Abstract

A new route for the preparation of nanocrystalline TiO2 particles based on the pH swing method assisted by ultrasonic irradiation in the presence of a surfactant (Pluronic P-123) has been successfully achieved. The prepared TiO2 catalysts were calcined from 400 to 800 °C and characterized by X-ray powder diffraction (XRD), transmission electron microscopy (TEM), Fourier transformed infra-red spectroscopy (FTIR), gas adsorption measurements (BET) and thermogravimetirc measurements (TAG/DTA) analyses. Characterization results revealed that the enhancement in the particle size of TiO2 by the pH swing method could be controlled by combining the pH swing with ultrasonic irradiation. Increasing the calcination temperatures led to an increase in both the particle and pore size, whereas the surface area and pore volume gradually decreased. A synergistic effect was observed in the combined process of pH swing with ultrasonication, yielding small TiO2 particles as well as high surface area, pore volume, pore diameter, and crystalline anatase phase. The activity of the catalysts was investigated for the oxidation of 4-chlorophenol (4-CP). TiO2 prepared with 15 times pH swing and calcined at 700 °C was found to show the highest rate for the oxidative degradation of 4-CP when compared to the TiO2 sample prepared with just 1 time pH swing and to the commercial P-25 TiO2 Degussa photocatalyst. Thus, a novel approach in controlling the various physico-chemical parameters of TiO2 nanoparticles was developed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The synthesis of mesoporous TiO2 nanoparticles has attracted a great deal of attention due to the unique characteristics of the mesoporous nanoparticles which are different from macro-size particles. Especially, in studies of environmental and electronic applications, TiO2 nanoparticles show tremendous changes in activity. They are widely used in environmental cleaning processes as photocatalysts, in the fabrication of solar-fuel cells, light emitting diodes, and other useful applications [1–10]. In addition to environmental remediation processes, much attention has been focused on mesoporous TiO2 for solar cells and fuel cells since TiO2 nanoparticles are highly efficient materials [2–5]. In fact, Haque et al. [2] have reported the importance of mesoporous TiO2 nanoparticles for the preparation of highly efficient light emitting diodes.

In recent years, the application of ultrasound, as a new technology for the preparation of nanoparticles, especially TiO2, has been explored [11–20]. During this method, ultrasonic waves consisting of compression and rarefraction cycles produce cavitation bubbles in a liquid. After several compression cycles, the cavitation bubbles collapse violently and adiabatically at extremely high temperatures of up to 5,000 °C and pressures of about 500 atm. [11, 20]. Such extreme temperatures and pressures within a small reactor can induce many changes in the morphology of TiO2 nanoparticles during the preparation process. Generally, ultrasonic irradiation is favorable for the fragmentation of TiO2 particles and also increased high-velocity interparticle collisions among the particles which can prevent the formation of larger particles. These two effects are, thus, important advantages in the use of ultrasonic irradiation for the preparation of nanomaterials [12, 20].

Yang et al. [21] firstly synthesized large-pore mesoporous and high surface area semiconductor metal oxides such as TiO2, ZrO2, WO3 and SnO2, using amphiphilic poly (alkyl oxide) block co-polymers as a structure-directing agent. Since the application of surfactant for the synthesis of mesoporous TiO2 was implemented, many researchers have prepared TiO2 with surfactants [15, 21–26] along with ultrasonic irradiation to synthesize nanoparticles.

The pH swing method is another method for the preparation of mesoporous TiO2 without any structure-directing agent. Our previous findings using the pH swing method also yielded TiO2 samples with high surface area, pore size and pore volume [6]. In the earlier method, we alternated the addition of TiCl4 (as an acid solution) and aqueous ammonia (as a basic solution) to water at regular intervals without adjusting the pH of the reaction mixture [6]. Although the TiO2 prepared by pH swing led to mesoporous TiO2 with nano-size particles, the increase in particle size by increasing the pH swing numbers could not be controlled and the activity for the oxidative degradation of organic compounds was not as high as that of commercial catalysts.

