Abstract

CO oxidation was investigated over Ag/CeO2 and CeO2 catalysts prepared by sol–gel method in this work. The catalytic activity of Ag/CeO2 was higher than pure CeO2. The chemico-physical properties of catalysts were characterized by XRD, TEM, XPS, H2-TPR and Raman spectroscopy. The characterization results indicated that a part of silver was inserted into the lattice of CeO2 and aroused the expansion of lattice. Raman studies of Ag/CeO2 demonstrated that the concentration of oxygen vacancies greatly increased at 5 vol.% CO/N2 atmosphere and gradually decreased at O2 atmosphere with the rising temperature from 30 to 300 °C respectively. However, a different behavior was observed over pure CeO2. The obtained Raman results showed that the oxygen storage capability of Ag/CeO2 was superior to that of CeO2 and larger amount of lattice oxygen of the former took part in the oxidation reaction evidenced by changes of oxygen vacancy. On the basis of characterization data, it was proposed that the introduction of Ag into CeO2 facilitated the activation of lattice oxygen and formation of oxygen vacancies. These features may be responsible for the higher catalytic activity of Ag/CeO2 for CO oxidation.

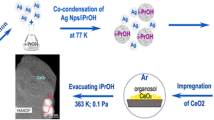

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Catalytic oxidation of CO has been an important subject in recent years, which has wide applications in different fields, including purification of environmental gas, treatment of exhaust gas from automobiles and selective oxidation of CO in reformer gas for fuel cell and so on.

Ceria (CeO2) has been used as a principal oxide support in catalytic oxidation of CO due to its remarkable oxygen storage capability (OSC) and redox ability. These properties originated from its easy creation and diffusion of oxygen vacancies, especially at the surface [1]. It was pointed out that the presence of oxygen vacancies was able to provide sites for oxygen activation and increase the diffusion rate of oxygen [2]. In order to enhance the oxygen vacancy levels, the doping of ceria has been an efficient method, which can result in the formation of defective fluorite structure [3, 4]. Rare earth metals and transition metals were frequently employed for this purpose [5–13]. Chen et al. [14] investigated the mechanism of CO oxidation on Fe-modified CeO2 using periodic density functional theory calculations and found that the addition of Fe promoted the formation of oxygen vacancies.

Supported silver catalysts have been investigated recently [15–18]. Imamura et al. [19] studied the catalytic activity of Ag/CeO2 and concluded that the high dispersion of silver helped to maintain the high activity for CO oxidation. Sarode et al. [20] investigated the local environment of Ag in Ag/CeO2 by extended X-ray absorption fine structure spectroscopy and found that Ag+ like species was presented. Scirè et al. [21] reported a comparative study on ceria supported group IB metal catalysts and proposed that a higher atomic radius of the IB metal and the presence of smaller crystallites of both IB metal and ceria resulted in a larger enhancement of reactivity of surface oxygen on ceria. Hegde et al. [22] reported that Ag seemed to be ionically dispersed on CeO2 crystallites and surface concentration of Ag was much higher than bulk. Among these studies, the mechanism of CO oxidation over Ag/CeO2 is still under debate. The roles of silver and ceria support have not been extensively explored about this system. In this work, the catalytic oxidation mechanism of CO over Ag/CeO2 was systematically studied with the aim to obtain more information. The correlation among silver nanoparticles, support and catalytic activity is addressed via experimental measurements. It was proposed that the introduction of Ag enhanced the OSC of Ag/CeO2 catalyst and favored the generation of oxygen vacancies and activation of lattice oxygen. These features may be mainly responsible for the better catalytic performance of Ag/CeO2 catalyst.

2 Experimental

2.1 Catalyst Preparation

Ag/CeO2 catalyst (Ag/Ce = 0.1) was prepared by a sol–gel method. An appropriate amount of AgNO3, Ce(NO3)3 and citric acid were dissolved into de-ionized water. The mixed solution was evaporated under stirring until the transparent gel was formed. The resulting gel was dried at 100 °C for 2 h, followed by the decomposition at 450 °C for 2 h to remove organics and the final calcinations at 600 °C for 3 h under static air. After grinding, the catalyst powder was obtained and the loading of Ag was about 6 wt.%.

