Abstract

The advantage of using particulate layers in water and air cleaning is in the combination of two important features in photocatalysis: high surface area of powder particles and immobilization of photocatalyst. The present paper deals with the preparation of particulate TiO2 layers using three different techniques: sedimentation, electrophoresis and dip-coating and different particulate photocatalyst namely P25 (Degussa) and anatase Ti1 and Ti2 of Czech production. Photocatalytic activity was tested using an aqueous solution of a model azo-dye Acid Orange 7. It was found that the method of preparation has not a significant impact on the photocatalytic properties of resulting layer. Surprisingly the immobilized powder with the lowest surface area and crystal size around 170 nm exhibit the best photocatalytic performance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Specific surface area is often considered as an important factor in photocatalysis. It is due to the fact that holes and electrons react with water and oxygen, respectively, both adsorbed at photocatalyst particle surface. Using of small particles (few tens nanometres) containing suspension leads to high specific surface available for photocatalytic reactions. But this approach is linked to the problem with separation of photocatalyst and solution. Separation of photocatalyst particles can be achieved by filtration or sedimentation but this increases the technological and economical demand of whole purification process. The deposition of photocatalyst particles seems to be suitable solution of this problem. There are many ways of TiO2 film preparation. In this work we concentrated to the preparation of porous, particulate, photocatalytically active layers, their characterization and photocatalytic activity determination.

So far the most photoactive particulate films were prepared from powder P25 (Degussa) by either sedimentation [1] or by electrophoresis [2]. Sedimentation is a process where photocatalyst particles are deposited on the support from suspension (usually 5–10 g/dm3) using gravitation [1, 3–7]. Sometimes suspension is slightly acidified (e.g., nitric acid). After some time of sedimentation the rest of suspension is removed and support with particulate layer is dried. Electrophoresis technique is based on the migration of positively charged titanium dioxide particles in applied electric field to negatively charged support. Most widely used is suspension in methanol [2, 7–9] due to the suppression of hydrogen and oxygen evolution at high potential (10 V). Spraying is a technique based on the deposition of photocatalyst suspension in the form of small drops on a suitable support. Other possible technique is dip-coating from particle suspension which is often used for the preparation of sol–gel layers. This technique seems to be suitable for deposition of very thin films of uniform distribution.

Generally layers of particulate photocatalyst deposited using the above mentioned techniques have bad adhesion to the support. This can be improved by thermal annealing at 300 °C which has proved to have no effect on surface area [10]. Further increase in temperature then leads to the partial sintering and improved electrical contact among particles resulting in an increase in IPCE [11].

Very often the type of powder catalyst together with the technique of particles deposition has a crucial effect on the properties of particulate films [7]. Therefore, the present paper deals with the preparation of particulate TiO2 layers using different techniques (sedimentation, electrophoresis and dip-coating) and different powder photocatalyst, namely P25 (Degussa), anatase Ti1 and Ti2 of Czech production.

Photocatalytic properties were determined using mono-azo dye Acid Orange 7 (AO7) as a model compound. AO7, a sodium salt of (2-hydroxy-1-naphtylazo) benzensulphonic acid has several advantages. It has absorption band with a maximum at 485 nm (with extinction coefficient e = 21,400 M−1 cm−1) [12] and absorption minimum at irradiation wavelengths around 350 nm. Therefore, AO7 absorbs only a small part of the emitted radiation while the majority of it is absorbed by the photocatalyst. Moreover, none of the stable degradation intermediates of AO7 absorbs at wavelengths longer than 300 nm. That is why the absorption spectroscopy method can be used for precise determination of the concentration changes of AO7 during the whole photocatalytic degradation process [13, 14].

The aim of the present work was the comparison of photocatalytic behaviour of three commercial photocatalyst in either suspended and immobilized form using azo dye Acid Orange 7 with particular interest to the method of immobilization.

2 Experimental

2.1 Film Preparation

All TiO2 layers were deposited on conducting glass substrates: F:SnO2 (Solems, France), sheet resistivity: 10 Ohms/square. Layers were prepared by sedimentation and dip-coating from aqueous suspension and by electrophoresis from methanol suspension. Sedimentation was performed by placing of small amount of aqueous catalyst suspension on the substrate and following drying (water removal). In the present case the different layer thickness was achieved using constant volume (2 ml) of varying concentration from 0.05 to 0.5 g dm−3 for surface area 10 cm2. Electrophoretic layers were prepared by applying a constant voltage (−10 V vs. a counter electrode of stainless steel) and varying electrophoresis time (5, 10, 20, 30 s) using powder catalyst suspended in methanol at a slurry concentration of 10 g dm−3. For dip-coating technique the different amount of photocatalyst deposited was achieved by the concentration in the suspension and by the number of coating. Deposited layers were after drying at laboratory condition heated at 300 °C for 30 min. From the weight gain of samples after deposition the amount of catalyst in the film was calculated.

