Abstract

Molten inorganic salts and salt hydrates are highly efficient solvents for cellulose. The acetylation and deacetylation of the polymer dissolved in this group of cellulose solvents was investigated. The formation of cellulose acetates in molten salts with low water content and low acidity was confirmed by FT-IR-spectroscopy and 13C-CP/MAS-NMR spectroscopy. The degree of substitution was investigated by 1H-NMR measurements after perpropionylation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Molten inorganic salt hydrates were not only established as very efficient solvents of cellulose (Fischer et al. 1999a, b; Leipner et al. 2000), but they are also an interesting medium for the derivatization of this biopolymer.

Chemical functionalization reactions of cellulose starting from the polymer in homogeneous phase have undoubtedly broadened the diversity of products and reaction paths. Advances claimed for reactions starting with dissolved cellulose are a full availability of hydroxyl groups, permitting control of both the degree of substitution (DS) and the distribution of the functional groups (Heinze and Glasser 1998).

Besides the classical routes an overview of possibilities for synthesis of cellulose acetate is available (Heinze and Liebert 2001). The following classification is given:

-

Homogeneous esterification,

-

New methods of heterogeneous esterification and

-

Regioselective esterification.

The homogeneous esterification can take place in derivatizing and non-derivatizing cellulose solvents. Inorganic molten salt hydrates represent a new class of non-derivatizing solvents for cellulose. Therefore, an important topic of our work in the field of cellulose functionalization was to evaluate molten salts and molten salt hydrates as reaction medium.

After investigation of carboxymethylation reactions, a classical example for the etherification (Heinze et al. 1999; Fischer et al. 2002), the aim of this work was to study the potential of inorganic molten salts as reaction medium for the esterification of cellulose. The most important ester of cellulose is still cellulose acetate and, consequently, molten salts were applied as medium for the acetylation of cellulose on one hand and as a medium for deacetylation of cellulose triacetates (CTA) on the other hand.

The focus of interest was the distribution of acetyl groups within the anhydroglucose unit (AGU), which may be controlled by the state of dissolution of the cellulose in the different types of molten salt hydrates. The cellulose acetate samples obtained were investigated by FTIR and in detail by means of 1H-NMR after perpropionylation and 13C-CP/MAS-spectroscopy. Moreover, the cellulose acetates were analyzed by means of X-ray and TG/DTA analysis.

Materials and methods

Materials

The cellulose used was a dissolving pulp (Rosenthal, Germany) with a degree of polymerization (DPw) of 1,255, determined as cellulose nitrate according to a method described by Fischer et al. (1994). NaSCN and LiSCN·2H2O were purchased from Riedel-de Haën, KSCN, CTA, vinyl laurate and vinyl acetate from Fluka, ZnCl2 and ethylene glycol diacetate from Merck, LiClO4·3H2O from Alfa Aesar and Acetic anhydride from Feinchemie Sebnitz, Germany.

Acetylation reaction, typical example

An eutectic mixture of 7.89 g NaSCN, 22.11 g KSCN (weight ratio = 26.3–73.7%) and 3.33 g LiSCN·2H2O (10% by total weight) was heated up to a temperature of 130 °C in a closed flask with magnetic stirrer and 0.5 g refined cellulose were added. The cellulose dissolved within a few minutes. The mixture was treated stepwise with 18 g acetic anhydride and was stirred at a temperature of 130 °C for a time of 3 h. During this reaction time the melt became yellowish, later it turned dark-brown color. Isolation was carried out by precipitation in 200 ml ethanol, dissolution of the precipitate in 30 ml DMSO and reprecipitation with 200 ml ethanol. The last two purifying steps were repeated three times (sample 7).

Deacetylation reaction

20 g ZnCl2 + 4H2O were heated to a temperature of 65 °C in a closed flask with magnetic stirrer and 0.3 g of CTA was added (sample 23). The CTA dissolved within 90 min. During the reaction time of 15 h the DS decreased at a value of 1.97. The products were purified with H2O and dried at a temperature of 50 °C.

Measurements

The FT-IR measurements were performed with a Nicolet 510 spectrometer using the KBr technique. The 1H-NMR analysis was carried out with a BRUKER DPX 400 after conversion of free hydroxyl groups with propionic acid as described by Heinze et al. (2000). 13C-NMR-spectra were measured with a BRUKER MSL 300. The TGA measurements were performed with SEIKO; X-ray-diffractogramms were measured with a Siemens D 5000.

