Abstract

Microbial cellulose is a pure form of cellulose with widespread applications. It is very applicable for medical usage specially wound dressings due to its high liquid absorbency and hygienic nature. In this study, microbial cellulose formed/coated on cotton gauze samples during its biosynthesis in a static medium (Hestrin & Scharm) for 6 days by Acetobacter Xylinium. Some essential factors of treated gauze samples, like water absorbency, drying time (water holding time), and amount of vertical wicking were determined and compared with untreated samples. Results showed that cotton gauze coating with microbial cellulose increases water absorbency and wicking ability over 30%, and reduces drying time about 33%. It can be concluded that covering of cotton gauze with microbial cellulose can promote some important characteristics of it specially for wound dressings.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Recent advances in the field of biomaterials beside their medical applications indicate the significance and potential of various microbial polysaccharides in the development of novel classes of medical materials (Bungay et al. 1997; Czaja et al. 2006; Jeon et al. 2009; Kumar et al. 2004). Several microbial-derived polysaccharides with novel and interesting physical and biological properties already have been applied in biotechnology products (i.e. hyaluronic acid, dextran, alginate, scleroglucan, PLA), (Cai et al. 2009; Czaja et al. 2006; Marchetti et al. 2009; Tan et al. 2009; Xu et al. 2009). Among them microbial cellulose (MC) is one of the most promising classes of microbial polysaccharides.

It is synthesized in abundance by Acetobacter Xylinum or other selected microbes (Kumar et al. 2004; Jeon et al. 2009; Goelzer et al. 2009; Yan et al. 2008). Most biosynthesized cellulose originates as a white gelatinous pellicle, which is called by Brown (1886) as “Microbial Cellulose”. This kind of cellulose shows a high degree of crystallinity and superior mechanical properties in comparison with the other forms of cellulose (Budhionoa et al. 1999; Tsuchida and Yoshinaga 1997; Klemm et al. 2001; Dubey et al. 2002; Maria et al. 2009; Kurosumi et al. 2009). It forms on the surface of a liquid medium at 30–40 °C, in a static or dynamic culture containing a suitable microbe like Acetobacter Xylinum. This microbe is a rod-shaped aerobic gram negative bacterium that occurs as a contaminant in vinegar production (Goelzer et al. 2009; Dubey et al. 2002; George et al. 2005; Pandey et al. 2005). It feeds and turns the glucose and other suitable organic components into cellulose (Kurosumi et al. 2009; Keshk and Sameshima 2005; Keshk 2006). Cellulose synthesis by Acetobacter is a complex process and involves first polymerization of single glucose residues into linear α-1,4-glucan chains, then extracellular secretion of these linear chains, and finally assembly and crystallization of the glucan chains into hierarchically composed ribbons. As a result of these processes, a three-dimensional, gelatinous structure is formed on the surface of the liquid medium (Czaja et al. 2007; Dubey et al. 2002; Oshima et al. 2008). The thick, gelatinous membrane formed in static culture conditions as a result of these processes is characterized by a 3-D structure consisting of an ultrafine network of cellulose nanofibers (3–8 nm), which are highly uniaxially oriented (Czaja et al. 2006; Klemm et al. 2001; Maria et al. 2009; Pinto et al. 2007; Svensson et al. 2005).

The physical and mechanical properties of microbial cellulose membranes arise from their unique structure, which differs significantly from the structure of plant cellulose. Basically, well-separated nano- and micro-fibrils of microbial cellulose create an extensive surface area that allows it to hold a large amount of water. The hydrogen bonds between these fibrillar units stabilize the whole structure and give it a great deal of mechanical strength (Dubey et al. 2002; Oshima et al. 2008; Czaja et al. 2006; Ciechanska 2004; Charpentier et al. 2006; Backdahl et al. 2006).

The 3-D structure, not found in vascular plant cellulose (Rezaee et al. 2005; Wan et al. 2006; Grzegorczyn and Ezak 2007), results in high cellulose crystallinity (60–80%) and as high tensile strength, elasticity, large surface area, and mold ability during fermentation, etc. (Oshima et al. 2008; Pinto et al. 2007; Hoenich 2006; Wan et al. 2006). The size of MC fibrils is about 100 times smaller than fibrils in plant cellulose. This unique nano-morphology results in a large surface area that can hold a large amount of water (up to 200 times of its dry mass) and at the same time displays great elasticity and high wet strength. Thus, microbial cellulose can absorb much higher volumes of liquids than plant-derived cellulose materials (Klemm et al. 2001; Czaja et al. 2007).

