Abstract

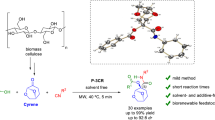

A novel cinchonine catalyst supported by carboxymethylcellulose (CMC) has been prepared with a simple approach. As-prepared CMC-supported cinchonine catalyst was used to catalyze the asymmetric Michael addition of 1,3-dicarbonyl compounds to N-benzylmaleimide at a very low loading (3 mol%). It has been found that desired adducts containing adjacent quaternary and tertiary stereocenters can be obtained in high efficiency (yield 80 %) and stereoselectivity (dr 75:25, ee 78 %). Moreover, as-prepared catalyst possesses good recyclability (at least 4 times).

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Enantioselective organocatalysis has grown with leaps and bounds [1], and a variety of chiral organic molecules such as chiral amino acid [2], cinchona alkaloid [3], urea plus thiourea [4], chiral diamine [5], and their derivatives have been used as catalysts in almost all types of enantioselective organocatalytic reactions [6–8]. Due to the unique stereostructure and excellent commercial availability, natural cinchona alkaloids like cinchonine (Fig. 1) have outstanding performance in the area of asymmetric catalysis [9, 10]. In 2006, Bartoli realized challenging asymmetric Michael reaction [11, 12] involving adjacent tertiary carbon and quaternary carbon centers adduct at low temperatures with the assistance of cinchona alkaloids [13]. In addition, cinchona alkaloids and their derivatives promote efficiently on many other asymmetric reactions [14–16], but their utility is often limited by the difficulty of separating the product from the catalyst. To overcome this drawback and contribute to resource conservation as well, many researchers [17–21] have made great efforts to develop diverse polymeric matrixes supported enantioselective catalysts which offer several advantages: the ease of physical separation of the polymer, the facilitated product purification and the potential recycling. The common organic polymeric supports are polystyrene, polyethylene glycol, sulfhydryl resin and so on [22–24]. However, few reports are currently available about natural polymers as solid supports of organocatalysts [25, 26].

Bearing those perspectives in mind, we pay special attention to cellulose, the most extensively distributed and renewable natural-polymer with advantages of non-toxicity, environmental acceptability and good degradability [27]. Particularly, we are extremely interested in carboxymethyl cellulose (CMC) (Fig. 1), the major commercial derivative of cellulose and the most common product of cellulose ether which widely used in pharmaceuticals, cosmetics and foods [28]. Thus in the present research we prepared CMC-loaded cinchonine as an efficient organocatalyst for the asymmetric Michael reactions of 1,3-dicarbonyl compounds (1a–e) and N-benzylmaleimide (2), hoping to acquire highly functionalized products with adjacent quaternary and tertiary carbon centers (Eq. 1; Bn refers to benzyl) [13].

2 Experimental

2.1 Equipments and Reagents

Commercial grade reagents and solvents were used without further purification; otherwise, where necessary, they were purified as recommended. Starting materials β-keto esters 1a–c as well as β-diketones 1d–e were purchased from Aldrich or Lancaster and used as received. Natural cinchona alkaloid, cinchonine (CN), was purchased from Sinopharm Chemical Reagent Co., Ltd (Shanghai, China) and used as received. Sodium carboxymethylcellulose (SCMC) was purchased from Tianjin Kermel Chemical Reagent Co., Ltd (Tianjin, China).

Analytical thin layer chromatography (TLC) was performed on GF254 silica gel plates. Infrared spectra were recorded with an Avatar 360 Fourier transformation infrared spectrometer (FTIR; Nicolet Company, USA). Elemental analysis was carried out with an Elementar Vario PE2400-II analyzer. Nuclear magnetic resonance (NMR) spectra were obtained from Bruker Avance 400 M system, and the chemical shifts of [1] H-NMR spectra were reported in relation to tetramethyl silane (δ = 0). Analytical high performance liquid chromatography (HPLC) was performed on Agilent 1100 equipped with a diode array ultraviolet detector, and Daicel Chiralpak AD or AS columns were used for the HPLC analysis.

2.2 Procedures for Synthesis of CMC-Supported Organocatalyst

2.2.1 Synthesis of CMC

Into a 100 mL beaker charged with 35 mL of ethanol was added 2.0 g of SCMC under vigorous stirring to generate mixed slurry. Into resultant slurry was added 3 mL of concentrated hydrochloric acid within 4–6 min under stirring, followed by heating to boil and additional 10–15 min of stirring after stop of heating. The reaction mixture was then filtered and precipitated with 95 % ethanol. The precipitate was collected and washed with 80 % ethanol at 60 °C until HCL was completely removed. As-washed precipitate was further washed with a small amount of anhydrous methanol and dried in an oven at 105 °C for 15 min yielding desired product, CMC white powder. The product was characterized by means of FTIR (ν = 3463, 2979, 2932, 1747, 1637, 1384, 1305, 1232, 1123, 1060, 1021, 893, 858, 664, 593, 438 cm−1).

