Abstract

Metallic doping effectively extends the light response range of TiO2 photocatalysts from the ultraviolet (UV) to the visible region. We prepared Ce-doped TiO2 nanotubes (Ce-TiO2 NTs) using a sol–gel process followed by a hydrothermal treatment. The Ce-TiO2 NTs were characterized by X-ray diffraction, transmission electron microscopy, Brunauer–Emmett–Teller surface area, X-ray photoelectron spectroscopy, UV–Vis diffuse reflectance spectroscopy (UV–Vis DRS), and photoluminescence (PL) spectroscopy. Given that the optical absorption was extended to wavelengths of 600 nm, the Ce-TiO2 NTs demonstrated excellent photocatalytic activity for degrading methylene blue under visible light irradiation. Ce-TiO2 NTs with various amounts of Ce doping (0.06–0.40 g of cerium nitrate hexahydrate added during preparation) were tested, and the 0.12Ce-TiO2 NTs showed the highest photocatalytic activity, 7 times higher than that of P25. For their efficient photodegrading of dyes under visible light, these Ce-TiO2 NTs may be useful for waste water treatment.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Semiconductor photocatalysts have a wide variety of applications, such as sustainable energy generation and environmental pollution treatment. TiO2 has been one of the most investigated photocatalytic materials, given its efficient photocatalytic activity and high stability [1, 2]. However, for practical photocatalytic applications, pure TiO2 is limited, because it is only active under ultraviolet (UV) light irradiation due to its large band gap of 3.2 eV for the anatase phase. A variety of methods have been used to enhance the photocatalytic behavior of TiO2, including non-metal doping [3–6] and metal doping [7–9]. Recently, extensive research has been conducted on the synthesis and characterization of TiO2 nanotubes owing to their novel properties, such as unique shape, size confinement in the radial direction, and large specific surface area [10–14]. TiO2 nanotubes combine the properties of layered titanates with the properties and applications of conventional TiO2 nanoparticles. The unique physicochemical properties of nanostructured titanates, together with their unusual morphology, make these materials very promising for many applications, such as catalysis (photocatalysis, electrocatalysis) [15–21], H2 storage and separation [22, 23], and lithium batteries [24, 25].

Among the rare earth elements used as photocatalyst dopants, cerium is an efficient electron acceptor that removes photogenerated electrons from electron–hole recombination sites, thereby increasing the quantum yield and enhancing the photocatalytic activity [26–28]. Ce doping is also known to inhibit loss of the catalyst surface area, which can improve catalytic activity, phase stability [29, 30], and preservation of ordered mesoporous structures [31, 32]. Moreover, it can easily form labile oxygen vacancies (OVs) because of the relatively high mobility of bulk oxygen species. Ce-doped TiO2 nanotubes (Ce-TiO2 NTs) have previously been prepared through hydrothermal treatment of rutile-phase TiO2 nanoparticles followed by impregnation of cerium salt, and their use for degradation of glyphosate with a high-pressure mercury lamp as a light source has been demonstrated [33]. Ce-TiO2 NTs have also been used for flame retardancy of an intumescent flame-retardant polystyrene system [34]. However, there have been no reports on the catalytic performance of Ce-TiO2 NTs under exclusive visible light conditions. To this end, we prepared Ce-TiO2 NTs using a sol–gel process followed by hydrothermal treatment, a method different from the previous reported [33–35]. The prepared Ce-TiO2 NTs were characterized by X-ray diffraction (XRD), transmission electron microscopy (TEM), Brunauer–Emmett–Teller surface area (BET), X-ray photoelectron spectroscopy (XPS), UV–vis diffuse reflectance spectroscopy (UV–Vis DRS), and photoluminescence (PL) spectroscopy. The prepared Ce-TiO2 NTs demonstrated 7 times more efficient than P25 (commercial TiO2 nanoparticles) in degrading methylene blue (MB) under visible light conditions. To the best of our knowledge, this study presents the first use of Ce-TiO2 NTs for degradation of organic materials under exclusive visible light conditions.