The small size of MC fibrils seems to be a key factor that determines its remarkable performance as a wound healing system (Czaja et al. 2006; George et al. 2005; Grzegorczyn and Ezak 2007). Furthermore, the never-dried cellulose membrane is a highly nano-porous material that allows for the potential transfer of antibiotics or other medicines into the wound, while at the same time serving as an efficient physical barrier against any external infection (Czaja et al. 2006; Grzegorczyn and Ezak 2007; Pitanguy et al. 1988).

On the basis of its recent clinical performance and according to the results of other research on the properties of this particular biomaterial, MC can be considered an ideal material for high-quality wound dressings (Dubey et al. 2002; Ciechanska 2004; Pitanguy et al. 1988).

In this study, it was intended to improve the conventional cotton gauze with coating its surface with microbial cellulose to benefit from the supreme properties of microbial cellulose like high water absorption ability, and to fill the spaces between yarns in gauze fabric for more isolation of the wound.

Materials and methods

Materials

Conventional cotton gauzes (plain weaved, 30 Ne yarn count, number of warp and weft per cm 7 and 10 orderly with quality approval number k/7/19234 from the Ministry of Health and Medical Education of Iran prepared from Latif Ltd, Semnan, Iran) used as the substrate for coating.

Acctobacter Xylinum ATCC 23768 was used for BC production. The microbe was provided from the Medical Sciences Faculty Tarbiat Modares University, Tehran, Iran.

Hestrin-Schramm’s medium culture prepared by adding glucose 2 g, peptone 0.5 g, yeast extract 0.5 g, disodium phosphate 0.27 g, and citric acid 0.115 g, to 1 liter of distilled water. The prepared culture mediums were sterilized by autoclaving in Erlenmeyer flasks and inoculated from the solid agar culture of G. xylinus (Marchetti et al. 2009).

Methods

Method of culture

To produce single face-coated samples, gauzes were cut to determined dimensions and placed in culture medium plates. The cultural medium liquid and the Acetobacter Xylinium were added to the plates and after 6 days coated gauzes were collected and washed with distilled water. Double face-coated samples were produced by treating each side for 3 days as mentioned in the procedure.

Static immersion test

The water absorption test was carried out according to BS 34491 (1990) standard called as “Static immersion test” for fabrics (like bandages, gauzes and, cotton for medical applications) with high capability of water absorption. Weighted dry samples were soaked in a filled beaker with distilled water for a minute then hanged for two minutes and weighted. The water absorption percentage (W) was obtained by Eq. (1). Each test repeated five times and the mean values for sample were reported.

where M 2 = weight of wet sample, and M 1 = weight of dry sample.

Water holding time

Drying time of samples was determined based on T-PACC method. First circular cuts (3.5 inch diameter) of samples were prepared and weighed. Then gauzes were wetted (sprayed) with 1CC distilled water and weighted. The reduced weight of samples due to water evaporation was measured every 15 min until the weight measuring differences between three successive measurements reached to a nonsignificance level. Each test was repeated five times, and the mean value was reported.

Vertical wicking test

To determine the wicking rate, samples were cut (in ribbon shape) with dimensions of 170 mm by 25 mm and placed straight in a beaker containing distilled water. The height of wicked water in different times (1, 5, and 10 min) recorded as wicking ability factor. Each test was repeated three times, and the mean value was reported.

Microscopic studies

To show the differences between treated and untreated gauzes after culture, projectina microscope (MODEL MMP-1000 Sweden) was used. Sample morphology and microstructure were examined by scanning electron microscopy (XL-300 SEM, Philips, made in Netherlands). Samples were sputter coated with a thin layer of gold to avoid electrical charging.

Results and discussion

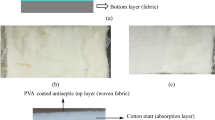

It can be seen in Fig. 1 that the grown microbial cellulose after six days filled and formed a pellicle between the spaces of warp and weft yarns of cotton gauze evenly. The weight of formed microbial cellulose on gauze cotton fabric was about 3 × 10−4 g/cm2.

The water absorption percentages of samples are shown in the Table 1. Comparing the data sets by analysis of variance “ANOVA” shows that the difference between untreated cotton gauze and treated ones is statistically significant (F ratio = 54.41 > F critical = 6.926; α = 0.01), but post-hoc range test (Duncan) showed that (homogeneous subsets of) means of single and double-coated gauzes are not different from each other. Both treated cotton gauze showed about 37 percent more capability in water absorption in comparison with untreated cotton gauze.

The micro and porous fibrous 3-D network of formed microbial cellulose on cotton gauze can be the most important factor of water absorption capability increasing. The presence of micro fibrils in microbial cellulose layer causes a great specific area that plays a significance role in water absorbency. This ability is very crucial for a wound dress in which water, wound exudates, and liquid drugs absorption abilities are highlighted. As it was mentioned, there was no significant difference in water absorption amount for one-side and two-side gauzes, so double-sided coating is not efficient in increasing water absorption capability.

