Abstract

The Keggin and Preyssler-structured tungstophosphoric acid catalysts anchored on the surface of modified SBA-15 (KNS and PNS) by grafting amine groups into system, and were characterized by infra-red spectroscopy, X-ray diffraction, N2-adsorption, Hammett indicator and UV-Vis spectroscopy. Their catalytic behaviors were investigated in the esterification of n-butanol with acetic acid. Characterization results for obtained catalysts verified the ordered hexagonal mesostructure of SBA-15 and preservation of the structures of heteropolyanions on amine-modified SBA-15. KNS and PNS catalysts with the 37 and 25% loadings of Keggin and Preyssler acids exhibited considerable conversions of n-butanol of 61.2 and 63.8% with both 100% selectivity for n-butyl acetate in the esterification reaction, respectively. Especially, tests of six-cycle reaction revealed good reusabilities of KNS and PNS due to their excellent water-resistance properties, and in contrast, the catalysts prepared by direct impregnation lost their high activities immediately at their second cycles. Active sites on the amine-modified SBA-15 retained the Keggin or Preyssler structure after reaction demonstrated by IR analysis. Also, reaction conditions such as the amount of catalyst, reaction time and temperature were explored.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Heteropolyacid (HPA) is a kind of significant catalytic material in both academic and industrial fields due to its unique properties such as strong Brønsted acidity, structure alterability, high proton mobility and environmental friendliness [1–3]. Keggin type heteropolyacid, for an example the tungstophosphoric acid (PW) with formula of H3PW12O40, has been widely studied and well known to be an efficient catalyst for a variety of organic reactions [4, 5]. Comparatively, the catalytic application of Preyssler’s anion has been largely overlooked. The Preyssler anion [NaP5W30O120]14− with an unusual doughnut-shaped structure consisting of a cyclic assembly of five PW6O22 units and with an approximate D 5h symmetry, has gained more research attention in recent years owing to its exclusive physicochemical properties including large number of balanced protons, strong acidity, high hydrothermal stability and wide pH range stability in solution [6–8]. A few of previous studies [9–13] has applied Preyssler HPAs as catalysts for organic synthesis. Majid et al. [14] reported that Preyssler heteropolyacid exhibited a high catalytic activity in the synthesis of 2,4,6-triarylpyridines under solvent-free condition. Also, Rahim et al. [15] revealed that Preyssler type catalyst showed high and stable long-term activity in the liquid phase alkylation of phenol with 1-octene.

The major disadvantages of HPA lie in extremely low surface area and water-solubility, which always limit its practical applications [16]. Impregnation is an easy way to increase its surface area by supporting HPA onto various carriers, such as silica, active carbon, molecular sieves, Al2O3 and so on [17]. However, HPA has the tendency to leach from carriers into polar reaction media, which leads to the poor catalytic reusability. Grafting method, mainly involving the pre-functionalization of carrier with organic components and chemical linkage of HPA, has been chosen to anchor HPA on carriers for avoiding leaching. Pizzio et al. [18] revealed that PW supported on amine-functionalized silica and SiMCM-41 exhibited negligible solubility and high activity in the synthesis of isoamyl acetate. Jin et al. [19] anchored Keggin-structured tungstovanadogermanic HPA (H5GeW11VO40) on the amine-silane functionalized SBA-15, through which HPA clusters were attached firmly to the surface of SBA-15 evidenced by spectroscopic characterizations. Very recently, our research group [20] successfully supported Preyssler-structured tungstophosphoric acid clusters on functionalized silica by grafting technique and observed excellent reusability in the esterification of n-butanol with acetic acid. SBA-15, a well-ordered hexagonal mesoporous silica with an uniform pore size up to approximately 30 nm, is an ideal support for acid catalyst for its thicker pore walls and higher thermal and hydrothermal stability [21, 22]. Up to now, the study of HPA catalysts grafted on the functionalized SBA-15 was mainly based on the Keggin type HPA for oxidation reactions.

In this work, we have successfully grafted Preyssler and Keggin type HPAs on the functionalized SBA-15 and observed their considerable catalytic activity with excellent reusability in the esterification of n-butanol with acetic acid.