However, based on the principles of this pH swing method, a new approach was investigated combining the use of ultrasonic irradiation and a surfactant with the pH swing method. The morphology of the TiO2 particles prepared with this newly adapted method was investigated and compared with the photocatalytic properties of other TiO2 catalysts. In order to compare the photocatalytic degradation performance, 4-chlorophenol was used as a pollutant [27, 28]. In this combined approach, TiO2 was synthesized by the pH swing method in the presence of the P-123 surfactant under ultrasonication and the results are discussed here.

2 Experimental

2.1 Catalyst Preparation

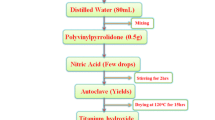

The principles behind the multi-gelation method of synthesizing the TiO2 particles are illustrated in Fig. 1. The TiCl4 solution was prepared by mixing equal weights of TiCl4 with crushed ice made from distilled water. The TiO2 photocatalysts were prepared by the alternate addition of a TiCl4 solution (7 mL) and aqueous ammonia solution (9 mL) into hot water (1,000 mL) with 10 g of a triblock co-polymer, Pluronic P-123 (EO20PO70EO20, BASF Company, USA), as the surfactant (premixed under vigorous stirring), heated and maintained at 80 °C under vigorous stirring. The pH swings were carried out with an ultrasonic bath type instrument under ultrasonic irradiation (Branson 8510, USA). After the reaction was completed, the catalysts were kept in an ultrasonication bath for 1 h for further irradiation. In the controlled pH swing method, 1 M HNO3 acid was used to bring down the pH to around 2 at each swing time and aqueous ammonia was used to adjust the pH at around 8. A white precipitate of hydrous TiO2 particles was formed. The complete process was then referred to as “one pH swing”. After 5 min, the alternate addition of the same quantity of both TiCl4 (7 mL) and aqueous ammonia (9 mL) was carried out to the same hydrous TiO2 particle system. This is referred to as “two pH swings”. In this way, photocatalysts with two different pH swing numbers, 1 and 15 times, were prepared under the same experimental conditions. Finally, a white precipitate of the hydrous TiO2 was first washed with excess ethanol to remove the P-123 and then with water, filtered, and dried at 120 °C for 15 h. The dried TiO2 was then calcined at various temperatures (400–800 °C) with an electric furnace under a flow of air and then ground to fine powder using a pestle and mortar.

2.2 Characterizations

The crystalline structure and morphology of the TiO2 particles (anatase, rutile and brookite) were investigated by X-ray powder diffraction (XRD, Rigaku RDA-1A X-ray diffractometer, D/MAX Ultima III, Japan) analysis using Cu Kα radiation with a Ni filter. The morphology and size distribution of the photocatalysts were recorded by transmission electron microscopy (TEM, JEOL, JEM 2100, Japan). Before analyses, the samples were placed on the surface of copper grids and dried under ambient conditions. The N2 BET surface area, pore volume, pore-size distribution, porosity, and pore diameter of the photocatalysts were determined by a BET analyzer (Micromeritics, ASAP 2020, USA). The surface-OH groups of the photocatalysts were determined by Fourier transformed infra-red spectroscopy (FTIR) using KBr in pellet form (FTIR, JASCO FT/IR-460 Plus, Japan). Thermal gravimetric analysis (TGA) and differential thermal analysis (DTA) were performed using a TGA-50A/ DSC-60A analyzer (Shimadzu, Japan).

