Abstract

A series of Cs promoted copper oxide catalysts were prepared by co-precipitation method and tested for the direct decomposition of nitrous oxide (N2O). The Cs promoted catalysts were more active particularly with a molar ratio of Cs/Cu at 0.1 compared to bulk CuO. Methods of XRD, BET, XPS, H2-TPR, and N2O-TPD were used to characterize these catalysts to evaluate structure activity relationship. The characterization results indicated that the addition of Cs could improve the reduction of Cu2+–Cu0 by facilitating the desorption of adsorbed oxygen species, during the N2O decomposition. The influences of oxygen and steam on N2O decomposition over these catalysts were also studied.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nitrous oxide (N2O) is a greenhouse gas with a long lifetime of about 150 years in the atmosphere [1, 2]. Although N2O is not the major contributor to global warming, it is much more potent than either of the other two most common anthropogenic greenhouse gases, CO2 and CH4. N2O is 310 and 21 times of the Global warming potential (GWP) of CO2 and CH4, respectively [1, 3]. Furthermore, N2O is an important source of stratospheric nitrogen oxides, which initiates a chain of cyclic reaction leading to stratospheric ozone destruction [1–4].

It is emitted from both natural and anthropogenic sources such as nitric acid and adipic acid plants and fluidized bed combustors for sewage-sludge or industrial wastes besides the medical exhaust biological and agricultural emissions [5]. The concentration of N2O in the atmosphere continues to increase, and this increase appears to be caused mainly by human activities. With increasing concerns about protecting our environment, the catalytic removal of N2O from exhaust becomes at most important. It was reported that N2O is easily decomposed to nitrogen and oxygen on various types of catalysts such as noble metals [5–7], metal oxides [8–12], and ion-exchanged zeolites [13–15]. However, few of them have been found to be active and stable enough for industrial applications, because their activities are severely inhibited by the presence of other gases such as O2. Moreover, oxygen atoms formed by the decomposition of N2O are hardly desorbed from the catalyst surface and accumulated on the surface, finally causing catalyst deactivation [5, 16].

Catalysts with copper oxide as an active component have been extensively employed in the recent past for the selective catalytic reduction of NOx and also for the synthesis and steam reforming of methanol [17–21]. Copper catalysts are very selective in hydrogenation–dehydrogenation reactions such as conversion of benzaldehyde to benzyl alcohol [17, 22], furfural to furfuryl alcohol [23] or the transformation of alcohols into their corresponding aldehydes or ketones [24–26]. Copper based catalysts for direct decomposition of N2O–N2 have been reported [27, 28]. Most of the catalysts are supported ones where Cu is supported on metal oxides and perovskits [29–35]. Zeolite supported Cu catalysts are also studied for N2O decomposition [36, 37]. There are no studies about the alkali promoted catalysts for this reaction. Generally alkalis promoted metal oxides exhibit better activity toward N2O decomposition at low reaction temperatures.

In the present paper, we report the catalytic performance of a Cs metal-doped catalyst for N2O decomposition. The effects of oxygen and steam on N2O decomposition are also studied. Discussions are made on the relationship between catalytic performance and structural properties revealed by characterization of catalysts.

2 Experimental

A series of Cs promoted CuO catalysts were prepared by conventional techniques. Cu(OH)2 was first precipitated from an aqueous solution of Cu(NO3)2 · 6H2O by the addition of required amount of aqueous Na2CO3, at room temperature until the pH reached a value of 10. The precipitate thus obtained was washed with distilled water, dried at 120 °C and then calcined at 400 °C for 4 h in flowing air. Cs was added to CuO by impregnation with an aqueous solution of cesium nitrate. The excess solution was removed on hot plate, followed by drying at 120 °C. All the catalyst samples were finally calcined at 450 °C for 5 h in flowing air. The Cs to Cu atomic ratio was varied from 0.05 to 0.2.