2.2 Characterization of Photocatalyst Layers

The surface morphology of layers was observed by SEM (Hitachi S4700). The crystalline phases in prepared layers were determined by X-ray diffraction using of Seifert XRD 3000 P diffractometer. Crystalline size was calculated from the Scherrer equation [15] using the X-ray diffraction peak at 2Θ = 25.3 (anatase). Specific surface area of powder photocatalysts were determined by nitrogen adsorption–desorption isotherms and calculated by the BET method [16].

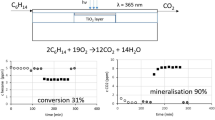

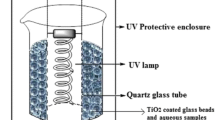

2.3 Photocatalytic Activity Measurement

As a photoreactor magnetically stirred rectangular cell from optical glass was used. Temperature was kept constant at value 20 °C using thermostat. Samples with catalyst layer were irradiated by UV light fluorescent tubes Sylvania Lynx CFS 11 W BL350. These tubes emit irradiation in the wavelength range from 320 to 390 nm with maximum at 355 nm. Initial concentration of AO7 was 1.0 × 10−5 mol/l, irradiated area and reactor volume was 1.5 cm2 and 30 ml, respectively. Using UV–VIS spectroscopy the concentration of AO7 was measured in regular intervals during irradiation.

3 Results and Discussion

3.1 Powder Catalysts

At first the photocatalytic activity of original powder photocatalysts was compared in aqueous suspension. Powder characterization was performed by SEM, XRD and BET and is summarised in Table 1. Agglomerate size was estimated from SEM images and for P25 and Ti1 it is very similar while for Ti2 it is lower. On the other side crystalline size is for each photocatalyst rather different and well corresponds to measured BET surface area. It means that aggregates of P25 and Ti2, observed by SEM, are porous and consist of approximately 10–20 particles while agglomerates of Ti1 are non-porous and in fact consist of 1–2 particles.

The photocatalytic degradation of AO7 in the suspensions of three photocatalysts is shown in Fig. 1. The Ti2 photocatalyst has the smallest photocatalytic activity despite its highest surface area. But ultrasonic treatment of Ti2 suspension before photocatalytic degradation measurement leads to an increase of photocatalytic activity about 200% (50% higher than P25). The reason of this is breaking of agglomerates and subsequent utilisation of high surface area for photocatalytic reaction but still the photocatalytic activity does not correspond to it’s surface area. From Fig. 1 we can also see that photocatalyst Ti1 has a similar photoactivity as P25 even its surface area is five times lower. It can be therefore concluded that unlike catalysis high surface area of TiO2 material is not the crucial parameter for the assessment of photocatalytic activity. Similarly in our previous work we observed that TiO2 photocatalyst with 5-times higher surface area then P25 exhibits even 2-times lower photoactivity [10]. Recently an interesting paper has been published [17] in which a correlation between photocatalytic activities and structural and physical properties of TiO2 powders was provided. The correlation was performed for 5 reaction, 35 samples and 5 parameters. Although the large coefficients for BET were expected (since large area is advantageous to adsorb reaction substrate) only large positive coefficient was observed for dehydrogenation of methanol in deaerated aqueous solution. For other systems it was either negative or very small. This further confirms that there is not a straight forward relation between photoactivity and surface area.

3.2 Method of Film Immobilization

Due to the much higher application potential in our further work we concentrate on immobilized layers. First of all three techniques of layer preparation were used (namely sedimentation, electrophoresis and dip-coating) and P25 films of various content of TiO2 (and of course layer thickness) were prepared.

The further step was the determination of the amount of absorbed light at maximum emission wavelength of used UV light source. There is a general meaning that the light scattering in suspensions disallows a sufficiently precise determination of the light intensity that is really absorbed by the photocatalyst. However, we found that complementary measurements of both transmission and reflection spectra using an integrating sphere performed with a set of particulate films of different thicknesses allow the estimation of true absorption spectra (Fig. 2) with only a very small deviations.

