Abstract

Azo linked Schiff-base[L] complexes of Mn(II)(1), Cu(II)(2) and Co(II)(3) obtained by template method, in the reaction of 4-(benzeneazo) salicylaldehyde with 1,2-propanediamine in the present of metal acetate, respectively. Complexes are used as catalyst for oxidation of cyclohexene with tert-butylhydroperoxide (TBHP); oxidation of cyclohexene catalyzed by these complexes gave 2-cyclohexene-1-one and 2-cyclohexene-1-ol as major products. Conversion of cyclohexene achieved was 95–100% with (1), (2) and (3), with selectivity of 57, 92 and 100% for 2-cyclohexene-1-one, respectively. The encapsulated Cu(II) complex (Cu–NaY) catalyzes the oxidation of cyclohexene using TBHP as oxidant in good yield. (Cu–NaY) under optimized reaction condition gave three reaction products. A maximum of 100% conversion of cyclohexene has been achieved where selectivity of 2-cyclohexene-1-one was 83%.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Many Schiff base complexes derived from salicylaldehyde show excellent catalytic activity in various homogenous and heterogeneous reactions [1–5].

The oxidation of hydrocarbons using Schiff base complexes has been in field of academic and industrial interest to analyze the catalytic activity of various metal complexes [6–10]. The activity of these complexes varied with the type of ligands, coordination sites and metal ions. There have been many reports on application of metal complexes in homogenous and heterogeneous catalysis for allylic oxidation of alkenes [11, 12]. Different reaction pathways have been employed for the allylic oxidation of alkenes with molecular oxygen, tert-butylhydroperoxide (TBHP), H2O2 and transition metal catalysts. Iqbal and co-workers carried out the oxidation of cyclohexene using cobalt(II) Schiff base complex, in the presence of molecular oxygen and 2-methylpropanal where the cyclohexenone and cyclohexenol (2:1,70%) are obtained as major compounds [13]. The chiral manganese Schiff base complex has been shown to catalyze the oxidation of cyclohexene into a mixture of cyclohexenol (15%), cyclohexenone (27%) and cyclohexenyl hydroperoxide (32%) without a coreductant under a flow of oxygen [14]. Copper (II) Schiff base complexes supported on SiO2 [15] and Al2O3 [16] were studied with TBHP for the oxidation of cyclohexene. These reactions provided a mixture of cyclohexenone (58, 48% respectively) and cyclohexenol (17, 9% respectively) as major products along with a trace of hydroperoxide in moderate yield.

Salavati-Niasari and co-workers carried out allylic oxidation of cyclohexene using Schiff base complexes of Cu(II), Ni(II), Co(II) and Mn(II) supported on alumina with TBHP and H2O2. The result showed allylic oxidation of cyclohexene with TBHP gave 2-cyclohexene-1-one, 2-cyclohexene-2-ol and 1-(tert-butylperoxy)-2-cyclohexene whereas, oxidation with H2O2 resulted in the formation of cyclohexene oxide and cyclohexene-1,2-diol. The reaction was catalyzed more successfully with Schiff base complex of manganese(II) ion supported on alumina than other Schiff base complexes [17–21].

Azo-linked Schiff base are being increasingly used in the textile, leather, and plastic industries [22–24]. Also azo derivatives have been utilized as indicators and radical reaction indicators. In addition, azo derivatives have the potential for use in electronic and drug delivery applications [25, 26]. A few Schiff base azo linked complexes are reported to be catalytically active towards oxidation [27]. Therefore, it is interesting to study azo linked compounds as catalysts.

In this study, we synthesized Mn(II), Cu(II) and Co (II) complexes containing azo-Schiff-base [L]derivatives of 1,2 propane diamine and 4-phenylazosalicylaldehyde, we studied their catalytic activity in the oxidation of cyclohexene by TBHP. In mobilization of copper(II) azo-Schiff base complexes (2) onto zeolite has been adopted to prepare heterogeneous catalyst and activities of these hybrids toward oxidation of cyclohexene by TBHP were studied.

