Abstract

The Meerwein–Ponndorf–Verley (MPV) reaction of cyclohexanone with 2-propanol in the liquid phase in the presence of two different nanocrystalline magnesium oxides, prepared by different methods, was investigated. The catalyst consisting of nanocrystalline magnesium oxide, which was prepared by calcination of magnesium methoxide in air at 400 °C, showed the highest activity in the conversion of cyclohexanone to cyclohexanol with 97% yield. The effect of calcination temperature of magnesium oxide on the cyclohexanol yield and reusability of the catalyst has been studied.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The Meerwein–Ponndorf–Verley (MPV) reduction is a convenient route for the preparation of saturated and α, β-unsaturated alcohols, which can be used as starting materials for the production of fine chemicals [1]. In recent years, development of asymmetric synthesis based on the MPV reduction has also been accelerated [2]. The MPV reaction involves the catalytic transfer of hydrogen atom from a secondary alcohol, in general and 2-propanol, in particular, to a carbonyl compound. Metal alkoxides are generally used as catalysts for the MPV reaction [3], and to obtain acceptable yields, metal alkoxide must be used in a large excess, which makes the removal and separation process rather difficult leaving aside the economical and environmental concerns. Attempts have been made by several authors to use alternative catalysts for the MPV reaction such as trimethylaluminum, dimethylaluminum chloride [4], iridium [5], ruthenium [6], plutonium [7], samarium [8] complexes, and bimetallic alkoxides [9] in homogenous systems. In spite of the advantage of the aforementioned metal complexes in MPV reactions, the separation and recovery of catalysts at the end of the process are difficult. To this end, heterogeneous catalysts for this reaction such as Al-free Zr-zeolite [10], supported zirconium propoxide [11], and MCM-41-grafted aluminum isopropoxide [12] have been developed. However, preparations of the majority of those catalysts are highly labor-intensive in contrast to metal oxides, which can be readily prepared. In this context, several authors have used metal oxides such as Al2O3 [13], hydrous ZrO2 [14], and MgO [15] in addition to Mg–Al mixed oxide [16] for MPV reaction. The Mg–Al mixed oxide is particularly interesting and the high activity of this catalyst is attributed to the presence of both basic and acidic sites [17]. Armendia et al. [18] showed that the Mg–Al mixed oxide prepared from the layered double hydroxides with an Mg/Al ratio of 2:1 and calcined at 500 °C shows the best catalytic activity in the reduction of cyclohexanone to cyclohexanol in the liquid phase by hydrogen transfer from 2-propanol. Interestingly, Kumbhar et al. [17] found that Mg–Al hydrotalcite with an Mg/Al ratio of 3:1 is a highly active and selective catalyst for the MPV reduction of 4-tert-butyl cyclohexanone. Considering that the number of acidic and basic sites can be influenced by the Mg/Al ratio and calcination temperature [18], and both acidic and basic sites can catalyze the MPV reduction, such a contradictory result is not unusual [13]. Niyama et al. [19] have shown that catalysts having adequate acidity and basicity can act as efficient catalysts in the MPV reaction. Apparently, in the MPV reaction that is catalyzed by Mg–Al mixed oxides, 2-propanol is adsorbed at the basic sites and ketone at the adjacent acidic sites before hydrogen-transfer reaction takes place. Therefore, it is expected that an oxide with a proper ratio of the acidic and basic sites, regardless of the oxide type, should be an efficient catalyst for the MPV reduction.

Recent development in the synthesis of nano-crystalline metal oxides, in general, and nano-crystalline magnesium oxide, in particular, by various chemical routes, provide an opportunity to use them in a wide variety of applications, including as a catalyst for the MPV reaction [20]. The MgO prepared by conventional methods, based on the decomposition of various magnesium salts, resulted in the formation of a coarse powder with small surface area. On the contrary, MgO prepared by the sol–gel route exhibits a smaller particle size, a larger surface area, and a large number of defects in crystalline structure [21]. Klabunde and co-workers [20] reported that defects on the nanocrystal surface promote the formation of basic and acidic sites; therefore, it is expected that nanocrystalline MgO prepared by various techniques should act as a suitable catalyst for the MPV reaction. In this paper, we report the effect of the preparation method of nanocrystalline magnesium oxide on the reduction yield of cyclohexanone to cyclohexanol in liquid phase.

