Abstract

The conversion of cyclohexanone, often identified as an intermediate in the conversion of lignin-derived compounds, was catalyzed by Pt/γ-Al2O3 in the presence of H2 at 573 K. Dehydrogenation was a kinetically significant reaction, indicated by a high selectivity for phenol. Oxygen-removal reactions are indicated by products including benzene, cyclohexene, and cyclohexene. Bimolecular reactions involving cyclohexanone and/or products of its conversion led to the formation of bicyclic C12 compounds, with 2-cyclohexylcyclohexan-1-one and 2-phenylphenol being the most abundant. Increasing the H2 partial pressure led to increased oxygen removal and faster formation of monocyclic and bicyclic hydrocarbons. At temperatures higher than 573 K, dehydrogenation became the dominant reaction class.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

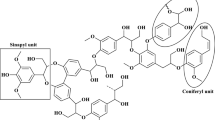

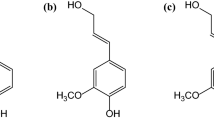

Lignin fractions, which consititute as much as about 30 wt% of plant biomass, offer excellent potential as feedstocks for renewable fuels and chemicals [1, 2]. Fast pyrolysis of lignin yields oxygen-rich bio-oils, which prominently include compounds such as phenols, guaiacols, and syringols [3–5]. Bio-oils upgrading reactions with H2 catalyzed by supported metals [6–8] can be used to remove oxygen from these compounds to minimize the instability and corrosivity of the liquids.

In investigations of the catalytic reactions of compounds representative of lignin bio-oils (such as phenol [9–12], anisole [13], and guaiacol [3, 14, 15]), cyclohexanone was observed to be a common reaction intermediate. Investigations of the catalytic reactions of cyclic ketones (e.g., cyclohexanone [16, 17] and cyclopentanone [18]) indicated the formation of hydrocarbons with higher carbon numbers than the reactant (typically, C10–C12), which could be useful as components for jet and diesel fuels [19]. However, there is limited information characterizing the reaction networks and kinetics of catalytic cyclohexanone transformations. Most of them are focused on the chemical routes to monocyclic compounds.

Our approach was to investigate the broader reaction network for cyclohexanone conversion with a specific goal of elucidating the oxygen-removal reactions catalyzed by a supported metal, Pt/γ-Al2O3; the reactions occurred in the near absence of catalyst deactivation. The data presented here include a statement of the reaction network and evidence of the influence of changes in the temperature and H2 partial pressure.

2 Experimental

Powders of Pt/γ-Al2O3 catalyst (1 wt% Pt, Sigma-Aldrich; BET surface area, 206 ± 1 m2/g, Pt dispersion, 0.25) were pre-treated in a flowing stream of H2/N2 as the catalyst was heated at a rate of 5 K/min to the desired reaction temperature and then held for 30 min prior to the start of reactant flow. Catalytic reactions were performed in a once-through packed-bed tubular reactor under the following conditions, with liquid reactant (99.8 wt% cyclohexanone) vaporized into a flowing gas stream (30% H2/70% N2 or H2): catalyst mass, 0.010–0.100 g (catalyst particles mixed with particles of inert, nonporous α-Al2O3); temperature, 523–623 K; pressure, 140 kPa; liquid reactant feed rate, 0.03 mL/min; and gas feed flow rate, 100 mL/min. The downstream product was condensed at 285–288 K. Liquid product samples that were collected periodically and uncondensed gaseous products that were flowing steadily were analyzed by gas chromatography (GC) and gas chromatography/mass spectrometry (GC–MS).

3 Results

More than 15 products of the cyclohexanone conversion catalyzed by Pt/γ-Al2O3 in the presence of H2 at 573 K were detected. These were identified by GC–MS, using the NIST EI mass spectral database with some compounds being identified with authentic standards. Initial conversions (in the absence of catalyst deactivation) were determined by extrapolating conversion data to zero time on stream (by using an exponential fit, as shown in Fig. 1). Only minimal yields of coke were observed, as the changes in mass of the packed beds containing catalyst and inert α-Al2O3 were generally <0.08%. Mass balance closures (Table 1) were typically 96.3 ± 4.6% (and generally greater than 90%).