2 Experimental

2.1 Instruments and Reagents

Infrared spectra were recorded as KBr pellets using Bruker Tensor 27 spectrometer. The visible spectra were determined using a Perkin Elmer, Lambda 35 UV/VIS. 1H NMR spectra were obtained on a Bruker Avance 300 MHz spectrometer using TMS as internal standard spectrometer. The reaction products of oxidation were determined and analyzed by GC–MS (Agilent Series 6890). X-ray diffractograms of the catalysts were recorded using XRD, Seifect, 3003 PTS diffractometer with a Cu-Kα target. The metal contents were measured by using PU900 Philips atomic absorption.

Analytical reagents grade cyclohexene, 1,2-propanediamine, salicylaldehyde, TBHP (solution 80% in di-tert-butylperoxide) were procured from Merck. Other reagents and solvents used were also of AR grade. Y-zeolite (Si/Al 4.5) was obtained in our laboratory.

2.2 Preparation of 4-(benzeneazo) Salicylaldehyde

4-(benzeneazo) salicylaldehyde was prepared using standard procedure [28].

2.3 Preparation of Ligand (H2L)

0.05 mol of 1,2-propanediamine was slowly added to a solution of 0.03 mol of 4-(benzeneazo) salicylaldehyde in 30 mL ethanol after refluxing the reaction mixture for 2 h. The solution was left at room temperature and the red precipitate was collected by filtering and washing with 15 mL of ethanol and then recrystallized from ethanol and dried at 50 °C overnight. Yield: 82%. Anal. cacld for C29H26N6O2 : C 71.23, H 5.30, N 17.14. Found: C 70.49, H 5.23, N 17.23. FT-IR (KBr, cm−1): 3,444br, 3,064w, 2,968w, 2,924w, 1,631 (C=N), 1,583sh, 1,490m, 1,438w, 1,369w, 1,283m, 1,105w, 835m, 767m, 688m. UV/VIS (CH2Cl2, λ, nm) 345, 280. 1H NMR (CDCl3, δ): 13.28 (s, 2H, OH), 8.46, 8.5 (s, 2H, –CH=N–), 7–7.9(m, 16H, aromatic H) 3.7–3.8 (m, 2H, CH2), 3.8–4 (m, 1H, CH), 1.51 (s, 3H, CH3).

2.4 Template Preparation of the Complexes (ML)

All complexes were prepared by template reaction in one step, 1 M hydrated metal acetate, 1 M 1,2-propanediamine and 2 M 4-(benzeneazo) salicylaldehyde in 30 mL ethanol, refluxed for 4 h. The precipitated solid were filtered off from the ice-cooled reaction mixture. The solid were washed with ethanol and then dried at 50 °C [29]. Analysis of complex 1. Anal. calcd for C29H24MnN6O2: C 63.0, H 4.53, N 15.22. Found: C 63.1, H 4.3, N 15.0. FT-IR (KBr, cm−1): 3,428br, 3,044w, 2,924w, 1,609s (C=N), 1,541sh, 1,463w, 1,379m, 1,297s, 1,224w, 1,151w, 1,115w, 1,046w, 1,017w, 920w, 827m, 764m, 687m, 658w. UV/VIS (CH2Cl2, λ, nm) 384, 257. Complex 2. Anal. calcd for C29H24CuN6O2: C 61.2, H 4.21, N 14.76. Found: C 60.94, H 4.26, N 14.51. IR (KBr, cm−1): 3,445br, 2,964w, 2,924w, 2,854w, 1,631s (C=N), 1,606s, 1,530w, 1,467m, 1,416w, 1,382s, 1,326m, 1,256w, 1,190w, 1,155w, 1,112m, 890w, 834m, 759m, 687m. UV/VIS (CH2Cl2, λ, nm) 381, 280. Complex 3. Anal. calcd for C29H27CoN6O3.5: C 63.63, H 4.73, N 14.6. Found: C 60.0, H 4.4, N 14.4. FT-IR (KBr, cm−1): 3,421br, 3,042w, 2,970w, 2,927w, 1,634s (C=N), 1,603s, 1,523m, 1,460m, 1,419w, 1,372m, 1,255w, 1,223 m, 1,143w, 1,133 m, 810 m, 766 m, 667 m. UV/VIS (CH2Cl2, λ, nm) 384, 280.