Moisture retaining of wound surface (preserving wet condition during wound care) accounts for a very important criterion in modern active wound dressing. Table 2 shows drying average time for each sample. The difference between untreated cotton gauze and treated ones is statistically significant (F ratio = 93.75 > F critical = 6.92; α = 0.01), but means of single and double-coated gauzes are not different from each other. The average water-holding ability (drying time) of treated gauze (single or double coated) is 33 percent higher than untreated ones. Holding capacity of liquids especially water is a fundamental factor to alleviate the pain and heal the wound.

Test results for vertical wicking ability of different samples are presented in Table 3. The difference between untreated cotton gauze and treated ones in each different times is statistically significant (F ratio (1 min = 112.5); (5 min = 258.33); (10 min = 161.33) > F critical = 10.92; α = 0.01). The means of single and double-coated gauzes are different just at one minute after starting of the test and then they show no significant differences between each other. Approximately, the wicking ability of treated gauzes is 30 percent more than untreated ones in different times. So by covering the cotton gauze with microbial cellulose, the rate of therapeutic liquid transport to the wound increases and the rate of exudate absorption decreases.

The SEM micrographs in Fig. 2 show the covered cotton gauze with microbial cellulose after 6 days culturing. The image in Fig. 2a shows the formed layer of microbial cellulose on cotton fibers of gauze fabric, but the image Fig. 2b shows that there is no growth of bacterial cellulose on the face of fabric that was in contact with culture liquid but not air because the synthesis of bacterial cellulose needs sufficient air during culturing. According to the previous mentioned results no significant difference was shown between one and double-sided coating in the case of studied factors, so it is preferable to coat just one side of gauze fabric with bacterial cellulose.

Conclusion

Microbial cellulose secreted by Acetobacter xylinum has unique properties including high water retaining capacity, nano fibrils, proper biodegradability, molding ability, and high tensile strength. Microbial cellulose has found many industrial applications in high-strength construction materials, food additives and biodegradable products and paper, textiles and biomaterials for cosmetics and medical applications, temporary skin substitute and micro vessel endoprothesis.

In this study, microbial cellulose was considered as a biopolymer with useful medical application in order to improve gauze properties. With coating of cotton gauze with microbial cellulose an approved wound dress can be produced. The modified gauze with microbial cellulose shows high capability of medical liquid absorption and greater dry time, which are the main feature of modern wound dressing. It is also possible to encapsulate various medical agents into this medium according to its unique fibrillar network.

References

Backdahl H, Helenius G, Bodin A, Annmark U, Johansson R, Risberg B, Gatenholm P (2006) Mechanical properties of bacterial cellulose and interactions with smooth muscle cells. Biomaterials 27:2141–2149

Budhionoa A, Rosidi B, Taher H, Iguchi M (1999) Kinetic aspects of bacterial cellulose formation in nata-de-coco culture system. Carbohydr Polym 40:137–143

Bungay H, Serafica G, Mormino R (1997) Environmental implications of microbial cellulose. In: Wise DL (ed) Global environmental biotechnology (Studies in Environmental Science). Elsevier Science, Amsterdam, pp 691–700

Cai X, Tong H, Shen X, Chen W, Yan J, Hu J (2009). Preparation and characterization of homogeneous chitosan–polylactic acid/hydroxyapatite nanocomposite for bone tissue engineering and evaluation of its mechanical properties. Acta Biomaterialia, In Press, Corrected proof, Available online 14 March 2009

Charpentier P, Maguire A, Wan W (2006) Surface modification of polyester to produce a bacterial cellulose-based vascular prosthetic device. Appl Surf Sci 252:6360–6367

Ciechanska D (2004) Multifunctional bacterial cellulose/chitosan composite materials for medical applications. Fibers & Textiles in Eastern Europe 12:69

Czaja W, Krystynowicz A, Bielecki S, Brown R (2006) Microbial cellulose—the natural power to heal wounds. Biomaterials 27:145–151

Czaja W, Young D, Kawecki M, Brown R (2007) The Future prospects of microbial cellulose in biomedical applications. Biomacromolecules 8:1–12

Dubey V, Saxena Ch, Singh L, Ramana K, Chauhan R (2002) Pervaporation of binary water–ethanol mixtures through bacterial cellulose membrane. Sep Purif Technol 27:163–171

George J, Ramana K, Sabapathy Sh, Jagannath J, Bawa A (2005) Characterization of chemically treated bacterial (acetobacter xylinum) biopolymer: some thermo-mechanical properties. Int J Biol Macromol 37:189–194

