-2100, UNIC, USA) at 280 nm (Paradkar and Dordick 1994). Extraction efficiency (E %) was defined as

where [E]o is the enzyme extracted into the organic phase and [E]aq is the enzyme initially present in the aqueous phase. The AOT concentration in the organic phase was measured using rhodamine 6G (R-6G) dye assay (Paradkar and Dordick 1994).

When toluene or other solvent was explored, the enzyme was first extracted by ion-pairing into isooctane, and then isooctane was evaporated by blowing pure nitrogen gas in the fume chamber at room temperature, and the residue (AOT–enzyme ion-pair complex) was redissolved in the same volume of toluene or other solvent.

The ion-pair extraction procedure was according to Zhang et al. (2010).

Determination of the catalytic capability of the ion-paired enzyme in solvents

The catalytic capability of the ion-pair complex was examined by modified fluorospectrophotometry (Konarzycka-Bessler and Bornscheuer 2003) using 4-hydrazino-7-nitro-2,1,3-benzoxadiazole hydrazine (NBD-H·NH2NH2) as fluorescent substrate. In solvents, ion-paired subtilisin Carlsberg could catalyze transesterification between vinyl ester and an alcohol substrate. One of the products, i.e., vinyl alcohol, would spontaneously convert to aldehyde by isomerization, which could then react with NBD-H·NH2NH2 to produce the fluorescent substance. Reactions were carried out at 37 °C under constant shaking (100 rpm, Dubroff metabolic shaking incubator, Precision) for more than 24 h. The enzyme-catalyzed transesterification was the rate-limiting step of the reaction series, and thus enzyme activity could be determined by fluorescence assay.

Fluorimetric analysis was performed using a 1420 multilabel counter fluorospectrophotometer (PerkinElmer, USA) at room temperature, with excitation at 485 nm and emission at 525 nm (gain 0). The reaction mechanism and detailed procedure were described previously (Zhang et al. 2010).

Transesterification of cotton fabrics

When fabrics (medical gauze and knitted cotton cloth) were used, in a typical reaction, 10 mg fabric was reacted with 50 mg vinyl esters in 4 mL solvent (isooctane, toluene, etc.) containing 1 mg/mL subtilisin Carlsberg. Reactions were carried out at 37 °C under constant shaking (100 rpm, Dubroff metabolic shaking incubator, Precision) for more than 24 h. A blank experiment was performed under the same conditions without the enzyme, and another blank was performed under the same conditions without solid substrate. After the reaction, the fabric was removed and the remaining liquids were centrifuged at 10,000 rpm for 5 min; the supernatant was collected for fluorescence analysis. The reacted fabrics were washed thoroughly with the same pure solvent (isooctane or toluene) three times to remove enzyme, surfactant, and residual vinyl propionate and were then analyzed by infrared (IR) spectroscopy to verify transesterification.

Characterization methods

The original or reacted fabrics were dried in vacuum and used for IR spectral analysis, which was carried out using a Nicolet Nexus Fourier-transform (FT)-IR spectrometer (Thermo Electron Co., USA). Spectra were collected by attenuated total reflection (ATR).

The degree of substitution (DS) of the modified fibers, i.e., the number of propionate groups per cellulose monosaccharide unit, was calculated from aldehyde production, and aldehyde amount was determined by aldehyde-fluorescence strength work curve.

For X-ray diffraction (XRD) measurements, the cotton cloth was gently pressed into small pellets using a laboratory press and analyzed with a Phillips X’pert MPD diffractometer using Cu Kα radiation (USA).

Thermogravimetric (TGA) assays were carried out using a Shimadzu TGA 50 analyzer (Japan) equipped with a platinum cell. Samples were heated at constant rate of 10 °C/min from 30 up to 800 °C, under nitrogen flow of 20 mL/min. The thermal decomposition temperature (T di) was taken as the onset of significant (≥0.5%) weight loss from the heated sample, after moisture loss.

Water-wetting behavior of the fabric samples was evaluated by water contact angle (WCA) using MobileDrop (KRUSS, Germany) (Bateni et al. 2003).

Scanning electron microscopy (SEM) images of unmodified and modified fabrics were obtained at magnification of 1,200× using an SEM (Hitachi S-4100, Japan).

Results and discussion

The presented data are averages of three replications.