2 Experimental Procedures

2.1 Photocatalyst Preparation

Ce-TiO2 NTs were prepared by a sol–gel process followed by hydrothermal treatment using tetrabutyl titanate (TBOT) as the host precursor and cerium nitrate hexahydrate as the dopant precursor. In a typical synthesis, 10 mL of TBOT was mixed with 10 mL of ethanol to make solution A. Various amounts of cerium nitrate hexahydrate (0.06–0.40 g), depending on the desired doping, together with 0.5 mL of HNO3, were dissolved in 10 mL of ethanol to make solution B. Then, solution A was slowly added to solution B accompanied by vigorous stirring. After 20 min, 2.5 mL of H2O was added dropwise to the mixture. The solution first became sol and then gel. The gel stood for 10–12 h and was then dried in an oven at 100 °C followed by a heat treatment at 550 °C for 4 h. The product was Ce-TiO2. Next, 400 mg Ce-TiO2 powder was mixed with 50 mL of a 10 M NaOH aqueous solution in a Teflon vessel. This solution was kept at 150 °C for 24 h. Then, the sample was washed with a 0.1 M HCl solution and deionized water, successively. Finally, the particles were dried in an oven at 60 °C. The samples were denoted xCe-TiO2 NTs, where x was the amount of cerium nitrate hexahydrate added in grams to solution B, as described above.

P25 (TiO2, 80 % anatase, 20 % rutile, Degussa Co. Ltd.) was used as a control catalyst. Pure TiO2 NTs were prepared in the absence of Ce-dopant as above described.

2.2 Characterization

Powder XRD was performed on a Rigaku D/MAX-2550 diffractometer with monochromatized Cu Kα radiation (λ = 1.5406 Å). TEM images were taken with a JEOL JEM-2010. The chemical states of the samples were examined by XPS (Perkin-Elmer PHI 5000C ESCA System) with Al Kα radiation operating at 250 W. UV–Vis DRS of P25 and Ce-TiO2 NT were recorded in the range from 220 to 800 nm using a Shimadzu UV-2600 spectrophotometer with BaSO4 as a reference. The surface area was determined with a standard BET apparatus (Micrometrics ASAP 2010 N). The PL spectra were measured by a fluorospectrophotometer (Horiba Fluoromax-4) using a Xe lamp as the excitation source at room temperature.

2.3 Measurement of Photocatalytic Properties

The photocatalytic measurements were carried out in an open thermostatic photoreactor. Before light irradiation, a suspension containing 100 mL of 20 mg MB solution and 15 mg of the catalyst was stirred for 30 min in the dark to allow sorption equilibrium. Then, the mixture was irradiated with a 300 W Xenon lamp equipped with a 400 nm cut-off filter. After a given time interval of irradiation, 4 mL aliquots were withdrawn. The residual concentration of MB in the aliquots was analyzed using a UV–vis spectrophotometer.

3 Results and Discussion

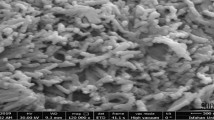

3.1 XRD and TEM Analysis

Figure 1 shows the XRD pattern of the Ce-TiO2 NTs. The spectra of the Ce-TiO2 NTs displayed peaks arising from titanate NTs [36]. From all the diffraction patterns, it was also clear that the Ce-TiO2 nanotubes were quite small, as the peaks were very broad. TEM measurements were performed to confirm this morphology. Figure 2 shows typical TEM images of the 0.12Ce-TiO2 NTs. The needle shapes were nanotubes with outer diameters of approximately 10 nm and lengths of hundreds of nanometers. Figure 2 indicates the nanotubes were hollow and open ended, and their diameters were nearly uniform. TEM examination of the sample indicated the content of NTs was close to 100 %, and the NTs were found been formed in the hydrothermal process.

3.2 BET and XPS Analysis

Figure 3 shows the nitrogen adsorption–desorption isotherm and pore size distribution curve of 0.12Ce-TiO2 NTs. The sample exhibited a type IV adsorption isotherm, which is typical of a well-defined mesoporous structure. The pore size distribution was estimated from the desorption branch of the nitrogen isotherm by the Barret–Joyner–Halenda (BJH) method. For the typical 0.12Ce-TiO2 NTs, the mean pore size and BET surface area were 6.3 nm and 209.6 m2 g−1, respectively. Compared with P25 (~50 m2 g−1), the larger surface area will allow the 0.12Ce-TiO2 NTs to adsorb more dye molecules and incident light.