The course of AO7 photodegradation on sedimented P25 layers of various TiO2 amounts is shown in Fig. 3. It can be seen that during the first 60 min of irradiation the concentration decreases linearly with time and thus the initial degradation rate R i (mol s−1 m−2) were calculated from the slope (dc/dt)t=60 min. Azo dye AO7 has been recently used as a model dye for tests of immobilized photocatalysts [18–20]. Similarly as in the present work the observed kinetics was zero order for either particulate [21] or transparent sol–gel TiO2 film [20].

Figure 4 shows the values of R i for layers prepared by various methods as a function of amount of photocatalyst. We can see that the crucial parameter is the amount of deposited photocatalyst while the applied procedure of the layer deposition had practically no effect on the resulting photocatalytic activity and all the data fit the same curve. This finding can be further supported by the observed morphology of prepared films (Fig. 5). The only small difference can be seen, sedimentation and dip-coating leads to rather smooth surface while layers prepared by electrophoresis have higher roughness.

The dependence of 1-T355 (representing the amount of absorbed light) on the amount of immobilized photocatalyst is shown also in Fig. 4. It can be seen that absorbed light increases up to 0.5 mg cm2 and than it is almost constant. The shape is similar as that of degradation rate R i. This means, not surprisingly, that for the degradation rate the crucial parameter is the amount of absorbed light. The optimal amount of P25 photocatalyst is in the range 0.3–0.5 mg/cm2 which corresponds to the hypothetical dense layer of thickness 0.6–1.25 μm. This is higher than the reported thickness of 0.44 μm associated with the formation of a monolayer of aggregated P25 particles [4]. There is a possible reason for the difference. In the present work the irradiation was from the solution/TiO2 interface while in the work of Mills and Wang [4] irradiation was from substrate/TiO2 interface.

The similar effect of the photocatalyst amount but in suspension was obtained by Vione et al. [22] who investigated the dependence of photoactivity on the TiO2 photocatalyst concentration. For P25 suspension above 0.5 g dm−3 there is no increase in photoactivity while for Wackherr TiO2 due to the lower scattering of radiation photoactivity increases up to 2 g dm−3.

3.3 Comparison of Different Catalysts

When we compare sedimentation, dip coating and electrophoresis, first one was quite simple and quick, but dip coating is complex method needing repetition of dipping and drying to obtain layer with sufficient thickness. Electrophoretic technique than requires the conductive support. For that reasons we used only sedimentation method for further layers preparations.

Morphology of layers prepared by sedimentation (0.5 mg/cm2) from various photocatalyst is shown in Fig. 6. The differences in surface roughness due to the unequal agglomerate size of individual photocatalyst materials can be seen. From cross-sections in Fig. 6 we can estimate the thickness of particular layers. It can be seen that for photocatalyst P25 the thickness is around 5 μm. Calculated porosity (using density of TiO2) is ~0.75 and this means that volume of pores is about 75%. For the other two catalysts the thicknesss cannot be easily determined due to not sufficient adhesion of particulate layer to the substrate.

Similarly as for P25 layers, complementary measurement of both transmission and reflection spectra using an integrating sphere gives true absorption spectra for particulate films consisting of three different powder photocatalyst of constant TiO2 amount (0.5 mg/cm2) (Fig. 7). It is clearly visible that P25 films absorb significantly higher amount of light than the films of the other two catalysts. We can further see that the absorbance in the visible part is not zero due to the light scattering and is significant especially for film consisting of Ti1 particles. The reason is in the much higher particle size of this powder (see Table 1). Separation of light absorption from light scattering in TiO2 particulate layers has to be performed and the values of 1-T at 355 nm is calculated.

The comparison of photodegradation efficiency of the prepared photocatalyst layers is shown in Fig. 8. In all cases the suspension was ultrasonically pretreated before the layer preparation. From the slope of concentration dependence during the first 30 min of irradiation the degradation rate of AO7 was calculated and shown in Table 2.

It has to be mentioned that the most frequently used dye for photoactivity test on photocatalytic surfaces is methylene blue (MB). Even this dye was found inappropriate for photoactivity assesment in visible wavelength range (see e.g., [23]) in the case of UV light MB is frequently used and is also involved in the ISO standards in Japan (JISR 1703-2) and Germany (DIN test method 52980). Recently the degradation of MB has been re-examined as a method to characterize the photocatalytic activity of TiO2 coatings [24]. Similarly as MB dye AO7 can be used as a model dye for photoactivity determination in UVA region. It could be supported by the obtained correlation between dyes AO7, MB and Resazurin/Resofurin system [20].

