Abstract

Graphene oxide functionalized with gama-aminopropyltriethoxysilane, is used as support for the immobilization of homogeneous heteropoly phosphotungstic acid. It is synthesized and characterized by SEM, XPS, XRD, 31P NMR and Raman. The effects of catalyst parameters and reaction conditions on the oxidation reaction of benzyl alcohol are systematically investigated. Under optimal conditions, the catalyst exhibit remarkably enhanced catalytic activity (conversion 76 % and selectivity 99 %). And the catalyst could be separated conveniently. Moreover, the loss of PW12O40 3− anion from the support under the reaction conditions is responsible for the deactivation of the catalyst.

Graphical Abstract

SEM images of a GO, b GO–N, c GO–N–PW (inset XPS spectrum of carbon), d GO–N–PW reused (inset XPS spectrum of carbon). The mechanism of deactivation was testified using the SEM images and the XPS spectrums in c (inset) and d (inset)

.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The oxidation of alcohols to aldehydes, especially benzyl alcohol to benzaldehyde, has attracted much attention in organic synthesis and industrial applications. Benzaldehyde is a valuable chemical in the perfumery, dyestuffs, pharmaceutical, and agrochemical industries [1–3]. Conventionally, stoichiometric oxidants, e.g. dichromate, chromium trioxide are employed in the process of alcohols oxidation. These oxidants are usually toxic or expensive and large amounts of wastes are produced together with the desired products [4]. Consequently, one of the preferred methods is to use hydrogen peroxide or molecular oxygen as an oxygen donor in catalytic oxidative reactions. The significant advantage of this method is that the main by-product is water. However, most of the catalyst systems using H2O2 are based on noble metals, which are expensive and difficult to prepare [5, 6]. In our work, the selective oxidation reaction of benzyl alcohol to benzyl aldehyde using low cost phosphotungstic acid loaded on gamma-aminopropyltriethoxysilane (APTES) coated graphene oxide (GO) is systemically investigated.

Polyoxometalates are a large family of bulky clusters of transition metal oxide anions with structural diversity. Recently, the polyoxometalates especially the Keggin-type heteropolyacid have received much attention in the oxidation of alcohols using aqueous 30 % H2O2 from the viewpoint of green chemistry [5]. However, the heteropolyacid is soluble in the polar solvents. Despite the effort devoted to silica and activated carbon [1, 6–8], little attention has been paid to the use GO as a support for homogeneous catalyst, although their thermal, mechanical and chemical stability together with a competitive cost make them ideal candidates to be used as a support in heterogeneous catalysis [9].

GO as an oxidant can oxidize benzyl alcohol to benzyl aldehyde. However, a large amount of GO and long time is required, which is deactivated in the next use [10, 11]. And there is no report on GO as a support in the oxidize reaction. Herein, we employ a lab- prepared GO as building blocks to further attach the catalytic homogeneous phosphotungstic acid inside its nanospace. The catalytic performance of the prepared hybrid catalysts are tested using the selective oxidation of benzyl alcohol to benzyl aldehyde as model reaction.

2 Experimental

2.1 Materials and Methods

Graphite power, gamma-APTES, phosphotungstic acid (HPW) were purchased from Sinopharm Chemical Reagent Co., Ltd. Toluene, H2SO4 and potassium permanganate (KMnO4) were purchased from Kun Shan Jing Ke Micro-electronics Material Co., Ltd., Other materials were obtained from local suppliers.

X-ray diffraction patterns of the catalysts were performed on a Bruker D8 diffractometer with Cu-Kα radiation from 0.5° to 70° with a scan speed 1°/min. Laser Raman experiments were recorded using a LabRAMHR Raman spectrometer equipped with a holographic notch filter, a CCD detector and a He–Ne laser radiating at 632.8 nm. X-ray photoelectron spectroscopy (XPS) measurements were obtained on a PHI-5500 spectrometer with Al Kα X-ray radiation as the X-ray source for excitation. 31P MAS NMR spectrums were recorded on a Varian Infinitypuls-300 spectrometer using a Chemagnetic 4 mm double-resonance probe. Scanning electron microscopy (SEM) was performed on a Philips XL 30 microscope operating at 30 kV.