2.3 Photocatalytic Activity Measurements

The photocatalytic activity was compared by the reaction rates for the oxidative degradation of 4-chlorophenol (4-CP). The photocatalyst (300 mg) was suspended in a quartz cell with an aqueous solution of 4-CP (2.5 × 10−4 M, 200 mL). Prior to UV light irradiation, the suspension was stirred for 30 min under oxygen atmosphere under dark conditions. The sample was then irradiated at 24 °C using UV light (transmitting range, λ 200–800 nm) from a 300 W Xe Arc lamp (Oriel Lamp, Model 66984, USA) with continuous stirring under oxygen atmosphere. At periodic intervals, up to 5 mL aliquots were taken from the system and filtered through a Millipore filter to remove the TiO2 particles. The percentage of degradation was then analyzed by a UV–Vis spectrophotometer at 225 nm (UV-mini 1240, Shimadzu) and the mineralization of 4-CP (TOC) was measured by a TOC analyzer (Pollution & Process Monitoring, England).

3 Results and Discussion

3.1 Principle of pH Swing Method with Ultrasonication

In this study, we have introduced the surfactant-mediated (Pluronic P-123) synthesis of TiO2 by a combination of pH swing with ultrasonication, as depicted in Fig. 1. With the pH swing method, the addition of acid can dissolve the smaller particles of hydrous TiO2 (Fig. 1) leaving only the larger particles. When the number of swings increases, the size of the particles also increases and this is the main drawback of the pH swing method [6]. However, by applying ultrasonication during the pH swing method, it is more easy to control the growth of the particles with respect to an increase in the number of pH swing times, as is detailed in our recent report on the influence of ultrasonication in controlling the particle size [20]. During pH swing, the particle size steadily increases along with the number of pH swings, however, this combined approach was successful in controlling the size of the particles, as depicted in Fig. 1.

3.2 X-ray Powder Diffraction (XRD)

Figure 2 shows the XRD patterns of all the TiO2 catalysts prepared by pH swing coupled with ultrasonication in the presence of the P-123 surfactant and calcined at different temperatures from 400 to 800 °C. The peaks that appear at around 2θ = 25°, 38°, 48°, 55°, and 63° correspond to the diffraction patterns of (101), (112), (200), (211), and (264) planes, respectively, of pure anatase. Similarly, the peaks at around 2θ = 27°, 35°, 41°, and 57° correspond to the diffraction patterns of (110), (101), (111) and (220) planes, respectively, of the pure rutile phase of TiO2. The crystallinity of the TiO2 particles was quantitatively estimated with the relative intensity of the (101) diffraction peak of the pure anatase [29]. It was clearly seen that the anatase peak intensity (101) gradually increased, becoming stronger and narrower with an increase in the calcination temperatures, indicating the enhancement of TiO2 crystallization. Maximum crystallinity with a higher anatase phase (95%) was attained at a calcination temperature of 700 °C for the 15 pH swings prepared catalysts, as shown in Fig. 2a, whereas at the same calcination temperature, around a 43% rutile phase was exhibited for the 1 pH swing prepared catalysts, as shown in Fig. 2b. The pH swing method could prevent the phase transition from anatase to rutile until 600 °C at higher pH swing numbers, as has been observed earlier studies. However, in this study, mostly an anatase phase was retained in the 15 times pH swing prepared TiO2 nanoparticles up to 700 °C. These results clearly indicate the effect of pH swing in preventing phase transition from anatase to rutile that was not subject to effects of ultrasonic irradiation.

3.3 BET Analysis

Sheng et al. [26] have reported on TiO2 synthesized with a surfactant under the influence of ultrasonication and possessing a surface area of 152 m2/g, pore volume of 0.3 cm3/g, and an average particle size of 5.6 nm. Also, Yu et al. [15] have synthesized TiO2 catalysts with a surfactant assisted by ultrasonication and calcined at 400 °C, possessing a surface area of 128 m2/g, pore size of 9.2 nm, and pore volume of 0.3 cm3/g. The surface area, pore size and pore diameter values of the TiO2 prepared with 1 time pH swing (see Table 1) were almost similar to the results reported by Yu et al.[15] and Sheng et al. [26]. However, in this study, it is interesting to note that the TiO2 prepared with 15 times pH swing and assisted by ultrasonication in the presence of the P-123 surfactant and calcined at 400 °C exhibited two times higher surface area (315 m2/g), high pore size (13 nm) and high pore volume (0.927 cm3/g), as shown in Table 2, when compared with previous reports by Sheng et al. [26] and Yu et al. [15]. This study emphasizes the importance of increasing the pH swing numbers in combination with ultrasonication in the presence of a surfactant. An increase in the pH swing numbers was shown to have a significant effect on the surface area and all of the important parameters of the TiO2 particles. Thus, for the formation of smaller particles with high surface area, not only the combination of pH swing with ultrasonication but also the assistance of ultrasonication with a surfactant was found to be essential. Such a coupled approach is, thus, shown to be an efficient technique for the synthesis of TiO2 nanoparticles.