The synthesized 0.12Ce-TiO2 NTs were further characterized by XPS to determine the main elements and chemical states on the TiO2 surface (Fig. 4). The surface of the 0.12Ce-TiO2 NTs sample was composed of Ti, O, C, and Ce. The binding energies of Ti 2p1/2 and Ti 2p3/2 for the 0.12Ce-TiO2 NTs sample were at 464.5 and 458.8 eV (Fig. 4b). There was no shift of Ti toward lower binding energy induced by doping with Ce, and Ti existed mainly in the form of Ti4+. Figure 4c illustrates the O 1s spectra for the 0.12Ce-TiO2 NTs sample. A prominent peak at 530.3 eV is ascribed to Ti–O bonds in TiO2. Figure 4d shows the Ce 3d XPS of the 0.12Ce-TiO2 NTs sample. The XPS of Ce 3d was quite complicated owing to the hybridization of Ce 4f with O 2p electrons and the partially-occupied valence of 4f orbitals. According to previous reports, XPS peaks denoted as V1 (881.8 eV), V3 (886.3 eV), U0 (894.9 eV), V4 (900.4 eV), U3 (904.1 eV), and U4 (913.1 eV) can be attributed to Ce4+ species, while V0 (880.5 eV), V2 (885.3 eV), U1 (896.9 eV), and U2 (902.6 eV) can be attributed to Ce3+ species [27, 37, 38]. Due to the very weak and complexity of the spectra, it was difficult to get good deconvolution of the spectra. We tentatively to propose that the Ce was probably doped in the structure of TiO2 NTs, given the apparent similarities of the observed binding energies of Ce3+/Ce4+ to those of the Ce-doped TiO2 [27].

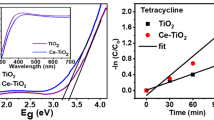

3.3 UV–Vis Diffuse Reflectance Spectra Analysis

Figure 5 shows the UV–vis diffuse reflectance spectra for the samples, along with commercial Degussa P25. The samples of Ce-TiO2 NTs absorb more strongly than the Degussa P25 in the visible light region. The absorbance of Ce-TiO2 NTs increases with increasing Ce doping. The absorbance of the 0.40Ce-TiO2 NTs sample in the visible light region was highest among these samples. This indicates that Ce doping can greatly improve the absorption of visible light. Specifically, the 4f electronic configuration of Ce plays a crucial role in generating electron–hole pairs with visible light absorption, improving visible light response [39].

3.4 Photocatalytic Measurements

We evaluated the photocatalytic activity of the Ce-TiO2 NTs by photodegrading MB under visible light (λ > 400 nm); the result is shown in Fig. 6. Commercial P25 powder and pure TiO2 NTs were used as control photocatalysts. From Fig. 6, it is clear that Ce-TiO2 NTs were significantly better for photodegrading MB than P25 as well as pure TiO2 NTs. Furthermore, the photocatalytic efficiency varied with the amount of Ce in the samples, and the 0.12Ce-TiO2 NTs exhibited the highest photocatalytic activity. When the Ce amount increases from 0.06 to 0.12 g, there is more of the dominant Ce4+ to capture electrons, thus a greater photocatalytic activity. However, if the Ce amount increases from 0.12 to 0.40 g, excess Ce4+ may introduce the indirect recombination of electrons and holes, thereby reducing the photocatalytic activity significantly [26]. Under visible light irradiation, 85 % of the initial dyes were decomposed by the 0.12Ce-TiO2 NTs after 2 h. In contrast, nearly 88 % of the initial dye still remained in the solution with P25 under the same experimental conditions. Several basic factors affect the photocatalytic process, such as light absorption, adsorption of contaminant molecules, and the charge transportation and separation [40, 41]. One reason for the better photocatalytic performance of Ce-TiO2 NTs is the enhanced adsorption of the MB, which is a prerequisite for good photocatalytic activity [42, 43]. As reactants must collide with Ce-TiO2 NTs and remain in contact for the photocatalysis to proceed, enhanced adsorption of MB provides a high concentration of reactants close to the surface of the Ce-TiO2 NTs, thus resulted in the increased photoactivity; while for the non-adsorbed reactants, they just collide with the Ce-TiO2 NPs by chance, and will pass back into solution and can only react further when they collide with the Ce-TiO2 NPs again. We observed that after equilibrium in the dark for 30 min, a large amount of dye was adsorbed on the surface of the Ce-TiO2 NTs, whereas most dye molecules remained in solution with bare P25 as the catalyst. The second reason for the enhanced photocatalytic ability of Ce-TiO2 NTs is ascribed to the Ce4+ dopant. The excited electron can be trapped by Ce4+ ions because of its varied valences and special 4f level, as illustrated by the following equations [43, 44]:

The photoactivity of non-doped pure TiO2 NTs was much lower than that of the Ce-doped TiO2 NTs (Fig. 6), indicating the significant role played by the Ce-dopant. This suggested that it was the Ce-dopant rather than the NTs morphology responsible for the enhanced photocatalitic activity. In the meantime, owing to the nanosized effect of the nanotubes, the decrease in electron–hole recombination and fast interfacial charge carrier transfer may have also contributed to the improvement of photocatalytic performance of the 0.12Ce-TiO2 NTs.

