Abstract

Scolecite is one kind of natural zeolite. A three component Biginelli reaction using scolecite as a novel heterogeneous acid catalyst is demonstrated. The short reaction time, clean reaction conditions, consistent yields and minimum environmental effects are important features of the reaction.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Biginelli reaction, discovered in 1893, for the synthesis of multi-functionalized 3,4-dihydropyrimidin-2(1H)-one (DHPM) is an important milestone in the history of MCRs [1]. The process consists of three component condensation of an aldehyde, urea and open chain β-dicarbonyl compound in presence of catalytic amount of HCl in ethanol at reflux temperature to afford DHPM in moderate yield [2]. The DHPM nucleus exhibits a broad spectrum of biological effects such as anti-viral, anti-tumor, antibacterial and anti-inflammatory activities [3]. Furthermore, appropriately functionalized DHPMs have emerged as potent calcium channel blocker, antihypertensive agents, α1a-adrenrgic antagonists and neuropeptide Y (NPY) antagonists [4]. This great biological importance of DHPM nucleus has prompted the development of new improved methodologies for Biginelli reaction, including transition metal Lewis acid catalysis [5], solid phase synthesis [6], activation with certain additives [7], ionic liquids [8], microwave irradiation [9] and grinding techniques [10]. Recent decades have witnessed an exponential growth in the applications of heterogeneous catalysis to carry out synthetic transformations as a consequence of its significance in terms of enviro-economical and practical aspects [11]. The literature survey has revealed that there is relatively little number of reports on Biginelli reaction using heterogeneous acid catalysis. Most of the methods are based upon the impregnation of toxic acid such as HCl, H2SO4 and NaHSO4 on silica gel [12]. A truly heterogeneous acid catalyst such as montmorillonite KSF was previously demonstrated for an efficient synthesis of DHPM, but the reaction time (20–48 h) is relatively longer [13]. The natural Heulandite type zeolite [14] and ersorb–4 (E4) zeolites [15] are also reported for an efficient synthesis of DHPMs. Herein, we wish to report an efficient and rapid Biginelli reaction using scolecite as a novel heterogeneous acid catalyst (Scheme 1). The scolecite catalyst used is solid, non-corrosive, inexpensive and recyclable. The short reaction time (typically <1 h), clean reaction conditions, consistent yields and minimum environmental effects are important features of the reaction.

2 Experimental Section

Unless otherwise noted, commercially available chemicals with at least 98% purity were used throughout this study. All solvents were reagent grade and freshly distilled. Manually coated glass plates with silica gel were used for thin layer chromatography. IR spectra were recorded on a Shimadzu FTIR-1710 spectrophotometer. The 1H NMR spectra were recorded on 400 MHz instrument and the chemical shifts were reported with TMS as an internal standard. The representative spectral analysis for few of the products is given below:

Typical Procedure: A mixture of appropriate aromatic aldehyde (5 mmol), ethyl acetoacetate (5 mmol), urea or thiourea (6 mmol) and the catalyst, scolecite (2% weight with respect to all the reactants) in CH3CN (20 mL) was refluxed for the time mentioned in Table 2. The reaction was monitored by TLC. After completion of reaction, the catalyst was filtered under hot conditions and washed with acetone several times. The filtrate was distilled off under vacuum and the residue was recrystallized from ethanol to afford Biginelli reaction product in excellent purity.

2.1 Ethyl 1,2,3,4-Tetrahydro-4-(4-Methoxyphenyl)-6-Methyl-2-Oxopyrimidine-5-Carboxylate

Yellow solid, m.p. 201–202 °C (Lit.9b m.p. 200–201 °C); IR (KBr, cm−1): 3242, 3111, 2982, 2929, 2360, 1724, 1775, 1649, 1514, 1460, 1278, 1222, 1176, 1087, 1031, 790; 1H NMR (CDCl3, δ ppm): 1.19 (t, J = 9.6 Hz, 3H, CH3), 2.36 (s, 3H, CH3), 3.81(s, 3H, OCH3),4.12 (q, J = 9.2 Hz, 2H, OCH2), 5.37 (s, 1H, ArCH), 5.50 (s, 1H, NH),6.87(d, J = 8.8 Hz, 2H, ArH), 7.24 (d, J = 8.8 Hz, 2H, ArH), 7.54 (s, 1H, NH).

2.2 Ethyl 1,2,3,4-Tetrahydro-4-(3,4,5-Trimethoxyphenyl)-6-Methyl-2-Oxopyrimidine-5-Carboxylate

Yellow solid, m.p. 178–180 °C (Lit.9b m.p. 180–182 °C); IR (KBr, cm−1): 3234, 3103, 2933, 2360, 1724, 1712, 1654, 1589, 1508, 1464, 1419, 1329, 1244, 1166, 1097, 775; 1H NMR (CDCl3, δ ppm): 1.22 (t, J = 9.6 Hz, 3H, CH3), 2.37 (s, 3H, CH3), 3.84 (m, 9H, 3OMe), 4.14 (q, J = 9.6 Hz, 2H, OCH2), 5.39 (s, 1H, ArCH), 5.63 (s, 1H, NH), 6.55 (s, 2H, ArH), 7.77 (s, 1H, NH).

