Abstract

This paper reviews the progress in our development of the three-way catalyst with a noble metal sintering suppression technology based on the support anchoring effect. The catalytic activity on this catalyst is far superior to the conventional catalyst, but with lower noble metal loading.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, automobile is necessary and indispensable for our daily life. More than 50 million cars are manufactured every year, and totally over 700 million cars are being used worldwide. Gasoline-engine cars emit the pollutants of carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) in the exhaust gases. Since three-way catalysts were introduced for detoxifying the three pollutant gases in the US and Japan in 1977, they played an important role for environmental protection and be absolutely necessary in each vehicle. They reduce the pollutant emission drastically, but more efforts are still needed to improve the catalytic performance and meet the upcoming more stringent emission restrictions.

The circumstance met by the exhaust catalysts is far more different from that of catalysts used in chemical factories. The composition, temperature, and flow amount of automotive exhaust gases vary continuously with driving conditions. The automotive catalyst is requested to purify infinitesimally small amounts of the toxic gases in the exhaust perfectly under the unsteady condition, and meanwhile has a life-long durability.

Basically, the three-way catalysts are composed of several components, including noble metals, Pt and Rh as the active site, alumina-based supports with a high surface area even at high temperatures, and ceria-based oxides as an oxygen storage component. One of the biggest issues for three-way catalysts is the degradation of catalytic activity caused by sintering of noble metals as active sites. Many attempts had been tried to improve catalytic activity after ageing the catalysts, such as enhancing the noble metal dispersion with high surface area supports, adding some promoters, and improving thermal stability of these supports and promoters, etc [1–11]. Thermal stabilization of alumina support has been conducted. Addition of rare earth and alkaline earth compounds to alumina in a transition state has prevailed as one of the most useful techniques [6, 7]. The thermal stability of ceria-zirconia compound as oxygen storage material has been largely improved by mixing with nano-sized alumina particles as a diffusion barrier [10, 11]. However, no efficient solution for suppressing noble metals sintering had been established and eventually resulted in the large usage of noble metal in the automotive three-way catalysts to meet the stringent emission restrictions. On the other hand, as the very sparse resources, the usage of noble metals as active sites should be reduced as much as possible for the automotive catalysts.

Through the investigation of sintering behavior of noble metals on the oxide supports, it was found that some supports could efficiently suppress noble metal sintering that is caused by anchoring effect on the supports. As a result, a new three-way catalyst has been successfully developed by applying this concept.

In this paper, the progress in the development of the new three-way catalyst is reviewed. The sintering behavior of noble metals, particularly Pt, is explained first by a systematical investigation on clarifying the effect of ageing in exhaust gases atmosphere. The suppression mechanism of Pt on cerium-based oxide and anchoring effect on the catalysts are then discussed, and the development process of the new three-way catalyst is also presented.

2 Sintering Behavior

Characterizations of deactivation phenomena on thermally aged catalysts are extremely important in terms, not only of improvement in the catalyst life, but also of suitable use of noble metal resources as described above.

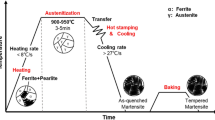

It was well known that severe thermal experiences of the catalysts lead to the sintering of noble metals and lose catalytic activity. Sintering of noble metals has been widely investigated and the sintering rate of noble metals is largely dependent on the experimental conditions, e.g., substrate morphology, purities of catalyst species and support materials, composition of ageing atmospheres, temperature, and time [12–17]. In particular, ageing atmosphere in high temperature region was the key point for noble metal sintering through our experience. Therefore, noble metal sintering and variation in the activity of noble metal catalysts were systematically characterized with a simplified catalyst system, a single noble metal loaded on alumina support and aged in various atmospheres with various oxygen contents [18]. Figure 1 shows the catalytic activity of an aged Pt catalyst in 5 vol% O2 synthetic exhaust gas at 1,100 °C compared with that of the fresh one. Clearly the activity of the aged Pt catalyst degraded significantly. The NO conversion profiles over the catalysts aged in gases with various O2 contents are shown in Fig. 2. With increasing O2 contents in the aged atmosphere, the catalytic activity decreased apparently. Table 1 lists the Pt particle sizes obtained from XRD data on the aged catalysts. The particle size remarkably increased with increasing O2 content. It is known that Pt-supported on alumina sinters easily under oxidative conditions [12–14]. The results shown in Fig. 2 and Table 1 demonstrate that sintering of Pt particles is accelerated by increasing O2 content in the ageing atmosphere, and leads to the deterioration of the activity of Pt catalysts. Similar results were gained on Rh loaded alumina catalyst (Fig. 3), namely with increasing oxygen concentration, the Rh particle size increased and consequently the catalytic activities decreased. The effect of Pt sintering on the catalytic activity was more significant compared with that of Rh. The degree of sintering depends on the vapor pressure of a given species on the catalysts.