The specific surface areas of the catalyst samples were estimated using N2 adsorption at −196 °C by the single-point BET method on a Micromeritics Chemisorb 2700 instrument. The samples were oven-dried at 120 °C for 12 h and flushed in situ with He gas for 2 h before the measurements.

X-ray powder diffraction patterns were recorded on a Siemens D5000 diffract meter, using CuKα radiation (1.5406 Å) at 40 kV and 30 mA and secondary graphite monochromatic. The measurements were obtained in steps of 0.045° with a count time of 0.5 sec and in the 2θ of 2–80°. Identification of the solid phase was made with the help of JCPDS files.

Temperature programmed reduction of the catalysts was carried out in a flow of 10% H2Ar mixture gas at a flow rate of 30 ml/min with a temperature ramp of 10 °C/min. Before the TPR run the catalysts were pretreated in argon at 300 °C for 2 h. The hydrogen consumption was monitored using a thermal conductivity detector.

Temperature programmed desorption of N2O was performed in a fixed-bed flow reactor interfaced with a micro-gas chromatograph (Varian CP-4900). Prior to the experiment, the catalyst sample was pretreated in H2 flow (30 ml/min) at 400 °C for 1 h. After this the sample was flushed with He gas at the same temperature for 1 h and cooled to room temperature in He flow. The sample was exposed to 5,000 ppm N2O (balance He) gas for 1 h at room temperature, followed by flushing with He until no N2O was observed in the vent gas. After these treatments, the N2O-TPD was carried out in a flow of He (80 ml/min) with a heating rate of 10 °C/min.

The XPS measurements of the catalysts were conducted on a Kratos Axis 165 apparatus equipped with a dual anode (Mg and Al) using a MgKα source. The carbon 1 s binding energy of 284.6 eV was used as a reference for determining the binding energies. A charge neutralization of 2 eV was used to balance the charge up of the sample. The binding energy values of the samples were reproducible within ±0.1 eV.

The direct decomposition of N2O was carried out in a fixed-bed continuous flow reactor. The reactant mixture consisted of one or more of 2,500 ppm N2O, 4% O2, and 2% H2O along with He as the diluent. The gas mixture was passed over a 0.5 g catalyst at a total flow rate of 60 ml/min. The effluent gas was analyzed by micro-gas chromatography using molecular sieve and poroplot Q columns. The steady-state catalytic activity was measured at temperatures between 200 and 550 °C, in steps of 50 °C.

3 Results and Discussion

The physico-chemical properties of bulk CuO and Cs promoted Cu catalysts are presented in Table 1. The BET surface area of the bulk CuO and Cs promoted CuO are very low.

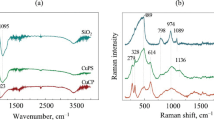

XRD patterns of the bulk CuO and Cs promoted CuO with different Cs/CuO ratios are shown in Fig. 1. XRD pattern of the samples shows the characteristic peaks of CuO with 2θ values at 32.4, 35.6, 38.6, 48.8, 53.5, 58.4, 61.6, 66.1, and 68.1 [38]. At higher Cs/Cu ratios, peaks due to the crystalline Cs2O3 phases are noticed, in addition to CuO. The intensity of these peaks was found to increase with increase in Cs loading. The XRD patterns suggest that at higher Cs content the crystallites of Cs2O3 are formed on the surface of CuO.

TPR profiles of bulk CuO and Cs doped CuO are shown in Fig. 2. The bulk CuO shows a single and broad reduction peak at around 350 °C related to the single step reduction of Cu2+–Cu0. Cs doped CuO, consists of two well-resolved reduction peaks at around 300–340 and 400–450 °C. According to the literature [39–41], the low-temperature peak can be ascribed to the reduction of Cu2+–Cu1+; while the higher one is due to the reduction of Cu+ to Cu0. As the Cs content increased the reduction peak related Cu+–Cu0 shifted to high temperature. The low temperature peak is not varied for the very low Cs content i.e., upto 0.1 and above this content both the low and high temperature reduction peaks are shifted to higher temperatures. The TPR results suggest that the presence of small amount of Cs is effective in stabilizing the lower oxidation state of Cu. A similar type of trend has been reported, which is an indication of electronic promoting function of Cs to Al–Cu catalysts [42]. At higher Cs content CuO reduction peaks were shifted to higher temperatures. It is known that at high concentrations of Cs it migrate to Cu surface leading to reduction inhibiting counter effect [43].