2 Experimental

2.1 Catalyst Preparation

The Keggin type tungstophosphoric acid was purchased from Sinopharm Chemical Reagent Company, and SBA-15 was delivered by Prof. Dongyuan Zhao’s group of Fudan University. The Preyssler-structured tungstophosphoric acid catalyst was prepared according to the previous method with some modifications [23]. About 33 g of Na2WO4 · 2H2O was dissolved in 30 mL of H2O by vigorously stirring, into which 26.5 mL of aqueous solution of phosphoric acid (85% by weight) was added. The mixture was sealed into a Teflon bottle at 120 °C for 18 h. Following this, 30 mL of H2O and 10 g of KCl were added into the above mixture to form the precipitate with a white color. The white precipitate was obtained by filtration and washed successively by 2 M of aqueous solution of CH3COOK and methanol. The precipitate was dried and recrystallized twice to obtain the potassium salt of Preyssler HPA. The Preyssler acid was prepared by the passage of an aqueous solution of the potassium salt through a column of H+ ion-resin, followed by the evaporation of the elute in oven.

The preparation of amine-modified SBA-15 (NS) is as follows. 2 g of SBA-15 dispersed in 50 mL of toluene was refluxed, and then 10 mL of 3-aminopropyltriethoxy silane (KH550) was injected into the above suspension with further stirring for 24 h. The sample (designated as NS) was obtained by filtration, washed by Soxhlet apparatus for 24 h, and finally dried in vacuum at 70 °C for 12 h. The adsorption of HPA on the surface of NS was carried out by the following procedure: 0.4 g of NS was added into an aqueous solution of HPA (0.2 g of Keggin or Preyssler acid in 100 mL of H2O) with vigorously stirring for 24 h at room temperature. Solids were recovered by filtration, washed with water and dried at 110 °C for 12 h. The obtained samples are designated as KNS and PNS respectively.

Supported Keggin and Preyssler HPA catalysts (designated as KS and PS, respectively) were also prepared by impregnating SBA-15 into aqueous solutions of Keggin or Preyssler acids. After constant stirring overnight at the room temperature, the mixtures were subjected to evaporation and drying to get the solid products. The loading of HPA acid (37%KS and 25%PS) was prepared by changing the concentration of aqueous solution of HPA. Before charged into the reaction media, KS and PS were pre-activated at 300 °C for 3 h.

2.2 Characterization

X-ray power diffraction (XRD) pattern was obtained on the Bruker D8 Advance diffractometer using the Ni-filtered CuKa radiation at 40 kV and 20 mA. The FT-IR spectra were measured on Nexus 870 FT-IR spectrometer by KBr pellets. BET surface areas were achieved by N2 adsorption on the ASAP2020 Micromeritics analyzer. The loadings of HPA for KNS and PNS samples were measured by UV–Vis spectra. After the adsorption of HPA onto the surface of NS, the amount of heteropoly species stayed in solution were estimated by using a Perkin Elmer Lambda 35 spectrometer with a quartz cell of 10 mm optical path. For the quantitative analysis, standard curves were obtained by using aqueous solutions of HPA with different concentrations. The HPA loadings by weight (37%KNS and 25%PNS) were obtained by calculating the weight difference of initially employed HPAs and leached HPAs in filtrate. The acid strengths of catalysts were measured with Hammett indicators, including anthraquinone (pKa = −8.20), p-nitrotoluene (pKa = −11.35), p-nitrochlorobenzene (pKa = −12.70), m-chloronitrobenzene (pKa = −13.60) and 2, 4-dinitrofluorobenzene (pKa = −14.52).

2.3 Catalytic Test

The esterification of n-butanol with acetic acid was performed in a three-necked glass flask with a Teflon-coated magnetic stirrer and a water-removal accessory. 7.4 mL of acetic acid and 11.9 mL of n-butanol (1:1 molar ratio), 120 °C of reaction temperature, 360 min of reaction time, and 0.6 wt.% of catalyst content in reaction media were used as the typical reaction conditions. The products were analyzed by Gas Chromatograph using SE-54 capillary column with FID as the detector, and the conversion was determined by the internal standard method with n-pentane as the standard substance. The reusability of catalyst was tested as follows. After a reaction, solid catalyst was separated from liquid by filtration and washed by water. Then the water-treated catalyst was dried at 100 °C and putted into reactant mixture of next reaction.