It is worth to note that the photoactivity of the Ce-TiO2 NTs doesn’t necessarily coinside with the samples’ absorption trend in the visble region. A little variation of the Ce-dopant amount will influence the photocatalytic performance remarkablely. Only the sample with appropriate amount of Ce-dopant, that is the 0.12Ce-TiO2 NTs, displayed the highest photoactivity, which was also corroborated by the following PL behavior.

3.5 PL Behavior

The PL spectra exhibited the features for excited states and related defects based on the electronic structure and optical characteristics [45–47]. Figure 7 shows the PL spectra of the samples measured with an excitation wavelength of 300 nm at room temperature. PL peaks between 400 and 500 nm were observed for all samples, which indicates recombination of photogenerated electrons and holes [48, 49]. The 0.12Ce-TiO2 NTs showed the lowest overall PL compared to the other samples. This indicates the rate of recombination of photogenerated charge carriers was lowest on the surface of the 0.12Ce-TiO2 NTs. Furthermore, the intensities of the PL spectra increased with increasing Ce beyond 0.12 g, because excess Ce on the surface possibly introduced recombination centers or new trap sites on the surface of the samples [50]. The PL measurement results thus confirmed that the sample with lower intensity of the PL spectrum displays a higher photocatalytic activity.

4 Conclusions

We have demonstrated a new method of preparing Ce-doped TiO2 NTs, a sol–gel process followed by a hydrothermal treatment. The prepared Ce-TiO2 NTs exhibited excellent photocatalytic activity for photocatalytic degradation of MB under exclusive visible light conditions. The concentration of the Ce dopant has a great effect on the photocatalytic activity. An appropriate amount of doped Ce is crucial for achieving high photocatalytic activity. The 0.12Ce-TiO2 NTs sample, with mean pore size of 6.3 nm and high surface area of 209.6 m2 g−1, showed the highest photocatalytic activity among the tested Ce-doped TiO2 NTs (0.06Ce–0.40Ce). The 0.12Ce-TiO2 NTs sample exhibited 7 times higher efficiency than that of P25 in visible light driven degradation of MB, and the prepared Ce-TiO2 NTs may find potential application in waste water treatment.

References

Fujishima A, Zhang X, Tryk DA (2008) Surf Sci Rep 63:515

Hashimoto K, Irie H, Fujishima A (2005) Jpn J Appl Phys 44:8269

Lee YF, Chang KH, Hu CC, Lin KM (2010) J Mater Chem 20:5682

Asahi R, Morikawa T, Ohwaki T, Aoki K, Taga Y (2001) Science 293:269

Li D, Haneda H, Hishata S, Ohashi N, Kolodiazhnyi T, Haneda H (2005) Chem Mater 17:2596

Umebayashi T, Yamaki T, Tanaka S, Asai K (2003) Chem Lett 32:330

Choi W, Termin A, Hoffmann MR (1994) J Phys Chem 98:13669

Subramanian V, Wolf EE, Kamat PV (2003) Langmuir 19:469

Zhu JF, Deng ZG, Chen F, Zhang JL, Chen HJ, Anpo M, Huang JZ, Zhang LZ (2006) Appl Catal B 62:329

Kasuga T, Hiramatsu M, Hoson A, Sekino T, Niihara K (1998) Langmuir 14:3160

Kasuga T, Hiramatsu M, Hoson A, Sekino T, Niihara K (1999) Adv Mater 11:1307

Yao BD, Chan YF, Zhang XY, Zhang WF, Yang ZY, Wang N (2003) Appl Phys Lett 82:281

Yang JJ, Jin ZS, Wang XD, Li W, Zhang JW, Zhang SL, Guo XY, Zhang ZJ (2003) Dalton Trans 20:3898

Bavykin DV, Parmon VN, Lapkin AA, Walsh FC (2004) J Mater Chem 14:3370

Lin CH, Chien SH, Chao JH, Sheu CY, Cheng YC, Huang YJ, Tsai CH (2002) Catal Lett 80:153