2.2.2 Synthesis of Catalyst CMC–CN

Carboxymethylcellulose (0.88 g) and CN (4 mmol, 1.2 g) were added into a 50 mL round-bottomed flask charged with CH2Cl2 (20 mL) and dehydrating agent dicyclohexylcarbodiimide (DCC, 4 mmol, 0.82 g) in the presence of 4-dimethylaminopyridine (DMAP, 0.0244 g) as the catalyst. Resultant mixture was stirred at room temperature for 48 h, and then ethanol was added into the flask to remove remnant CN. Catalyst CMC–CN, a creamy-white solid, was obtained after filtering, washing with ethanol, dimethylformamide (DMF), methanol and acetone, drying in vacuum. CN loading was determined by Element analysis as 0.19 mmol g−1. Then the product was characterized by means of FTIR (ν = 3444, 3066, 2939, 2870, 1751, 1637, 1592, 1509, 1454, 1425, 1384, 1209, 1113, 1050, 995.5, 950, 905, 835, 802, 754, 664, 634, 579, 459 cm−1).

2.3 General Procedures for Catalytic Enantioselective Michael Reaction

To the solution of 1,3-dicarbonyl compound (0.2 mmol) in toluene (1.0 mL) were added N-benzylmaleimide (0.24 mmol) and as-synthesized chiral catalyst CMC–CN (3 mol%) at room temperature under stirring. The mixture was continuously stirred until no 1,3-dicarbonyl compound was detected by TLC analysis. The reaction mixture was then filtrated to remove the catalyst. Resultant crude product was purified by flash column chromatography after evaporation of the solvent.

3 Results and Discussion

CMC–CN is prepared by following a two-step straightforward synthetic strategy depicted in Scheme 1. Briefly, SCMC is acidified with hydrochloric acid generating CMC. Resultant CMC is then allowed to react with cinchonine via DCC condensation giving target product CMC–CN, and it can be confirmed by the IR spectra of the CMC and CMC–CN (Fig. 2).

For initial screening experiments, a model system comprising of ethyl 2-oxocyclopentanecarboxylate (1a) and N-benzylmaleimide (2) leading to 3a catalyzed by CMC–CN has been studied, and relevant results are summarized in Table 1, where the results for the model reaction with 3 mol% CN or 3 mol% CMC in toluene at room temperature are also provided for a comparative study. It can be seen that 3 mol% CN gives a good yield of 89 % and high enantioselectivity of 79 %, but 3 mol% CMC possesses nearly zero catalytic activity for the model reaction (Table 1, entries 1 and 2). As to CMC–CN under the identical conditions, catalytic activity comparable to that of CN is obtained (yield 80 %, ee 78 %; Table 1, entry 3). To identify desired reaction medium, we have studied a total of nine organic solvents for the model reaction. As shown in Table 1, reaction media play an important role in the reaction process, and less polar solvents such as toluene and diethyl ether show higher selectivity than polar solvents including DMF and isopropyl alcohol (Table 1, entries 3–12). Then we have attempted to upgrade the asymmetric induction level of 3 mol% CMC–CN by lowering reaction temperature to 0 °C when the optimized solvent toluene is adopted. To our disappointment, both isolated yield and stereoselectivity reduced at 0 °C (ee 57 %, dr 58:42). Moreover, since different catalyst loadings may give different reaction outcomes including yield and stereoselectivity, we have carried out further experiments by changing the catalyst loading in a range of 1–10 mol%. As listed in Table 1, the introduction of a larger amount (10 mol%) of catalyst accelerated the reaction but lowered the diastereoselectivities. Compared with 10 mol% catalyst, the level of enantioselectivity and yield did not significantly decline when the catalyst loading is reduced to 3 mol%. But continue to reduce the catalyst dosage, the result was unsatisfactory (Table 1, entry 14). Considering both the economical and practical aspects, we suggest the desired dosage of CMC–CN as 3 mol%.

Further, we have investigated the role of multiple additives in relation to the optimization of experimental procedures while formic acid, acetic acid and trifluoroacetic acid (TFA) are separately used as the additives for the model reaction.

None of the screened additives offers good activity or selectivity, and relevant reaction rate is very slow.

Results about the scope of the Michael reaction are summarized in Table 2. It can be seen that almost all of the trisubstituted carbon Michael donors can react with N-benzylmaleimide (2), but only a trace amount of Michael adduct is obtained when they react with acyclic β-ketoesters (Table 2, entry 2). In the meantime, cyclic β-ketoesters are well converted into corresponding 1,4-adducts in moderate yields with moderate diastereoselectivity and enantioselectivity (Table 2, entry 1); and high diastereoselectivity and enantioselectivity can be obtained with β-diketones which are considered as a class of particularly challenging substrates (Table 2, entries 3 and 4).