Change in cyclohexanone conversion catalyzed by Pt/γ-Al2O3 at a WHSV of 56 (g of reactant)/(g of catalyst × h) at 573 K and 140 kPa. An exponential fit of the data was used to approximate the initial conversion. The fitting equation is as follows and is represented by the line on the figure: X = 0.22e−0.009t, where X is cyclohexanone conversion and t is time on stream

The predominant product was phenol; less abundant products were water, cyclohexane, cyclohexene, cyclohexen-1-one, cyclohexanol, and benzene. Several bicyclic (C12) products were detected, including bicyclohexane, cyclohexylbenzene, cyclohexyloxycyclohexane, biphenyl, diphenyl ether, cyclohexyloxybenzene, 2-cyclohexylcyclohexanol, 2-cyclohexylcyclohexan-1-one, dibenzofuran, 2-(1-cyclohexen-1-yl)cyclohexanone, 2-cyclohexylidenecy-clohexan-1-one, 2-phenylphenol, and 2-phenylcyclohexanone. Most of these products were observed at trace levels, except for 2-cyclohexylcyclohexan-1-one and 2-phenylphenol.

Selectivities for formation of the most abundant products formed at an initial cyclohexanone conversion of 0.22 are summarized in Table 2. These data show that dehydrogenation is an important class of reaction observed for the supported metal catalyst, exemplified by the formation of phenol from cyclohexanone. Reactions with H2 also led to hydrogenation and to oxygen removal as water (i.e., by hydrodeoxygenation (HDO)), exemplified by the formation of benzene from phenol. Dehydration reactions also occurred, leading to removal of oxygen as water without the need for H2, as illustrated by the formation of cyclohexene from cyclohexanol The bicyclic products were presumably formed in bimolecular reactions (coupling reactions) of (a) two cyclohexanone molecules, (b) cyclohexanone with one of the cyclohexanone conversion products (such as cyclohexene), and (c) two cyclohexanone conversion products.

To determine an approximate reaction network for the conversion of cyclohexanone catalyzed by Pt/γ-Al2O3 in the presence of H2, selectivity vs. conversion plots (e.g., Fig. 2) were used to identify products as primary or not [20, 21]; a positive intercept indicates a primary product (these designations are empirical, falling short, for example, of providing information about intermediates that were too reactive to be detected).

Selectivity for the formation of phenol (closed circles) and cyclohexanol (open circles) in the conversion of cyclohexanone catalyzed by Pt/γ-Al2O3 in the presence of H2 at 573 K and 140 kPa. Data for each product were fitted with a straight line and extrapolated to zero conversion; intercepts of regression lines significantly different from zero selectivity at zero conversion (analyzed with 95% confidence limits) indicate primary products, both phenol and cyclohexanol

The selectivity-conversion data (Figs. 2, 3, 4, and 5) indicate that phenol, cyclohexene, 2-cyclohexen-1-one, cyclohexanol, benzene, 2-cyclohexylcyclohexan-1-one, and 2-phenylphenol were primary products, whereas cyclohexane was a non-primary product. Data characterizing the values of the intercepts and the attendant errors are summarized in Table 3.

Selectivity for the formation of 2-cyclohexen-1-one (squares) and cyclohexane (triangles) in the conversion of cyclohexanone catalyzed by Pt/γ-Al2O3; reaction conditions are stated in the text. Data for each product were fitted with a straight line and extrapolated to zero conversion; intercepts of regression lines significantly different from zero selectivity at zero conversion (analyzed with 95% confidence limits) indicate primary products, in this case 2-cyclohexen-1-one, and those not significantly different from zero (analyzed with 95% confidence limits) are considered to be evidence of non-primary products, in this case cyclohexane

Selectivity for the formation of benzene (triangles) and cyclohexene (squares) in the conversion of cyclohexanone catalyzed by Pt/γ-Al2O3; reaction conditions are stated in the text. Data for each product were fitted with a straight line and extrapolated to zero conversion; intercepts of regression lines significantly different from zero selectivity at zero conversion (analyzed with 95% confidence limits) indicate primary products, in this case both benzene and cyclohexene

Selectivity for the formation of 2-phenylphenol (×) and 2-cyclohexylcyclohexan-1-one (+) in the conversion of cyclohexanone catalyzed by Pt/γ-Al2O3; reaction conditions are stated in the text. Data for each product were fitted with a straight line and extrapolated to zero conversion; intercepts significantly different from zero selectivity at zero conversion (analyzed with 95% confidence limits) indicate primary products, in this case both 2-phenylphenol and 2-cyclohexylcyclohexan-1-one

A semi-logarithmic plot of the fraction of cyclohexanone unconverted as a function of inverse space velocity (Fig. 6) is nearly linear, indicating that the overall cyclohexanone conversion is well represented by first-order kinetics over the conversion range investigated. The pseudo first-order rate constant for the disappearance of cyclohexanone was found to be 90 L/(g of catalyst × h).