3 Results and Discussion

3.1 Comparison of Various Catalysts

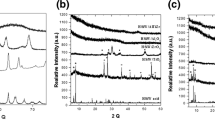

Small-angle XRD patterns of various SBA-15 supported samples are illustrated in Fig. 1. It can be seen that three well-resolved diffraction peaks of pure SBA-15 can be clearly observed at 2θ = 0.98o, 1.66o and 1.88o and assigned to crystal face (100), (110) and (200), respectively. Compared with pure SBA-15, the intensity of reflections of (100) peak of NS, PNS and KNS was significantly decreased, which could be mainly attributed to the effect of pore-filling of organic components and HPA clusters that reduced scattering contrast between the pores and the framework of SBA-15 [24, 25]. This is in agreement with previous cases of assembling HPA into MCM-41 and SBA-15[19, 26, 27]. Furthermore, (100) peaks of parent SBA-15, NS, PNS and KNS gradually shifted to higher angles, implying the decreasing tendency of pore size due to the introduction of organic components and HPA clusters into the pore channel of SBA-15. The more shift of d100 of PNS than that of KNS is mainly resulted from the larger size of Preyssler HPA molecular than the Keggin one [28]. For PNS and KNS, the detection of (110) and (200) reflections proved that both of them kept ordered hexagonal pore arrays of SBA-15. Particularly, KNS did not show as clear peaks of (110) and (200) as those of PNS. This might be the result of the larger number of Keggin HPA anions introduced into the channels of SBA-15. The wide-angle XRD patterns of PNS and KNS gave no diffraction peaks of HPAs rather than the base line for amorphous SBA-15, which implies that attached HPAs did not aggregate together into crystals, the size of which is large enough to be detected by XRD. This means the high dispersion of HPAs on the pore walls of SBA-15.

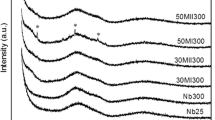

FT-IR spectra of the Preyssler HPA, PNS, 25%PS and pure SBA-15 were illustrated in Fig. 2. The Preyssler HPA sample prepared in this work showed all the IR vibration peaks assigned to the Preyssler structure, and the locations of featured peaks are in well agreement with those in the previous reports [23, 26]. In detail, the Preyssler HPA sample displayed vibrations at 1165, 1082 and 1021 cm−1 for P–O stretching, 940 and 913 cm−1 for W–O–W stretching, 788 cm−1 for W = O stretching, and 573 cm−1 for P–O bending. For pure SBA-15, a strong absorption band at 1100 cm−1 with a shoulder at 1165 cm−1 assigned to Si-O-Si asymmetric vibrations were observed [29]. This might hinder the clear observation of three P–O stretching peaks for PNS due to the strong background. However, the two W–O–W stretching peaks at 940 cm−1 and 913 cm−1 could be clearly detected for PNS, which strongly suggests that the Preyssler’s anions was adsorbed onto the surface of SBA-15 through KH550 and retained its own structure. A previous study showed that the reaction of Preyssler HPA with amine groups on functionalized support affected the position of the W-O-W stretching peaks [26]. However, in Fig. 2, PNS only showed widening of W-O-W stretching peaks without observing a clear shift. On the other hand, for 25%PS, no peaks of Preyssler structure could be observed obviously. This is partially because of the strong background of pure SBA-15, but the more important reason may be that the direct interaction between Preyssler’s anions and hydroxyls in pore walls of SBA-15 mostly caused distortion of anions, and thus substantially weakened the IR vibrations.

