Abstract

A sensitive method is presented for the investigation of planar Ziegler-Natta model catalysts by means of attenuated total internal reflection Fourier transform infrared spectroscopy. A solution of MgCl2 in ethanol, optionally containing an internal donor, was spin-coated directly onto a planar ZnSe ATR crystal. Ethylene and propylene polymerization was monitored in situ and ex-situ, respectively, and interaction of a diester internal donor with MgCl2 and TiCl4 was investigated. The isotacticity of the polypropylene produced in the presence and absence of donor was estimated based on characteristic peaks in the infrared spectra.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

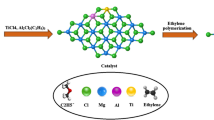

Ziegler-Natta catalysts (ZNC) play a dominant role in polyolefin production. The annual production of polypropylene (PP) now exceeds 40 million tonnes and most PP is produced using MgCl2-supported catalysts of type MgCl2/TiCl4/Lewis base. The Lewis base, typically an ester or ether present in the solid catalyst, is generally referred to as the internal donor and is a major factor determining the stereospecificity of the catalyst [1–3]. Internal donors bind strongly to the MgCl2 support [4–7]. It is believed that the internal donor blocks particular sites on the MgCl2 surface which otherwise, upon coordination with TiCl4, would generate precursors of non-stereospecific active sites [4, 8, 9]. On the other hand, as previously indicated [10–12], there is strong evidence for the presence of a donor in the vicinity of isospecific active species. Ziegler-Natta catalysts for PP are used in combination with an aluminum alkyl cocatalyst such as AlEt3 or AliBu3 and an additional Lewis base, termed the external donor, is generally added in polymerization.

In our previous work, we have described the preparation and characterization of a model Ziegler-Natta catalyst, starting from the spin-coating of a MgCl2 solution (with or without donor) in ethanol on a flat silicon wafer [13, 14]. Treatment with TiCl4 and AlEt3 resulted in an active catalyst for ethylene and propylene polymerization. Next, we developed a preparation method by which the spin-coated support precursor could be converted by controlled crystal growth into well-formed crystallites [15]. Incorporation of different internal donors such as a diether and esters in the crystal growth process generated large crystallites and provided strong evidence that the dependence of the distribution of the active species in ZNC for polypropylene on the nature of internal donor is related to the ability of the donor to steer the formation of a particular MgCl2 crystallite face during catalyst preparation [16].

Infrared (IR) spectroscopy is one of the most useful research tools for the study of surface species in solid catalysts. It can be applied to probe the state of carbonyl groups in ester internal donors, since the νC=O absorption band is very sensitive to coordination with a Lewis acid. IR spectroscopy has been extensively applied to Ziegler-Natta catalysts [17]. With regard to propylene polymerization catalysts, most of the work has focused on the spectral changes in the νC=O of the internal aromatic ester in various stages of catalyst preparation [17–31].

Analogous to our previous approach, we are now using a ZnSe crystal to deposit the MgCl2 (with or without donor) from ethanol solution via spin coating, aiming to investigate the ZN catalysts by means of a new technique in the field: attenuated total reflectance (ATR) infrared spectroscopy. To this end, the wafer has now been replaced by an internal reflection element such as ZnSe, which allows application of ATR-FTIR spectroscopy. The advantage of ATR-Fourier transform infrared (FTIR) is that the sensitivity is enhanced because the absorbance is proportional to the number of reflections in the ATR crystal [32].

In this work, we introduce a complete experimental set up for in situ and ex-situ ATR-FTIR studies. Two experimental studies are included to demonstrate the use and to document the performance of the set-up: (1) the interaction of MgCl2 with donor, followed by an estimation of the isotacticity of polypropylene prepared in systems with and without donor and (2) in situ ethylene polymerization as a proof of principle.