Presuming that hydrogenation, dehydrogenation, HDO, and coupling reactions are the important reaction classes; by recognizing which compounds were primary and which were non-primary products; and by using our chemical judgment of the most likely classes of reaction for formation of the minor and trace products, we inferred the reaction network of Fig. 7 for cyclohexanone conversion catalyzed by Pt/Al2O3 in the presence of H2.

Reaction network for the conversion of cyclohexanone and H2 catalyzed by Pt/γ-Al2O3 at 573 K. Reactions are postulated on the basis of the products identified, including trace compounds, and their formation as a result of the likely reaction classes identified in the text. Hydrogenation/dehydrogenation/hydrodeoxygenation reactions are represented by dashed arrows and condensation/isomerisation/alkylation/dehydration reactions by solid arrows

Our data and the literature broadly show that H2 plays a crucial role as a co-reactant in several reactions leading to the removal of oxygen from organic compounds in the presence of supported metal catalysts [6]. To assess the influence of H2 partial pressure on the cyclohexanone conversion, we performed the reaction experiments at two different H2 partial pressures. The initial conversion at 573 K was almost unchanged (approximately 0.22) when the reactant gas was switched from 70% N2/30% H2 (\( P_{{{\text{N}}_{2} }} \) = 92 kPa, \( P_{{{\text{H}}_{2} }} \) = 39 kPa, P cyclohexanone = 9 kPa) to 100% H2 (\( P_{{{\text{H}}_{2} }} \) = 131 kPa, P cyclohexanone = 9 kPa). The comparison of product distributions resulting from this change in reaction conditions is shown in Table 2.

Cyclohexanone conversions at a space velocity of 56 (g of cyclohexanone)/(g of catalyst · h) increased as the temperature was raised (0.09 at 523 K, 0.22 at 573 K, and 0.32 at 623 K). Data characterizing the conversion of cyclohexanone as a function of time on stream at various temperatures are shown in Fig. 8. The temperature dependence of the product distributions is summarized in Table 4.

4 Discussion

The reaction network presented in Fig. 7 accounts for major, minor, and trace products in the reactions catalyzed by Pt/γ-Al2O3; it contains more detail than reaction networks reported for the conversion of cyclohexanone in the presence of supported metals and other catalysts. In most of the reported work, only little characterization of reaction networks was presented; the catalysts were sulfided Ni–W [22], Ni/Al2O3 [23], Ni–Mo/Al2O3 [24], Pd/HY zeolite [25], Pt/HZSM-5 [16], and sulfonic acid ion exchange resin [17].

We observed results that are broadly consistent with these reports in terms of the classes of reactions, but we observed different products corresponding to the different catalysts and operating conditions. In the comparable work with the Ni/Al2O3 catalyst [23], cyclohexane was the only major product (formed with a yield of 90%) (the authors did not report the conversion)—in contrast, phenol was our major product, with a selectivity of 90% at a conversion of 0.22 (Table 2). We suggest that the differences are associated with the lower reaction temperature in the reported work (463 K vs. 573 K in our work) and the higher H2 to cyclohexanone molar feed ratio (~290:1 vs. 5:1 in our work).

Our data show that in the conversion catalyzed by Pt/γ-Al2O3, phenol and 2-cyclohexen-1-one were formed as primary products, by dehydrogenation of the cyclohexane ring. Hydrogenation of cyclohexanone also occurred simultaneously, as shown by the fact that cyclohexanol was also a primary product. From the selectivity-conversion data, we infer that dehydrogenation was kinetically more favorable than hydrogenation under our reaction conditions as the selectivity for formation of phenol (90%) was significantly higher than the selectivity for formation of cyclohexanol (7%) (Table 2).

These results suggest that cyclohexene was formed as a primary product. We suggest that cyclohexene could be produced along with water by direct HDO of cyclohexanone. In a sequential reaction pathway, dehydration of the primary product cyclohexanol could also have led to formation of cyclohexene [9, 10, 16, 24, 25]. Benzene could be formed either by HDO of phenol or dehydrogenation of cyclohexene. It is unlikely that benzene is produced in a single reaction from cyclohexanone. Thus, we suggest that benzene was not a primary product, although the conversion-selectivity plot (Fig. 4) is consistent with such a designation (although it does not distinguish primary products from higher-order products when the latter are formed via highly reactive, undetectable intermediates). Consequently, we infer that the non-zero selectivity for formation of benzene at zero cyclohexanone conversion implies a relatively high rate of benzene formation relative to phenol and cyclohexene formation.