The FT-IR spectra of the Keggin HPA, KNS, 37%KS and pure SBA-15 are given in Fig. 3. The four characteristic bands of Keggin-structured H3PW12O40 appeared at 1080 cm−1 (P-O), 982 cm−1 (W = O), 897 cm−1 (W–O–W) and 800 cm−1 (W–O–W) [22]. After immobilizing Keggin type HPA on amine-modified SBA-15, two characteristic bands at 1080 and 800 cm−1 were obscured by the background of SBA-15; the bands at 982 cm−1 and 897 cm−1 shifted to 947 cm−1 and 860 cm−1 respectively. These shifts probably are the result of the interaction of HPA with the amine groups in the functionalized SBA-15 and the formation of ion pair [26]. Additionally, the bands of 37%KS turned out to be the same situation as the bands of 25%PS that was obscured by the presence of SBA-15.

Table 1 listed BET surface areas of various catalysts. Both pure Preyssler and Keggin type HPAs had extremely low surface areas of 0.3 and 6.2 m2/g, respectively, and pure SBA-15 possessed a high specific surface area of 424.8 m2/g. After modifying pure SBA-15 with 3-aminopropyltriethoxy silane, the surface area of NS drastically dropped to 268.9 m2/g, which is attributed to the agglomeration of silica particles and/or occupation of pores with organic components [26]. By supporting Preyssler and Keggin type HPAs onto NS, the surface areas of PNS and KNS samples further decreased to 208.1 m2/g and 154.1 m2/g, respectively, due to the immobilization of HPAs. And surface areas of supported Preyssler and Keggin HPA catalysts prepared simply by impregnation were 337.5 m2/g for PS and 326.9 m2/g for KS. In addition, the pore volumes of SBA-15, NS, PNS and KNS were also measured by N2 adsorption technique, which gave the decreasing tendency in the following order: SBA-15 (0.81 cm3/g) > NS (0.70 cm3/g) > PNS (0.58 cm3/g) > KNS (0.50 cm3/g). The change of pore volumes of the four samples confirms the indication by Fig. 1 that the pore size decreased after introducing the organic components and HPA clusters into the pore channel of SBA-15.

The acid strength (H 0) for various catalysts is also displayed in Table 1. As expected, both pure HPAs showed superacidity with H 0 being lower than −11.9. The Preyssler one (−14.52) was stronger in acidity than Keggin one (−13.6). When HPAs were supported on SBA-15, KS showed weaker acidity with H 0 of −12.7 compared with PS of −13.6. After HPAs anchored on NS, Both PNS and KNS showed the same acid strength with H 0 of −11.35. The acidity of grafted HPAs was weaker than those of impregnated ones, which might ascribe to the chemical interaction of ≡ Si(CH2)3NH3 + and HPA anions with the formation of the salt ≡ Si(CH2)3NH · HPA [30].

The catalytic activities of various catalysts for esterification of n-butanol with acetic acid are shown in Table 1. Under the employed reaction conditions, n-butyl acetate was the only detected product for all catalysts. One can see from Table 1 that without any added catalysts, 35.8% of conversion of n-butanol was obtained due to the acid environment provided by one of the reactants, acetic acid. The pure SBA-15 and NS showed very similar conversions to the blank test for the absence of acidic sites. Pure Preyssler HPA exhibited a very high conversion of 98.5% and pure Keggin HPA gave a conversion of 76.2%. 25%PS catalyst showed a higher conversion (92.7%) than 37% KS did (83.4%) due to the more efficient active sites of PS. PNS catalyst with HPA loading of 25% had a similar conversion with KNS with 37% HPA loading (63.8% vs 61.2%). To compare the activities of various catalysts, the turnover number was calculated. The turnover number presented in Table 1 indicates that impregnated HPAs (25%PS and 37%KS) were more active than their corresponding pure HPAs (Preyssler and Keggin HPA) and grafted HPAs (PNS and KNS). And also, considering much lower surface areas of grafted HPAs than those of impregnated HPAs, it was certain that grafted HPAs showed a higher activity in terms of per square meter of catalyst surface area than the later ones. It is also notable that the catalytic activity of Preyssler HPA is more efficient than that of Keggin HPA.