2 Experimental Section

2.1 Instrumentation

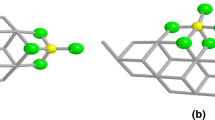

The FTIR spectra were collected using a Nicolet Protege 460 Fourier transform infrared spectrometer equipped with a heated HATR flow cell for Spectra-Tech ARK with a ZnSe 45° crystal. A schematic representation of the trapezoidal ZnSe ATR crystal with bevels at an angle of 45° (Harrick Scientific Prod. Inc.) is given in Fig. 1. The cut-off of the ZnSe crystal is at 700 cm−1. The data points of the collected spectra were the average of four scans at a spectral resolution of 4 cm−1 for all measurements and the spectra were automatically collected. ZnSe was used as a background for FTIR measurements on spin-coated MgCl2·donor·nEtOH and its reaction product with TiCl4, as well as for a TiCl4/donor complex (not spin-coated but deposited as powder). The FTIR measurement of donor in solution was carried out using ZnSe with the appropriate solvent as background. In this manner the solvent was masked, enhancing the visibility of donor signals. For the polypropylene (ex-situ) measurements, ZnSe was used as background. All the spectra were measured in transmittance mode unless otherwise stated.

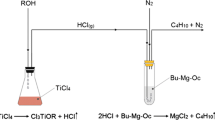

2.2 ATR-FTIR Set Up

For the study of the flat model catalyst for in situ ethylene polymerization, an ATR-IR flow cell set up has been constructed. This set-up includes solution containers, a reactor and the flow cell, all of which can be connected to gas supplies with a pressure up to ten bars and a vacuum system (Fig. 2). A solution (e.g., AlEt3 in anhydrous benzene) can be introduced to the reactor, where the solution will be saturated with ethylene at a desired pressure. The ethylene-saturated solution is introduced into the ATR cell under the ethylene pressure in a flow mode with the speed controlled by a flow meter. Both the reactor and the ATR cell can be set to a desired temperature up to 150 °C. As polymer grows on the ZnSe crystal, infrared spectra are recorded to monitor the polymerization.

Schematic representation of the ATR-IR flow cell set up for in situ ethylene polymerization (courtesy of W. Han [33])

2.3 Materials

Anhydrous magnesium chloride (beads, 99.9%), absolute ethanol (99.9%), titanium tetrachloride (99.9%), triethylaluminum (25 wt.% in toluene) and benzene (99.8%) were purchased from Aldrich Chemicals and used as received. HPLC-grade toluene was taken from an argon-flushed column packed with alumina and stored over 4 Å molecular sieves. Diisobutyl phthalate (≥98%) was provided by Aldrich and used as received. Propylene was supplied by Linden (3.5). Ethylene was supplied by Praxair (3.5).

2.4 Catalyst/Sample Preparation, Ethylene and Propylene Polymerization

All manipulations of air- or water-sensitive compounds were carried out using glove box techniques. Spin coating of MgCl2 from solution in ethanol was carried out as described previously [13]. When a donor (diisobutyl phthalate) was present, the donor/MgCl2 molar ratio was 0.1. After this step, reaction of TiCl4 with the MgCl2/donor·nEtOH or MgCl2·nEtOH was carried out by treatment with a 10% v/v TiCl4 solution in toluene at room temperature for 30 min. After washing with toluene to remove physisorbed TiCl4, the model catalyst was dried under nitrogen.

In the case of ethylene polymerizations (in situ) the ZnSe crystal (after deposition of MgCl2/EtOH and treatment with TiCl4) was assembled into a flow cell under glove box conditions then closed/sealed and transferred to the ATR-FTIR set up. The time-resolved ATR-FTIR polymerization experiment at room temperature was performed as follows. Anhydrous benzene was introduced into the flow cell and a FTIR spectrum was collected for reference. In the meantime, a AlEt3 solution in benzene (1 mg mL−1) had been saturated with ethylene under a 2 bar pressure in a reactor. The ethylene-saturated AlEt3 solution was then allowed to flow to the ATR flow cell at a rate of 20 g h−1 [33].

Propylene polymerization (ex-situ) was carried out at room temperature in a glass reactor equipped with a magnetic stirrer. The ZnSe crystal, with the model catalyst, was dipped into about 20 mL of a 1 mg mL−1 solution of the co-catalyst, AlEt3, in toluene, inside the glass reactor. The reactor was pressurized with 3 bar of propylene and polymerization was allowed to run for the desired time. The thickness of the polymer films grown on ZnSe was determined using a Tencor P-10 profilometer.

