A non-thermal, atmospheric pressure plasma with a titanium dioxide catalyst were combined to destroy difluorochloromethane, CCl2F2, (CFC-12) in gas streams of nitrogen and air using two configurations; one where the catalyst was incorporated directly into the plasma and the other where the catalyst was downstream of the plasma. The single stage reactor, in both gas streams, gave significant enhancement of the CFC-12 destruction with high energy efficiency. Both configurations decreased NOx production when processing in air. No loss in catalyst surface area or activity was observed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Halogenated volatile organic compounds, such as chlorofluorocarbons, CFCs, released into the troposphere pose a real environmental threat as greenhouse gases and ozone depleting chemicals. This has forced researchers to identify new methods and technologies to allow the safe and economic destruction of such waste gases. Most studies on the decomposition of CFCs have used thermal or catalytic methods [1]. Several groups have used catalysts such as γ-alumina, [2,3], TiO2 [4,5], TiO2 mixes [6–8] and zeolites [9–12]. Others have tried to overcome the problems associated with these methods, such as the large energy requirement for producing high temperatures and the possible formation of dioxins by looking at alternatives including the use of plasma discharges. Thermal plasmas using a plasma-arc torch have been employed [13] to convert CFC-12 into the less environmentally damaging CFC-13, CClF3, and a microwave plasma torch has also been used [14] to destroy CFC-12 in atmospheric pressure air. A surface-induced plasma discharge has been shown [15] to achieve 93% decomposition of CFC-12. Gal et al. [16] examined the chemical transformations of low concentrations of CFCs using non-thermal plasma processing in nitrogen gas streams. We have also studied the removal of CFC-12 by non-thermal plasma processing at atmospheric pressure in both air and nitrogen gas streams [17].

It has been demonstrated that the use of a plasma discharge in conjunction with a catalyst gives a synergistic effect due to plasma-activated catalysis when applied to the destruction of gaseous pollutants such as VOCs, halogenated solvents and NOx [18–20]. Recently, Ogata et al. [21,22] have studied the destruction of CFC-13, CClF3, in atmospheric pressure argon using a surface plasma discharge packed with different catalysts. In this letter, we show that the combination of plasma and catalysis methods using TiO2 gives enhanced destruction of CFC-12, CCl2F2, in nitrogen and air at atmospheric pressure and demonstrates selectivity in the end-products.

Experimental

The experimental arrangement is a modification of that used previously [17]. The baseline measurements, termed plasma-alone, used a dielectric pellet-bed plasma reactor consisting of a glass tube of 24 mm internal diameter with two electrodes 25 mm apart, packed with 12 cm3 barium titanate beads (3.5 mm diameter) through which the gas mixture passed. An AC voltage of 16.5 kVpk-pk at a frequency of 10.25–13.25 kHz was applied between the electrodes. Using a digital storage oscilloscope (Tektronix TDS 3012), current and voltage waveforms were recorded for the discharge by using a calibrated high voltage probe and measuring the current across a 1 kΩ resistor in the return earth path from the reactor. This indicated an electrical input power of 1.1 W and a plasma energy density of 66 J litre−1.