Results and discussion

Acetylation

Within the scope of this work investigation towards the acetylation of cellulose was performed in LiClO4·3H2O at a temperature of 110 °C and in a eutectic mixture of NaSCN (23.67 wt%)/KSCN (66.33 wt%) and LiSCN·2H2O (10 wt%) at a temperature of 130 °C using different acetylation reagents (acetic anhydride, vinyl acetate, ethylene glycol diacetate and vinyl laurate).

In LiClO4·3H2O almost no acetylation was observed. LiClO4·3H2O is a molten salt hydrate which is characterized by higher values of acidity and so deacetylation as competing reaction is possible. However the results show that the deacetylation depends on the acidity of the molten salt hydrates. For deacetylation of cellulose acetate (DS = 2.9) ZnCl2 + 4H2O was used (see section “deacetylation”). The values for the acidity of this melt (λmax (Fe) = 495.02 nm and λmax (MK) = 396.23) and LiClO4·3H2O (λmax (Fe) = 501.09 nm and λmax (MK) = 389.01) are similar. Otherwise the water content of this melt and the hydrolysis of acetic anhydride by water at higher temperature is another cause for not taking place of acetylation in LiClO4·3H2O.

In contrast, acetylation of cellulose is well possible in the mixture of NaSCN/KSCN/LiSCN·2H2O using acetic anhydride. Former investigations showed that the acidity of thiocyanates is generally lower than the acidity of perchlorates (Fischer et al. 1998). On the other hand this melt of thiocyanates has rather low water content and so the hydrolysis of acetic anhydride is also comparably low.

Thus, for the first time the one-step-synthesis of cellulose acetate with different degrees of substitutions in molten salts was successful.

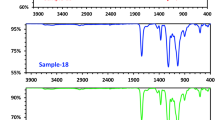

The products formed in molten thiocyanates were at first characterized by means of FT-IR spectroscopy. Signals of the carbonyl groups at 1,740–1,750 cm−1 were determined indicating the formation of cellulose acetate (Heinze and Liebert 2004).

Furthermore selected samples were characterized by means of 1H-NMR spectroscopy for the determination of the partial degrees of substitution (PDS) as described by Heinze et al. (2000). Analysis of propionylated samples revealed a preferred functionalization of the primary OH-groups.

As shown in Table 1 the DS depends on molar ratio between AGU and acetic anhydride as well as reaction time. A DS of about 1 is accessible within 30 min (samples 4 and 6). For the reaction a high surplus of acetic acid anhydride is necessary. With a molar ratio of 1:100 a DS of 2.41 can be obtained within 3 h (sample 1). All the values for molar ratio, reaction time, DS and the Partial Degree of Substitution (PDS) for some selected samples are given in Table 1. The given values are the DS values of the acetyl groups.

PDS values were determined for samples 1, 3, 4, 6 and 11. The distribution of substituents mostly shows the highest conversion for the C-6-postion. This is the same preference as for carboxymethylation in molten salt hydrates. In our opinion it confirms the proposed coordination in the salt-water-system. These data showed that interactions between cellulose and molten salts containing lithium occur preferably at position 2 and 3 of cellulose (Brendler et al. 2001) and a subsequent reaction succeeds at the free reactive sites.

In Fig. 1 the comparison of the PDS-values for these selected samples is shown. The values for the positions 2 and 3 are given as sum.

Furthermore, the cellulose acetates synthesized in molten thiocyanates were characterized by means of X-ray-diffraction. Low crystallinity was determined, that means products with disordered structure are formed. This may be due to the acetylation procedure and work up. After the actual reaction the melts were cooled down rapidly. Crystallization both of the melts as well as the cellulose acetate occurs. But during this process the faster crystallization of the salt inhibits the defined superstructure formation of the acetate, so amorphous samples are formed. A typical X-ray-diffractogramm is shown in Fig. 2.

Such amorphous products are characterized by a high reactivity on one hand and a lower thermal resistance on the other. A comparison of commercial cellulose acetates (Fluka DS = 2.9 and DS = 2.5) with the obtained products shows, that the last-mentioned have a higher mass-loss in the beginning and a lower melting point (250 °C) then the commercial products (melting point = 295–350 °C). The results of thermal analysis are shown in Fig. 3.

The spectroscopic characterization of some selected samples was possible by means of 13C-CP/MAS NMR. All these samples appear the typical signals of the acetyl group and the cellulose backbone appeared. Shape analysis of the signal confirmed the low crystallinity of the samples. The samples synthesized in molten salts do not corresponded to the two crystalline polymorphs of cellulose acetates known from the literature (Kono et al. 2002).