3 Results and Discussion

3.1 ATR-FTIR of MgCl2/DIBP·nEtOH, MgCl2/DIBP·nEtOH/TiCl4 and TiCl4/Donor

Coordination of the diester donor onto MgCl2 support along with the treatment with TiCl4 was studied by ATR-FTIR. A 0.1 M ratio donor/MgCl2 was applied, comparable to that present in a typical Ziegler-Natta catalyst [34]. It is well established that the coordination of donors such as esters onto MgCl2 supports (ethyl benzoate/MgCl2 complexes have been extensively studied) occurs via the carbonyl group [17–20, 24, 26, 28–31].

Overview FTIR spectra of neat DIBP, DIBP in ethanol and DIBP/MgCl2 complexes in the region of C=O and C–C–O bands are shown in Fig. 3. The C=O band of DIBP upon complexation with MgCl2 undergoes a shift to lower wavenumbers, i.e., 1,695 cm−1 (Fig. 3, left panel, spectrum c and d). This result is in agreement with previous reported data [31]. IR spectra of carbonyl groups (C=O in phthalates) of internal donors adsorbed on MgCl2 can be best described as a superposition of several overlapping vibration bands from a variety of surface complexes as previously reported by Potapov et al. [31]. The aromatic ring modes maintain their position upon coordination to MgCl2 (Fig. 3, left panel, spectrum a, b, c and d). Upon increasing the concentration of DIBP in the MgCl2/ethanol solution, the DIBP signals become stronger as observed in spectrum d of Fig. 3 (left panel).

Left panel a, Neat DIBP donor; b, DIBP in ethanol (15 mmol L−1); c, spin coated layer of DIBP/MgCl2 from ethanol (DIBP/MgCl2 ~0.1); d, spin coated layer of DIBP/MgCl2 from ethanol (DIBP/MgCl2 ~0.4). The inserted spectra represent C=O band and aromatic ring modes of DIBP before (solid line) and after (dashed line) complexation with MgCl2. Right panel a, DIBP donor coordinated to MgCl2 (DIBP/MgCl2 = 0.1); b, TiCl4/DIBP complex (1:1). The inserted spectra represent spin coated DIBP/MgCl2 (0.1 molar ratio) before (solid line) and after (dashed line) treatment with TiCl4

It is observed from the FTIR spectra of the DIBP/MgCl2 complexes that ratios of 0.1 and 0.4 give similar shifts of the C=O band to lower stretching frequency. A donor/MgCl2 ratio as high as 0.4:1 is not compatible with a support structure comprising, for example, hexagonal crystallites of MgCl2 with coordination of the donor on surface sites, as such sites represent only a small fraction of the total Mg present. It is more likely that, at high donor/MgCl2 ratios, the product has a chain-type structure, taking into account the fact that 2:1 adducts of (monodentate) Lewis bases and MgCl2 comprise MgCl2 chains with two molecules of Lewis base (LB) coordinated to each magnesium atom [35]. Another observation in Fig. 3 (left panel) is the shift to higher wavenumbers, i.e., ~1,320 cm−1 of the C–C–O band (spectrum c and d) upon complex formation with MgCl2. This upshift has been reported for EB/MgCl2 complexes and attributed to the so called resonance strengthening effect [24, 29].

The next step involved treatment with TiCl4. Figure 3 (right panel) shows the spectra of DIBP/MgCl2 and TiCl4/DIBP complexes (spectra a and b, respectively). The C=O band of the TiCl4/DIBP complex has shifted further downward, generating a peak splitting in the region 1,640–1,581 cm−1. Comparable results have been reported previously [21, 22]. The TiCl4/DIBP complex formation resulted in a yellowish solid product. Lastly, treatment of DIBP/MgCl2 film with TiCl4 induced a minor downshift in the vibrational frequency of the functional group, i.e., C=O band. The inserted spectra in Fig. 3 (right panel) show the C=O bands of a DIBP/MgCl2 complex, along with aromatic ring modes, before (solid line) and after (dashed line) treatment with TiCl4. The spectrum after treatment with TiCl4 indicates that only a minor shift to lower wavenumbers of the C=O band has occurred. The latter suggests that DIBP remains strongly coordinated to the MgCl2 support after TiCl4 treatment.