3.2 Catalytic Reusability

The catalytic reusability of four catalysts in the esterification of n-butanol with acetic acid is illustrated in Fig. 4. It can be seen that although fresh 25%PS and 37%KS catalysts are very active with high conversions of 92.7% and 83.4%, both dropped largely to 64.5 and 54.9% at the second run. This indicated very instable catalytic activities for the PS and KS catalysts prepared by impregnation mostly due to the severe leaching property of HPA. In contrast, conversions over PNS and KNS catalysts reduced very slowly when the catalysts were reused. At the third run the conversions were 62.3 and 60.2%, which are very comparative to 63.8 and 61.2% over fresh catalysts, respectively. On the other hand, the decrease of conversion arising from catalysts lost during separation and transfer of catalysts into the next reaction cycle cannot be excluded. This observation reveals satisfied reusabilities for PNS and KNS catalysts, which means that HPAs have only a slight tendency to leach from the functionalized SBA-15 in reaction. The well stability of HPAs on functionalized SBA-15 is attributed to the strong chemical interaction of ≡ Si(CH2)3NH3 + and HPA, where modified SBA-15 with a positive charge provided sites for HPA as a charge-compensating component [31, 32]. The above results imply that the amine groups in the NS played a key role for the immobilization of HPAs. Figure 5 compares FI-IR spectra of PNS and KNS samples before and after reaction. The W–O–W stretching peaks for Preyssler structure at 940 and 913 cm−1 were still clearly recognized after reaction and also bands assigned to Keggin structure at 947 cm−1 (W = O) and 860 cm−1 (W–O–W) of used KNS were observed, demonstrating that Preyssler and Keggin HPAs still stayed on the surface of amine-modified SBA-15 and kept their own structures. Owing to the stable activity of PNS and KNS, effects of some important reaction conditions were measured over the two catalysts in the following.

3.3 Effect of Reaction Time

Figure 6 showed the influence of reaction time on the conversion of n-butanol over PNS and KNS. It is obvious that the conversion increased with increase of reaction time up to 240 min, and PNS played a bit higher catalytic efficiency than KNS, the conversion of n-butanol increased very slowly along with the increase of reaction time after 240 min.

3.4 Effect of Catalyst Content in Reaction Media

Influence of catalyst content in reaction media on the conversion of n-butanol over PNS and KNS is shown in Fig. 7. It can be seen that both conversions reached a plateau value at the catalyst content of 0.6 wt.%, and beyond this point, no increase of conversion could be observed.

3.5 Effect of Reaction Temperature

Figure 8 showed the effect of the reaction temperature on the conversion of n-butanol over PNS and KNS. The conversion increased steadily when the reaction temperature was enhanced from 110–140 °C, and the conversion was nearly 80% when the temperature reached to 140 °C. However, by-products were showed up when the reaction temperature was up to 130 °C. Therefore, 120 °C is considered as a suitable reaction temperature.

4 Conclusions

In this work, catalysts PNS and KNS were prepared by grafting Preyssler and Keggin type heteropoly acids, respectively, onto the 3-aminopropyltriethoxy silane modified SBA-15, and these acids retained their HPAs structures and still possessed strong acidity. In the esterification of n-butanol with acetic acid at the 120 °C of reaction temperature, 360 min of reaction time, 1:1 molar ratio of acetic acid with n-butanol, and 0.6 wt.% of the catalyst content in reaction media, PNS and KNS exhibited conversions of n-butanol of 63.8 and 61.2%, respectively, with 100% selectivity for n-butyl acetate. PS and KS catalysts prepared directly by impregnating HPA on SBA-15 showed high conversion of 92.7 and 83.4%. However, their catalytic activities in esterification decreased drastically at the second reaction cycle, in contrast, both PNS and KNS showed excellent reusabilities during six-cycle tests due to water-resistant property of HPAs on the surface of functionalized SBA-15.

