Abstract

Palladium-alumina cryogel was prepared from palladium nitrate and aluminum sec-butoxide through a sol–gel processing and subsequent freeze drying. The cryogel showed higher thermal stability of palladium and catalytic CO oxidation activity than the corresponding xerogel and impregnation catalysts. The superior stability and activity were ascribed to the uniform distribution of palladium ions in the boehmite gel by the one-pot preparation of palladium-boehmite co-gel, and also to the suppression of transfer and aggregation of the metal during the subsequent freeze drying. As a result palladium ions were finely distributed and stabilized throughout the alumina cryogel support, which consequently suppressed the sintering of palladium at elevated temperatures.

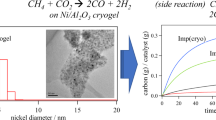

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Palladium has become increasingly important to substitute platinum and rhodium in automotive three-way catalysts. Among the precious metals, however, since the melting point of palladium (1555 °C) is much lower than that of platinum (1768 °C) and rhodium (1964 °C), the sintering occurs more easily in the metallic state. On the other hand, it is also known that the stability of the oxide is, on the contrary, higher for the palladium than for others. For stabilizing the palladium so that the sintering was suppressed, the oxides of rare earth and alkaline earth such as La, Sr and Ba were employed as additives [1–6]. The addition of these metal oxides resulted in increasing the decomposition temperature of palladium oxide to metallic palladium, by which the catalytic activity was improved. In addition the stability of alumina support was also improved by these additives through retardation of phase transformation to α-Al2O3.

The sol–gel technique has also been employed to prepare the stable palladium catalysts [7]. The corresponding aerogels were also prepared by eliminating the solvent in the pores of the gel under the supercritical conditions [8, 9]. The advantage of the aerogels is considered as follows: (a) uniform distribution of the metal throughout the support, (b) well-defined pore size distribution of the support, (c) large surface area, and (d) thermally stable metal and support. However, the commercial application of the aerogels is considered limited because of the high cost in production [10]. The supercritical drying should be the serious barrier because the drying is carried out at high pressures using an autoclave, being hazardous for practical production. In addition, palladium ions might be removed from the gel during the solvent exchange and subsequent supercritical drying. Furthermore the palladium ions might be reduced during the drying to give palladium black with large size [9].

On the other hand, the cryogels, highly porous solid materials obtained through freeze drying, are fascinating and practical [11]. This is because the drying is safe, economical, and there is very little fear of the removal of the palladium ions from the gel and uncontrolled reduction to palladium black during the drying. The solvent exchange is unnecessary if the gel is prepared in an aqueous solution. Despite the simple drying method, very few studies have been performed on the preparation and catalysis of the cryogels so far [10–13]. In this article palladium-alumina cryogel was prepared through a sol–gel processing and subsequent freeze drying, and the thermal stability of palladium, the metal dispersion, and catalytic CO oxidation activity were investigated by comparison to those of the corresponding xerogel and impregnation catalysts.

2 Experimental

To 20 mL of hot water (86 °C) purified by a Milli-Q water purifier, ca. 0.029 mol of aluminum sec-butoxide (Kanto Chemicals) was added for the hydrolysis of the alkoxide; the unclear sol was stirred vigorously for 5 min. Then 8 mL of 1 mol L−1 HNO3 (Wako) was added to the sol for peptization, refluxing at the temperature for 1 h with vigorous stirring. Whereas ca. 3.9 g of Pd(NO3)2 solution (ca. 2.0 wt%) was added to 4 mL of pure water and then, 0.15 mL of ethylenediamine was added to the solution, followed by allowing to stand for 30 min at room temperature. The palladium solution prepared was added to the peptized boehmite sol with stirring. Urea (0.4 g) was added to the mixed sol for gelation, followed by keeping at 86 °C for 24 h without stirring. The gel obtained was collected in a 200 mL beaker and frozen rapidly by liquid nitrogen. The frozen gel was subsequently dried under vacuum less than 10 Pa by a laboratory freeze drier (Tokyo Rikakikai, FDU-810). The dried gel was heated in air at 500–1100 °C for 1 h. The palladium content was 5 wt%. For comparison, the gel was dried under the normal drying conditions to obtain xerogel. Furthermore the palladium catalyst was prepared by a conventional impregnation technique using pure alumina cryogel (surface area: 287 m2 g−1) and commercial alumina (Taimei Chemicals, 200 m2 g−1) as catalyst supports. The alumina cryogel was prepared by the method as described above without adding the palladium source. Hereafter the impregnation catalyst using the alumina cryogel is denoted as Imp(cryo) whereas Imp(com) for the commercial alumina.