3.2 Ex-situ ATR-FTIR of Propylene Polymerization

The propylene polymerization was carried out over a model catalyst under glove box conditions similar to those on a Si wafer [13]. Polymerization was carried out in a Schlenk reactor in a solution of the cocatalyst for 24 h at room temperature and 3 bar pressure. The thickness of the PP layer was less than 1 μm [14]. When the DIBP donor was incorporated (DIBP/MgCl2 ~0.1), propylene polymerization was run under the same conditions but for 20 h. The thickness of the PP layer on ZnSe was about 20–25 μm. This corresponds to a polymer yield of 0.3 kg PP g−1 MgCl2. We previously reported yields up to 1 kg PP g−1 MgCl2 after 24 h propylene polymerization in presence of a diether as internal donor [14]. The lower yield of PP in the presence of DIBP as internal donor, as opposed to a diether donor, is to be expected taking into account that esters are to a large extent removed from the support by alkylation and complexation reactions with the cocatalyst (AlEt3) [36].

Figure 4a shows overview spectra of polypropylene obtained when no internal donor was incorporated (24 h polymerization) and polypropylene obtained when DIBP donor was incorporated (2 h polymerization). Both spectra reveal features characteristic of those of an IR spectrum of isotactic polypropylene [37]. The band located at 997 cm−1, originating from isotactic helices of polypropylene, is present in both spectra [37]. It is reported that the volume fraction of long isotactic sequences is reflected by the intensity of this band [38]. The intensity of this band is sensitive not only to the helical configuration but also to the long-range lateral packing.

The band of solid isotactic polypropylene at 974 cm−1 is reported to be due to the hybridized vibrations of the methyl rocking mode (asymmetric with respect to the H–C–methyl plane) and the asymmetric stretching mode of the main chain CH–CH2 bonds (axial and equatorial) [38]. The bands at 1,458–1,376 cm−1 may arise from CH2 scissoring [39], whereas the bands in the region 2,949–2,838 cm−1 are attributed to asymmetric and symmetric CH2 stretch.

The ratio of absorption intensities A997/A974 has been reported to be a measure of the tacticity [38, 40–42]. Figure 4b again displays infrared spectra of polypropylene obtained without and with DIBP donor present during polymerization, showing the absorption band at 997 cm−1 due to isotactic helices and the absorption band at 974 cm−1. In an attempt to estimate the isotacticity index of the PP, based on the A997/A974 ratio (I.I. = A997/A974 × 100) as previously reported [40, 41], we found that the isotacticity index for PP prepared with no donor was around 60%, as opposed to ~75% for the PP prepared in the presence of DIBP as internal donor. 13C NMR, which is a more reliable indicator of tacticity, revealed mmmm pentad contents of 57 and 63%, respectively, for the polymers prepared in the absence and presence of DIBP.

Kim and Somorjai [43] reported the formation of isotactic PP with model donor-free heterogeneous catalysts prepared under ultra-high vacuum techniques. Our results are in line with reported values for PP produced with MgCl2/TiCl4/AlR3 (I.I. = 40–60%) and that produced with MgCl2/TiCl4/DIBP/AlR3 in the absence of any external donor [1].

3.3 In Situ ATR-FTIR of Ethylene Polymerization

The new ATR-FTIR set up was tested for the in situ ethylene polymerization. Kinetic investigations of ethylene polymerization using supported catalysts are usually carried out by measuring the consumption of ethylene gas [44, 45]. It is of interest to quantitatively monitor in real time the formation of the polyethylene inside the reactor. To this end the ZnSe crystal, after deposition of MgCl2, was treated with TiCl4 and then polymerizations were allowed to run in the ATR-FTIR flow cell. Application of ATR-FTIR to monitor the vibrational bands of the PE offers the possibility to study the catalyst performance in its working state and acquire in situ information on the reaction kinetics.

ATR-FTIR results of a polymerization experiment using the Ziegler-Natta catalyst are shown in Fig. 5. The polymerization was carried out in benzene, which has a clear window in the region 2,800–2,980 cm−1. The model catalyst was initially treated with the solution of cocatalyst in benzene (carried out in situ in the cell) to remove ethanol/water present in the system, before starting the polymerization by introducing a cocatalyst solution saturated with ethylene (2 bar). Spectra collected during polymerization in this wavenumber region show the CH2 asymmetric stretching band at 2,917 cm−1 and the symmetric stretching band at 2,849 cm−1 of polyethylene (Fig. 5a). These spectra have been measured at 1 min intervals. The intensity of the band at 2,917 cm−1 is plotted versus polymerization time in Fig. 5b, where the intensity refers to the integrated area of the CH2 stretching band in absorbance unit in the ATR-FTIR spectrum. The intensity of the CH2 stretching band (2,917 cm−1) of polyethylene clearly increases with polymerization time.