2.3 Ethyl 1,2,3,4-Tetrahydro-6-Methyl-2-Oxo-4-p-Tolylpyrimidine-5-Carboxylate

Yellow solid, m.p. 212–214 °C (Lit.10d m.p. 213–216 °C); IR (KBr, cm−1): 3244, 3113, 3039, 2978, 2929, 1732, 1709, 1647, 1419, 1313, 1214, 1089, 756; 1H NMR (CDCl3, δ ppm): 1.19 (t, J = 9.2 Hz, 3H, CH3), 2.34 (s, 3H, ArCH3), 2.35 (s, 3H, CH3), 4.08 (q, J = 9.6 Hz, 2H, OCH2), 5.38 (s, 1H, ArCH), 5.58 (s, 1H, NH), 7.13 (d, J = 10.4 Hz, 2H, ArH), 7.22 (d, J = 10.8 Hz, 2H, ArH), 7.77 (s, 1H, NH).

2.4 Ethyl 4-(4-Chlorophenyl)-1,2,3,4-Tetrahydro-6-Methyl-2-Oxopyrimidine-5-Carboxylate

Yellow solid, m.p. 213–215 °C (Lit.9b m.p. 212–213 °C); IR (KBr, cm−1): 3240, 3111, 2980, 2931, 2360, 1722, 1706, 1654, 1452, 1290, 1220, 1087, 781; 1H NMR (CDCl3, δ ppm): 1.19 (t, J = 9.2 Hz, 3H, CH3), 2.36, 3H, CH3), 4.11 (q, J = 8.4 Hz, 2H, OCH2), 5.40 (s, 1H, ArCH), 5.66 (s, 1H, NH), 7.29 (m, 4H, ArH), 7.70 (s, 1H, NH).

2.5 Ethyl 1,2,3,4-Tetrahydro-4-(4-Methoxyphenyl)-6-Methyl-2-Thioxopyrimidine-5-Carboxylate

Yellow solid, m.p. 153–155 °C (Lit.19 m.p. 154–155 °C); 1H NMR (CDCl3, δ ppm): 1.19 (t, J = 9.2 Hz, 3H, CH3), 2.37 (s, 3H, CH3), 3.79 (s, 3H, OCH3), 4.11 (q, J = 9.6 Hz, 2H, OCH2), 5.36 (s, 1H, ArCH), 6.87, (d, J = 11.6 Hz, 2H, ArH), 7.21 (d, J = 9.2 Hz, 2H, ArH), 7.31 (s, 1H, NH),7.93 (s, 1H, NH).

2.6 Ethyl 1,2,3,4-Tetrahydro-4-(3,4,5-Trimethoxyphenyl)-6-Methyl-2-Thioxopyrimidine-5-Carboxylate

Yellow solid, m.p. 192–193 °C (Lit.9b m.p. 193–195 °C); 1H NMR (CDCl3, δ ppm): 1.24 (t, J = 9.6 Hz, 3H, CH3), 2.38 (s, 3H, CH3), 3.86 (m, 9H, 3OMe), 4.16 (q, J = 9.6 Hz, 2H, OCH2), 5.39 (s, 1H, ArCH), 6.53 (s, 2H, ArH), 7.03 (s, 1H, NH), 7.56 (s, 1H, NH).

2.7 Ethyl 4-(4-Chlorophenyl)-1,2,3,4-Tetrahydro-6-Methyl-2-Thioxopyrimidine-5-Carboxylate

Yellow solid, m.p. 183–185 °C (Lit.10d m.p. 184–185 °C); IR (KBr, cm−1): 3329, 3174, 3103, 2983, 2935, 2360, 1722, 1573, 1465, 1371, 1282, 1203, 1093, 806, 746; 1H NMR (CDCl3, δ ppm): 1.21 (t, J = 9.6 Hz, 3H, CH3), 2.38 (s, 3H, CH3), 4.12 (q, J = 9.6 Hz, 2H, OCH2), 5.40 (s, 1H, ArCH), 7.15 (s, 1H, NH), 7.27 (d, J = 8.4 Hz, 2H, ArH), 7.33 (d, J = 8.4 Hz, 2H, ArH), 7.68 (s, 1H, NH).