Several bimolecular reactions are suggested to produce the 12-carbon bicyclic compounds identified in our product stream. We infer that the apparent primary product 2-cyclohexylcyclohexan-1-one was formed by condensation of cyclohexanone and the primary product cyclohexene. Because the intermediate cyclohexene must be formed first, we infer that the alkylation of cyclohexanone with cyclohexene is not a primary reaction and that 2-cyclohexylcyclohexan-1-one is thus not a primary product. The product 2-cyclohexylcyclohexan-1-one could also have been formed by hydrogenation of either 2-(1-cyclohexen-1-nyl)cyclohexanone or 2-cyclohexylidenecyclohexan-1-one, which we infer were produced by aldol condensation of cyclohexanone molecules [10, 17]. Dehydrogenation of these two aldol condenation products could also have led to another of the apparent primary products, 2-phenylphenol, consistent with the inference that the dehydrogenation reaction occurred rapidly under current operating conditions.

Similarly, bicyclic C12 compounds were detected in cyclohexanone conversion catalyzed by Pt/HY zeolite [25] and Pt/HZSM-5 [16]; these products include bicyclohexane, cyclohexylcyclohexene, cyclohexylbenzene, 2-(1-cyclohexen-1-yl)cyclohexanone, 2-cyclohexylidenecyclohexan-1-one, 2-cyclohexylcyclohexan-1-one, 2-phenylcyclohexanone, 2-phenylcyclohexanol, 2-cyclohexylphenol, and 2-phenylphenol. These results suggest the occurrence of the same reaction classes that were observed when the catalyst was Pt/γ-Al2O3, Pt/HY zeolite, or Pt/HZSM-5. We infer that cyclohexylcyclohexene and cyclohexylbenzene were formed by alkylation of cyclohexene and benzene with cyclohexene [16]. Bicyclohexane could have been produced by subsequent hydrogenation of cyclohexylcyclohexene. We also infer that dehydration of 2-cyclohexylcyclohexan-1-one could have led to the formation of 2-phenylcyclohexanone. 2-Phenylcyclohexanol could have been formed by pathways including dehydrogenation of 2-cyclohexylcyclohexane and hydrogenation of 2-phenylcyclohexanone. 2-Cyclohexylphenol could have been formed by alkylation of phenol, either with cyclohexanol or cyclohexene [26, 27].

Tricyclic products reported by Alvarez [16] and Silva [25] were not detected in our products, consistent with the presence of weaker acid sites in our catalyst (containing γ-Al2O3) than in the catalysts used in the earlier investigations (HY zeolite and HZSM-5). However, we were able to identify other products that were not reported by Alvarez and Silva, including cyclohexyloxycyclohexane, diphenyl ether, and cyclohexyloxybenzene. We infer that these compounds were formed in bimolecular reactions that involve cyclohexanol, which these authors did not observe. It is possible that rapid dehydration of cyclohexanol (to give cyclohexene) occurred more rapidly with HY zeolite and with HZSM-5 than with γ-Al2O3, giving cyclohexanol the opportunity to react to give cyclohexyloxycyclohexane or cyclohexyloxybenzene.

We infer that platinum sites catalyze hydrogenation, dehydrogenation, and HDO and that acidic sites (in HY zeolite, HZSM-5, and γ-Al2O3) catalyze dehydration, isomerization, alkylation, and condensation reactions.

When the H2 partial pressure in the feed was increased approximately threefold, hydrogenation and HDO were significantly favored, as shown by the higher selectivities for cyclohexane, benzene, cyclohexene, and cyclohexanol in this case (Table 2). We infer that dehydrogenation was kinetically less important, as 2-cyclohexen-1-one and phenol were formed with lower selectivities when the H2 partial pressure was 131 kPa. The higher selectivities for deoxygenated bicyclic C12 compounds (cyclohexylbenzene and biphenyl) bolster the inference that oxygen removal is favored by higher H2 partial pressures. Thus, the results highlight the importance of H2 for oxygen removal reactions and point to the possible advantage of high H2 partial pressures in potential practical processes when oxygen removal is a goal.

The product distribution in the conversion of cyclohexanone is strongly affected by temperature. The data shown in Table 4 show that higher temperatures result in higher selectivities for most products formed by dehydrogenation (especially phenol) and in lower selectivities for products formed by hydrogenation. However, the data do not allow a simple general statement explaining how selectivities for oxygen removal and bimolecular reactions are influenced by temperature because of the occurrence of unresolved parallel and sequential reactions.