The TiO2 photocatalysts prepared without using P-123 surfactant exhibited less surface area and less pore volume when compared with those prepared using P-123. For example, the catalysts calcined at 700 °C without P-123 possessed 19 m2/g BET surface area, while a surface area measuring 45 m2/g was observed for P-123. Similar results have been reported by Yu et al [15]. The physico-chemical characteristics such as, surface area, crystallinity, particle size, etc., of TiO2 catalysts prepared by 15 times pH swing were less than those prepared using P-123 surfactant irrespective of the different calcination temperatures from 400 to 750 °C. Thus, this work was mainly focused on the preparation of TiO2 using P-123 under the influence of ultrasonication, adopting pH swing method.

With the pH swing method, parameters such as particle size, surface area, pore size, pore diameter, and percentage of anatase phase, show enhancement with an increase in the number of pH swings. However, in the combined preparation method, the particle size decreased with an increase in the number of pH swings upon ultrasonication (Tables 1 and 2), although all other parameters showed an increase similar to the uncombined method. For example, the average particle size of the TiO2 at 1 time pH swing was 28 nm, whereas the average particle size with 15 times pH swing was 21 nm under the same experimental conditions (at 650 °C calcined). This is in contrast to the case of the pH swing method without ultrasonication in which the particle size of the TiO2 catalysts prepared under similar conditions without ultrasonication and P-123 increased from 8 to 12 nm by increasing pH swings numbers from 5 to 15. In general, pH swings will dissolve the smaller particles and leave only the larger particles. However, when the particles were subjected to ultrasonication, the growth of the particles was affected due to fragmentation and also an increase in high-velocity interparticle collisions, preventing the formation of large particles [20]. Furthermore, the average particle sizes of TiO2 without ultrasonication, in the absence of P-123 surfactant, and with pH swing numbers increasing from 5 to 15 were 8–12 nm. However, the particle size was increased to 28 nm for 1 time pH swing and to 21 for 15 times pH swings. The increase in particle sizes even after the influence of ultrasonication is mainly due to the presence of surfactant. The surfactant generally increases the particle size along with pores, which in turn enhances the surface area more efficiently [15, 26]. This is an additional advantage of P-123 with ultrasonication using pH swing method.

This combined approach of using ultrasonication coupled with pH swing and a surfactant is, thus, an important advantage enabling the synthesis of TiO2 nanoparticles with high pore volume and pore diameter as well as well-controlled particle sizes.

3.4 TGA/DTA Studies

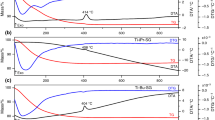

The TGA/DTA curves of the TiO2 catalysts prepared by 15 times pH swing are shown in Fig. 3. The DTA curves of the as-prepared TiO2 catalyst, i.e., without calcinations, is shown in Fig. 3a and exhibits two exothermic peaks. A deep valley at around 80 °C represents a small endothermic effect corresponding to the ethanol and adsorbed water on the mesoporous TiO2 [15, 26]. The exothermic peaks appearing at around 300 and 420 °C can be attributed to the removal of the surfactant P-123 and crystallization of amorphous TiO2, respectively. A small exothermic peak observed at 510 °C is attributed to the combustion of carbonized P-123 which is left over due to the quickly rising temperature during DTA analysis. A small peak at 646 °C is attributed to the transformation of a small portion of TiO2 from anatase to rutile phase. The TGA curve shows two weight losses (Fig. 3b), the first at around 100 °C corresponding to the removal of ethanol and adsorbed water on TiO2. The second weight loss of 18% at around 250–450 °C and corresponding peaks in DTA indicate the removal of the P-123 surfactant. Weight loss in the TGA curve stabilizes after 600 °C, corresponding to the DTA patterns.