Light-off performance in the simulated exhaust gas on the fresh Pt alumina catalyst and the aged one in 5 vol% O2 simulated exhaust gas at 1,100 °C for 5 h [18]

NO conversion profiles on the aged Pt alumina catalysts in various O2 content exhaust gas at 1,100 (or 1,000) °C for 5 h [18]

NO conversion profiles on the aged Rh alumina catalysts in various O2 content exhaust gas at 1,100 (or 1,000) °C for 5 h [18]

These results suggest the importance to suppress the noble metal sintering, particularly Pt, in oxidizing atmosphere. Therefore, Pt is subjected to the principal species for sintering suppression.

3 Sintering Suppression and the Mechanism [19]

Through the catalyst development, it was found that Pt sintering behavior differed by the kinds of supports. Figure 4 shows the transmission electron microscopy (TEM) images of Pt/alumina and Pt/CZY as ceria-based oxide after ageing treatment at 800 °C in air for 5 h. On the aged Pt/alumina, Pt particles larger than 100 nm were observed, while on the other hand, no explicit Pt particles are detected on the CZY by energy dispersive X-ray analysis. Moreover, the results by the CO pulse adsorption method indicated that Pt on the alumina sintered markedly, but did not on the ceria-based oxide (Fig. 5).

TEM images of Pt supported catalysts after ageing at 800 °C in air for 5 h. a Pt/alumina, b Pt/CZY(CeO2(50 wt%)-ZrO2(46 wt%)-Y2O3(4 wt%)) [19]

Pt particle sizes on the fresh and aged catalysts by CO pulse adsorption method [19]

To clarify the cause of the inhibited Pt sintering on CZY, the state of the aged catalysts was investigated by X-ray absorption fine-structure (XAFS). Figure 6 shows the X-ray absorption near-edge structure (XANES) spectrum at Pt L3-edge for the aged catalysts and reference samples. The steeply rising absorption edge is referred to as the “white line”. In the case of the Pt L-edge XANES, the absorption intensity of the white line reflects the vacancy in the 5d orbital of Pt atoms [20]. A large white line was observed on oxidized Pt, whereas a small white line was observed on reduced Pt. The white line intensity of Pt/alumina was the same as that of Pt foil, suggesting that the Pt on alumina was in the Pt metal state after the ageing. In contrast, the white line intensity of Pt/CZY was similar to that of PtO2, implying that high-oxidation state Pt species was present mainly in the aged Pt/CZY. The average oxidation state of Pt can be quantitatively evaluated from the white line intensity and the oxidation state of PtOx on some metal oxide supports [21]. On the basis of this linear relationship, the estimated oxidation state of Pt was zero in the aged Pt/alumina, and 3.53 in the aged Pt/CZY. It is well known that PtO2 decomposes to Pt metal under oxidizing conditions from around 600 °C according to the thermodynamics phase diagram [22]. Pt existing in metal state on alumina after ageing at 800 °C in the oxidizing atmosphere was consistent with the thermodynamic speculation. On the other hand, the CZY support could stabilize a high-oxidation state of Pt even after ageing. Thus, it is suggested that the strong metal-support interaction in the Pt/CZY under oxidizing condition causes the stabilization of the high-oxidation state of Pt.