5 Conclusions

The catalytic conversion of cyclohexanone catalyzed by Pt/γ-Al2O3 in the presence of H2 involves several kinetically significant classes of reactions, including hydrogenation, dehydrogenation, HDO, dehydration, isomerization, alkylation, and condensation. Dehydration was found to be kinetically the most significant among the observed reaction classes and was even more favored at the higher temperatures under the conditions of our experiments. Acid-catalyzed alkylation and condensation reactions evidently precede the formation of several bicyclic C12 products. The data suggest that high H2 partial pressures will be advantageous for selective oxygen removal. The results lead to a better understanding of the catalytic reactions of cyclic oxygen-containing compounds, and they can be incorporated into the reaction networks reported earlier for the conversion of aromatic oxygen-containing compounds such as guaiacol, anisole, and phenol.

References

Huber GW, Iborra S, Corma A (2006) Chem Rev 106:4044

Zakzeski J, Bruijnincx PC, Jongerius AL, Weckhuysen BM (2010) Chem Rev 110:3552

Elliott DC, Hart TR (2009) Energ Fuel 23:631

Czernik S, Bridgwater AV (2004) Energ Fuel 18:590

Mohan D, Pittman CU, Steele PH (2006) Energ Fuel 20:848

Furimsky E (2000) App Catal A Gen 199:147

Elliott DC (2007) Energ Fuel 21:1792

Laurent E, Delmon B (1994) App Catal A Gen 109:77

Zhao C, Kou Y, Lemonidou AA, Li XB, Lercher JA (2009) Angew Chem Int Ed Engl 48:3987

Hong DY, Miller SJ, Agrawal PK, Jones CW (2010) Chem Commun 46:1038

Yan N, Yuan Y, Dykeman R, Kou Y, Dyson PJ (2010) Angew Chem Int Ed Engl 48:3987

Senol OI, Ryymin EM, Viljava TR, Krause AOI (2007) J Mol Catal A Chem 277:107

Runnebaum RC, Nimmanwudipong T, Block DE, Gates BC (2010) Catal Lett 141:817

Gutierrez A, Kaila RK, Honkela ML, Siloor R, Krause AOI (2009) Catal Today 147:239

Nimmanwudipong T, Runnebaum RC, Block DE, Gates BC (2011) Catal Lett 141:779

Alvarez F, Magnoux P, Ribeiro FR, Guisnet M (1994) J Mol Catal 92:67

Mahajan YS, Kamath RS, Kumbhar PS, Mahajani SM (2008) Ind Eng Chem Res 47:25

Huang J, Long W, Agrawal PK, Jones CW (2009) J Phys Chem C 113:16702

Simonetti DA, Dumesic JA (2008) Chem Sus Chem 1:725

Bhore NA, Klein MT, Bischoff KB (1990) Ind Eng Chem Res 29:313

Bhore NA, Klein MT, Bischoff KB (1990) Chem Eng Sci 45:2109

Olivas A, Samano EC, Fuentes S (2001) App Catal A Gen 220:279

Maier WF, Bergmann K, Bleicher W, Schleyer PvR (1981) Tetrahedron Lett 22:4227

Durand R, Geneste P, Moreau C, Pirat JL (1984) J Catal 90:147

Silva AI, Alvarez F, Ribeiro FR, Guisnet M (2000) Catal Today 60:311

Raje VP, Bhat RP, Samant SD (2005) J Mol Catal A Chem 240:172

Anand R, Gore KU, Rao BS (2002) Catal Lett 81:33

Acknowledgments

We thank Jennifer Heelan for advice on gas chromatography, Professor Alexander Katz of the University of California, Berkeley, for providing access to instruments for determining catalyst physical properties, and Ryan Limbo and Jonathan Doan for help with the experiments. Financial support for this work was provided by Chevron Technology Ventures, a division of Chevron U.S.A., Inc. An Agilent Technologies Foundation Research Project Gift provided a GC7890 Refinery Gas Analyzer. Tarit Nimmanwudipong acknowledges a Fulbright Open Competition Scholarship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nimmanwudipong, T., Runnebaum, R.C., Tay, K. et al. Cyclohexanone Conversion Catalyzed by Pt/γ-Al2O3: Evidence of Oxygen Removal and Coupling Reactions. Catal Lett 141, 1072–1078 (2011). https://doi.org/10.1007/s10562-011-0659-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-011-0659-2