2.5 Incorporation of Copper(II) in NaY (Metal Exchanged Y-Zeolite)

Na–Y zeolite (2 g) was suspended in 100 mL distilled water which contained copper(II) nitrate (2 mmol). The mixture was then stirred for 24 h. The solid was filtered and washed with de-ionized water and dried at room temperature to give a light blue powder of Cu–NaY [30]. Calcination of the prepared copper(II)-incorporated zeolite was avoided to arrest the migration of copper (II) ions from the vicinity of the super cage [31].

2.6 Immobilization of CuL in Cu–NaY

Cu–NaY (1 g) and H2L (2 g) in acetonitrile solution was mixed in a round bottom flask. The reaction mixture was heated at 100 °C for 5 h in an oil bath with constant stirring. The resulting material was taken out and extracted with acetonitrile using soxhlet extractor till the complex was free from un-reacted ligand. The non-complexed metal ions present in the zeolite were removed by exchanging with aqueous 0.01 M NaCl solution. The resulting solid was finally washed with hot distilled water till no precipitation of AgCl was observed in reacting filtrate with AgNO3 solution. This was then dried at 150 °C for several hours till constant weight was achieved.

2.7 Homogeneous Oxidation of Cyclohexene

To a solution of cyclohexene (10 mmol), metal complex (0.1 g) in CH3CN (10 mL), was added TBHP (25 mmol). The resulting mixture was refluxed under nitrogen atmosphere, the products were collected at different time intervals, identified and quantified by GC and verified by GC–MS. The concentrations of products were determined using benzyl chloride as internal standard.

2.8 Heterogeneous Oxidation of Cyclohexene

TBHP (25 mmol) cyclohexene (10 mmol) and catalyst (0.2 g) were mixed in 10 mL of CH3CN and the reaction mixture was heated at 84 °C with continuous stirring in an oil bath under nitrogen atmosphere. The products were collected at different time intervals and identified and quantified by GC and verified by GC–MS. The concentration of products were determined, using benzyl chloride as internal standard.

3 Results and Discussion

The complexes (Scheme 1) are air-stable colored solids, insoluble in water, partly soluble in ethanol and methanol and soluble in DMSO and DMF. Analytical data suggest that the metal–ligand stoichiometry is 1:1.

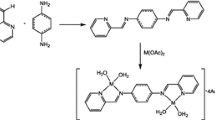

Scheme 1

The complexes (1), (2) and (3) showed a sharp band in the range 1,608–1,634 cm−1 attributable to the azomethine group of Schiff base ligand [32, 33].

Synthesis of complex CuL encapsulated in the nano cavity of zeolite-Y involved the exchange of copper(II) ion with Na(I) of Na–Y followed by reaction of metal exchanged zeolite-Y with H2L in solution. The flexible Schiff base ligand was allowed to react with Cu–NaY (scheme 2).

Scheme 2

It is expected that the CuL complex will be formed in the super cage as well as on the surface of the Y zeolite. It seems soxhlet extraction with CH3CN effectively washes the hybrid material. The non complexed Cu(II) ions in zeolite were removed by exchanging with aqueous 0.01 M NaCl solution. The resulting solid was finally washed with distilled water till no precipitation of AgCl was observed on reacting the filtrate with AgNO3 solution. The intensity of the peaks in encapsulated CuL–NaY is, though, weak due to their low concentration in zeolite matrix. Comparison of spectra of Cu–NaY, CuL–NaY with the complex (2) provides evidence for the coordinating mode of catalyst. IR spectra of the hybrid material showed an intense band at 1,011 cm−1 attributable to the asymmetric stretching of Al–O–Si chain of zeolite. The symmetric stretching and bending frequency bands of Al–O–Si framework of zeolite appear at 723 and 458 cm−1, respectively [34]. The diffraction patterns of encapsulated copper complex and Na–Y are essentially similar except a slight change in intensity of the band in encapsulated complex. This observation indicates that the framework of the zeolite has not structurally changed during encapsulation.