Pt L3-edge XANES spectra for supported Pt catalysts after aged at 800 °C in air with the standard samples of Pt foil and PtO2 powder [19]

Fourier transforms (FT) of the aged catalysts and reference samples are presented in Fig. 7. The quantitative curve-fitting analysis of the extended X-ray absorption fine-structure (EXAFS) spectra was performed for the inverse FT on the Pt-oxygen and Pt-cation (Pt, Ce and Zr) shells. In the FT spectrum of Pt foil, the peak at 2.76 Å is assigned to Pt–Pt bond. In the FT spectrum of PtO2 powder, the peaks at 2.04 and 3.10 Å are assigned to the Pt–O and Pt–O–Pt bonds, respectively. As for the aged Pt/alumina, only the intense peak at 2.76 Å, which corresponds to the Pt–Pt bond, was observed. The FT spectrum of Pt/alumina coincided with that of Pt foil. The coordination number (CN) of the Pt–Pt shell in the aged Pt/alumina was 11.5, indicating that the Pt metal particles on alumina after ageing were at least 20 nm in size [23]. The FT spectrum of Pt/CZY after ageing was obviously different from that of the Pt/alumina. The position of the first peak at 2.02 Å was close to that of PtO2, and this peak was fitted with the Pt–O bond. It should be noted that the second evident peak, which was absent in both Pt foil and PtO2 powder, was found 3.01 Å. A curve-fitting simulation of this second peak was carefully performed, and this peak was concluded to be a Pt–O–Ce bond. The CN of Pt–Ce shell in the aged Pt/CZY was 3.5. This value is lower than the saturated CN of 12 in a cubic fluorite structure, indicating that Pt ions exist on the surface of the CZY support. In addition, intense Pt–Pt or Pt–O–Pt peaks could not be observed in the aged Pt/CZY, suggesting that there are no large Pt metal or oxide particles on the support. In other words, highly dispersed Pt oxides are present on the surface of the CZY support. Figure 8 shows the FTs of the aged Pt/CZY, which in the same spectrum mentioned in Fig. 7, and the reduced Pt/CZY after ageing. The aged Pt/CZY was reduced by 5% H2 at 400 °C. After the reducing treatment, the Pt–O peak in the aged Pt/CZY decreased significantly, and the Pt–O–Ce peak almost disappeared. In addition, intense Pt–Pt peak could not be observed in the reduced Pt/CZY. These results suggest that the Pt–O–Ce bond breaks by the reduction treatment and that Pt metal particles are highly dispersed on the CZY support. According to the results from the CO pulse method mentioned above, the estimated average size of Pt metal particles in the reduced Pt/CZY after ageing is ca. 1 nm.

Fourier-transforms of Pt L3-edge EXAFS spectra for the CZY catalysts after aged at 800 °C in air and subsequent reduction treatment [19]

Based on the observations above, Fig. 9 illustrates the sintering suppression mechanism of Pt supported on ceria-based catalyst. In the case of alumina support, since the interaction between Pt and alumina is weak, Pt particles are apt to migrate across the surface of the alumina and sinter easily in oxidizing high temperature condition. In contrast, the ceria-based oxide support stabilizes a high-oxidation state of Pt, and then the formation of the rigid Pt–O–Ce bond acts as an anchor. The formation of the Pt–O–Ce bond on the support suppresses the sintering of Pt.

In order to generalize the Pt-support interaction, a systematic investigation was conducted on Pt catalysts supported on various oxides, such as SiO2, TiO2, etc. On various Pt catalysts after ageing test in air, (1) Pt particle size by the CO pulse method, (2) Pt oxidation state by height of white line in XANES spectra, and (3) electron density of oxygen in the supports by X-ray photoelectron spectroscopy (XPS) binding energy of O 1 s electron, were characterized. In terms of the electron density of oxygen in the support, the binding energy of the O(1 s) electron in the support oxide was analyzed by XPS. The binding energy of the O(1s) electron decreased as SiO2 > Al2O3 > ZrO2 > TiO2 > CeO2 > CZY. Figure 10 shows the correlation among the three factors, and these three factors are perfectly correlated with each other. That is, the white line height increases with decreasing binding energy of the O1S electron. Subsequently, Pt particle size increases as the electron density of oxygen in the support decreases. As a result, the sintering suppression effect on Pt can be controlled by the electron density of oxygen in the support through the Pt-support interaction.

Pt–oxide support interaction and correlation with Pt sintering in an oxidizing atmosphere [19]

Considering the application of this concept toward a practical use, Pt should be metallic state in stoichiometic atmosphere of main driving condition, and form Pt–oxide bond in occasional oxidizing condition. It was found that cerium-based oxide is suitable for Pt to achieve a good balance between catalytic activity and suppression the sintering (Fig. 11).