XPS measurements were performed to examine the influence of alkali metals on the surface electronic state of CuO. Figure 3 shows the XPS spectra of Cs/CuO with different Cs/Cu atomic ratios in the Cu 2p region. The peak of Cu 2p3/2 binding energy for all the samples appeared at around 934.2–934.6 eV. The Cu 2p3/2 binding energies for bulk CuO and Cs/Cu catalyst ratio with 0.1 are showed at 934.6 and 934.2 eV, respectively. The addition of Cs–CuO leads to a slight shift in BE of the Cu 2p3/2 to a lower value [44] is noticed. It is well known that electron donation from alkali metal to transition metals causes a change in the electronic state of Cu. A similar type of shift in the BE value has been reported for K promoted Co3O4 catalyst [45]. The reduction in BE values indicates a change in the electronic state of Cu which means that the Cu–O bond is weakened with the addition of Cs. No further shift in the BE of Cu 2p3/2 observed, when Cs/Cu atomic ratio is increased further. In agreement with this, the BE for Cs 3d3/2 did not change for any of the Cs promoted CuO catalysts.

The activity profiles of the catalysts for the decomposition of N2O are shown in Fig. 4. On the bulk CuO catalysts, the decomposition of N2O started at 250 °C and the complete conversion occured at 400 °C, whereas on the Cs promoted catalysts particularly with Cs/Cu ratio 0.05 and 0.1 attained 100% conversion of N2O at 300 °C itself. The presence of small amount of Cs monotonically increased the N2O decomposition at lower temperatures. Further increase in Cs content (Cs/Cu ratio above 0.15) leads to decrease in the N2O decomposition activity.

To understand the influence of Cs on CuO in enhancing the N2O decomposition activity, the bulk CuO and the Cs promoted CuO catalysts with Cs/Cu ratio of 0.1 are studied for the temperature programmed desorption of N2O. Figure 5 shows the temperature programmed desorption profiles of N2O adsorbed on CuO and Cs doped CuO (Cs/Cu = 0.1). The bulk CuO sample shows the desorption peak of O2 at a temperature of 420 °C and the Cs doped CuO samples show the O2 desorption peak at 340 °C. The desorption of N2 is occurred in three stages in the temperature range of 260–600 °C for bulk CuO and 160–550 °C for Cs promoted CuO catalysts. The first low temperature desorption peak can be attributed to the N2 produced by N2O dissociation. The second and third desorption peaks might be a result of the decomposition of a nitrate complex formed during TPD of N2O. The nitrate is formed via nitric oxide, which in turn is formed from N2O and surface oxygen atom. The existence of nitrate species during decomposition of N2O is already known [46]. It is apparent that the temperatures of O2 and N2 desorption were significantly shifted to lower values for the Cs containing CuO catalyst. The TPR result shows the early reduction of Cs promoted CuO catalyst when compare to bulk CuO. XPS results also suggest a change in electronic state of Cu with addition of small amount of Cs. The N2O decomposition activity and the deactivation of the catalysts depend on the ability of oxygen release from the surface. Generally, the catalysts for this reaction are readily deactivated by the strong adsorption of O2. The early desorption of O2 in case of Cs promoted catalysts might be the reason for its high activity at low reaction temperatures.