Goelzer F, Faria-Tischer P, Vitorino J, Sierakowski M, Tischer C (2009) Production and characterization of nanospheres of bacterial cellulose from acetobacter xylinum from processed rice bark. Mater Sci Eng 29:546–551

Grzegorczyn S, Ezak A (2007) Kinetics of concentration boundary layers buildup in the system consisted of microbial cellulose biomembrane and electrolyte solutions. J Memb Sci 304:148–155

Hoenich N (2006) Cellulose for medical application: past, present, and future. Bioresources 1:270–280

Jeon O, Bouhadir K, Mansour J, Alsberg E (2009) Photocrosslinked alginate hydrogels with tunable biodegradation rates and mechanical properties. Biomaterials 30:2724–2734

Keshk S (2006) Physical properties of bacterial cellulose sheets produced in presence of lignosulfonate. Enzyme Microb Technol 40:9–12

Keshk S, Sameshima K (2005) Evaluation of different carbon sources for bacterial cellulose production. Afr J Biotechnol 4:478–482

Klemm D, Schumann D, Udhardt U, Marsch S (2001) Bacterial synthesized cellulose—artificial blood vessels for microsurgery. Prog Polym Sci 26:1561–1603

Kumar C, Joo H, Choi J, Koo Y, Chang Ch (2004) Purification and characterization of an extracellular polysaccharide from haloalkalophilic Bacillus sp. I-450. Enzyme Microb Technol 34:673–681

Kurosumi A, Sasaki Ch, Yamashita Y, Nakamura Y (2009) Utilization of various fruit juices as carbon source for production of bacterial cellulose by acetobacter xylinum NBRC 13693. Carbohydr Polym 76:333–335

Marchetti F, Bergamin M, Bosi S, Khan R, Murano E, Norbedo S (2009) Synthesis of 6-deoxy-6-chloro and 6-deoxy-6-bromo derivatives of scleroglucan as intermediates for conjugation with methotrexate and other carboxylate containing compounds. Carbohydr Polym 75:670–676

Maria L, Santos A, Oliveira Ph, Barud H, Messaddeq Y, Ribeiro S (2009) Synthesis and characterization of silver nanoparticles impregnated into bacterial cellulose. Mater Lett 63:797–799

Oshima T, Kondo K, Ohto K, Inoue K, Baba Y (2008) Preparation of phosphorylated bacterial cellulose as an adsorbent for metal ions. React Funct Polym 68:376–383

Pandey L, Saxena Ch, Dubey V (2005) Studies on pervaporative characteristics of bacterial cellulose membrane. Sep Purif Technol 42:213–218

Pinto R, Marques P, Martins M, Neto C, Trindade T (2007) Electrostatic assembly and growth of gold nanoparticles in cellulosic fibres. J Colloid Interf Sci 312:506–512

Pitanguy I, Salgado F, Maracaja P (1988) Utilization of the cellulose pellicle biofill as a biological dressing. Rev Bras Cir 78:317–326

Rezaee A, Solimani S, Forozandemogadam M (2005) Role of plasmid in production of Acetobacter xylinum biofilms. Am J Biochem Biotechnol 1:121–125

Svensson A, Nicklasson E, Harrah T, Panilaitis B, Kaplan D, Brittberg M, Gatenholm P (2005) Bacterial cellulose as a potential scaffold for tissue engineering of cartilage. Biomaterials 26:419–431

Tan H, Chu C, Payne K, Marra K (2009) Injectable in situ forming biodegradable chitosan–hyaluronic acid based hydrogels for cartilage tissue engineering. Biomaterials 30:2499–2506

Tsuchida T, Yoshinaga F (1997) Production of bacterial cellulose by agitation culture systems. Pure Appl Chem 69:2453–2458

Wan Y, Hong L, Jia S, Huang Y, Zhu Y, Wang Y, Jiang H (2006) Synthesis and characterization of hydroxyapatite–bacterial cellulose nanocomposites. Compos Sci Technol 66:1825–1832

Xu J, Zhang J, Gao W, Liang H, Wang H, Li J (2009) Preparation of chitosan/PLA blend micro/nanofibers by electrospinning. Mater Lett 63:658–660

Yan Z, Chen Sh, Wang H, Wang B, Jiang J (2008) Biosynthesis of bacterial cellulose/multi-walled carbon nanotubes in agitated culture. Carbohydr Polym 74:659–665

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meftahi, A., Khajavi, R., Rashidi, A. et al. The effects of cotton gauze coating with microbial cellulose. Cellulose 17, 199–204 (2010). https://doi.org/10.1007/s10570-009-9377-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-009-9377-y