3.5 FTIR Spectra

Figure 4 shows the FTIR spectra of the TiO2 catalysts prepared by 15 pH swings with ultrasonication and calcinations at 500 and 700 °C. The FTIR spectra of all the other TiO2 catalysts showed almost similar patterns as these 15 pH swing samples. In Fig. 4, two peaks appear at around 1,650 and 3,400 cm−1, corresponding to the physically adsorbed water molecules and surface hydroxyl groups [15, 16]. Apart from these two peaks, no other peaks related to the surfactant or other C–C bonds were obtained. This clearly indicates that all the surfactant molecules are completely combusted during calcination at 500 °C. There is no surfactant or any other organic molecules present in the TiO2. The peak intensity at 1,650 cm−1 for the catalysts calcined at 500 °C was found to be higher than those calcined at 700 °C. It is known that at higher calcination temperatures, the surface hydroxyl groups (~3,400 cm−1) diminishes and mostly disappear after 600 °C. However, the TiO2 samples calcined at 700 °C had more surface hydroxyl groups, leading to the higher activity of the TiO2 catalysts.

3.6 TEM Analysis

TEM analysis provides information on the particle size, morphology, and crystallinity of the TiO2 catalysts. Figure 5 shows the TEM images of TiO2 prepared by the pH swing method coupled with ultrasonication and calcined at 500 and 700 °C for 3 h as a representative catalyst. The average particle size of all the particles were obtained from the TEM images and are listed in Tables 1 and 2 while the TEM values are consistent with the XRD data. The morphology of the particles was mostly irregular in shape. The shape was not uniform with both 1 and 15 times pH swing catalysts, as shown in the Fig. 4b. It can be seen that the particle size of TiO2 with 15 times pH swing are smaller than the catalysts with 1 time pH swing (Fig. 5B) due to the increase in pH numbers. Ultrasonication is, thus, seen to have a strong influence in the control of the particle size of TiO2 during the pH swing method. The difference in particle size ranged from 20 to 40 nm in the case of TiO2 prepared by 15 times pH swing, as shown in the TEM image (Fig. 5B).

3.7 Photocatalytic Activity of TiO2 Nanoparticles

The photocatalytic activity of the catalysts was compared by the reaction rates for the oxidative degradation of 4-CP in aqueous phase. The TiO2 catalysts prepared at 15 times pH swings and calcined at 700 °C exhibited higher photocatalytic activity for the degradation of 4-CP degradation than the other samples calcined at temperatures from 400 to 800 °C, as shown in Table 3. Similarly, for 1 time pH swing, the catalysts calcined at 650 °C showed the maximum efficiency for the degradation of 4-CP (Table 3). Moreover, Fig. 6 illustrates the percentage rate for the degradation of 4-CP by three different catalysts including the commercial P-25 Degussa TiO2. Figure 6 shows that 15 pH swing TiO2 with 700 °C calcination showed the maximum percentage for the degradation of 4-CP, even higher than P-25. It is known that the photocatalytic degradation efficiency greatly depends on the particle size, surface area, and anatase/rutile phase ratio as well as the pore size and pore volume of the TiO2 particles [6, 26]. In contrast, the catalysts calcined at 700 °C possessed a larger particle size (28 nm) with less surface area and pore volume (Table 2) but exhibited maximum degradation of 4-CP in 1 h irradiation time. A similar trend was observed with TiO2 prepared with 1 time pH swing. The catalytic activity for the degradation of 4-CP was also enhanced by increasing the calcination temperature (Table 3). This can be ascribed to the increase in anatase crystallinity (Fig. 2). After 650 °C calcinations with 1 time pH swing and 700 °C with 15 times pH swings, a more rutile phase which is an undesired phase for photocatalytic degradation reactions was formed. Furthermore, Tryba et al. [32] have reported that the production rate of the OH radical is very high with standard TiO2 photocatalysts (Japan) when calcined at 700 °C. They have estimated the production of OH radicals by a fluorescence method and found that the maximum production of OH radicals is achieved with TiO2 catalysts calcined at 700 °C. They have reported a small content of the rutile phase <10 mass%, which is beneficial for OH radical production, suggesting that the photo-formed electrons and holes were retarded, reflecting a high yield of OH radicals. Hence, the OH production rate is also proportional to the crystallinity of the anatase phase. In addition, the crystallite size is also an important factor and showed significant influence in the production of OH radicals. It was found that TiO2 particles of around 30 nm in size can produce more OH radicals [32]. They also emphasized that the lattice strain is minimum for TiO2 at almost zero with the catalysts calcined at around 700 °C. When crystallite or rutile phase increases, the lattice strain also increases to a greater extent. The degradation rate of methylene blue in an aqueous phase showed maximum degradation with TiO2 catalysts calcined at 700 °C, as reported by Tryba et al. [32].