Stability of the CuO and Cs promoted CuO catalyst for N2O decomposition was examined at 400 and 300 °C respectively, and the results are shown in Fig. 6. The Cs promoted catalyst maintained >90% N2O conversion for the period study i.e., 12 h. It is noteworthy that the Cs promoted catalyst exhibited a stable activity during the entire time of operation. However, the bulk CuO catalyst has started deactivating with in 3 h of operation. This might be due to the accumulation of oxygen on the surface of CuO. It is well known that noble metal catalysts have quite highly activity for decomposition of N2O, more over Rh catalyst was reported to catalyze the reaction even at room temperature [47]. However, oxygen atoms formed by the decomposition of N2O were accumulated on the Rh surface, and therefore, the activity of the catalyst decreased suddenly after high N2O conversion for a while. On the contrary, the present Cs promoted CuO catalyst maintained high activity for more than 12 h. This result suggests that oxygen formed by the decomposition of N2O is easily desorbed from the surface of the present catalyst.

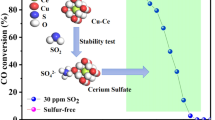

The presence of excess O2 and H2O often inhibited the decomposition reaction of N2O over most of the catalysts for N2O decomposition [4, 5, 14, 48–51]. Figure 7a, b shows N2O conversion in the presence of O2 and H2O over CuO and Cs promoted CuO catalysts, respectively. Although pure CuO had showed good activity for N2O decomposition, the Cs promoted CuO led to a significant improvement in catalytic performance for N2O decomposition, making the N2O conversion curves to shift more than 100 °C to lower temperatures. The presence of excess O2 and water (steam) inhibited the N2O decomposition reaction, which suggests that molecular oxygen and water competed with N2O to adsorb on active sites of the catalyst, thus suppressing the decomposition of N2O. The inhibition of O2 for N2O decomposition over Cs promoted CuO is weaker compared to bulk CuO, indicating that the adsorption of O2 on CuO is stronger than that on Cs promoted catalysts.

4 Conclusions

The present results demonstrate that the addition of Cs to CuO leads to an enhanced catalytic activity for the direct decomposition of N2O. The Cs promoted CuO catalysts showed stable activity over bulk CuO catalyst. The XPS, TPR, and TPD measurements suggest that desorption of oxygen was promoted by the addition of Cs–CuO catalyst. The catalyst with Cs/Cu ratio of 0.1 exhibits the best catalytic activity even in the presence of O2, H2O during N2O decomposition.

References

Thiemens MH, Trogler WC (1991) Science 251:932

Perez-Ramirez J, Kapteijn F, Schöffel K, Moulijn JA (2003) Appl Catal B 44:117

Trogler WC (1999) Coord Chem Rev 187:303

Kapteijn F, Rodriguez-Mirasol J, Moulijn JA (1996) Appl Catal B Environ 9:25

Centi G, Galli A, Montanari B, Perathoner S, Vaccari A (1997) Catal Today 35:113

Yuzaki K, Yarimizu T, Aoyagi K, Ito S, Kunimori K (1998) Catal Today 45:129

Haber J, Machej T, Janas J, Nattich M (2004) Catal Today 90:15

Satsuma A, Maeshima H, Watanabe K, Suzuki K, Hattori T (2000) Catal Today 63:347

Drago R, Jurczyk K, Kob N (1997) Appl Catal B Environ 13:69

Kannan S, Swamy CS (1999) Catal Today 53:725

Armor JN, Braymer TA, Farris TS, Li Y, Petrocelli FP, Weist EL, Kannan S, Swamy CS (1996) Appl Catal B 7:397