a Series of spectra of polyethylene growing on a flat ZnSe surface. Spectra are shown in the region of interest (asymmetric and symmetric band of CH2). b Plot of the intensity of the band at 2,917 cm−1 versus polymerization time showing the increase in the intensity of CH2 stretching bands of PE during polymerization

ATR-FTIR analysis during real time polymerization demonstrates the future prospective of the method to determine polymerization kinetics. However, it is not straightforward to correlate the intensity of the ATR spectra directly with the polymerization rate. The evanescent ATR wave decays with distance from the crystal surface [46] and the intensity does not depend linearly on the thickness of the polymer layer. In other words, the decay of the evanescent wave leads to saturated band intensity for thick polymer films. To obtain kinetic information, a calibration curve of the dependence of the ATR-FTIR band intensity on the amount of the PE formed is needed.

The thickness of the polyethylene film reached ~1.5 μm after 20 min ethylene polymerization, which corresponds to a polymer yield of 0.055 kg PE g−1 MgCl2. The decrease in activity of PE grown in situ on ZnSe compared with the PE grown ex-situ on Si [13] can be attributed to minor water contamination in the ATR-IR cell.

4 Conclusions

Attenuated total reflection Fourier transform infrared spectroscopy (ATR-FTIR) can be used both for the investigation of donor/MgCl2 interactions in Ziegler-Natta catalysts and for real-time monitoring of catalyst activity in olefin polymerization. Coordination of a diester donor on MgCl2 occurs via the C=O functional group. TiCl4 and electron donors interact strongly with each other, but in the Ziegler-Natta catalyst the donors coordinate strongly to the MgCl2 support and remain relatively unperturbed by the presence of TiCl4. ATR-FTIR can also be used to validate/estimate the isotacticity of polypropylene produced in a model catalytic system. The present work is now being extended to investigation of in situ coordination of electron donors onto the surface of the MgCl2 support.

References

Albizzati E, Cecchin G, Chadwick JC, Collina G, Giannini U, Morini G, Noristi L, Resconi L (2005) In: Pasquini N (ed) Polypropylene handbook, 2nd edn. Carl Hanser Verlag, Munich (Ch. 2)

Chadwick JC (2001) Macromol Symp 173:21

Cecchin G, Morini G, Pelliconi A (2001) Macromol Symp 173:195

Sergeev SA, Bukatov GD, Zakharov VA, Moroz EM (1983) Makromol Chem 184:2421

Terano M, Kataoka T, Keii T (1986) In: Keii T, Soga K (eds) Catalytic polymerization of olefins. Kodansha-Elsevier, Amsterdam, p 407

Sormunen P, Hjertberg T, Iiskola E (1990) Makromol Chem 191:2663

Terano M, Saito M, Kataoka T (1992) Makromol Chem Rapid Commun 13:103

Busico V, Corradini P, De Martino L, Proto A, Savino V, Albizzati E (1985) Makromol Chem 186:1279

Sacchi MC, Tritto I, Shan C, Mendichi R, Noristi L (1990) Macromolecules 24:6823

Sacchi MC, Forlini F, Tritto I, Mendichi R, Zannoni G, Noristi L (1992) Macromolecules 25:5914

Morini G, Albizzati E, Balbontin G, Mingozzi I, Sacchi MC, Forlini F, Tritto I (1996) Macromolecules 29:5770

Busico V, Cipullo R, Monaco G, Talarico G, Vacatello M, Chadwick JC, Segre AL, Sudmeijer O (1999) Macromolecules 32:4173

Andoni A, Chadwick JC, Milani S, Niemantsverdriet JW, Thüne PC (2007) J Catal 247:129

Andoni A, Chadwick JC, Niemantsverdriet JW, Thüne PC (2007) Macromol Symp 260:140

Andoni A, Chadwick JC, Niemantsverdriet JW, Thüne PC (2007) Macromol Rapid Commun 28:1466