Optimal conditions for ion-pair extraction of subtilisin Carlsberg into isooctane

The main parameters affecting ion-pair extraction of subtilisin Carlsberg into isooctane were optimized according to Zhang et al. (2010). Figure 1 shows that the preferred pH of the aqueous phase was 5.0–6.0. The optimal concentration of CaCl2 was 2.0 mmol/L (Fig. 2). The optimal initial AOT concentration in the solvent phase was 4.0 mmol/L (Fig. 3).

Effect of aqueous-phase pH on enzyme extraction efficiency and catalytic efficiency of transesterification of enzyme in isooctane. ○: catalytic efficiency/%; ■: extraction efficiency/%. Conditions: pH 4.4–6.0, 10 mM NaAc-HAc buffer with 2 mM CaCl2 for ionic strength, 3 mM AOT concentration in isooctane, 1.0 mg/mL initial concentration of enzyme in the aqueous phase, magnetic stirring with phases mixing at 250 rpm for 1 h; transesterification reactions were carried out at 37 °C under constant shaking (100 rpm) for 3 h with vinyl propionate and 1-propanol as transesterification substrates

Effect of CaCl2 concentrations on extraction efficiency of enzyme and catalytic efficiency of enzyme in isooctane. ○: catalytic efficiency/%; ■: extraction efficiency/%. Conditions: 1.0 mg/mL initial concentration of enzyme in the aqueous phase (10 mM NaAc-HAc buffer, pH 5.0), and 3 mM AOT was employed initially in isooctane; ionic strength was controlled by varying the concentration of CaCl2; magnetic stirring with phases mixing at 250 rpm for 1 h; transesterification reactions were carried out at 37 °C under constant shaking (100 rpm) for 3 h with vinyl propionate and 1-propanol as transesterification substrates

Effect of initial AOT concentration on extraction efficiency of enzyme in isooctane and catalytic efficiency of enzyme in isooctane. ○: catalytic efficiency/%; ■: extraction efficiency/%. Conditions: 1.0 mg/mL enzyme in acetate buffer (pH 5.0, 10 mM) containing 2 mM CaCl2 was magnetically stirred with phases mixing at 250 rpm for 1 h; transesterification reactions were carried out at 37 °C under constant shaking (100 rpm) for 3 h with vinyl propionate and 1-propanol as transesterification substrates

It should be pointed out that the optimal pH for extraction efficiency was far lower than the optimal pH for specific activity of the ion-paired enzyme in isooctane (Fig. 1). With increasing aqueous-phase pH, the enzyme extracted into isooctane exhibited stronger catalyzing capability. The optimum aqueous-phase pH for enzyme-catalyzed transesterification in isooctane was around 7.5. Subtilisin Carlsberg may retain its most stable structure near pH 7.5 in water solution. Lower or higher pH distorted its three-dimensional structure and destroyed its catalytic capability. This distortion could be retained by the enzyme even after transfer into isooctane, so its specific transesterification catalyzing capability decreased for lower or higher aqueous pH.

Transesterification capabilities of the enzyme in isooctane and toluene were examined with 1-propanol and vinyl propionate as transesterification substrates. The results (Fig. 4) showed that the specific catalytic efficiency of ion-paired subtilisin Carlsberg in toluene was only 80% of that in isooctane. The increase of hydrophobicity (log P) of the solvents (log P of isooctane and toluene: 4.5 and 2.5, respectively) resulted in an increase in catalytic capability of the enzyme dissolved in each solvent. This may be due to the fact that hydrophilic solvents are capable of stripping bonded water from enzyme molecules, thus reducing enzyme stability and activity (Persson et al. 2002).

Transesterification of cellulosic fabrics in organic solvents

Medical gauze and knitted cotton cloth with affluent hydroxyl groups were chosen as solid substrates for modification by transesterification reactions using subtilisin Carlsberg in isooctane. Although both the vinyl propionate and enzyme were solubilized in isooctane, fluorescence results showed that no transesterification occurred between the vinyl ester and hydroxyl residual groups on the fabrics. The reason may be poor interaction between the hydrophobic solvent and the hydrophilic substrates. IR spectrum also verified that no transesterification reactions occurred on these solid substrates in isooctane (Fig. 5).