In Fig. 4 13C-CP/MAS NMR spectra of three typical samples synthesized in the molten thiocyanate mixture are shown in comparison to a commercial Fluka product.

Additional acetylation experiments in the mixture of NaSCN/KSCN/LiSCN·2H2O with vinyl acetate, ethylene glycol diacetate and vinyl laurate did not yield cellulose esters during a reaction time of 10 h. Prolongation of the conversion could give an acetylated product and will be part of the ongoing research.

Deacetylation

In a final set of experiments the deacetylation of cellulose triacetate (CTA) in ZnCl2 + 4 H2O was studied. The values for deacetylation of the CTA-samples are shown in Table 2.

The samples were investigated by means of FT-IR, the DS and PDS were again determined by the 1H-NMR spectroscopy after perpropionylation. No side reactions were observed. As illustrated in Table 2 the deacetylation depends on the reaction time, i.e. the DS can be simply controlled by the time of treatment. Consequently, this procedure is a defined and simple deacetylation path for cellulose acetates.

Conclusions

Salt melts, e. g. eutectic mixtures of NaSCN/KSCN/LiSCN·2H2O are not only new solvents for cellulose; they can also be applied as media for chemical derivatization. Beside etherification the acetylation as typical esterification is possible too. The synthesis of cellulose acetates only can be carried out in molten salts with low water content and low acidity.

Unlike the commercial production of cellulose acetates (DS 2.5) which is usually performed as a two-step-reaction the synthesis of well soluble cellulose acetates in molten salts is possible in one step. The molar ratios between AGU and acetic anhydride as well as the reaction time have a strong influence on the obtainable DS. So the required DS can be obtained.

References

Brendler E, Fischer S, Leipner H (2001) 7Li NMR as probe for solvent-cellulose interactions in cellulose dissolution. Cellulose 8:283–288

Fischer K, Schmidt I, Hintze H (1994) Untersuchungen zur Substituentenverteilung in Cellulosexanthogenat. Das Papier 48:769–774

Fischer S, Voigt W, Fischer K, Spange S, Vilsmeier E (1998) Behaviour of cellulose in hydrated melts. Molten Salt Forum 5–6:477–480

Fischer S, Voigt W, Fischer K (1999a) The behaviour of cellulose in hydrated melts of the composition LiX nH2O (X = I−, NO3−, CH3COO−, ClO4−). Cellulose 6:213–219

Fischer S, Leipner H, Brendler E, Voigt W, Fischer K (1999b) Molten inorganic salt hydrates as cellulose solvents. ACS Symposium Series 737:143–150

Fischer S, Thümmler K, Pfeiffer K, Liebert T, Heinze Th (2002) Evaluation of molten inorganic salt hydrates as reaction medium for the derivatization of cellulose. Cellulose 9:293–300

Heinze Th, Glasser W (1998) The role of novel solvents and solution complexes for the preparation of highly engineered cellulose derivatives. ACS Symposium Series No. 688:2–18

Heinze Th, Liebert T (2001) Unconventional methods in cellulose functionalization. Prog Polym Sci 26:1689–1762

Heinze Th, Liebert T (2004) Chemical characteristics of cellulose acetate. Macromol Symp 208:167–237

Heinze Th, Liebert T, Klüfers P, Meister F (1999) Carboxymethylation of cellulose in unconventional media. Cellulose 6:153–165

Heinze Th, Dicke R, Koschella A, Kull AH, Klohr E-A, Koch W (2000) Effective preparation of cellulose derivatives in a new simple cellulose solvent. Macromol Chem Phys 201:627–631

Kono H, Erata T, Takai M (2002) CP/MAS 13C NMR study of cellulose and cellulose derivatives. 2. Complete assignment of the 13C resonance for the ring carbons of cellulose triacetate polymorphs. J Am Chem Soc 124(25):7512–7518

Leipner H, Fischer S, Brendler E, Voigt W (2000) Structural changes of cellulose dissolved in molten salt hydrates. Macromol Chem Phys 201:2041–2049

Acknowledgments

The financial support of the Deutsche Forschungsgemeinschaft (DFG) is gratefully acknowledged. Moreover, the authors would like to thank the “Fachagentur nachwachsende Rohstoffe e. V.” (project 22021905) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thümmler, K., Fischer, S., Peters, J. et al. Evaluation of molten inorganic salt hydrates as reaction medium for the esterification of cellulose. Cellulose 17, 161–165 (2010). https://doi.org/10.1007/s10570-009-9344-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-009-9344-7