Finally, we have also investigated the recovery and recycling of CMC–CN under the optimal reaction condition described in Table 3, where the catalyst recovered from the reaction of entry 3 in Table 1 is employed for four additional cycles. It can be seen that catalyst CMC–CN reused for up to four cycles afford target products in fine yields of 75–80 %, and the enantiomeric excess remain around 70–80 %. This means that as-prepared catalyst CMC–CN can be reused for at least 4 times while its stereoselectivity is well retained.

A plausible reaction mechanism for the Michael reaction of N-benzylmaleimide with 1,3-dicarbonyl compounds catalyzed by CMC–CN is proposed in Scheme 2, which is based on the stereochemistry of 1,4-adducts. The reaction involves two stages: the formation of dihydrogen bond between the enolic form of 1,3-dicarbonyl compounds and the tertiary amine of loaded cinchonine, and the interaction of N-benzylmaleimide with the hydroxyl group of CMC via hydrogen bond [29]. The latter helps to activate the maleimide towards the nucleophilic attack.

4 Conclusion

We have developed a novel polymer supported catalyst—natural polymer CMC loaded alkaloid cinchonine for the asymmetric conjugate addition of 1,3-dicarbonyl compounds to N-benzylmaleimide, acquiring Michael adducts in good yields and with high enantioselectivities. As-prepared CMC–CN catalyst is highly efficient even at a low loading of 3 mol%, and it can be reused for at least 4 times while its stereoselectivity is well retained.

References

Pellissier H (2007) Tetrahedron 63:9267

List B, Lerner RA, Barbas CF III (2000) J Am Chem Soc 122:2395

Cucinotta CS, Kosa M, Melchiorre P, Cavalli A, Gervasio FL (2009) Chem Eur J 15:7913

Okiho T, Hoashi Y, Takemoto Y (2003) J Am Chem Soc 125:12672

Pedrosa R, Andrés JM, Manzano R, Rodríguez P (2010) Eur J Org Chem 2010:5310

List B, Yang JW (2006) Science 313:1584

Misaki T, Takimoto G, Sugimura T (2010) J Am Chem Soc 132:6286

Notz W, Tanaka F, Barbas CF III (2003) J Org Chem 68:9624

Jew S, Park H (2009) Chem Commun 46:7090

Szőllősi G, Bartók M (2001) Chirality 13:614

Jiang ZY, Ye WP, Yang YY, Tan CH (2008) Adv Synth Catal 350:2345

Lattanzi A, Fusco CD, Russo A, Poater A, Cavallo L (2012) Chem Commun 48:1650

Bartoli G, Bosco M, Carlone A, Cavalli A, Locatelli M, Mazzanti A, Ricci P, Sambri L, Melchiorre P (2006) Angew Chem Int Ed 45:4966

Yeboah EM, Yeboah SO, Singh GS (2011) Tetrahedron 67:1725

Czarnecki P, Plutecka A, Gawroński J, Kacprzak K (2011) Green Chem 13:1280

Nakamura S, Hayashi M, Hiramatsu Y, Shibata N, Funahashi Y, Toru T (2009) J Am Chem Soc 131:18240

Youk SH, Oh SH, Rho HS, Lee JE, Lee JW, Song CE (2009) Chem Commun 16:2220

Thierry B, Plaquevent JC, Cahard D (2005) Mol Divers 9:277

Giacalone F, Gruttadauria M (2007) Tetrahedron Lett 48:255

Corma A, Iborra S, Rodríguez I, Iglesias M, Sánchez F (2002) Catal Lett 82:237

Szőllősi G, London G, Baláspiri L, Somlai C, Bartók M (2003) Chirality 15:S90

Li J, Yang GX, Yang XR, Qin YY, Cui YC (2011) Tetrahedron Asymmetry 22:613

Qin YY, Yang GX, Yang LL, Li J, Cui YC (2011) Catal Lett 141:481

Danelli T, Annunziata R, Benaglia M, Cinquini M, Cozzi F, Tocco G (2003) Tetrahedron Asymmetry 14:461

Zhang HF, Zhao WS, Zou J, Liu Y, Li RT, Cui YC (2009) Chirality 21:492

Qin YY, Zhao WS, Yang LL, Zhang X, Cui YC (2012) Chirality 24:640

Reddy KR, Kumar NS, Reddy PS, Sreedhar B, Kantam ML (2006) J Mol Catal A: Chem 252:12

Barbucci R, Magnani A, Consumi M (2000) Macromolecules 33:7475

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yang, L., Zhou, D., Qu, C. et al. Carboxymethylcellulose Supported Cinchonine as a Recyclable Catalyst for Asymmetric Michael Reaction. Catal Lett 142, 1405–1410 (2012). https://doi.org/10.1007/s10562-012-0915-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-012-0915-0