All the important criteria, which Tryba et al. [32] mentioned for high catalytic activity, correspond well with the catalysts prepared by 15 times pH swing and calcined at 700 °C combined with ultrasonication in the presence of a surfactant (Table 2). The TiO2 prepared with 1 time pH swing did not contribute to a high activity at 700 °C due to the formation of a more rutile phase (43%), which inhibits the production of OH radicals, as has been reported by Tryba et al. [32].

The supporting information by Tryba et al. [32] substantiates the higher activity of the catalysts prepared at 700 °C than all the other TiO2 photocatalysts calcined at different temperatures. Furthermore, parameters such as the particle size, surface area, anatase/rutile ratio, and pore volume showed higher values when compared with our previous pH swing method [6]. It is evident that the ultrasonic-assisted pH swing method in the presence of a surfactant can produce TiO2 nanoparticles with enhanced photocatalytic activity. This study clearly reveals that the catalytic activity depends not only on the particle size and surface area but also on the production of OH radicals while the generation of OH radicals depends on the crystallite size, lattice strain, anatase/rutile phase, and the calcination temperature.

Without using the surfactant P-123, the photocatalytic degradation of 4-CP was found to be 50% for the catalysts calcined at 700 °C using 15 times pH swings, which was less than P-25 catalysts. At the same time, 77% degradation of 4-CP was achieved with TiO2 prepared with P-123 under similar experimental conditions. The catalytic activity of the TiO2 catalysts without P-123 was insignificant across various calcination temperatures due to the low surface area and hence, this work was mainly focused on the preparation of TiO2 using P-123 under the influence of ultrasonication, adopting pH swing method.

4 Conclusions

A new route using an ultrasonic-assisted pH swing method for the preparation of TiO2 with the surfactant P-123 enabled the synthesis of photocatalysts with improved surface area, high crystalline, big size nanoparticles, and anatase/rutile phase content, when compared with TiO2 prepared by ultrasonic-assisted sol-gel or other methods. The drawback of the pH swing method, i.e., the enhancement of particle size with respect to an increase in the number of pH swings could be surmounted by this coupled method. The catalysts developed by the combined process evidenced excellent activity, even higher than P-25. This method was, thus, found to be a versatile approach for the preparation of efficient nano-size TiO2 photocatalysts suitable not only for environmental applications but also for electronic applications such as LED and solar cells.