Nitrogen adsorption was carried out using a volumetric adsorption instrument of Belsorp-mini (Nippon Bel). The pore radius distribution curve was obtained from the adsorption branch using the BJH method [14]. XRD pattern of the catalyst was recorded on an X-ray powder diffractometer at 30 kV and 30 mA using RAD-1VC (Rigaku). CO adsorption was examined in helium carrier gas by a conventional pulse technique. The decomposition of PdO to Pd and O and the recombination of the metallic palladium with oxygen to form the palladium oxide were continuously observed in air by thermogravimetry (TG) using TGA-50 (Shimadzu). The catalyst after the 700 °C calcination was placed on a platinum pan, and the temperature was ramped from room temperature to 1000 °C at 10 °C min−1 and subsequently cooled down to 400 °C at −10 °C min−1. The CO oxidation on the catalysts (15 mg) was carried out under the gas compositions of CO (1%), O2 (2%) and Ar (97%), totally 50 mL min−1; the catalyst temperature was ramped at a constant rate of 5 °C min−1. The reactants (CO and O2) and product (CO2) were continuously monitored by a quadrupole mass spectrometer using M-200GA-DM (Anelva).

3 Results

Figure 1 shows the BET surface area of the catalysts. The surface area decreased with heating temperature for all the catalysts. Between the two sol–gel catalysts the surface area was lower for the cryogel than for the xerogel. The surface area of Imp(cryo) was roughly similar to that of the cryogel. The pore radius distribution curves of the catalysts are shown in Fig. 2. At 500 °C, the peak of the curve was located at smaller pore radius for the cryogel than for the xerogel. The area of the curve, corresponding to the pore volume, was larger for the xerogel than for the cryogel; however, the latter may have larger amount of micropores. The curve of Imp(cryo) was located at larger pore radius than that of the xerogel. All the curves became small and shifted to large pore radius with heating temperature: the peak was located still at smaller and larger pore radius for the cryogel and Imp(cryo), respectively, than for the xerogel.

Figure 3 shows the XRD patterns of the catalysts. No diffraction peaks were observed for the cryogel at 500 °C, whereas those for PdO were seen for other catalysts. Among the latters the diffraction peaks were smaller and broader for the xerogel than for the impregnation catalysts. The diffraction peaks were still unobserved for the cryogel at 700 °C. At 800 °C the peaks corresponding to PdO appeared for the cryogel; however they were very small and broad. At 900 °C, although the diffraction peaks appeared clearly, the peaks were smaller than those of other catalysts. The crystallite size of palladium oxide was calculated from the full width at half maximum (FWHM) of the diffraction peak at 2θ = 33.9° corresponding to PdO (101); the size at 900 °C was 10, 16, 13 and 13 nm, respectively, for the cryogel, xerogel, Imp(cryo) and Imp(com). The crystallite size was smaller for the cryogel than for others.

Table 1 shows the dispersion of palladium on alumina calculated by CO chemisorption. The dispersion was higher for the cryogel than for others. The dispersion was not changed markedly for each catalyst below 800 °C, whereas above the temperature it decreased seriously. The reduction was less marked for the cryogel than for others.