Therefore, isooctane was substituted by toluene, which is slightly less hydrophobic than isooctane. In toluene, fluorescence detection showed that transesterification occurred on both medical gauze and knitted cotton cloth. IR spectra verified this result (Fig. 6), exhibiting ester C=O peaks at 1,730 cm−1.

IR spectrum of the fabrics modified in toluene: (A) medical gauze; (B) knitted cotton cloth. Arrow: C=O group appears after transesterification reaction. Conditions: enzyme concentration in toluene was 1 mg/mL; temperature for transesterification was 37 °C under constant shaking (100 rpm) for 24 h with vinyl propionate as acyl donor

Compared with isooctane, toluene has greater capability to swell hydrophilic solid polymers. In toluene, the hydroxyl group on the swelled cellulosic fabrics became more accessible to the ion-paired enzyme, facilitating the enzymatic reaction.

Time course

Time courses of transesterification of medical gauze and knitted cotton cloth catalyzed by the subtilisin–AOT ion pair in toluene are shown in Fig. 7. Transesterification mainly took place up to 15 h. The final DS of medical gauze and knitted cotton cloth was 0.00282 and 0.00228, respectively. Due to its sparse, net-like structure, medical gauze was more accessible to the enzyme and thus had higher DS. Transesterification efficiency was affected by the nature of the fabric. It should be pointed out that the transesterification efficiencies of the glucose unit of these two solid polymers were all less than 0.3%, while the transesterification efficiency of small-molecular substrates such as 1-propanol was more than 80% within 8 h under the same conditions.

Transesterification time courses of cotton fabrics in toluene. ●: medical gauze; ▲: knitted cotton cloth. Conditions: enzyme concentration in toluene was 1 mg/mL; the mass weight of medical gauze and knitted cotton cloth was 10 mg; temperature for transesterification was 37 °C under constant shaking (100 rpm) for more than 24 h with 50 mg vinyl propionate as acyl donor

Characterization of the modified fabrics

X-ray diffraction and scanning electron microscopy

The cotton fabrics modified by transesterification retained the XRD pattern of the original fabrics (Fig. 8), suggesting that the reaction involved mainly amorphous regions of the outer layers of the fibers, without obviously affecting their crystallinity or ultrastructure.

SEM analysis was used to characterize changes in the surface morphology of the fibers. SEM micrographs of the modified cotton cloth and its unmodified counterpart showed no obvious surface changes (Fig. 9). The surface of modified cotton cloth was also smooth. The morphological changes of cotton cloth were negligible.

Thermal degradation

The thermal behavior of unmodified and modified cotton fabrics was assessed by using TG and DTG at heating rate of 10 °C/min (Fig. 10). Generally, the transesterified cotton fabrics showed similar TG profiles to the original fabrics but less thermal stability. TG profiles exhibited a single weight-loss step with maximum decomposition temperature of about 365 °C. The transesterified fibres were in general less stable, since they started to decompose at lower temperature than their unmodified counterparts. Compared with unmodified cotton fabrics, the thermograms (heating rate 10 °C/min) of the cellulose esters showed extra separate degradation steps, with degradation temperatures at 240–260 °C, tentatively assigned to the esterified fraction of the fibres (Freire et al. 2006). Another maximum peak (315–370 °C) was attributed to unmodified cellulose.

Water-wetting behavior

General water-wetting of fabrics was characterized by water contact angle (WCA) formed by water drops on the cotton fabrics surface. WCAs of the transesterified cotton fabrics were higher than those of their untreated counterparts (Fig. 11). This is consistent with the expectation that the fabric surface became more hydrophobic following acylation of hydroxyl groups.

Conclusions

The transesterification-active enzyme subtilisin Carlsberg was successfully solubilized in solvents by ion-pair extraction with AOT. The optimal pH and CaCl2 concentration of the aqueous phase for ion-pair extraction were 5.0 and 2 mmol/L, respectively, while the optimal pH for enzyme dissolved in solvent to catalyze transesterification reaction was around 7.5. The transesterification-catalyzing capability of ion-paired subtilisin Carlsberg with vinyl propionate and 1-propanol as substrates increased with the hydrophobicity of the solvent. The enzyme–AOT ion pair could catalyze transesterification of cotton fabrics in toluene, but not in isooctane. IR spectra verified transesterification in toluene.