2 Experimental

2.1 Materials and Methods

Magnesium turning, magnesium chloride, magnesium oxide, cyclohexanol, and isopropanol were purchased from Merck and used as received. Methanol was analytical grade and dried and distilled over magnesium turning before use. X-ray diffraction pattern of powders were recorded on a Philips PW-1730 diffractometer with Cu Kα radiation and crystalline size of MgO samples was estimated from the X-ray line broadening by using the Scherrer equation [22]. The morphology of powders was observed using a Philips CM-200 FEG transmission electron microscopy (TEM). GC analyses were carried out on a Shimadzu GC-17A with FID detector. GC–MS were recorded on Agilent Technology (HP, 6890) instrument equipped with a CBP5-M25 capillary column (internal: 0.22 mm, length: 30 mm). The basic properties of magnesium oxides were analyzed by infrared spectroscopy using carbon dioxide as a probe. The infrared spectra of the samples were obtained (KBr) on a Shimadzu 4600 spectrophotometer. Each freshly calcined magnesium oxide sample (0.5 g) was charged into a quartz tube and out gassed at 200 °C for 5 h under flow of nitrogen. Temperature of the sample was brought down to 25 °C and then carbon dioxide was introduced into the quartz tube until complete saturation of basic sites was insured. After saturation, the physisorbed carbon dioxide was removed by out gassing the sample at 50 °C under vacuum. The relative basicity of the samples was calculated using the intensity of the carbonate ion band at 1,437 cm−1.

2.2 Preparation of Nano-crystalline MgO

Preparation of magnesium methoxide was carried out under the atmosphere of dry nitrogen, using standard Schlenk techniques. Magnesium methoxide was prepared by the direct reaction of magnesium turning with dry methanol in the presence of iodine and then crystallized from methanol. The crystalline magnesium methoxide was filtered in an inert atmosphere and then dried under reduced pressure and used as a precursor. Two different nanocrystalline MgO samples used in this study were: (1) from hydrolysis of magnesium chloride similar to the previously reported method (MgO-2) [23], (2) from direct pyrolysis of magnesium methoxide in air at 400 °C for 3 h (MgO-3).

2.3 Catalytic Reaction: General Procedure

The reaction condition reported by Ruiz et al. [18] was used for the catalytic test. Catalytic hydrogen-transfer was performed in liquid phase. In a typical reaction, 2-propanol (3.6 g, 60 mmol), cyclohexanone (0.30 g, 3 mmol), and freshly calcined magnesium oxide (1 g) were taken in a 25 mL round-bottom flask fitted with a reflux condenser. The reaction mixture was heated to reflux temperature (82 °C) in oil bath and stirred magnetically at 1,000 rpm. Aliquots were withdrawn by a syringe at different times during the reaction and analyzed by gas chromatography and mass spectrometry. Quantification of the product was made by GC with the aid of a standard. The reaction was also carried out in the absence of magnesium oxide in exactly the same way as in its presence. For catalyst recovery, the used catalyst was washed with methanol and then calcined at 400 °C for 3 h before use.

3 Results and Discussion

3.1 Characterization of Catalysts

XRD measurements showed that the prepared magnesium oxides were periclase phase. Formation of periclase magnesium oxide as the sole crystalline phase at 400 °C is consistent with an earlier report [24]. The particle size of magnesium oxides was estimated from line broadening of the peak at 2θ = 42.9° with d value of 2.11 Å, corresponding to (200) plane, by using the Scherrer equation [22]. This was confirmed by the TEM micrographs shown in Fig. 1a, b. The size of magnesium oxide, prepared by pyrolysis of magnesium alkoxide, somewhat was larger than the one prepared by hydrolysis of magnesium chloride. The estimated size of magnesium oxides along with their surface areas are listed in Table 1.