2.2 Preparation of the Catalysts

2.2.1 Synthesis of GO

GO was prepared using a modification hummers method [12]. In a typical reaction, 5 g graphite, 5 g NaNO3, and 230 mL H2SO4 were stirred in an ice bath for about 20 min. After 30 g KMnO4 added to the system the solution was transferred to a 45 °C oil bath and stirred for about 2 h. Next, 400 mL of water was added quickly, and the solution was stirred for 30 min while the temperature was raised to 90 °C. Finally, 1,000 mL of water was added to this mixture, followed by the addition of 30 mL H2O2 (30 %), turning the color of the solution form dark brown to yellow. The warm solution was then filtered and washed with deionized water until sulfate and chlorine could not be detected by BaCl2 and AgNO3. The resulting graphite powder was dried at 60 °C in vacuum for 24 h.

2.2.2 Preparation of APTES Coated Graphite Oxide

The APTES coated GO was prepared according to protocols in the literature [13]. Exfoliation of the graphite oxide (1 g) in toluene (500 mL, dried by sodium) was performed using ultrasonication with a power of 300 W for 60 min. After APTES added the system was heated to 45 °C under argon atmosphere for 3 h, and refluxed at 120 °C for about 3 h. After the reaction, the resultant was washed with toluene at least 5 times to remove the unreacted APTES, and then the coated GO was dried at 60 °C in vacuum for 12 h. The product was abbreviated as GO–N for short.

2.2.3 Anchoring of Phosphotungstic Acid Onto APTES Coated Graphite Oxide

Different amount of phosphotungstic acid (1, 2, 3 g) was dissolved in 100 mL acetonitrile and then 3 g GO–N was dissolved in above solution and refluxed for 4 h. The filter cake was washed with acetonitrile at least 5 times to remove the unreacted phosphotungstic acid and then dried at 60 °C under vacuum. The final product was designated as GO–N–PW (x/y) (x/y referred to the weight ratio of GO–N and phosphotungstic acid).

2.3 Catalytic Activity Test

All reactions were carried out in three neck 100 mL bottle equipped with a magnetic stirring bar and reflux condenser. Typically 100 mg catalyst was dispersed into 24.9 mmol aqueous H2O2 and stirred for 10 min, 8.3 mmol benzyl alcohol was added to the above solution. The mixture was stirred constantly at the required temperature heated to 100 °C for 6 h. Finally, the filtrate was analyzed by GC. The catalyst was washed with ethanol for 3 times and dried at 60 °C in vacuum for the next use.

3 Results and Discussion

3.1 Characterization of the Catalysts

The XRD patterns of the catalysts and the intermediates were shown in Fig. 1. GO showed a peak at 12.6° and the peak at 26.5° associated with graphite completely disappeared (Fig. 1a), indicating the successful insertion of oxygen species between the graphitic layers [14]. After anchoring APTES on GO, the strong peak at 12.6° disappeared and a new peak at 21.7° was observed corresponding to a well ordered material with an interlayer distance of 0.41 nm, which could accommodate the APTES molecule (Fig. 1b). HPW showed a typical pattern of Keggin anion structure (Fig. 1c). GO–N–PW (1/1) showed no typical peaks attributed to Keggin structure except the peaks related to GO (Fig. 1d). These results indicated that the HPW species on GO–N samples were in a high-dispersed state. It suggested that HPW anions were immobilized on the GO–N via a chemical bonding interaction.