We can see that the effect of ultrasonic pretreatment of suspension before layer preparation is much higher for photocatalyst Ti2 (about 100%) than for photocatalysts Ti1 and P25 where it was almost negligible. Similarly the effect of ultrasonic pretreatment on the photodegradation rate of AO7 on P25 and Ti1 in suspensions was also almost negligible. Nevertheless the effect of ultrasonic pretreatment of Ti2 suspension on the degradation rate in suspension (Fig. 1) is much higher (increase about 200 %). This means that ultrasonic pretreatment of Ti2 suspension results in breakage of agglomerates but during subsequent layer formation partial re-agglomeration of photocatalyst particles takes place.

4 Conclusion

It was shown that the technique of TiO2 immobilization does not have a significant effect on photoactivity, the crucial parameter is the amount of deposited TiO2. From the comparison of the various photocatalytic particles it results that the choice of the best photocatalyst depends on whether the photocatalytic degradation rate is measured in suspension or on immobilized particulate layer. In the case of photocatalytic degradation in suspension photocatalyst Ti2 with the highest surface area is the most effective, but in the case of photocatalytic degradation on immobilized layers, photocatalyst Ti1 exhibits the highest photocatalytic activity. From UV–VIS spectroscopy it results that even the layer of P25 absorbs higher amount of UV light than other photocatalyst layers the particulate layer prepared from powder with the highest crystalline size and smallest surface area posses the best photocatalytic properties.

References

Vinodgopal K, Stafford U, Gray KA, Kamat PV (1994) J Phys Chem 98:6797

Byrne JA, Eggins BR, Brown NMD, McKinney B, Rouse M (1998) Appl Cat B Env 17:25

Kominami H, Murakami S, Kera Y, Ohtani B (1998) Catal Lett 56:125

Mills A, Wang J (1998) J Photochem Photobiol A Chem 118:53

Beydoun D, Amal R, Low G, Gary KC, McEvoy S (2000) J Phys Chem B 104:4387

Bhattacharyya A, Kawi S, Ray MB (2004) Catal Today 98:431

Waldner G, Krýsa J (2005) Electrochim Acta 50:4498

Byrne JA, Eggins BR (1998) J Electroanal Chem 45:61

Waldner G (2003) Heterogeneous Photocatalytic and Photoelectrocatalytic Purification of Water. Dissertation

Krýsa J, Keppert M, Jirkovský J, Štengl V, Šubrt J (2004) Mater Chem Phys 86:333

Krýsa J, Keppert M, Waldner G, Jirkovský J (2005) Electrochim Acta 50:5255

Rao KVS, Lavédrine B, Boule P (2003) J Photochem Photobiol A 154:189

Kiriakidou F, Kondarides DI, Verikios XE (1999) Catal Today 54:119

Chen Y, Yang S, Wang K, Lou L (2005) J Photochem Photobiol A 172:47

Scherrer P (1918) Gott Nachr 2:98

Brunauer S, Emmett PH, Teller E (1951) J Am Chem Soc 73:373

Prieto-Mahaney OO, Murakami N, Abe R, Ohtani B (2009) Chem Lett 38:238

Li J, Wang H, Li G, Wu Y, Quan X, Liu Z (2007) Plasma Sci Technol 9:469

Bandara J, Klehm U, Kiwi J (2007) Appl Catal B Environ 76:73

Zita J, Krýsa J, Mils A (2009) J Photochem Photobiol A Chem 203:119

Vinodgopal K, Kamat PV (1995) Environ Sci Tech 29:841

Vione D, Minero C, Maurino V, Carlotti ME, Picatonotto T, Pelizzeti E (2005) Appl Cat B Env 58:79

Yan X, Ohno T, Nishijima K, Abe R, Ohtani B (2006) Chem Phys Lett 429:606

Tschirch J, Fdillert R, Bahnemann D, Proft B, Biedermann A, Goer B (2008) Res Chem Intermed 34:381

Acknowledgment

Authors wish to thank the Ministry of Education of the Czech Republic for funding this research, project Nanopin No. 1M0577 and MSM 6046137301.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zlámal, M., Krýsa, J. & Jirkovský, J. Photocatalytic Degradation of Acid Orange 7 on TiO2 Films Prepared from Various Powder Catalysts. Catal Lett 133, 160–166 (2009). https://doi.org/10.1007/s10562-009-0170-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-009-0170-1