2.2 XRD, H2-TPR, TEM, XPS, BET and Raman

The X-ray powder diffraction (XRD) analysis was performed on a Bruker D8 powder diffractometer using a Cu Kα radiation (40 kV and 40 mA). The diffractograms were recorded in the 2θ range of 10–80° with a 2θ step size of 0.02° and a scanning speed of 6° min−1. Rietveld refinements were carried out with the program Jade 5.0 and the average crystal size was determined by the Scherrer’s equation. Hydrogen temperature programming reduction (H2-TPR) measurements were carried out using a commercial temperature programming system. 30 mg catalyst was heated in the flow of 5 vol.% H2/N2 (45 mL min−1) at a heating rate of 10 °C min−1 from 100 °C to 800 °C. The amount of H2 uptake during the reduction was measured by thermal conductivity detector (TCD).

The BET surface areas of the samples were measured on a Micromeritics ASAP 2020 instrument by N2 adsorption at −196 °C. The samples were degassed at 120 °C and 1 × 10−4 Pa for 10 h before the measurements.

Transmission electron microscopy (TEM) images of the catalysts were recorded on a JEOL JEM-2100 microscope operating at 200 kV. The samples were dispersed in ethanol and kept in an ultrasonic bath for 15 min, then deposited on a carbon-covered copper grid for each measurement.

X-ray photoelectron spectra of the catalysts were recorded on Kratos Axis Ultra DLD surface analysis instrument using an Al Kα radiation (1,484.6 eV) as primary excitation. The binding energies were calibrated by C1s (284.8 eV). XPS elemental spectra were acquired in the fixed analyser transmission (FAT) mode with 0.1 eV energy steps at a pass energy of 40 eV. The samples were pressed into thin discs and mounted on a sample rod.

Raman measurements were performed on a Renishaw invia Raman spectroscope using a 300 mW 785 nm laser as the excitation source with a dwell time of 10 s and number of scans of 1. The microscope used a 50× objective and 1,200 g mm−1 grating. Raman measurements during the reaction processes were carried out on a Linkam THMS 600 thermal cell, coupled to the Raman equipment. The cell allowed the use of controlled atmosphere and temperature. The flowing gas used in Raman measurements was 5 vol.% CO/N2 and O2 (99.99 %). About 10 mg sample was pressed into a slice (diameter 5 mm) and inserted into the cell. Then the cell was heated from room temperature to 300 °C with a heating rate of 10 °C min−1 under a gas flow. Each spectrum was collected after the sample was held for 5 min at the desired temperature point under the flow. Finally, the sample was cooled to room temperature.

2.3 Catalytic Activity Evaluation

The CO oxidation reaction was performed in a conventional continuous flow fixed-bed microreactor. The catalyst (50 mg) was evenly mixed with 100 mg SiO2 granules (0.3–0.5 mm) to reduce the pressure drop and packed into the reactor. Before reaction, the catalyst did not undergo any pretreatments. The reaction was carried out at a heating rate of 5 °C min−1 up to the chosen temperature and the sample was held for 5 min at the desired temperature point from room temperature to 300 °C. The reactant flow consisted of a mixture of 5,000 ppm CO (10 mL min−1) and air (40 mL min−1). The mixture with a total gas flow of 50 mL min−1 was fed to the reactor at atmospheric pressure and passed over the catalysts for 20 min. The effluent gases were analyzed on-line by a gas chromatograph equipped with a FID detector.

3 Results and Discussion

3.1 The Catalytic Performance of CeO2 and Ag/CeO2 for CO Oxidation

Figure 1 displays the CO conversion as a function of reaction temperature for pure CeO2 and Ag/CeO2 catalysts. As shown in Fig. 1, no significant CO conversion was observed when the reaction temperature increased to 140 °C and this value was below 10 % even when the temperature reached 300 °C on the bare CeO2. Compared to the pure CeO2, Ag/CeO2 was more active. A remarkable increase of CO conversion on Ag/CeO2 was observed up to 180 °C and the complete conversion was achieved at 250 °C. These results revealed that the Ag/CeO2 displayed much better catalytic behavior toward CO oxidation than CeO2, indicating that the presence of Ag greatly enhanced the catalytic activity.

3.2 XRD

The XRD patterns of CeO2 and Ag/CeO2 are presented in Fig. 2. The profile of the bare ceria reveals the presence of diffraction peaks related to CeO2 phase in the cubic crystal structure of fluorite type. The average particle size of the CeO2 was calculated to be around 20 nm according to the Scherrer’s equation, and this value was confirmed by TEM. Compared to the pattern of CeO2, two additional weak peaks at about 38.2° and 44.2° were observed on the Ag/CeO2 catalyst, which were ascribed to the diffraction peaks of Ag (111) and Ag (200) [19, 21]. The average diameters of silver and ceria particles calculated by the Scherrer’s equation were 16 and 15 nm respectively. Considering that the peak at 38.2° can be attributed to both Ag and Ag2O species, it must be pointed out that the presence of Ag2O can’t be fully excluded. However, according to the discussion of XRD in literature [21], metallic Ag species predominated over Ag2O in Ag/CeO2 catalyst in this work.