The TiO2 catalyst (Alfa Aesar) was prepared by being ground and sieved. The 500–850μm fraction was used in the experiments and the surface area was determined as 137 m2 g−1 using nitrogen BET (Coulter SA 3100). In the one-stage plasma-catalysis reactor, 5 mL of catalyst was added to the BaTiO3 beads giving a 8:1 BaTiO3:catalyst ratio and a slightly reduced electrical input of 0.90 W (54 J L−1). A two-stage reactor configuration was also used where 0.5 mL of the TiO2 catalyst was placed directly downstream after the plasma with a 96:1 BaTiO3:catalyst ratio. The operating temperature of the plasma and catalyst is ∼150°C in the single stage reactor and ∼140°C for the catalyst in the two-stage arrangement. The carrier gas, pure nitrogen or synthetic air (80% nitrogen with 20% oxygen) was used as supplied (BOC Gases). The flow of the carrier gas and CFC-12 (Argo International) was maintained by mass flow controllers (MKS Mass Flo) and passed through the reactor at a pressure of 1 bar. No attempt was made to dry the gases. The residence time was 0.25 s for a total flow rate of 1 L min−1. The space velocities were 10,000 and 120,000 h−1 GHSV for the one-stage and two-stage reactor configurations, respectively. The degree of destruction of CFC-12 and the identity of the end products of the plasma processing were monitored on-line by infrared spectroscopy using a long-path gas cell (2.76 m Venus Series) and a FTIR Spectrometer (Shimadzu 8300) with a resolution of 1 cm−1. In the plasma reactor, the concentration of the end-products reached a stable level after about 20 min of processing and the results presented were recorded after 1.5 h. Infrared spectra of the catalyst surfaces before and after processing were taken using ATR-IR (Perkin Elmer, Spectrum One with ATR Sampling Accessory).

Results

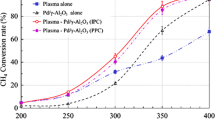

The results for the destruction of ∼ 500 ppm of CFC-12 are shown in figures 1 and 2 for plasma-catalysis processing in nitrogen and air, respectively. The destructions and concentrations of the end-products are given in table 1. The baseline gas-phase result for the CFC-12 destruction with plasma alone is 21 and 12% for processing in nitrogen and air gas streams, respectively. The products as detected by FTIR are CO, CO2, COF2, HCl and N2O in nitrogen gas streams and CO, CO2, COF2, HCOCl, NO, NO2 and N2O in air. The oxygenated species produced during the processing in nitrogen are due to an intrinsic source of oxygen in the BaTiO3 beads which is an accepted phenomenon [23]. We believe that the source of hydrogen in the HCl and HCOCl products comes from trace amounts of moisture in the gas streams or adsorbed onto surfaces and that HCl and HCOCl are not primary products of the decomposition but arise from secondary reactions of water with reaction intermediates or end-products.

In the nitrogen gas stream (figure 1), the destruction of CFC-12 is enhanced to 27% using plasma in combination with the TiO2 catalyst in a one-stage reactor configuration, whereas the destruction in the two-stage configuration is comparable to the plasma-alone value of 21%. In the air gas stream (figure 2), the one-stage plasma-catalysis reactor configuration more than doubles the CFC-12 destruction to 27% from the plasma-alone value of 12%. A modest increase is observed for the two-stage reactor configuration with a CFC-12 destruction of 14%. The concentration of the undesirable NOx by-product from plasma processing in air is also decreased from 468 ppm, to 368 and 336 ppm in the one- and two- stage reactor configurations, respectively (table 1). This reduction in NOx comes from the elimination of NO which is completely removed in the two stage configuration with the amount of NO2 remaining unchanged.

ATR-IR shows modification to the catalyst surfaces had occurred after 8 h of processing with less parent Ti–O bonds present especially in air streams. Due to the high absorbance of bulk Ti–O and Ti–O2 bonds below 1200 cm−1, possible chlorine and fluorine bonds cannot be identified successfully. Nitrates and NOx are thought to be present in the region between 1225 and 1575 cm−1 with no other significant new peaks visible on the spectra.

Studies were also made for a range of other catalysts (γ-alumina and the zeolites, HZSM-5, NaZSM-5, NaA and NaX). The combination of plasma and catalyst failed to enhance the destruction of CFC-12 in air streams in either configuration although NOx was reduced in all cases particularly when using NaX in a one-stage configuration. Ogata et al. [21] report that plasma-catalysis using Al2O3 catalyst does not enhanced the destruction of CFC-13 whilst TiO2 does.