3.1 Catalytic Activities

The oxidation of cyclohexene with TBHP was carried out to test the efficiency of the prepared catalysts. The results of the reactions are given in Table 1. The hybrid catalyst showed good catalytic activity. It is noteworthy that neither the mother zeolite NaY nor the Cu–NaY exhibited any noticeable catalytic activities. It should be noted that atomic absorption spectroscopic analysis shows copper is not leaching out during oxidation reactions, as no copper was detected in the liquid phase of the reaction mixture after completion of the reaction.

The oxidation of cyclohexene catalyzed by complexes (1–3) with TBHP gives excellent conversion of 95–100% (selectivity, 57–100%) of 2-cyclohexene-1-one under homogeneous conditions.

The effect of various reaction media on oxidation of cyclohexene catalyzed by complexes 2 has been studied. A graphical representation of the relative efficacies of the catalysts in different solvents has been given in Fig, 1. The efficiency of the catalysts in different solvents decreases in the order acetonitrile > dichloromethane > chloroform.

The effect of amount of catalyst and TBHP on the oxidation of cyclohexene catalyzed by complex 2 has been studied. A graphical representation of these effects is shown in Fig 2a–b. Therefore, an amount of 0.1 g of catalyze and as shown in Fig. 2b the 3.5:1 molar ratio is the best to obtain the optimum cyclohexene conversion of 100% in 4 h reaction time.

The effect of various reaction media on the oxidation of cyclohexene catalyzed by CuL–NaY also has been studied. In all the oxidation reactions, 2-cyclohexene-1-one was formed as major product. In acetonitrile and dichloromethane the conversion of cyclohexene are 100 and 98%, respectively, but the selectivity of 2-cyclohexene-1-one in CH3CN and CH2Cl2 is 83 and 74%, respectively. Therefore, for the best solvent, CH3CN, polarity, hydrophilicity and size of the solvent molecule may also play some role on the reaction rate [35].

The formation of the allylic oxidation products 2-cyclohexene-1-one and 2-cyclohexene-1-ol shows the preferential attack of the activated C–H bond over the C = C bond (scheme 3). The formation of 1-tert-butylperoxy-2-cyclohexene shows the presence of radical reaction [36]. TBHP as an oxidant promoted the allylic oxidation pathway and epoxidation decreased, especially under the acidic properties of zeolite encapsulated with divalent and trivalent transition metal ions; those complexes have been observed by other researchers [37–39] .

Scheme 3

4 Conclusion

Complexes MnL, CuL and CoL have been synthesized and used as catalysts in oxidation of cyclohexene. All complexes are found to be catalytically active under homogenous conditions. Reaction conditions have been optimized considering different parameters to get maximum conversion of substrate. A maximum of 100% conversation has been obtained with CoL under inert atmosphere. The selectivity of the major product of 2-cyclohexene-1-one was 88%.

Complex CuL has been encapsulated in the super cages of zeolite-Y. Its encapsulation has been ensured by different studies. CuL–NaY has potential catalytic activity for oxidation of cyclohexene. Reaction conditions have been optimized considering different parameters to get maximum conversion of cyclohexene. 100% conversion of cyclohexene has been achieved with CuL–NaY using TBHP as oxidant. The selectivity of 2-cyclohexene-1-one and 2-cyclohexene-1-ol are 83 and 17%, respectively. Heterogeneous catalysis is stable and free from leaching as confirmed by testing the filtrate for the corresponding metal ion.