As shown in the insert of Fig. 2, it could be seen that the diffraction peak at 28.5o on Ag/CeO2 catalyst shifted to lower angle compared to that of pure CeO2, which suggested that a part of Ag incorporated into the lattice of CeO2 and aroused the expansion of the lattice [6, 7]. The inserted Ag increased the crystal defects of CeO2, which might accelerate the activation of lattice oxygen in the reaction. The particle sizes and surface areas of catalysts are presented in Table 1. It could be seen that the size of Ag particles from TEM was 18 nm, which was slightly larger than the value from XRD in Ag/CeO2. In addition, the particle size of CeO2 estimated from XRD was similar to the value from TEM.

3.3 TPR

Figure 3 shows the TPR profiles of pure CeO2 and Ag/CeO2 catalysts. In the examined temperature range (40–800 °C), pure CeO2 exhibits two well resolved reduction peaks. One centered at 510 °C and the other was above 790 °C. The former one belonged to the reduction of the surface capping oxygens of ceria [6, 23, 24], while the latter one, more intense, was ascribed to the reduction of bulk oxygen of ceria [25]. For Ag/CeO2 sample, two main reduction peaks were observed. The first one around 168 °C could be assigned to the reduction of surface capping oxygen of ceria interacting with silver species [6, 20]. An obvious shift of the reduction peak toward lower temperature was due to the interaction between silver and ceria. It was indicated that the presence of silver improved the reducibility of surface oxygen on CeO2 and facilitated the oxygen transfer across the solid–gas interface during reaction [26]. The second one at 725 °C was attributed to the reduction peak of bulk oxygen of ceria. The TPR results showed that the presence of silver significantly improved the reducibility of surface capping oxygen of ceria.

3.4 TEM

TEM measurements were carried out in order to obtain the particle sizes and morphologies of catalysts. As indicated in Fig. 4a, the CeO2 crystallized in a cubic shape with particle size being around 21 nm. The d spacing for the lattice was 0.313 nm, which corresponded to the CeO2 (111) lattice plane of the cubic cell [27, 28]. In the case of Ag/CeO2 sample, the average sizes of Ag and CeO2 particles were around 18 and 16 nm respectively (Fig. 4b). The d spacing of Ag was 0.204 nm, which was corresponding to the Ag (200) [29].

3.5 XPS and BET

XPS spectrum of Ag3d electron is presented in Fig. 5. The binding energy of Ag (3d5/2) peak was at 367.7 eV. Compared to Ag metal, a lower shift of the Ag3d binding energy was observed, which demonstrated the presence of +1 state of Ag [17, 21, 30]. The peak curve could be fitted into a pair of peak with binding energies of 367.6 and 368.1 eV, which were attributed to Ag+ and neutral Ag atom, respectively [31–33].

The BET surface areas of CeO2 and Ag/CeO2 were 32 and 45 m2 g−1 respectively (Table 1). An increase in the specific surface area (compared to the pure CeO2) may be due to the evolution of a new porosity by the introduction of Ag into the CeO2 structure and small Ag nanoparticle on the surface of ceria [7].

3.6 Raman

Figure 6 shows the Raman spectra of pure CeO2 and Ag/CeO2 catalysts. The main band at 462 cm−1 was assigned to the F2g vibration mode of fluorite structure of CeO2 [34]. For Ag/CeO2 catalyst, there is an additional band centered at 560 cm−1, which was ascribed to the oxygen vacancies in the CeO2 [12, 35]. The generation of oxygen vacancies was due to the incorporation of Ag into the lattice of ceria [5]. Moreover, there was a small variation in the Raman shift of F2g mode of the two samples. This shift should be related to the change of the M–O vibration frequency after incorporation with Ag [36, 37]. Therefore, these Raman results indirectly confirmed the interaction between Ag and the CeO2 support.