Discussion

We have shown that the combination of plasma and a TiO2 catalyst has a particular synergistic effect on the destruction of CFC-12 in both nitrogen and air streams giving similar levels in both cases in contrast to plasma-alone where processing in air is much less effective than in nitrogen as we observed previously [17]. The destruction of CFC-12 in air is increased by 125% by incorporating a TiO2 catalyst directly into the plasma discharge. An additional benefit of combining plasma and catalyst is that there is also a reduction in the yield of NOx when processing in an air stream. In considering the nature of plasma-activation of a catalyst, it is clear that the identity of the plasma-generated species available to the catalyst will influence its ability to destroy CFC-12. In the one-stage reactor configuration where the plasma and catalyst are in intimate contact, there is the possibility of contributions from electron- and photon-induced processes, surface-discharges and short-lived radicals and excited species whereas only long-lived radicals, reaction intermediates and products can activate the catalyst in a two-stage configuration. The nature of the active sites and the surface-adsorbed species will also be important.

The reaction mechanism for the gas-phase plasma destruction of CFC-12 in air has been outlined in a previous paper [17]. The main reaction routes are summarised in figure 3. CFC-12 has a large cross-section for dissociative electron attachment [16,17] and this is the primary step in the decomposition of CFC-12 together with a minor participation by collision dissociation by metastable nitrogen, N2(A3∑ +u ) in the case of processing in pure nitrogen. The CF2Cl radical recombine with O2 to form a peroxy-radical which then is converted into COF2 and further oxidised along with other intermediate species into CO and CO2. In dry systems, the halogen end-products are assumed to be Cl2 and F2 as confirmed by Wang et al. [1] in their plasma study. Our FTIR system cannot detect F2 and Cl2.

In a plasma discharge in air, NO, NO2 and N2O are commonly produced [17,24] and are undesirable end-products. They arise because excited-state nitrogen atoms formed in the plasma discharge react with molecular oxygen to form NO, which is further oxidised by atomic oxygen and ozone to NO2

Further reaction of atomic nitrogen with NO2 gives rise to N2O,

which can also be formed by the following reaction

These reactions of nitrogen species in the discharge containing oxygen account for the reduction in the plasma-alone destruction of CFC-12 seen in air compared with a nitrogen gas stream (21–12%) as they occur with greater efficiency than decomposition reactions of CFC-12. In the plasma-catalysis experiments, the catalyst provides additional decomposition pathways that enhance CFC-12 destruction and remove the distinction between processing in air or nitrogen.

TiO2 is a well known photocatalyst and has Schottky defects giving n-type semiconductive properties and a band gap of 3.2 eV. It is suggested that photocatalysis occurs as photons can activate the catalyst’s band gap of 3.2 eV [25,26]. Absorption of near-UV light at wavelengths <385 nm is followed by electron–hole pair generation which produces radical cations, OH·− from any chemisorbed water and O ·−2 in aerated systems, with oxidative activity attributed mostly to valence-band holes, O ·−2 /·O2H and H2O2 [27]. Degradation of the CFC-12 occurs through combined reductive and oxidative processes on TiO2 [28]. The use of TiO2 in this way operates at atmospheric pressure and reaction products are usually CO2, H2O or HCl in the case of chlorinated organic compounds [25]. Our packed bed plasma reactor is a weak source of UV light but the electrons in the discharge have a mean energy of 3–4 eV and it is suggested [29] that the impact of plasma-generated electrons on the TiO2 surface in the one-stage configuration can produce electron–hole pairs in the same manner as photon absorption

Nakamura et al. [30] have shown that oxygen vacancies are created by plasma excitation of TiO2 and that electrons can be trapped on these vacancies. Ogata et al. [22] have suggested that plasma action on TiO2 directly activates lattice oxygen and OH in the TiO2. It is those species which dissociate the CFC and account for the equal destruction efficiency observed in both N2 and air in contrast to the pure plasma dissociation of CFC-12 where the destruction in nitrogen was more efficient than in air [17].