Cellulosic fabrics (medical gauze and knitted cotton cloth) were modified with vinyl propionate through transesterification reactions catalyzed by the proteinase subtilisin Carlsberg-AOT ion pair in toluene. DS of medical gauze and knitted cotton terry cloth was 0.00282 and 0.00228, respectively. X-ray diffraction and SEM results showed transesterification involved in amorphous regions of the outer layers of the fibers. The crystallinity of the cellulose after modification barely changed. The thermal stability of the modified cotton fabrics (including medical gauze and knitted cotton cloth) decreased slightly. The medical gauze and knitted cotton cloth became more hydrophobic after modification by transesterification.

References

Bateni A, Susnar SS, Amirfazli A, Neumann AW (2003) A high accuracy polynomial fitting approach to determine contact angles. Colloids Surf A Physicochem Eng Asp 219:215–231. doi:10.1016/S0927-7757(03)00053-0

Bruno FF, Akkara JA, Ayyagari M, Kaplan DL, Gross R, Swift G, Dordick JS (1996) Enzymatic modification of insoluble amylose in organic solvents. Macromolecules 28:8881–8883. doi:10.1021/ma00130a028

Castillo B, Sola RJ, Ferrer A, Barletta G, Griebenow K (2007) Effect of PEG modification on subtilisin Carlsberg activity, enantioselectivity, and structural dynamics in 1,4-dioxane. Biotechnol Bioeng 99:9–17. doi:10.1002/bit.21510

Freire CSR, Silvestre AJD, Pascoal Neto C, Belgacem MN, Gandini A (2006) Controlled heterogeneous modification of cellulose fibers with fatty acids: effect of reaction conditions on the extent of esterification and fiber properties. J Appl Polym Sci 100:1093–1102. doi:10.1002/app.23454

Karmakar SR (1998) Application of biotechnology in the pre-treatment processes of textiles. Colourage Annu 45:75–86

Konarzycka-Bessler M, Bornscheuer UT (2003) A high-throughput-screening method for determining the synthetic activity of hydrolases. Angew Chem Int Ed 42:1418–1420. doi:10.1002/anie.200390365

Lin Y, Adebajo MO, Kloprogge JT, Martens WN, Frost RL (2006) X-ray diffraction and Raman spectroscopic studies of Zn-substituted carrboydite-like compounds. Mater Chem Phys 100:174–186. doi:10.1016/j.matchemphys.2005.12.028

Paradkar VM, Dordick JS (1994) Mechanism of extraction of chymotrypsin into isooctane at very low concentrations of Aerosol OT in the absence of reversed micelles. Biotechnol Bioeng 43:529–540. doi:10.1002/bit.260430614

Persson M, Mladenoska I, Wehtje E, Adlerceutz P (2002) Preparation of lipases for use in organic solvents. Enzyme Microb Technol 31:833–841. doi:10.1016/S0141-0229(02)00184-9

Roy I, Gupta MN (2005) Enhancing reaction rate for transesterification reaction catalyzed by Chromobacterium lipase. Enzyme Microb Technol 36:896–899. doi:10.1016/j.enzmictec.2005.01.022

Roy I, Sharma A, Gupta MN (2004) Obtaining higher transesterification rates with subtilisin Carlsberg in nonaqueous media. Bioorg Med Chem Lett 14:887–889. doi:10.1016/j.bmcl.2003.12.021

Tonova K, Lazarova Z (2008) Reversed micelle solvents as tools of enzyme purification and enzyme-catalyzed conversion. Biotechnol Adv 26:516–532. doi:10.1016/j.biotechadv.2008.06.002

Xie J, Hsieh YL (2001) Enzyme-catalyzed transesterification of vinyl esters on cellulose solids. J Polym Sci Part A Polym Chem 39:1931–1939. doi:10.1002/pola.1170

Zhang Y, Gu JD, Wang SG, Fan XR (2010) Preparation and properties of surfactant-bacillolysin ion-pair in organic solvent. Chem Pap 64:443–449. doi:10.2478/s11696-010-0018-6

Acknowledgments

This research was funded by the National Natural Science Foundation of China (50703016) and Jiangnan University Research Funds (2009LYY03).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Fan, X. Surface modification of cotton fabrics by transesterification with ion-paired subtilisin Carlsberg in solvents. Cellulose 17, 903–911 (2010). https://doi.org/10.1007/s10570-010-9428-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-010-9428-4