Raman spectra during the reaction processes were also recorded in order to obtain surface information of catalysts. Figure 7 shows the Raman spectra of CeO2 and Ag/CeO2 in 5 vol.% CO/N2 and O2 atmospheres at different temperature points. As shown in Fig. 7a, three bands at 275, 460 and 530 cm−1 were observed on the spectra of Ag/CeO2 catalyst under 5 vol.% CO/N2 flow. It has been reported that the Raman band at 246 cm−1 over Ce0.67Zr0.33O2 was ascribed to the oxygen vacancy [38]. Meanwhile, the changing trend of the band at 275 cm−1 was consistent with that of the peak at 530 cm−1 in this work. Hence, it was reasonable to assign the band at 275 cm−1 to the oxygen vacancies. It could be seen from Fig. 7a that the intensity of the peak at 530 cm−1 significantly increased with the rising temperature and this peak could still be obviously observed after the sample was cooled to room temperature (data not shown). Generally, the ratio between the areas of bands at 530 (A530) and 460 cm−1 (A460) is a measurement of the number of oxygen vacancies in the material, in such a way that the higher the A530/A460 value, the higher the number of oxygen vacancies were [7, 39]. As shown in Fig. 7a, it was found that the ratio of A530/A460 significantly increased under CO flow with the rising temperature. However, the Raman peak at 530 cm−1 hardly appeared on the spectra of CeO2 at the same conditions (Fig. 7b), suggesting that there were higher amount of oxygen vacancies in the Ag/CeO2. This, in turn, also indicated that CO oxidation consumed lattice oxygen of CeO2, leading to the formation of surface oxygen vacancy in the 5 vol.% CO/N2 flow. This consumption of lattice oxygen of CeO2 over Ag/CeO2 may be related to the weak binding between the oxygen atoms and the ceria [40]. Compared the Raman spectra of two samples, it was strongly suggested that the inserted Ag facilitated the breaking of bond between Ce–O and the release of lattice oxygen, which is in agreement with the Mars–van Krevelen (MVK) mechanism [41].

Nevertheless, the Raman spectra were very different when the Ag/CeO2 catalyst was exposed to O2 atmosphere (Fig. 7c). For Ag/CeO2 catalyst, the intensity of the bands ascribed to oxygen vacancies gradually decreased with the increase of temperature, almost disappearing at 200 °C. However, as shown in Fig. 7d, the feature bands of pure CeO2 in O2 atmosphere were similar to that in CO/N2 atmosphere. It was obvious that the presence of Ag on Ag/CeO2 played an important role. It was proposed that O2 molecules were activated by Ag over Ag/CeO2, and then rapidly occupied the surface oxygen vacancies with the increase of temperature. It is well accepted that the improvement of OSC of ceria is via reversible oxygen-vacancy formation and partial reduction [42, 43]. Herein, the OSC of Ag/CeO2 was superior to that of CeO2, which should be attributed to the larger amount of lattice oxygen of the former taking part in the reaction. The presence of Ag could promote the activated oxygen filled in the oxygen vacancies, which acted as the active sites for the next oxidation reaction.

4 Conclusions

The Ag/CeO2 catalyst prepared by sol–gel method exhibited much higher activity than pure CeO2 for CO oxidation. The presence of silver significantly improved the reducibility of surface capping oxygen of ceria. In addition, the inserted Ag increased the crystal defects of CeO2, which may accelerate the activation of lattice oxygen in the reaction. The Raman results during the reaction processes demonstrated that the release of lattice oxygen led to the formation of oxygen vacancies under CO atmosphere and the resulting vacancies were sealed by oxygen under O2 atmosphere on Ag/CeO2 catalyst, which indicated that the presence of Ag improved the OSC of ceria. The obtained results showed that the great increases in the concentration of oxygen vacancies and lattice oxygen were mainly responsible for the higher catalytic activity of Ag/CeO2 for CO oxidation.

References

Sayle TXT, Parker SC, Catlow CRA (1992) J Chem Soc Chem Commun 14:977

Guzman J, Carrettin S, Corma A (2005) J Am Chem Soc 127:3286

Hu ZP, Metiu H (2011) J Phys Chem C 115:17898

Trovarelli A (1996) Catal Rev Sci Eng 38:439

Reddy BM, Thrimurthulu G, Katta L (2009) J Phys Chem C 113:15882

Laguna OH, Sarria FR, Centeno MA, Odriozola JA (2010) J Catal 276:360

Hernández WY, Centeno MA, Romero-Sarria F, Odriozola JA (2009) J Phys Chem C 113:5629

Yu Q, Wu X, Tang C, Qi L, Liu B, Gao F, Sun K, Dong L, Chen Y (2011) J Colloid Interf Sci 354:341