2.8 Ethyl 1,2,3,4-Tetrahydro-6-Methyl-4-(3-Nitrophenyl)-2-Thioxopyrimidine-5-Carboxylate

Yellow solid, m.p. 205–207 °C (Lit.19 m.p. 205–207 °C); IR (KBr, cm−1): 3178, 3136, 2987, 2343, 1716, 1660, 1595, 1533, 1475, 1344, 1274, 1208, 1103, 736, 650; 1H NMR (CDCl3, δ ppm): 1.25 (t, J = 9.6 Hz, 3H, CH3), 2.47 (s, 3H, CH3), 4.16 (q, J = 9.6 Hz, 2H, OCH2), 5.55 (s, 1H, ArCH), 7.31 (s, 1H, NH), 7.55 (m, 1H, ArH), 7.68 (d, J = 10.4 Hz, 1H, ArH), 7.76 (s, 1H, NH), 8.19 (m, 2H, ArH).

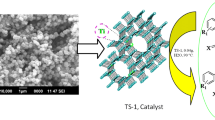

3 Details of Scolecite

Zeolite minerals have been discovered in a wide variety of sedimentary environments, ranging from the present day soils and saline lakes to land-laid and marine fluffs, and ancient, low grade metamorphic rocks [14]. Scolecite is one kind of natural zeolite which occurs in cavities in basic volcanic rocks, and is also found in some metamorphosed calcareous rocks [15]. Scolecites have a frame work structure in which every (Si, Al)O4 tetrahedron has each of its oxygen shared with the other terahedra [16]. The two types of channels running through the structure cause small cavities at the intersections. These cavities contain water molecules and exchangeable cations. The aluminosilicate frame of scolecite has small monoclinic distortion. In scolecite, Ca2+ ions are co-ordinated by three water molecules and four framework oxygen atoms, i.e. Ca2+ ions are in sevenfold co-ordination. Scolecite possesses both the Lewis and the Bronsted acidity. The Lewis acidity is due to Al3+ at the crystal edges and Bronsted acid character is due to the dissociation of the intercalated water molecules co-ordinated to cations.

4 XRD Characterization of Natural Occurring Scolecite Type Zeolite

The natural occurring scolecite type zeolite was collected from the Ellora valley, village Satara, Aurangabad, Maharashtra of the Deccan traps of India. It was subsequently washed with distilled water and acetone for several times, dried and crushed into fine powder which was further washed with distilled water 3–4 times and dried at 110 °C in an oven. The resulting sample was heated at 500 °C in high temperature Muffle furnace (SONAR) for 1 h at rate 3 °C per minute and naturally cooled. These materials were characterized by XRD using a model D8 Bruker AXS with monochromatic Cu radiation (40 kV and 30 mA) at room temperature. The XRD spectra are shown in Figs. 1 and 2. It is seen that the sample are crystalline in nature. Due to calcinations, the high intensity peak has been shifted at 2θ = 38.29° and broad hump were observed in Fig. 2, the region of 2θ = 25–35°. It shows that the crystal structure collapse at high temperature which was not seen in the Fig. 1.

The XRD data leads to the following cell dimension a = 4.817416 A°, b = 4.817416 A°, c = 34.11858 A°. The high values of unit cell dimension are also reported for Edingtonite type zeolite [17]. The average particle size found to be 1.9915 A° and hexagonal crystal system.

5 Results and Discussion

The optimum reaction conditions were initially investigated by considering three component condensation of benzaladehyde, (2 mmol), ethyl acetoacetate (2 mmol) and urea (2 mmol) in different solvents. The quantity of the catalyst used was with respect to the total weight percentage of the initial three components. The results are summarized in Table 1.

It follows from Table 1 that CH3CN is the best solvent for Biginelli reaction using 2% weight of scolecite for getting maximum yield of 4a in a short reaction time of half an hour. After cooling the reaction mixture (Table 1, entry 3), it was observed that 4a was precipitated. This factor troubled the separation of the catalyst from the reaction mixture. Therefore, it was necessary to filter the reaction mixture under hot conditions repeatedly. The recovered catalyst was washed several times with acetone and dried at 100 °C. The separated catalyst was again reused for Biginelli reaction and this was repeated three times. In these cases, the yield of 4a was found to be 87, 79 and 73% in successive three times use. Thus, the activity of the catalyst scolecite was found to be diminished after its recyclability. The products of reaction were purified by recrystallization process in ethanol solvent. With these optimized reaction conditions in hand, several substituted aromatic aldehydes were treated with ethyl acetoacetate and urea or thiourea and the results are summarized in Table 2.

Aromatic aldehydes carrying either electron releasing or electron withdrawing substituents in the ortho, meta and para-positions afforded high yields of DHPMs. An important feature of this procedure is the survival of variety of functional groups such as nitro, bromo, chloro and ether under the reaction conditions. Thiourea also reacts under similar reaction conditions to form the corresponding 3,4-dihydropyrimido-2(1H)-thiones in good to excellent yields. The structures of all the products were confirmed by comparing melting point and spectral data with those in the literature. (Table 3)

In conclusion, we have successfully carried out Biginelli reaction using scolecite as a new heterogeneous acid catalyst for the synthesis of DHPMs. The experimental procedure is quick and simple. Furthermore, this method is advantageous because of clean reaction conditions, consistent yields and minimum environmental effects.