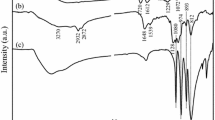

Figure 2 showed the Raman spectra of GO (a), GO–N (b), GO–N–PW (1/1) (c) and HPW (d). GO showed peaks at 1,594 and 1,363 cm−1, which were attributed to the G band (the vibration of sp2 carbon atoms) and the D band (the vibration of the sp3 carbon atoms), respectively (Fig. 2a). The spectrums of GO and GO–N exhibited similar patterns but their intensity ratios of D to G bands were a little different. Compared with GO, GO–N gave a high ratio of D to G, suggesting an increasement in the average size of sp3 carbons due to the incorporation of carbon atoms during the chemical treatment. (Fig. 2b). HPW showed Raman bands at 216, 233, 996 and 1,009 cm−1, which could be easily assigned to the Keggin structure of the PW12O40 3− anion (Fig. 2c) [15]. GO–N and GO–N–PW showed the similar D to G ratio because of the average size of carbon atoms remaining unchanged after HPW anchored to GO–N. The peaks of Keggin structure disappeared, which indicated that HPW species on GO–N samples were in a high-dispersed state (Fig. 2d). This result was identical to the XRD results.

We used 31P NMR spectrum to investigate the local environment of HPW on the samples. The chemical shift of the phosphorous atom depended not only on its local environment but also on other factors, such as associated water molecules, solid supports and so on [15]. Figure 3 revealed the 31P MAS NMR spectra of HPW and GO–N–PW (1/1). The single resonance at −15 ppm corresponded to the tetrahedral coordination of PO4 3− in the keggin unit (Fig. 3a). The new peak at −13 ppm could be attributed to the dehydrated PW anions (Fig. 3b). The 31P NMR spectra suggested the removal of structural water and three protons in the course of PW12O40 3− anchoring from solution on base functional groups of the support [5].

XPS was usually used as a tool to investigate the type and the valence state of the elements on the catalyst. Successful coating of the APTES onto the GO was identified by the detection of silicon element and nitrogen element (Fig. 4a, b). The strong W4f peak was observed in the spectrum, but the signal of P was very weak (Fig. 4c). We thought that the P element could not be detected by XPS because the P element was surrounded by W atom in the PW12O40 3− anion [16]. (31P MAS NMR detected the P element).

Figure 5 showed the SEM images of the catalysts and the intermediates. GO exfoliated to laminated structure after chemical treatment (Fig. 5a).We could observe that GO and GO–N also showed laminated structure after APTES and HPW coated on to GO (Fig. 5b, c). However, the structure assembled and some blot polluted the structure after 3 times used (Fig. 5d), which may be the cause of deactivation, the cause would be discussed later in this paper.

3.2 Catalytic tests

Table 1 showed that various loading of PW anions of GO–N–PW (x/y) had crucial effects on the catalytic activity of the corresponding catalysts in solvent-free condition. Obviously, the three composite catalysts showed higher selectivity than HPW in the same conditions and could be recycled conveniently. Among the three catalysts, GO–N–PW (1/1) showed the highest catalytic activity, which due to the richer PW12O40 3− anions on the catalyst. Though the PW12O40 3− anions on the catalyst GO–N–PW (3/1) catalyst was lower than that of the catalyst GO–N–PW (2/1), the oxidative groups was more abundant than that in GO–N–PW (2/1) which may influence the catalytic activity. Then the conversion of benzyl alcohol was higher with catalyst GO–N–PW (3/1) [10, 11].

The oxidation of benzyl alcohol was carried out with different amounts GO–N–PW (1/1) in the reaction mixture of substrate at reflux system. Table 2 illustrated that when the mount of catalyst increased from 0.1 to 0.5 g, the conversion of benzyl alcohol had been increased, according to the active sites became richer in the system. When the catalyst amount was increased to 0.3 g, the selectivity of benzyl aldehyde decreased quickly. Over oxidation of benzyl aldehyde to benzoic acid was the cause of low selectivity. So we chose 0.2 g catalyst as the best condition to optimize other factors.

The effect of reaction temperature on the oxidation of benzyl alcohol was also examined using the GO–N–PW (1/1) catalyst. The benzyl alcohol conversion and selectivity at different temperatures (from 40 to 120 °C) was shown in Table 3. The benzyl aldehyde selectivity was almost unchanged, whereas the conversion depended on the reaction temperature. The elevated temperature contributed to a higher benzyl alcohol conversion. However, when the temperature was higher than 100 °C, the conversion was almost not changed. So we used the temperature 100 °C to optimize other conditions.