Reddy BM, Katta L, Thrimurthulu G (2010) Mater Chem 22:467

Reddy BM, Lakshmanan P, Bharali P, Saikia P, Thrimurthulu G, Muhler M, Gruünert W (2007) J Phys Chem C 111:10478

Wang S, Zheng XC, Wang XY, Wang SR, Zhang SM, Yu LH, Huang WP, Wu SH (2005) Catal Lett 105:163

Lendzion-Bieluń Z, Bettahar MM, Monteverdi S, Moszyński D, Narkiewicz U (2010) Catal Lett 134:196

McBride JR, Hass KC, Poindexter BD, Weber WH (1994) J Appl Phys 76:2435

Chen HT, Chang JG (2011) J Phys Chem C 115:14745

Taylor SH, Rhodes C (2006) Catal Today 114:357

Comsup N, Panpranot J, Praserthdam P (2010) J Ind Eng Chem 16:703

Derekaya FB, Güldür Ç (2010) Int J Hydrogen Energy 35:2247

Yu L, Shi Y, Zhao Z, Yin H, Wei Y, Liu J (2011) Catal Commun 12:616

Imamura S, Yamada H, Utani K (2000) Appl Catal A 192:221

Sarode PR, Priolkar KR, Bera P, Hegde MS, Emura S, Kumashiro R (2002) Mater Res Bull 37:1679

Scirè S, Riccobene PM, Crisafulli C (2010) Appl Catal B 101:109

Bera P, Patil KC, Hegde MS (2000) Phys Chem Chem Phys 2:3715

Tang X, Zhang B, Li Y, Shen W (2004) Catal Today 93:191

Trovarelli A, Dolcetti G, De Leitenburg C, Santoni A (1992) J Chem Soc Faraday Trans 88:1311

Damyanova S, Pawelec B, Arishtirova K, Huerta MVM, Fierro JLG (2008) Appl Catal A 337:86

Zhang H, Zhu A, Wang X, Wang Y, Shi C (2007) Catal Commun 8:612

Han MM, Wang XJ, Shen YN, Tang CH, Li GS, Smith JRL (2010) J Phys Chem C 114:793

Barrabés N, Föttinger K, Llorca J, Dafinov A, Medina F (2010) J Phys Chem C 114:17675

Wu P, Zhang H, Du N, Ruan L, Yang D (2009) J Phys Chem C 113:8147

Zheng Y, Chen C, Zhan Y, Lin X, Zhu J (2008) J Phys Chem C 112:10773

Arabatzis IM, Stergiopoulos T, Bernard MC, Labou D, Neophytides SG, Falaras P (2003) Appl Catal B 42:187

Li B, Li H, Xu Z (2009) J Phys Chem C 113:21526

Gao J, Arunagiri T, Chen J, Goodwill P, Chyan O (2000) Chem Mater 12:3495

Pu ZY, Liu XS, Jia AP, Xie YL, Lu JQ, Luo MF (2010) J Phys Chem C 114:10857

Reddy BM, Bharali P, Saikia P, Khan A, Loridant S, Muhler M, Grünert W (2007) J Phys Chem C 111:1878

Katta L, Sudarsanam P, Thrimurthulu G, Reddy BM (2010) Appl Catal B 101:101

Luo MF, Yan ZL, Jin LY, He M (2006) J Phys Chem B 110:13068

Li G, Wang Q, Zhao B, Shen M, Zhou R (2011) J Hazard Mater 186:911

Pu ZY, Lu JQ, Luo MF, Long XY (2007) J Phys Chem C 111:18695

Shapovalov V, Metiu H (2007) J Catal 245:205

Huang M, Fabris S (2008) J Phys Chem C 112:8643

Skorodumova NV, Simak SI, Lundqvist BI, Abrikosov IA, Johansson B (2002) Phys Rev Lett 89:166601

Trovarelli A (1996) Catal Rev-Sci Eng 38:439

Acknowledgments

This work was financially supported by Research Center of Analysis and Test of East China University of Science and Technology. The authors are grateful to Dr. J. X. Li, L. H. Zhou, Y. Q. Song and Professor Y. P. Du for helpful discussions.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Kang, Y., Sun, M. & Li, A. Studies of the Catalytic Oxidation of CO Over Ag/CeO2 Catalyst. Catal Lett 142, 1498–1504 (2012). https://doi.org/10.1007/s10562-012-0893-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-012-0893-2