3.2 Catalytic Studies of Various Nano-crystalline MgO in MPV Reaction of Cyclohexanone with 2-Propanol

Table 2 shows the performance of the different nanocrystalline magnesium oxides as catalysts in the hydrogen transfer from 2-propanol to cyclohexanone, and Fig. 2 shows the yield of cyclohexanol as a function of time for MgO-3. The catalytic activity of commercial magnesium oxide is significantly lower than the catalytic activity of other magnesium oxides listed in Table 2. Interestingly, MPV reaction of cyclohexanone with 2-propanol over different nanocrystalline magnesium oxides shows different activities. It is a well-established fact that in the MPV reaction, the presence of acid–base pair sites are required for the proton of alcohol to be adsorbed at the basic sites and ketone at the neighboring acidic sites before the reaction takes place [18]. Therefore, the difference in activity of nanocrystalline magnesium oxides in MPV reaction in this work suggests that the total number of basic and acidic sites in various nano-crystalline magnesium oxides, prepared by various methods in this study, should be different. Therefore, higher performance of MgO-3 probably is associated with the greater numbers of acid–base pair sites. For further elucidation of the crucial role of basic sites of nano-crystalline magnesium oxide in the hydrogen transfer process, both nanocrystalline and commercial magnesium oxides were exposed to carbon dioxide under similar conditions, and then the amount of chemisorbed carbon dioxide on each sample was estimated from the carbonate band in the infrared spectrum. Basicity was assessed by assuming that one molecule of carbon dioxide was chemisorbed at each single basic site on the surface. All samples showed carbonate ion band at 1,437 cm−1 with relative band intensities of about 4:2:1 for MgO-3, MgO-2 and MgO-1. Interestingly, the nanocrystalline MgO-3 which was prepared by pyrolysis of magnesium methoxide in air at 400 °C, showed higher amount of carbonate ion after exposing to carbon dioxide. This clearly shows that a higher number of basic sites are present in the magnesium oxide prepared by pyrolysis of magnesium methoxide. This is in accordance with the decrease in catalytic activity of both nanocrystalline and commercial magnesium oxides after exposing them to carbon dioxide. The relative amount of adsorbed carbon dioxide for MgO-3, MgO-2 and MgO-1 to a good extent is in agreement with their relative catalytic activities (4.6:2.48:1) in MPV reaction of cyclohexanone with 2-propanol. IR spectrum of the precursor obtained after exposure of magnesium methoxide to air showed residual OH peak in the MgO lattice, whose intensity decreased in subsequent calcination. Apparently, similar to the sol–gel derived magnesium oxide [25], during calcination, dehydroxylation takes place and causes anion vacancies to form, and finally, aggregation of magnesium ions around them produce locally accumulated positive charge [21]. Those locally accumulated positive charges act as acidic sites that are needed for adsorption of ketone. As mentioned earlier, in addition to the acidic sites for the MPV reaction, basic sites are also needed, and a comprehensive study shows that the magnesium oxide prepared by the sol–gel method fulfills this requirement [21]. Apparently, the metal oxides derived from metal alkoxides, in general, and magnesium oxide in particular, are endowed with hydroxyl groups, in which some of the hydroxyl groups are embedded in the crystalline structure and generate defects [26]. Furthermore, considering that the smaller nanocrystalline powder contain more defects and consequently higher concentration of basic sites than larger particle size powder [20], lower crystalline size and higher surface area of MgO-3 also is consistent with the higher catalytic activity of it.

This study was completed by carrying out MPV reaction with the MgO-3 that was calcined at various temperatures. Notably, the MgO-3 calcined at 400 °C was the most active, followed by those calcined at 500 and 600 °C. Considering the fact that the number of basic sites of magnesium oxide, their strength, and also the number of Mg vacancies decrease with the increase in calcination temperature [21], decrease in cyclohexanol yield is logical. This was in accordance with the decrease in the total amount of adsorbed carbon dioxide molecules for magnesium oxide that was calcined at higher temperature.

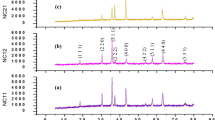

The MgO-3 that was used for the catalytic hydrogen transfer from 2-propanol to cyclohexanone was recovered and reused after proper treatment to examine its possible recyclability. After the first run, the catalyst was separated from the reaction mixture by filtration and washed several times with methanol and then calcined in air at 400 °C for 3 h. The catalytic activity of the used catalyst in the MPV reaction of cyclohexanone and 2-propanol is illustrated in Fig. 3. Apparently, the catalyst remains active with no significant loss of activity at least for four consecutive uses, which indicates that there is no poisoning of the active sites of the catalyst by deposition of coke during recycling of the catalyst.