References

Homs JM (1999) Angew Chem Lnt Ed Engl 38:3588

Samsel EG, Srinivasan K, Kochi JK (1985) J Am Chem Soc 107:7606

Jacobsen EN, Wu MH (1999) Comprehensive asymmetric catalysis. Springer, Berlin

Gennari C, Piarulli U (2003) Chem Rev 103:3071

Makio H, Kashiwa N, Fujita T (2002) Adv Synth Catal 344:477

Jorgenson KA (1987) J Chem Soc Chem Commun (18):1405

Kureshy KI, Khan NH, Abdi SHR, Iyer P, Bhatt AK (1997) J Mol Catal A Chem 120:101

Bousquet C, Gilheany DG (1995) Tetrahedron Lett 36:7739

Imanishi H, Katsuki T (1997) Tetrahedron Lett 38:251

Adhikary C, Bera R, Dutta B, Jana S, Bocelli G, Cantoni A, Chaudhuri S, Koner S (2008) Polyhedron 27:1556

Punniyamurthy T, Velusamy S, Iqbal J (2005) Chem Rev 105:329

Punniyamurthy T, Rout L (2008) Coord Chem Rev 252:134

Reddy MM, Punniyamurthy T, Iqabl J (1995) Tetrahedron Lett 36:159

Wabg RM, Hao C-J, Wang Y-P, Li S-B (1999) J Mol Catal A Chem 147:173

Mukheryee S, Samanta S, Roy BC, Bhaumik A (2006) Appl Catal A Gen 301:79

Salavati-Niasari M, Salemi P, Davar F (2005) J Mol Catal A Chem 238:215

Salavati-Niasari M, Farzaneh F, Ghandi M (2002) J Mol Catal A Chem 186:101

Salavati-Niasari M, Banitaba SH (2003) J Mol Catal A Chem 201:43

Salavati-Niasari M, Hassani M, Davar F (2006) Catal Commun 7:955

Salavati-Niasari M, Mirsattari (2007) J Mol Catal A Chem 268:50

Salavati-Niasari M (2007) J Mol Catal A Chem 274:58

Catino SC, Farris E (1985) Concise encyclopedia of chemical technology. John Wiley, New York

Venkataraman K (1970) The chemistry of synthetic dyes. Academic press, New York and London

Egli R, Peter AP, Freeman HS (1991) Colour chemistry: the design and synthesis of organic dyes and pigments. Elsevier, London

Zhou YS, Zhung LJ, Zeng XR, Vital JJ, You XZ (2000) J Mol Struct 25:553

Hard H (1983) Organic chemistry-a short course, 6th edn. Haughton Miffin Company, Boston

Ispir E (2009) Dyes pigments 82:13

Vogel A (1956) A text-book of practical organic chemistry. Longman, New York

Liu J, Wu B, Zhang B, Liu Y (2006) Turk J Chem 30:41

Koner S (1998) Chem Commun 593

Delabie A, Pierloot K, Groothaert MH, Schoonheydt RA, Vanquickenborne LG (2002) Eur J Inorg Chem 33:515

Lashanizadegan M, Boghaei MD (2000) Synth React Inorg Met-Org Chem 30:88

Maurya MR, Chandrakar AK, Chand S (2007) J Mol Catal A Chem 274:192

Barrer RM (1982) Hydrothermal chemistry of zeolite. Academic Press, New York

Neumann R, Abu-Gnim C (1990) J Am Chem Soc 112:6025

Salavati-Niasarani M (2008) J Mol Catal A Chem 283:120

Sheldon RA (1993) Top Cur Chem 164:21

Salavati-Niasari M, Shaterian M, Ganjali MR, Norouzi P (2007) J Mole Catal A Chem 261:147

Saha PK, Dutta B, Jana S, Bra R, Saha S, Okamoto K, Koner S (2007) Polyhedron 26:563

Acknowledgment

Authors are grateful to Alzahra-University for providing financial support to undertake this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lashanizadegan, M., Zareian, Z. Homogenous and Heterogeneous Catalytic Activity of Azo-Linked Schiff Base Complexes of Mn(II), Cu(II) and Co(II). Catal Lett 141, 1698–1702 (2011). https://doi.org/10.1007/s10562-011-0709-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-011-0709-9