References

Kozhevnikov IV (1998) Chem Rev 98:171

Misono M (1990) Appl Catal 64:1

Mizuno N, Misono M (1997) Curr Opin Solid State Mater Sci 2:84

Kozhevnikov IV (2007) J Mol Catal A: Chem 262:86

Nakato T, Toyoshi Y, Kimura M, Okuhara T (1999) Catal Today 52:23

Heravi MM, Zadsirjan V, Bakhtiari K, Oskooie HA, Bamoharram FF (2007) Catal Commun 8:315

Alizadeh MH, Razavi H, Bamoharram FF, Hassanzadeh MK, Khoshnavazi R, Zonoz FM (2003) Kinet Catal 44:524

Fernández JA, López X, Bo C, Graaf C, Baerends EJ, Poblet JM (2007) J Am Chem Soc 129:12244

Feizi N, Hassani H, Hakimi M (2005) B Kor Chem Soc 26:2087

Arabi M, Amini MM, Abedini M, Nemati A, Alizadeh M (2003) J Mol Catal A: Chem 200:105

Alizadeh MH, Kermani T, Tayebee R (2007) Monatsh Chem 138:165

Bamoharram FF, Heravi MM, Roshani M, Jahangir M, Gharib A (2007) J Mol Catal A: Chem 271:126

Heravi MM, Bakhtiari K, Daroogheha Z, Bamoharram FF (2007) J Mol Catal A: Chem 273:99

Heravi MM, Bakhtiari K, Daroogheha Z, Bamoharram FF (2007) Catal Commun 8:1991

Hekmatshoar R, Heravi MM, Sadjadi S, Oskooie HA, Bamoharram FF (2008) Catal Commun 9:837

Kozhevnikov IV, Kloetstra KR, Sinnema A, Zandbergen HW, Bekkum H (1996) J Mol Catal A:Chem 114:287

Gu YB, Wei RP, Ren XQ, Wang J (2007) Catal Lett 113:41

Pizzio LR, Vázquez PG, Cáceres CV, Blanco MN (2003) Appl Catal A: Gen 256:125

Jin H, Wu Q, Zhang P, Pang W (2005) Solid State Sci 7:333

Wu S, Zhang W, Wang J, Ren X (in press) Catal Lett

Zhao D, Feng J, Huo Q, Melosh N, Fredrickson GH, Chmelka BF, Stucky GD (1998) Science 279:548

Liu QY, Wu WL, Wang J, Ren XQ, Wang YR (2004) Microporous Mesoporous Mater 76:51

Alizadeh MH, Harmalker SP, Jeannin Y, Frère JM, Pope MT (1985) J Am Chem Soc 107:2662

Zhu J, You WS, Zhu ZM, Sun ZG, Zhang LC, Gu YP (2005) Chem Res Chin Univ 21:264

Zhang WH, Shi JL, Wang LZ, Yan DS (2000) Chem Mater 12:1408

Tarlani A, Abedini M, Nemati A, Khabaz M, Amini MM (2006) J Colloid Interface Sci 303:32

Xu W, Luo Q, Wang H, Francesconi LC, Stark RE, Akins DL (2003) J Phys Chem B 107:497

Kaba MS, Song IK, Duncan DC, Hill CL, Barteau MA (1998) Inorg Chem 37:398

Lapkin A, Bozkaya B, Mays T, Borello L, Edler K, Crittenden B (2003) Catal Today 81:611

Kaleta W, Nowinska K (2001) Chem Commun 535

Li W, Li L, Wang Z, Cui A, Sun C, Zhao J (2001) Mater Lett 49:228

Kim H, Jung JC, Yeom SH, Lee K, Yi J, Song IK (2007) Mater Res Bull 42:2132

Acknowledgments

The authors thank the Natural Science Foundation of China (Nos. 20306011 and 20476046) and the Qinlan Project of Jiangsu Province for Excellent Young Researchers.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material

Rights and permissions

About this article

Cite this article

Wu, S., Wang, J., Zhang, W. et al. Preparation of Keggin and Preyssler Heteropolyacid Catalysts on Amine-modified SBA-15 and Their Catalytic Performances in Esterification of n-Butanol with Acetic Acid. Catal Lett 125, 308–314 (2008). https://doi.org/10.1007/s10562-008-9559-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-008-9559-5