Conceptual scheme of a suitable support for Pt [26]

4 Specification and Development

Thermal durability of cerium oxide is insufficient for automotive use. Therefore, cerium-based compound containing some additives such as cerium–zirconium oxide are generally used in practical exhaust catalyst. From the results of XAFS analysis described above (Fig. 7), the Pt–O–Ce is identified to form on cerium site with neighboring cerium as cation site in cerium-based oxide. Accordingly, the amount of the site for Pt–O–Ce bond can be estimated from cerium composition and surface area of each cerium-based compound. Figure 12 shows the effect of Pt loading amount on a cerium-based oxide (CeO2(55 wt%)-ZrO2) after ageing test at 950 °C [24]. Δ[dis] means the difference of the Pt dispersion on the aged catalyst from that on the fresh one. In this case, the amount of site for Pt–O–Ce bond corresponds to 0.25 wt% Pt loading amount on the sample. The result indicates that Pt did not sinter at all when Pt loading is lower than 0.25 wt%, while Pt sintered when its loading is higher than 0.25 wt%. The degradation tendency of catalytic activities on these samples correlated very well.

Effect of Pt loading amount for sintering suppression. Pt loaded ceria-based oxide was aged at 950 °C for 5 h in a simulated exhaust gas. Pt dispersion was measured by the CO pulse adsorption method after an oxidation–reduction pretreatment at 800 °C [26]

Figure 13 shows the catalytic activities of 0.1 wt% Pt loaded on three different supports. Among the three catalysts, the catalytic activity of the catalyst with cerium-based oxide support did not degraded and turned out to be the highest even after the ageing test at 900 °C [25].

Effect of support oxides for catalytic activities at 0.1 wt% Pt loading after aged at 900 °C in a simulated exhaust gas [26]

Cerium-based oxide is suitable for Pt support to achieve a good balance between catalytic activity and the sintering suppression as described above. On the other hand, for Rh catalyst, zirconia-based oxide was found to meet the requirements by the similar mechanism. Rh is more stable in the oxide state and thus generates stronger interaction with oxide supports compared with Pt in oxidizing condition. Therefore, due to its lower electron density than ceria-based oxide, zirconia-based oxide support is suitable for Rh support.

Considering a catalyst configuration with noble metals of Pt and Rh and support oxides, three-type of catalysts was compared; (1) both Pt and Rh coexistence on ceria-based oxide, (2) blend with Pt and Rh supported separately on ceria-based oxide, (3) blend with Pt on ceria-based oxide and Rh on zirconia-based oxide [26]. Figure 14 shows catalytic activity of the three after ageing test at 1,000 °C. The last one which Pt loaded on the ceria-based oxide and Rh on zirconia-based oxide, exhibited the best catalytic activity, because the sintering of Pt and Rh were both efficiently suppressed by the interaction with their own suitable supports.

Effect of configuration with 0.2 wt% Pt and 0.17 wt% Rh in catalysts for catalytic activities after aged at 1,000 °C in a simulated exhaust gas [26]

From these results, a new three-way catalyst was designed with the concept of the support anchoring effect. Figure 15 shows the catalytic activity in engine test after engine ageing treatment [27].

Performance of the developed catalyst with the Pt-support interaction concept in engine bench test after engine ageing [27]

The developed catalyst in which Pt loaded on ceria-based oxide and separately Rh on zirconia-based oxide shows high catalytic activity compared with the conventional one although the developed catalyst contained fewer precious metal. This catalyst has been put into practical use in gasoline-engine automobiles since 2005.

5 Conclusion

One of the biggest issues for three-way catalysts is the degradation of catalytic activity caused by sintering of noble metals as active sites. Suppression of the noble metal sintering, particularly Pt, was studied systematically leading to the successful development of a new three-way catalyst. It was found that the Pt sintering on the catalysts occurred in high temperature ageing, especially under oxidizing atmosphere. The atomic level X-ray absorption analysis on the support effect to the Pt sintering was conducted under an oxidizing atmosphere and it revealed that, the Pt–O–M (M: cation of oxide, i.e., cerium oxide) bond formed on some oxide supports (MOx) acting as an anchor to suppress the Pt sintering, and the strength of the Pt–oxide support interaction well correlated with the electron density of oxygen in the support oxide.