From the data in Table 4, we could see that conversion of benzyl alcohol was increased with the ratio of H2O2 from 2 to 6. However, when the molecular ratio of H2O2 to benzyl alcohol was larger than 3–1 the selectivity was decreased from 99 to 57 % because benzyl acid was produced resulted from over oxidation of benzyl aldehyde. So we chose the ratio 3 as the best condition.

As was described in Table 5, the catalyst could be used 2 times, but the selectivity is also 99 % for the third use. Entry 2 and 3 both used a large amount of GO in the system, and the reusability of the catalyst was not referred in the literature.

The carbon XPS signature of the fresh catalyst and the catalyst after 3 times used were shown in Fig. 5c, d (inset). After 3 times used, sp2 carbon diminished than the fresh catalyst, which attributed to the leaching of PW12O40 3− anion. Figure 5c, d indicated that the structure of the catalyst assembled and some blot polluted the structure after 3 times used. From the SEM and XPS results, we could conclude that deactivity of the catalyst resulted from some active sites leaching from the support and some substrates polluted the catalyst. We can use graphene hydrogel load Au, Ag, Cu [17–19] to solve the problem of circulation in the future.

4 Conclusions

In conclusion, we have synthesized HPW/GO composite catalyst and applied it in the oxidation of benzyl alcohol for the first time. XRD, Raman revealed that HPW species on GO–N samples were in a high-dispersed state. 31P NMR and XPS showed that HPW is immobilized on the GO–N as charge compensating components. The leaching of active sites and the pollution of the catalyst after 3 times used is the cause of deactivation, which is testified by XPS and SEM. The amount of GO can be reduced and reaction time is shortened than that reported by other literatures [5, 11, 19].

References

Mallick S, Rana S, Parida K (2012) Int Eng Chem Res 51:7859

Choudhary VR, Dumbre DK, Jana SK (2003) Catal Lett 86:229

Tang Q, Chen Y, Zhou CJ (2009) Catal Lett 128:210

Wang X, Wu G, Li L (2012) Appl Catal B 115–116:7

Tian R, Liu C, Yin D (2012) Microporous Mesoporous Mater 158:77

Leng Y, Wang J, Jiang P (2012) Catal Commun 27:101

Li J, Liu CY, Liu Y (2012) J Mater Chem 22:8426

Kumar GS, Vishnuvarthan M, Murugesan V (2006) J Mol Catal A 260:49

Dongil AB, Bachiller-baeza B, Rodriguez-Ramos I (2012) Catal Commun 26:149

Dreyer DR, Jia HP, Bielawski CW (2010) Angew Chem Int Ed 49:6813

Mirza-Aghayan M, Kashef-Azar E, Boukherroub R (2012) Tetrahedron Lett 53:4962

Cote LJ, Kim F, Huang J (2009) J Am Chem Soc 131:1043

Lin Y, Lin J, Song M (2011) J Mater Chem 21:3455

Liu F, Sun J, Xiao F (2012) J Mater Chem 22:5495

Gao R, Zhu Q, Dai W (2012) RSC Adv 2:6087

Moulder JF, Stickle WF, Bomben KD (1995) Handbook of X-ray photoelectron spectroscopy. Physical Electronics, MN

Xu Y, Sheng K, Shi G (2010) ACS Nano 4:4324

Zhang L, Shi G (2011) J Phys Chem C 115:17206

Yang X, Qiu L, Li D (2011) Angew Chem Int Ed 50:7325

Acknowledgments

This work was financially supported by the National natural Science Foundation of China (No. 21073064, 21003049).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, K., Chen, T., Hou, Z. et al. Graphene Oxide as Support for the Immobilization of Phosphotungstic Acid: Application in the Selective Oxidation of Benzyl Alcohol. Catal Lett 144, 314–319 (2014). https://doi.org/10.1007/s10562-013-1121-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-013-1121-4