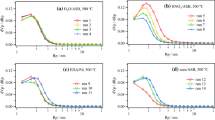

The decomposition of and reformation to PdO were examined in air by TG. The TG profiles indicated the weight decrease around 900 °C and subsequently weight increase around 600 °C. The former was ascribed to the decomposition of palladium oxide to metallic palladium and oxygen, whereas the latter was attributed to the recombination of the metallic palladium with oxygen to form the palladium oxide [2]. The differential analysis of the TG profiles clearly indicated the decomposition temperature to be ca. 936, 909, 887 and 886 °C for the cryogel, xerogel, Imp(cryo) and Imp(com), respectively (Fig. 4). The decomposition proceeded at higher temperatures for the sol–gel catalysts than for the impregnation ones. Between the sol–gel catalysts the temperature was higher for the cryogel than for the xerogel, whereas between the impregnation catalysts the difference was small. The temperature of the reformation was ca. 626, 619, 595 and 600 °C for the cryogel, xerogel, Imp(cryo) and Imp(com), respectively. The reformation also proceeded at higher temperatures for the sol–gel catalysts than for the impregnation ones; between the formers the temperature was higher for the cryogel than for the xerogel.

Figure 5 shows the CO oxidation on the catalysts. After the 500 °C heating, the activity was higher for the cryogel than for others (Fig. 5a). Even after the 800 °C heating the cryogel exhibited the higher activity than other catalysts whereas the xerogel lost the activity significantly (Fig. 5b). When the catalysts were heated in hydrogen after the 500 °C air-heating, the activity was improved on the cryogel whereas deteriorated on others (Fig. 5c). The activity was still higher on the cryogel than on others after the 800 °C air-heating and subsequent hydrogen-heating (Fig. 5d).

4 Discussions

When palladium nitrate was added to the boehmite sol as it was during the sol–gel processing, the uncontrolled reduction of the palladium ions to give palladium black occurred. By employing a chelating agent of ethylenediamine, such reduction was successfully suppressed, bringing about the superior dispersion of the metal throughout the alumina support. The chelator may play a role in stabilizing the palladium ions through the interaction between the lone pair of nitrogen in amino groups and the LUMO of the palladium ions. It should be noted, between the two sol–gel catalysts, that the stability and the dispersion were higher for the cryogel than for the xerogel despite the same wet gel with palladium ions. As for the xerogel, the transfer and aggregation of the palladium in the wet gel should proceed with ease during the normal drying accompanying the evaporation of water and the shrinkage of gel. As a result the thermal stability and dispersion were deteriorated, giving large particles at high temperatures. As for the cryogel, on the other hand, such transfer and aggregation should be suppressed during the freeze drying because the water was sublimated from the frozen gel without the shrinkage. Owing to the superior drying technique, the palladium ions were still distributed throughout the dried gel, bringing about the high stability and dispersion.

It was found from the TG experiments that the decomposition of palladium oxide to metallic palladium and oxygen proceeded at higher temperature for the cryogel than for others. It was also observed that the reformation of palladium oxide from metallic palladium and oxygen occurred at higher temperature for the cryogel than for others. The particle size of palladium was considered to be smaller for the cryogel than for others judging from the dispersion; the finer particles might be more prone to remain and/or become the oxide, retarding the decomposition despite the absence of any additives such as the oxides of rare earth and alkaline earth.

Furthermore it was reported, on the sol–gel catalysts, that the sintering of precious metals was suppressed when the particle size was matched to the average pore diameter [15]. The pores acted as chemical-traps and slowed down the diffusion of the particles as the size reaches the size of the pores [16]. In the present cryogel, the particle size of palladium estimated from the dispersion was ca. 2.5 nm after the 500 °C heating, in good agreement with the maximum pore diameter of ca. 3.0 nm. Also for the 800 °C heating, the particle size was estimated to be ca. 3.0 nm, whereas the maximum pore diameter was around ca. 4.0 nm. Although the particle size was not precisely determined by TEM at the present stage, such diffusion might be retarded in the cryogel. The comparison of the particle sizes between those from TEM and CO chemisorption may reveal the relationship between the stability and encapsulation [17, 18].