Kleinhammes A, Wagner GW, Kulkarni H, Jia Y, Zhang Q, Qin LC, Wu Y (2005) Chem Phys Lett 411:81

Cao J, Sun JZ, Li HY, Hong J, Wang M (2004) J Mater Chem 14:1203

Hodos M, Horvath E, Haspel H, Kukovecz A, Konya Z, Kiricsi I (2004) Chem Phys 399:512

Xu JC, Lu M, Guo XY, Lia HL (2005) J Mol Catal A 226:123

Wang M, Guo DJ, Li HL (2005) J Solid State Chem 178:1996

Wang YG, Zhang XG (2004) Electrochim Acta 49:1957

Bavykin DV, Lapkin AA, Plucinski PK, Friedrich JM, Walsh FC (2005) J Phys Chem B 109:19422

Lim SH, Luo J, Zhong Z, Ji W, Lin J (2005) Inorg Chem 44:4124

Zhou YK, Cao L, Zhang FB, He BL, Liz HL (2003) J Electrochem Soc 150:A1246

Armstrong AR, Armstrong G, Canales J, Bruce PG (2005) J Power Sources 146:501

Xie JM, Jiang DL, Chen M, Li D, Zhu JJ, Lv XM, Yan CH (2010) Colloids Surf A 372:107

Li F, Li X, Hou M, Cheah K, Choy W (2005) Appl Catal A 285:181

Fang J, Bi XZ, Si DJ, Jiang ZQ, Huang WX (2007) Appl Surf Sci 253:8952

Francisco MSP, Mastelaro VR (2002) Chem Mater 14:2514

Xiao J, Peng T, Li R, Peng Z, Yan C (2006) J Solid State Chem 179:1161

Oveisi H, Jiang X, Nemoto Y, Beitollahi A, Yamauchi Y (2011) Microporous Mesoporous Mater 139:38

Yuan S, Chen Y, Shi L, Fang J, Zhang J, Yamashita H (2007) Mater Lett 61:4283

Xue WL, Zhang GW, Xu XF, Yang XL, Liu CJ, Xu YH (2011) Chem Eng J 167:397

Wu Y, Kan YC, Song L, Hu Y (2012) Polym Adv Technol 23:1612

Chen X, Cao S, Weng X, Wang H, Wu Z (2012) Catal Commun 26:178

Chen X, Wang H, Gao S, Wu Z (2012) J Collid Interf Sci 377:131

Chang LH, Sasirekha N, Chen YW, Wang WJ (2006) Ind Eng Chem Res 45:4927

Larachi F, Pierre J, Adnot A, Bernis A (2002) Appl Surf Sci 195:236

Liu C, Tang X, Mo C, Qiang Z (2008) J Solid State Chem 181:913

Zhang LW, Fu HB, Zhu YF (2008) Adv Funct Mater 18:2180

Zhang H, Lv XJ, Li YM, Wang Y, Li JH (2010) ACS Nano 4:380

Morales W, Cason M, Aina O, de Tacconi NR, Rajeshwar K (2008) J Am Chem Soc 130:6318

Cao XP, Li D, Jing WH, Xing WH, Fan YQ (2012) J Mater Chem 22:15309

Nasir M, Xi ZH, Xing MY, Zhang JL, Chen F, Tian BZ, Bagwasi S (2013) J Phys Chem C 117:9520

Wang RC, Lin HY (2011) Mater Chem Phys 125:263

Zeng HB, Cai WP, Liu PS, Xu XX, Zhou HJ, Klingshirn C, Kalt H (2008) ACS Nano 2:1661

Zeng HB, Duan GT, Li Y, Yang SK, Xu XX, Cai WP (2010) Adv Funct Mater 20:561

Xu L, Guo Y, Liao Q, Zhang J, Xu D (2005) J Phys Chem B 109:13519

Candrinou C, Boukos N, Stogios C, Travlos A (2009) Microelectron J 40:296

Nasira M, Bagwasi S, Jiao YC, Chen F, Tian BZ, Zhang JL (2014) Chem Eng J 236:388

Acknowledgments

This study was financially supported by NSF of China (#21271072) and the Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning and was sponsored by the Shanghai Pujiang Program (# 13PJ1401900).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, P., Liu, L., Cui, SC. et al. Synthesis, Characterization of Ce-doped TiO2 Nanotubes with High Visible Light Photocatalytic Activity. Catal Lett 144, 2107–2113 (2014). https://doi.org/10.1007/s10562-014-1377-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-014-1377-3