Such a mechanism cannot operate in the two-stage configuration as photons and electrons will not penetrate beyond the discharge to the downstream catalyst and the plasma-activated species will be reactive intermediates and long-lived species (e.g. ozone [22]) giving reduced enhancement in the CFC-12 destruction. Karmakar and Greene [5] investigated the thermal decomposition of CFC-12 on TiO2 at 200–400°C without UV excitation and found the catalyst to have the maximum activity and stability compared with others tested previously including zeolites. They observed conversion to CO2 and halogen acids and interestingly a 75% reduction in surface area after 4 days, most of which (50%) took place during the initial 1–1.5 h of reaction. We do not observe any surface reduction with our surface areas remaining essentially unchanged at ∼ 137 m2 g−1. Their explanation of the decreased surface area was fluorination of the surface i.e. replacement of surface oxygen and/or hydroxyls by fluorine. Deactivation of the catalyst was due to the loss of TiO2 as halides and oxyhalides and production of TiOF2 as a solid in the reactor and the activity deteriorated due to loss in catalyst weight and surface area. It would seem that under our plasma-catalysis condition, the TiO2 catalyst does not undergo such degradation suggesting that plasma-generated species are more effective than those generated thermally. Karmakar and Greene [5] found that if water was added to the feed gas then the surface area was not affected to the same extent. This agrees with photocatalytic work by Alberici et al. [25] who found that the titania surface becomes partially dehydroxylated as the processing proceeds and if hydroxyl radicals are consumed in the heterogeneous oxidation reactions, then the surface must be continuously rehydrated if long-term catalytic activity is to be maintained.

Titanium dioxide is used often in conjunction with other metal oxides such as V2O5 for the selective catalytic reduction (SCR) of NO to N2 by ammonia. Hashimoto et al. [31] have studied the photocatalytic oxidation of NO on TiO2 where the NO reacts with the O −2 to give nitrate, NO −3 , on the titania surface. Dors et al. [32] have examined the SCR of NOx with ammonia on plasma-activated TiO2 and suggest that trapped electrons formed by the mechanism suggested by Nakamura et al. [30] can form O −2 in dry air steams giving trapped nitrate ions, NO −3 upon adsorption of NO. This suggests a mechanism for NO removal on plasma-activated surfaces and it is noteworthy that we observe NOx reduction that is essentially brought about by NO removal. ATR-IR indicates the presence of nitrates on the surface of the catalyst supporting this mechanism for NOx removal.

Conclusion

Plasma-assisted catalysis using TiO2 shows particular effectiveness for the destruction of CFC-12. The one-stage packed-bed reactor configuration, in both gas streams, gives significant enhancement of the CFC-12 destruction to 27% at a relatively low energy consumption (∼ 54 J L−1). In contrast, Ogata et al. [21] get a ∼34% destruction of 1% CFC-13 in argon with an energy efficiency using a surface discharge plasma-catalysis configuration with an energy input of 1200 J L−1. In both plasma-catalysis configurations for processing in air, there is a decrease in the yield of the unwanted NOx by-product. The mechanism of plasma-catalysis destruction is thought to be due to the plasma activating the TiO2 by electron-impact and photon absorption in a one-stage configuration with degradation occurring through combined reductive and oxidative processes on the catalyst surface. In the two-stage configuration, reactive intermediates and long-lived species created in the discharge enhance the destruction on the TiO2 surface. No loss in surface area or activity was observed during plasma-catalysis processing in contrast to studies with only a catalyst although ATR-IR indicates that the catalyst surface does appear to have been slightly modified.