Considering the actual application with this concept of Pt-support interaction, Pt on the catalyst should be in a metallic state under stoichiometric atmosphere of main driving condition, and form Pt–oxide bond occasionally under oxidizing condition. To achieve a good balance between catalytic activity and the sintering suppression, it was found that ceria-based oxide is suitable for Pt. The effect of Pt loading amount on Pt sintering was investigated to ascertain the proper Pt amount on ceria-based oxide supports. Pt sintering did not occur with a certain Pt loading amount after an oxidizing durability ageing, and its catalytic activity also did not deteriorate at all after the ageing. This Pt amount corresponded well with the number of Pt–O–Ce sites on the support. For the catalysts with the same Pt loading but on the other different oxide supports, such as zirconia and alumina, their catalytic activities deteriorated severely after the ageing, while on the other hand, zirconia-based oxide was verified to be the appropriate support for Rh through the similar investigation.

Through optimizing the configuration of Pt and Rh in the catalyst, a novel three-way catalyst with Pt loading on ceria-based oxide and separately Rh on zirconia-based oxide was devised and developed successfully. This catalyst with lower noble metal content exhibited higher catalytic activity compared with the conventional catalyst after a durability test.

References

Gandhi KC, Piken AG, Shelef M, Delosh RG (1976) SAE paper No. 760201

Trovarelli A (1996) Catal Rev Sci Eng 38:439

Kaspar J, Fornasiero P, Hickey N (2003) Catal Today 77:419

Ozawa M, Kimura M, Sobukawa H, Yokota K (1992) R&D Rev of Toyota CRDL 27–3:43

Nagai Y, Yamamoto T, Tanaka T, Yoshida S, Nonaka T, Okamoto T, Suda A, Sugiura M (2002) Catal Today 74:225

Miyoshi N, Matsumoto S, Ozawa M, Kimura M (1989) SAE paper No. 891970

Ozawa M, Kimura M, Isogai A (1990) J Less-Common Met 162:297

Oudet F, Courtine P, Vejux A (1988) J Catal 114:112

Ismagilov ZR, Shkrabina RA, Koryabkina NA, Arendarskii DA, Shikina NV (1998) Stud Surf Sci Catal 116:507

Suzuki T, Morikawa A, Sobukawa H, Kimura M, Suda A, Sugiura M (2001) 88th Meeting. Catal Soc Jpn 3A09

Kanazawa T, Suzuki J, Takada T, Suzuki T, Morikawa A, Suda A, Sobukawa H, Sugiura M (2003) SAE paper No. 2003-01-087

Burch R (1985) In: Bond GC, Webb G (eds) Catalysis, vol 7. The Royal Society of Chemistry, London, p 175

Fiedorow RMJ, Wanke SE (1976) J Catal 43:34

Fiedorow RMJ, Chahar BS, Wanke SE (1978) J Catal 51:193

Harris PJF (1986) J Catal 97:527

Bartholomew CH (2001) Appl Catal A 212:17

Birgersson H, Eriksson L, Boutonnet M, Jaras SG (2004) Appl Catal B 54:193

Shinjoh H, Muraki H, Fujitani Y (1991) Stud Surf Sci Catal 71:617

Nagai Y, Hirabayashi T, Dohmae K, Takagi N, Minami T, Shinjoh H, Matsumoto S (2006) J Catal 242:103

Mansour AN, Cook JW, Sayers DE (1984) J Phys Chem A 88:2330

Yoshida H, Nonoyama S, Yazawa Y, Hattori T (2005) Phy Scr T 115:813

Livingstone SE (1973) Pergamon Text Inorg Chem 25

Greegor RB, Lytle FW (1980) J Catal 63:476

Hatanaka M, Takahashi N, Tanabe T, Nagai Y, Dohmae K, Shinjoh H (2007) 100th Meeting. Catal Soc Jpn 3G27

Hatanaka M, Takahashi N, Tanabe T, Nagai Y, Suzuki N, Morikawa A, Kadoura H, Shinjoh H (2008) 102th Meeting. Catal Soc Jpn 4D02

Shinjoh H, Hatanaka M, Nagai Y, Tanabe T, Takahashi N, Yoshida T, Miyake Y (2009) Top Catal. doi:10.1007/s11244-009-9371-5

Yoshida T, Sato A, Suzuki H, Tanabe T, Takahashi N (2006) SAE paper 2006-01-10

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shinjoh, H. Noble Metal Sintering Suppression Technology in Three-way Catalyst: Automotive Three-way Catalysts with the Noble Metal Sintering Suppression Technology Based on the Support Anchoring Effect. Catal Surv Asia 13, 184–190 (2009). https://doi.org/10.1007/s10563-009-9076-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10563-009-9076-6