4 Conclusions

This work shows that the nanocrystalline magnesium oxide prepared from magnesium methoxide is an efficient catalyst for the reduction of cyclohexanone by hydrogen transfer of 2-propanol. The catalytic activity is associated with the presence of surface acid–base pairs, which can be influenced by the calcination temperature. The high basicity of the nanocrystalline magnesium oxide prepared in this work with high potential of recyclability will be of interest for use in basic catalytic reactions such as aldol condensation and other fine chemical synthesis.

References

Creyghton EJ, Huskens J, van der Waal JC, van Bekkum H (1997) In: Blaser HU, Baiker A, Prins R (eds) Heterogeneous catalysis and fine chemicals IV. Elsevier, Amsterdam, p 531

Ooi T, Miura T, Ohmasu K, Saito A, Maruoka K (2004) J Biomol Chem 2:3313

Ooi T, Ichikawa H, Marooka K (2001) Angew Chem Int Ed 40:3610

Campbell EJ, Zhou H, Nguyen ST (2001) Org Lett 3:2391

Maillard D, Nguefack C, Pozzi G, Quici S, Balada B, Sinon D (2000) Tetrahedron Asymmetr 11:2821

Petra DGI, Reek JNH, Schoemaker PCJ, Leeuwen PWNM (2000) Chem Commun 683

Warner BP, D’Alessio JA, Morgan AN, Burns CJ, Schake AR, Watkin JG (2000) Inorg Chim Acta 309:45

Molander GA, Mckie JA (1993) J Am Chem Soc 115:5821

Misra SN, Shukla RS, Gagnani MA (2005) J Colloid Interf Sci 281:164

Zhu Y, Chuah G, Jaenicke S (2004) J Catal 227:1

Zhu Y, Jaenicke S, Chuah GK (2003) J Catal 218:396

Anwander R, Palm C, Gerstberger G, Groeger O, Engelhardt G (1998) Chem Commun 1811

Ivanov VA, Bachelier J, Audry F, Lavalley JC (1994) J Mol Catal 91:45

Kuno H, Takahashi K, Shibagaki M, Shimazaki K, Matsushita H (1991) Bull Chem Soc Jpn 64:312

Aramendia MA, Borau V, Jimenez C, Marinas JM, Ruiz JR, Urbano FJ (2001) J Colloid Interf Sci 238:385

Ruiz JR, Jimenez-Sanchidrian C, Hidalgo JM (2007) Catal Commun 8:1036

Kumbhar PS, Sanchez-Valente J, Lopez J, Figueras F (1998) Chem Commun 535

Aramendia MA, Borau V, Jimenez C, Marinas JM, Ruiz JR, Urbano FJ (2003) Appl Catal A 255:301

Niyama H, Echigoya E (1972) Bull Chem Soc Jpn 45:938

Lucas E, Decker S, Khaleel A, Seitz A, Fultz S, Ponce A, Li W, Carnes C, Klabunde KJ (2001) Chem Eur J 7:2505

Wang JA, Novaro O, Bokhimi X, Lopez T, Gomez R, Navarrete J, Llanos ME, Lopez-Salinas E (1997) J Phys Chem B 101:7448

Culltiy BD (1978) Element of X-ray powder diffraction. Wiley, New York

Xu B-Q, Wei J-M, Wang H-Y, Sun K-Q, Zhu Q-M (2001) Catal Today 68:217

Zhang G, Hattori H, Tanabe K (1989) Bull Chem Soc Jpn 62:2070

Itoh H, Utamapanya S, Stark JV, Klabunde KJ, Schlup JR (1993) Chem Mater 5:71

Derouance EG, Fripiat JC, Andre JM (1974) Chem Phys Lett 28:445

Acknowledgments

The financial support of Iranian National Science Foundation (Grant No. 84201) and the Research Council of University of Tehran University is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Heidari, H., Abedini, M., Nemati, A. et al. Nanocrystalline Magnesium Oxide as a Versatile Heterogeneous Catalyst for the Meerwein–Ponndorf–Verley Reduction of Cyclohexanone into Cyclohexanol: Effect of Preparation Method of Magnesium Oxide on Yield. Catal Lett 130, 266–270 (2009). https://doi.org/10.1007/s10562-009-9885-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-009-9885-2