References

Ramon DJ, Yus M (2005) Angew Chem Int Ed 44:1602

Bigginelli P (1893) Gazz Chim Ital 23:360

(a) Kappe CO (1993) Tetrahedron 49:6937; (b) Kappe CO (2000) Acc Chem Res 33:879; (c) Kappe CO (2000) Eur J Med Chem 35:1043 and the references cited therein

Mayer TU, Kapoor TM, Haggarty SJ, King RW, Schreiber SL, Mitchison TJ (1999) Science 286:971

(a) LaCl3: Lu J, Bai Y, Wang Z, Yang B, Ma H (2000) Tetrahedron Lett 41:9075; (b) CeCl3: Bose DS, Fatima L, Mereyala HB (2003) J Org Chem 68:587; (c) Ce(NO3)3: Adib M, Ghanbary K, Mostofi M, Ganjali MR (2006) Molecules 11:649; (d) InCl3: Ranu BC, Hajra A, Jana U, J Org Chem 65:6270; (e) ZrCl4: Lu J, Bai YJ (2002) Synthesis 4:66; (f) CdCl2: Chari MA, Syamasundar K (2004) J Mol Catal A 221:137

Dallinger D, Yu Gorobets N, Kappe CO (2003) Org Lett 5:1205

(a) CAN: Yadav JS, Subba Reddy BV, Bhaskar Reddy K, Raj KS, Prasad AR (2001) J Chem Soc Perkin Trans 1:1939; (b) I2: Saxena I, Borah DC, Sarma JC (2005) Tetrahedron Lett 46:1159; (c) Mn(OAc)3: Bussolari JC, McDonnell PA (2000) J Org Chem 65:6777

(a) Hu EH, Sidler DR, Dolling UH (1998) J Org Chem 63:3454; (b) Dondoni A, Massi A (2001) Tetrahedron Lett 42:7975; (c) Peng J, Deng Y (2001) Tetrahedron Lett 42:5917

(a) Kappe CO, Kumar D, Varma RS (1999) Synthesis 1799; (b) Hu EH, Sidler DR, Dolling UH (1998) J Org Chem 63:3454; (c) Yadav JS, Subba Reddy BV, Jagan Reddy E, Ramalingam J (2000) J Chem Res(s) 354.

Ranu BC, Hajra A, Dey SS (2002) Org Process Res Develop 6:817

(a) Corma A (1997) Chem Rev 97:2373; (b) Clark JH, Macquarrie D (1996) J Chem Soc Rev (1996) 303

(a) Silica-H2SO4: Fu NY, Yuan YF, Gao Z, Wang SW, Wang JT, Peppe C (2002) Tetrahedron Lett 58:480; (b) SiO2-HCl: Karade HN, Sathe M, Kaushik MP (2007) Molecules 12:1341; (c) SiO2/NaHSO4: Salehi H, Guo Q-X (2004) Synth Commun 34:171

Montmorillonite KSF: Ramalinga K, Vijayalakshmi P, Kaimal TNB (2001) Synlett 863

Tajbakhsh M, Mohajerani B, Heravi MM, Ahmadi AN (2005) J Mol Catal A Chem 216

Hegedus A, Hell Z, Vigh I (2006) Synth Commun 129

(a) Hay RL (1966) Geol Soc Amer Spec Paper 21:85; (b) Hay RL (1978) In: Sand LB, Mumpton FA (eds) Natural zeolites, occurrence, properties and use. Pergamon Press, New York, p 135

Scherillo A (1938) Periodio Min Roma 7:61

(a) Falth L, Hanseen S (1979) Acta Crystal 325:1878; (b) Fellers BD (2006) U.S Patent No. 7004328 B2

(a) Hay MH (1934) Mineral Mag 23:483; (b) Taylor WH (1935) Mineral Mag 24:208; (c) Taylor WH, Jackson R (1933) Z Kristallogr 86:53

Acknowledgment

The authors are thankful to University Grants Commission, New Delhi for the financial assistance under Major Research Project Scheme (F. No. 32-245/2006).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Meterials

Rights and permissions

About this article

Cite this article

Shinde, S.V., Jadhav, W.N., Lande, M.K. et al. Scolecite as a Novel Heterogeneous Acid Catalyst for an Efficient Synthesis of 3,4-Dihydropyrimidin-2(1H)-ones Via Multi-component Biginelli Reaction. Catal Lett 125, 57–61 (2008). https://doi.org/10.1007/s10562-008-9508-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-008-9508-3