Thus it was revealed that the finer palladium particles formed in the alumina cryogel were stabilized as the oxide form and distributed throughout the support with higher dispersion. The higher catalytic activity on the cryogel should therefore be ascribed to the finer and more stable palladium particles dispersed on the alumina. On the other hand, the activity patterns shown in Fig. 5 were not always explainable by the dispersion except for the cryogel. It was reported that the active site of palladium was in a partially oxidized state, PdO x , rather than to be in a completely oxidized state or the metallic one [19–21]. The discrepancy in the activity patterns might be due to the predisposition toward such active state during the catalytic reaction.

5 Conclusions

Palladium ions were finely distributed throughout the boehmite gel by the one-pot sol–gel processing, during which the formation of palladium black was suppressed owing to ethylenediamine employed as a chelating agent for the metal ions. The transfer and aggregation of the palladium in the gel were retarded during the subsequent freeze drying. The finer palladium particles in the cryogel seemed more prone to be in a stable oxidized state rather than to be in a metallic one despite the absence of any additives such as rare earths and alkaline earths, bringing about higher stability, dispersion and activity.

References

Yamada T (2001). In: Iwamoto M (ed) Handbook of environmental catalyst. NTS, Tokyo, p 301

Chou TY, Leu CH, Yeh CT (1995) Catal Today 26:53

Fraga MA, de Souza ES, Villain F, Appel JG (2004) Appl Catal A 259:57

Yue BH, Zhou RX, Wang YJ, Zheng XM (2005) Appl Catal A 295:31

Liotta LF, Deganello G, Sannino D, Gaudino MC, Ciambelli P, Gialanella S (2002) Appl Catal A 229:217

Suhonen S, Valden M, Pessa M, Savimaki A, Harkonen M, Hietikko M, Pursiainen J, Laitinen R (2001) Appl Catal A 207:113

Lambert CK, Gonzalez RD (1999) J Mater Sci 34:3109

Mizushima Y, Hori M (1992) Appl Catal A 88:137

Armor JN, Carlson EJ, Zambri PM (1985) Appl Catal 19:339

Kirchnerova J, Klvana D, Chaouki J (2000) Appl Catal A 196:191

Pajonk GM (1997) Catal Today 35:319

Osaki T, Nagashima K, Watari K, Tajiri K (2007) Catal Lett 119:134

Osaki T, Nagashima K, Watari K, Tajiri K (2008) J Cera Soc Jpn 116:505

Barrett EP, Joyner LG, Halenda PH (1951) J Am Chem Soc 73:373

Zou WQ, Gonzalez RD (1993) Appl Catal A 102:181

Ruckenstein E (1975) J Catal 37:416

Martino A, Sault AG, Kawola JS, Boespflug E, Phillips MLF (1999) J Catal 187:30

Sault AG, Martino A, Kawola JS, Boespflug E (2000) J Catal 191:474

Yazawa Y, Yoshida H, Takagi N, Komai S, Satsuma A, Hattori T (1998) Appl Catal B 19:261

Yazawa Y, Yoshida H, Takagi N, Komai S, Satsuma A, Hattori T (1999) J Catal 187:15

Yoshida H, Yazawa Y, Hattori T (2003) Shokubai (Catal Catal) 45:38

Acknowledgments

This study has been supported by the New Energy and Industrial Technology Department Organization (NEDO) under the sponsorship of Ministry of Economics, Trade and Industry of Japan (METI).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Osaki, T., Yamada, K., Watari, K. et al. Palladium-alumina Cryogel with High Thermal Stability and CO Oxidation Activity. Catal Lett 142, 95–99 (2012). https://doi.org/10.1007/s10562-011-0692-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-011-0692-1