References

Wang Y.-F., Lee W.-J., Chen C.-Y., Wu Y.-P.G., Chang-Chien G.-P. (2000) Plasma Chem. Plasma Processing 20: 469

Kemnitz E., Kohne A., Lieske E. (1997) J. Fluor. Chem. 81: 197

Ng C.F., Shan S., Lai S.Y. (1998) Appl. Catal. B: Environ. 16: 209

Fu X., Zeltner W.A., Yang Q., Anderson M.A. (1997) J. Catal. 168: 482

Karmakar S., Greene H.L. (1995) J. Catal. 151: 394

Tajima M., Niwa M., Fujii Y., Koinuma Y., Aizawa R., Kushiyama S., Kobayashi S., Mizuno K., Ohuchi H. (1997) Appl. Catal. B: Environ. 12: 263

Lai S.Y., Pan W., Ng C.F. (2000) Appl. Catal. B: Environ. 24: 207

Deng X., Ma Z., Yue Y., Gao Z. (2001) J. Catal. 204: 200

Karmakar S., Greene H.L. (1994) J. Catal. 148: 524

Chatterjee A., Ebina T., Iwasaki T., Mizukami F. (2003). J. Mol. Struct. 630: 233

Kiricsi I., Nagy J.B. (2004) Appl. Catal. A: Gen. 271: 27

Tajima M., Niwa M., Fujii Y., Koinuma Y., Aizawa R., Kushiyama S., Kobayashi S., Mizuno K., Ohuchi H. (1996) Appl. Catal. B: Environ. 9: 167

Murphy A.B., McAllister T. (1998) Appl. Phys. Lett. 73: 459

Jasinski M., Mizeraczyk J., Zakrzewski Z. (2002) High Temp. Mater. Processes 6: 317

Kang H.C. (2002) J. Ind. Eng. Chem. 8: 488

Gal A., Ogata A., Futamura S., Mizuno K. (2003) J. Phys. Chem. A 107: 8859

Ricketts C.L., Wallis A.E., Whitehead J.C., Zhang K. (2004) J. Phys. Chem. A 108: 8341

Yamamoto T., Mizuno K., Tamori I., Ogata A., Nifuku M., Michalska M., Prieto G. (1996) IEEE Trans. Ind. Appl. 32: 100

H. Miessner, R. Rudolph, K.P. Francke, Chem. Commun. (1998) 2725.

Chen X., Rozak J., Lin J.C., Suib S.L., Hayashi Y., Matsumoto H. (2001) Appl. Catal. A: Gen. 219: 25

Ogata A., Kim H.H., Futamura S., Kushiyama S., Mizuno K. (2004) Appl. Catal. B: Environ. 53: 175

Ogata A., Kim H.H., Oh S.M., Futamura S. (2006) Thin Solid Films 506:373

Ogata A. (1998) Plasma Chem. Plasma processing 18: 363

Harling A.M., Whitehead J.C., Zhang K. (2005) J. Phys. Chem. A 109: 11255

Alberici R.M., Jardim W.F. (1997) Appl. Catal. B: Environ. 14: 55

Finklea H.O., Vithanage R. (1982) J. Phys. Chem. 86: 3621

Chen C., Lei P., Ji H., Ma W., Zhao J. (2004) Environ. Sci. Technol. 38: 329

Calza P., Minero C., Pelizzetti E. (1997) J. Chem. Soc. Faraday Trans. 93: 3765

Kang M., Kim B.J., Cho S.M., Chung C.H., Kim B.W., Han G.Y., Yoon K.J. (2002). J. Mol. Catal. A: Chem. 180: 125

Nakamura I., Negishi N., Kutsuna S., Ihara T., Sugihara S., Takeuchi E. (2000) J. Mol. Catal. A: Chem. 161: 205

Hashimoto K., Wasada K., Toukai N., Kominami H., Kera Y. (2000). J. Photochem. Photobiol. A, Chem. 136: 103

Dors M., Mizeraczyk J., Nichipor G.V., Mok Y.S. (2005). J. Adv. Oxid. Technol. 8: 212

Acknowledgments

Support of this work is by the UK Engineering and Physical Science Research Council and Accentus plc is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wallis, A.E., Whitehead, J.C. & Zhang, K. Plasma-assisted catalysis for the destruction of CFC-12 in atmospheric pressure gas streams using TiO2 . Catal Lett 113, 29–33 (2007). https://doi.org/10.1007/s10562-006-9000-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-006-9000-x