Chellam U, Xu ZP, Zeng HC (2000) Chem Mater 12:650

Pieterse J, Booneveld S, Brink R (2004) Appl Catal B Environ 51:215

Perez-Ramirez J, Kapteijin F, Mul G, Moulijn JA (2001) Chem Commun 8:693

da Cruz RS, Mascarenhas AJS, Andrade HMC (1998) Appl Catal B Environ 18:223

Tzitzios VK, Georgakilas V (2005) Chemosphere 59:887

Praliaud H, Mikhailenko S, Chajar Z, Primet M (1998) Appl Catal B 16:359

Radtke F, Koeppel RA, Minardi EG, Baiker A (1997) J Catal 167:127

Agrell J, Birgersson H, Boutonnet M, Melian-Cabrera I, Navarro RM, Fierro JLG (2003) J Catal 219:389

Kim TW, Song MW, Koh HL, Kim KL (2001) Appl Catal A 210:35

Ma Z-Y, Yang C, Wei W, Li W-H, Sun Y-H (2005) J Mol Catal A 23:75

Saadi A, Rassoul Z, Bettahar MM (2000) J Mol Catal A 164:205

Rao R, Dandekar A, Baker RTK, Vannice MA (1997) J Catal 171:406

Chary KVR, Sagar GV, Naresh D, Seela KK, Sreedhar B (2005) J Phys Chem B 109:9437

Fabina MT, Schmal M (1997) Appl Catal A 163:153

Fridman VZ, Davydov AA (2000) J Catal 195:20

Liu Z, Amiridis MD, Chen Y (2005) J Phys Chem B 109:1251

Tuti S, Pepe F, Pietrogiacomi D, Indovina V (2001) React Kinet Catal Lett 72:35

Yao K-W, Jaenicke S, Lin J-Y, Tan KL (1998) Appl Catal B Environ 16:291

Bennici S, Gervasini A (2006) Appl Catal B Environ 62:336

Ma J, Rodriguez NM, Vannice MA, Baker RTK (2000) Top Catal 10:27

Boissel V, Tahir S, Ann Koh C (2006) Appl Catal B Environ 64:234

Ohnishi C, Asano K, Iwamoto S, Chikama K, Inoue M (2007) Catal Today 120:145

Satsuma A, Maeshima H, Watanabe K, Hattori T (2001) Energ Convers Manage 42:1997

Alini S, Basile F, Blasioli S, Rinaldi C, Vaccari A (2007) Appl Catal B Environ 70:323

Turek T (1996) Appl Catal B Environ 9:201

Dandekar A, Vannice MA (1999) Appl Catal B Environ 22:179

Chang S-S, Lee H-J, Park HJ (2005) Ceram Int 31:411

Batista J, Pintar A, Mandrino D, Jenko M, Martin V (2001) Appl Catal A 206:113

Gentry SJ, Hurst NW, Jones A (1981) J Chem Soc Faraday Trans 177:603

Torre-Abreu C, Ribeiro MF, Henriques C, Delahay G (1997) Appl Catal B 14:261

de Auino AD, Cobo AJG (2001) Catal Today 65:209

Aika K-I, Hori H, Ozaki A (1972) J Catal 27:424

Chaturvedi S, Rodringuez JA, Hrbek J (1997) Surf Sci 384:260

Haneda M, Kintaichi Y, Bion N, Hamada H (2003) Appl Catal B Environ 46:473

Fanson PT, Stradt MW, Delgass WN, Lauterbach J (2001) Catal Lett 77:15

Centi G, Dall’Olio L, Perathoner S (2000) Catal Lett 67:107

Yan L, Ren T, Wang X, Ji D, Suo J (2003) Appl Catal B Environ 45:85

Kapteijn F, Marban G, Rodriguez-Mirasol J, Moulijn JA (1997) J Catal 167:256

Yuzaki K, Yarimizu T, Ito S-I, Kunimori K (1997) Catal Lett 47:173

Chang Y-F, McCarty JG, Wachsman ED (1995) Appl Catal B 6:21

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pasha, N., Lingaiah, N., Reddy, P.S.S. et al. Direct Decomposition of N2O over Cesium-doped CuO Catalysts. Catal Lett 127, 101–106 (2009). https://doi.org/10.1007/s10562-008-9641-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-008-9641-z