References

Anpo M (2004) Bull Chem Soc Jpn 77:1427–1442 and other references cited therein

Haque SA, Koops S, Tokmoldin N, Durrant JR, Huang J, Bradley DDC, Palomares E (2007) Adv Mater 19:683–687

Kim JY, Lee K, Coates NE, Moses D, Nguyen TQ, Dante M, Heeger AJ (2007) Science 317:222–225

Kamat PV (2007) J Phys Chem C 111:2834–2860

Wei M, Wang K, Yanagida M, Sugihara H, Morris MA, Holmes JD, Zhou H (2007) J Mater Chem 17:3888–3893

Neppolian B, Yamashita H, Okada Y, Nishijima H, Anpo M (2005) Catal Lett 105:111–117

Neppolian B, Jie HS, Ahn JP, Park JK, Anpo M (2004) Chem Lett 33:1562–1563

Yamashita H, Harada M, Misaka J, Takeuchi M, Neppolian B, Anpo M (2003) Catal Today 84:191–196

Teoh WY, Amal R, Madler L, Pratsinis SE (2007) Catal Today 120:203–213

Cong Y, Zhang JL, Chen F, Anpo M (2007) J Phys Chem C 111:6976–6982

Suslick KS (1990) Science 247:1439–1445

Suslick KS, Price GJ (1999) Ann Rev Mater Sci 29:295–326

Wang Y, Tang X, Yin L, Huang W, Hacohen YR, Gedanken A (2000) Adv Mater 12:1183–1186

Yu JC, Yu J, Ho W, Zhang L (2001) Chem Commun 1942–1943

Yu JC, Zhang L, Yu J (2002) Chem Mater 14:4647–4653

Yu JC, Zhang L, Yu J (2002) New J Chem 26:416–420

Ho W, Yu JC (2006) Mol Catal A: Chem 247:268–274

Oh CW, Lee GD, Park SS, Ju CS, Hong SS (2005) React Kinet Catal Lett 85:261–268

Awati PS, Awate SV, Shah PP, Ramaswamy V (2003) Catal Commun 4:393–400

Neppolian B, Wang Q, Jung H, Choi H (2008) Ultrason Sonochem 15:649–658

Yang P, Zhao D, Margolese DI, Chmelka BF, Stucky GD (1998) Nature 396:152–155

Han SJ, Choi SH, Kim SS, Cho M, Jang B, Kim DY, Yoon J, Hyeon T (2005) Small 1:812–816

Asokan S, Krueger KM, Colvin VL, Wong MS (2007) Small 3:1164–1169

Kominami H, Kohno M, Kera YJ (2000) Mater Chem 10:1151–1156

Koshitani N, Sakulkhaemaruethai S, Suzuki Y, Yoshikawa S (2006) Ceram Int 32:819–824

Sheng Q, Yuan S, Zhang J, Chen F (2006) Microporous Mesoporous Mater 87:177–184

Guillard C, Disdier J, Monnet C, Dussaud J, Malato S, Blanco J, Maldonado MI, Herrmann JM (2003) Appl Catal B: Environ 46:319–332

Horikoshi S, Tokunaga A, Watanabe N, Hidaka H, Serpone N (2006) Photochem Photobiol A: Chem 177:129–143

Yu J, Wang G, Cheng B, Zhou M (2007) Appl Catal B: Environ 69:171–180

Zhao D, Feng J, Huo Q, Melosh N, Fredrickson GH, Chmelka BF, Stucky GD (1998) Science 279:548–550

Yu H, Yu J, Cheng B, Liu S (2007) Nanotechnology 18:065604

Tryba B, Toyoda M, Morawski AW, Nonaka R, Inagaki M (2007) Appl Catal B: Environ 71:163–168

Acknowledgments

This research was supported by a grant (M1050000012805-J000012810) from the Korea Ministry of Science and Technology, through the National Research Laboratory Program and partially supported by Korea Science and Engineering Foundation (KOSEF).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neppolian, B., Celik, E., Anpo, M. et al. Ultrasonic-assisted pH Swing Method for the Synthesis of Highly Efficient TiO2 Nano-size Photocatalysts. Catal Lett 125, 183–191 (2008). https://doi.org/10.1007/s10562-008-9563-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-008-9563-9