Andoni A, Chadwick JC, Niemantsverdriet JW, Thüne PC (2008) J Catal 257:81

Arzoumanidis GG, Karayannis NM (1991) Appl Catal 76:221

Terano M, Kataoka T (1987) Macromol Chem 188:1477

Ferreira ML, Damiani DE (1994) J Polym Sci Part A: Polym Chem 32:1137

Terano M, Kataoka T (1986) Macromol Chem Rapid Commun 7:725

Jeong Y-T, Lee D-H (1990) Macromol Chem 191:1487

Terano M, Kataoka T, Hosaka M, Keii T (1988) In: Kaminsky W, Sinn H (eds) Transition metals and organometallics as catalysts for olefin polymerization. Springer, Berlin, p 56

Chien JCW, Dickinson LC, Vizzini JC (1990) J Polym Sci Part A: Polym Chem 28:2321

Bache Ø (1994) The chemistry of MgCl2-supported Ziegler-Natta catalyst studied by in situ infrared spectroscopy, Ph.D. thesis, Institutt for uorganisk kjemi, Norges Tekniske i Trondheim, Norway

Chien JCW, Wu J-C, Kuo C-I (1983) J Polym Sci: Polym Chem Ed 21:725

Terano M, Kataoka T (1990) J Polym Sci Part A: Polym Chem 28:2035

Spitz R, Lacombe J-L, Primet M (1984) J Polym Sci: Polym Chem Ed 22:2611

Rytter E, Nirisen Ø, Ystenes M, Øye HA (1988) Mikrochim Acta II:85

Bache Ø, Ystenes M (1994) Appl Spec 48:985

Potapov AG, Bukatov GD, Zakharov VA (2006) J Mol Catal A: Chem 246:248

Potapov AG, Bukatov GD, Zakharov VA (2007) Kinet Catal 48:403

Leewis CM, Kessels WMM, van de Sanden MCM, Niemantsverdriet JW (2006) J Vac Sci Technol 24:296

Han W (2007) Supported homogenous catalysts on flat model surfaces for ethylene polymerization, Ph.D. thesis, Eindhoven University of Technology, The Netherlands

Yaluma AK, Tait PJT, Chadwick JC (2006) J Polym Sci Part A: Polym Chem 44:1635

Di Noto V, Marigo A, Viviani M, Marega C, Bresadola S, Zannetti R (1992) Makromol Chem 193:123

Chadwick JC (2003) Ziegler-Natta Catalysts. Encycl Polym Sci Technol 6:517

Boor J (1979) Jr. Ziegler-Natta catalysts and polymerizations. Academic Press, New York (Ch. 3)

Miyazawa T (1964) Polym Lett 2:847

Fregonese D, Glisenti A, Mortara S, Rizzi GA, Tondello E, Bresadola S, Rizzi GA, Tondello E, Bresadola S (2002) J Mol Catal A: Chem 178:115

Koenig JL, Van Roggen A (1965) J Appl Polym Sci 9:359

Burfield DR, Loi PST (1988) J Appl Polym Sci 36:279

Koranyi TI, Magni E, Somorjai GA (1999) Top Catal 7:179

Kim SH, Somorjai GA (2006) PNAS 103:15289

Kaul FAR, Puchta GT, Schneider H, Bielert F, Mihalios D, Herrmann WA (2002) Organometallics 21:74

Semikolenova NV, Zakharov VA, Talsi EP, Babushkin DE, Sobolev AP, Echevskaya LG, Khysniyarov MM (2002) J Mol Catal A: Chem 182:283

Urban MW (1996) Attenuated total reflectance spectroscopy of polymers. American Chemical Society, Washington DC

Acknowledgments

This research forms part of the research program of the Dutch Polymer Institute (DPI), The Netherlands, under Project 387. We thank M. E. Donders at Eindhoven University of Technology for his assistance during the in situ measurements and Prof. R. Cipullo of the University of Naples for 13C NMR measurements of polypropylene tacticity. We also thank Prof. V. Busico of the University of Naples for valuable discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Andoni, A., Chadwick, J.C., Niemantsverdriet, J.W. et al. Investigation of Planar Ziegler-Natta Model Catalysts Using Attenuated Total Reflection Infrared Spectroscopy. Catal Lett 130, 278–285 (2009). https://doi.org/10.1007/s10562-009-0002-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-009-0002-3